High-resolution rotation-speed measuring device

A speed measurement, high-resolution technology, applied in the direction of measuring device, linear/angular velocity measurement, velocity/acceleration/shock measurement, etc., can solve the problems of missing sampling pulse, increase of measurement resolution, system error, etc., and achieve measurement resolution The effect of improving the rate, improving the measurement resolution and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

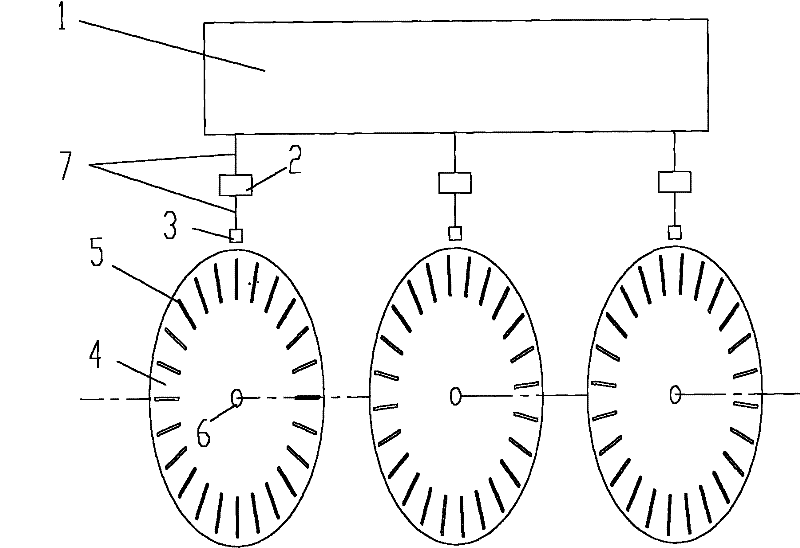

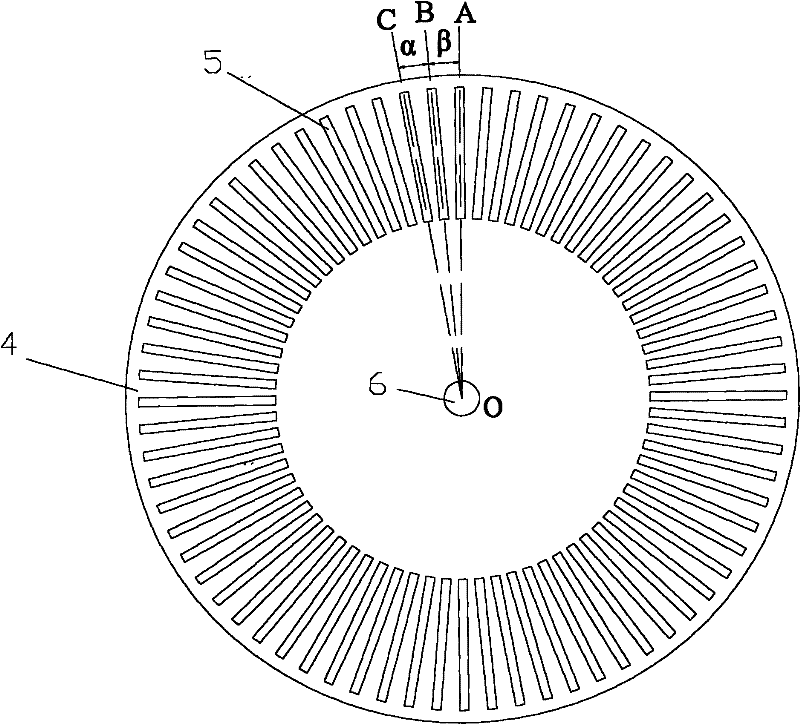

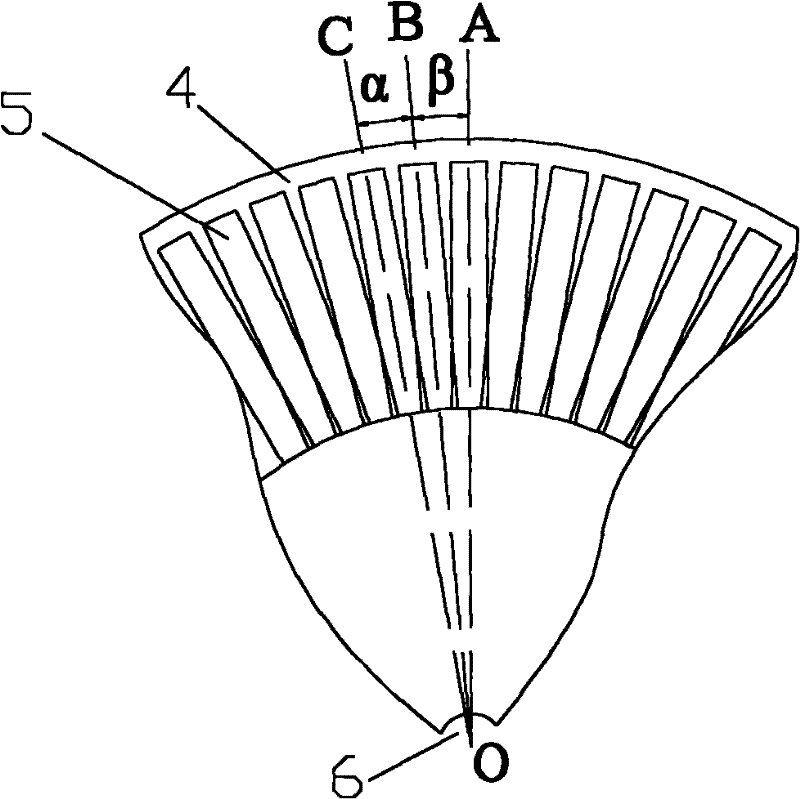

[0023] The present invention is composed of a computer 1 and more than two rotational speed acquisition units. figure 1 It is an embodiment composed of three rotational speed acquisition units. Wherein, the rotational speed acquisition unit includes a signal conditioning device 2, a sensing device 3 and a turntable 4, each turntable 4 is made of light-shielding materials, such as metal materials such as steel and aluminum, opaque plastics or other light-proof materials. Rectangular light-transmitting holes 5 are evenly distributed along the circumferential direction on the end surface of each turntable 4 , and the centerline of the rectangular light-transmitting holes 5 along the length direction passes through the center of the turntable 4 . Sensing device 3 can be such as Figure 7 The circuit shown is composed of groove optocouplers.

[0024] In each speed acquisition unit, the sensing device 3 is close to the rectangular light-transmitting hole 5 of the turntable 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com