Variable rod length articulated arm type coordinate measuring machine

A technology of coordinate measuring machine and articulated arm, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of poor working adaptability of measuring machines, different sizes of measuring spaces, and large measurement errors, so as to achieve the best measurement efficiency and improve measurement resolution , to achieve the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

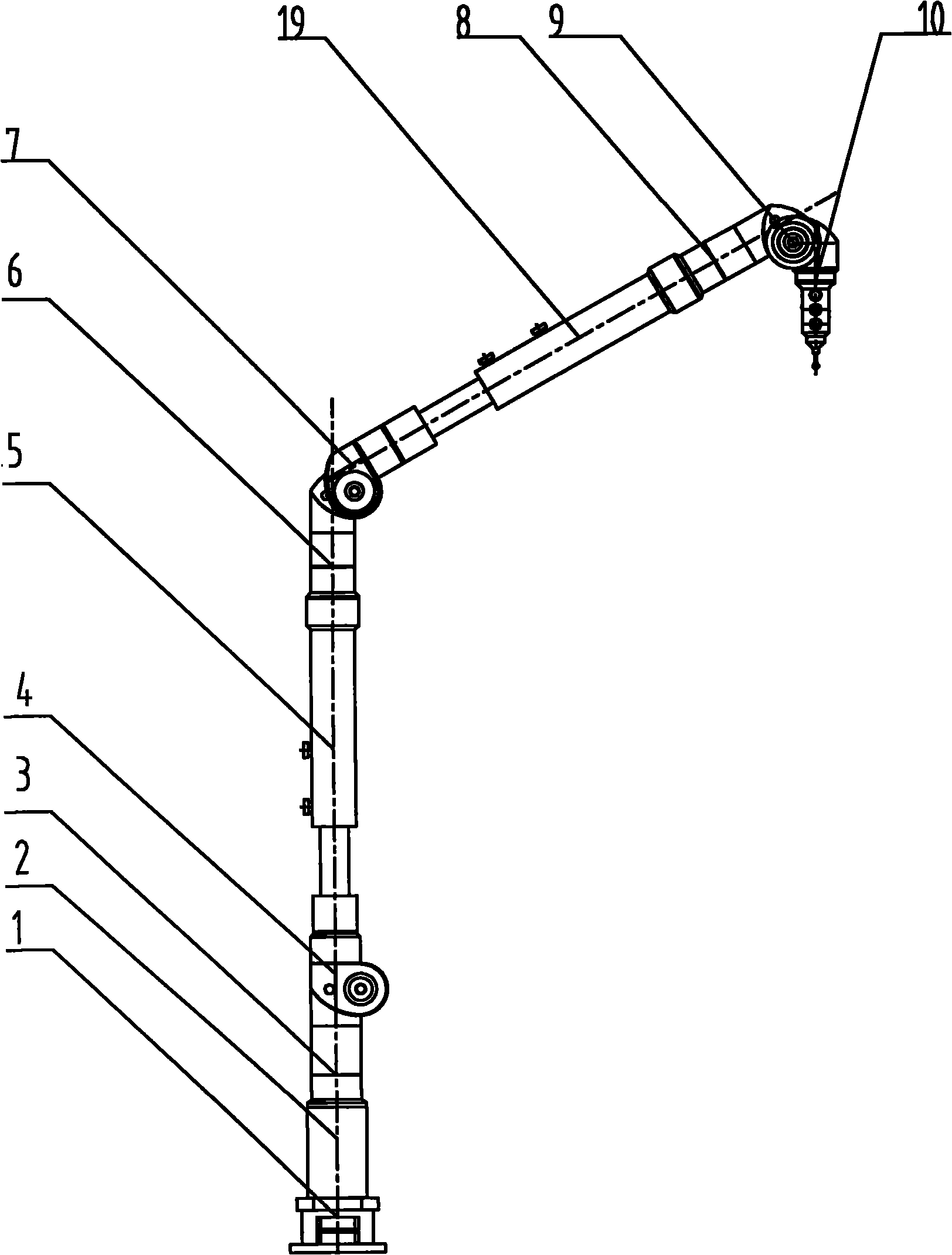

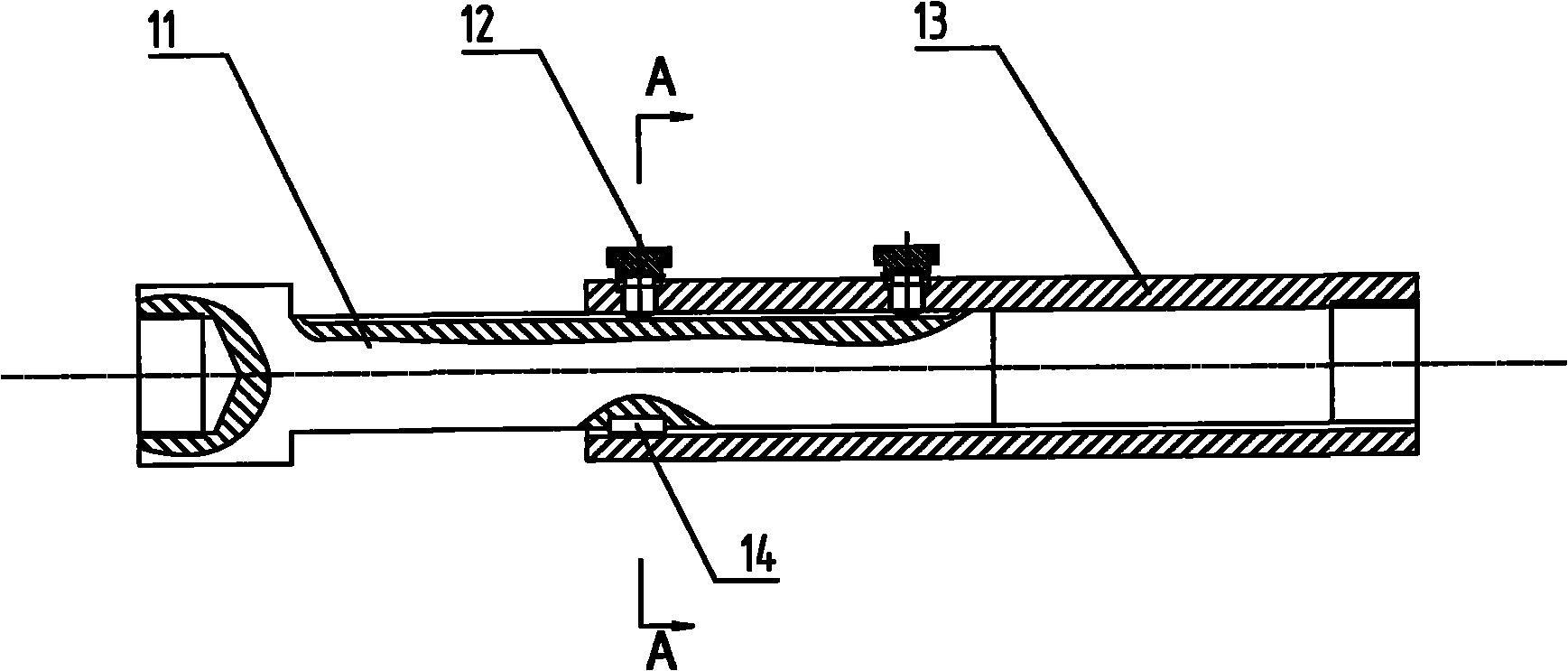

