Seaming mechanism of can manufacturing machinery

A seaming and mechanical technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of large volume, inability to process seven-layer seaming procedures, and repeated components, so as to achieve high processing efficiency, reduce parts composition, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, a preferred embodiment of the present invention will be cited and further described with reference to the accompanying drawings.

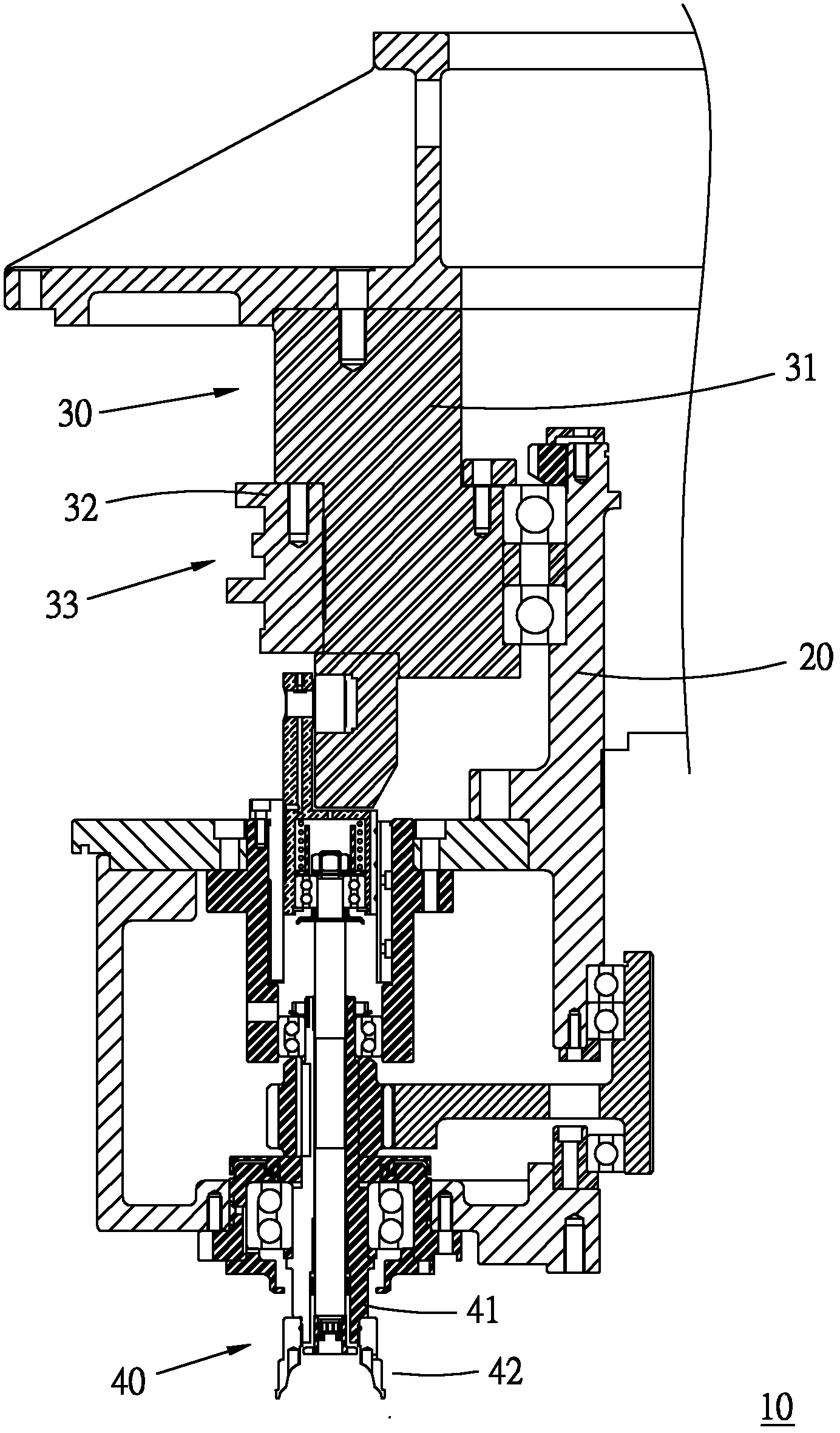