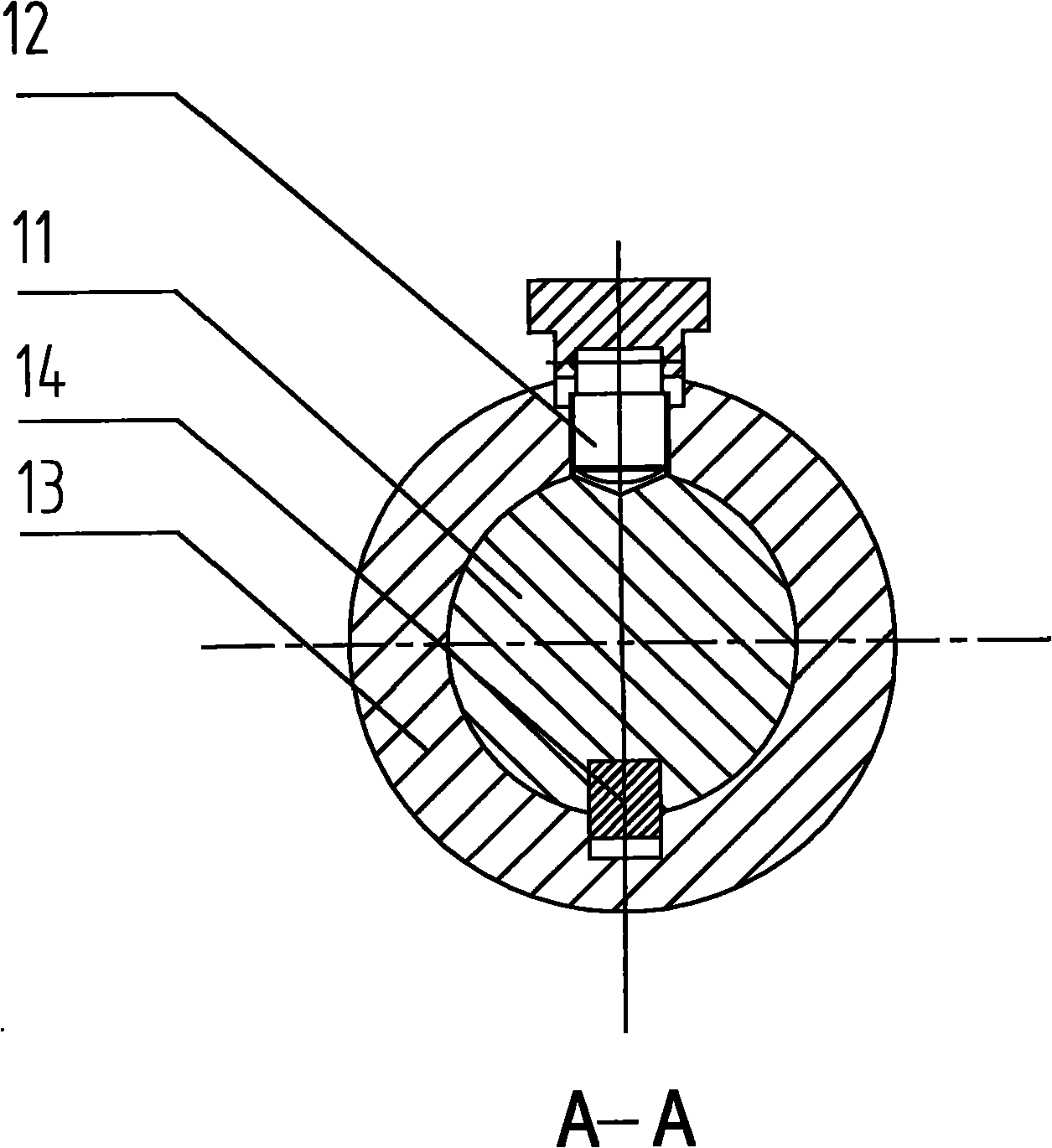

[0018] Such as figure 1 , figure 2 , image 3 Shown, the present invention comprises base 1, three rotating joints 3,6,8, three swing joints 4,7,9, base measuring arm 2, two measuring arms and probe 10; Base 1 and the first One end of a base measuring arm 2 is connected, the other end of the first base measuring arm 2 is connected with one end of the first rotary joint 3, the other end of the first rotary joint 3 is connected with one end of the first swing joint 4, and the first swing The other end of the joint 4 is connected with one end of the first measuring arm, the other end of the first measuring arm is connected with one end of the second rotating joint 6, the other end of the second rotating joint 6 is connected with one end of the second swing joint 7, and the second The other end of the second swing joint 7 is connected to one end of the second measuring arm, the other end of the second measuring arm is connected to one end of the third rotating joint 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com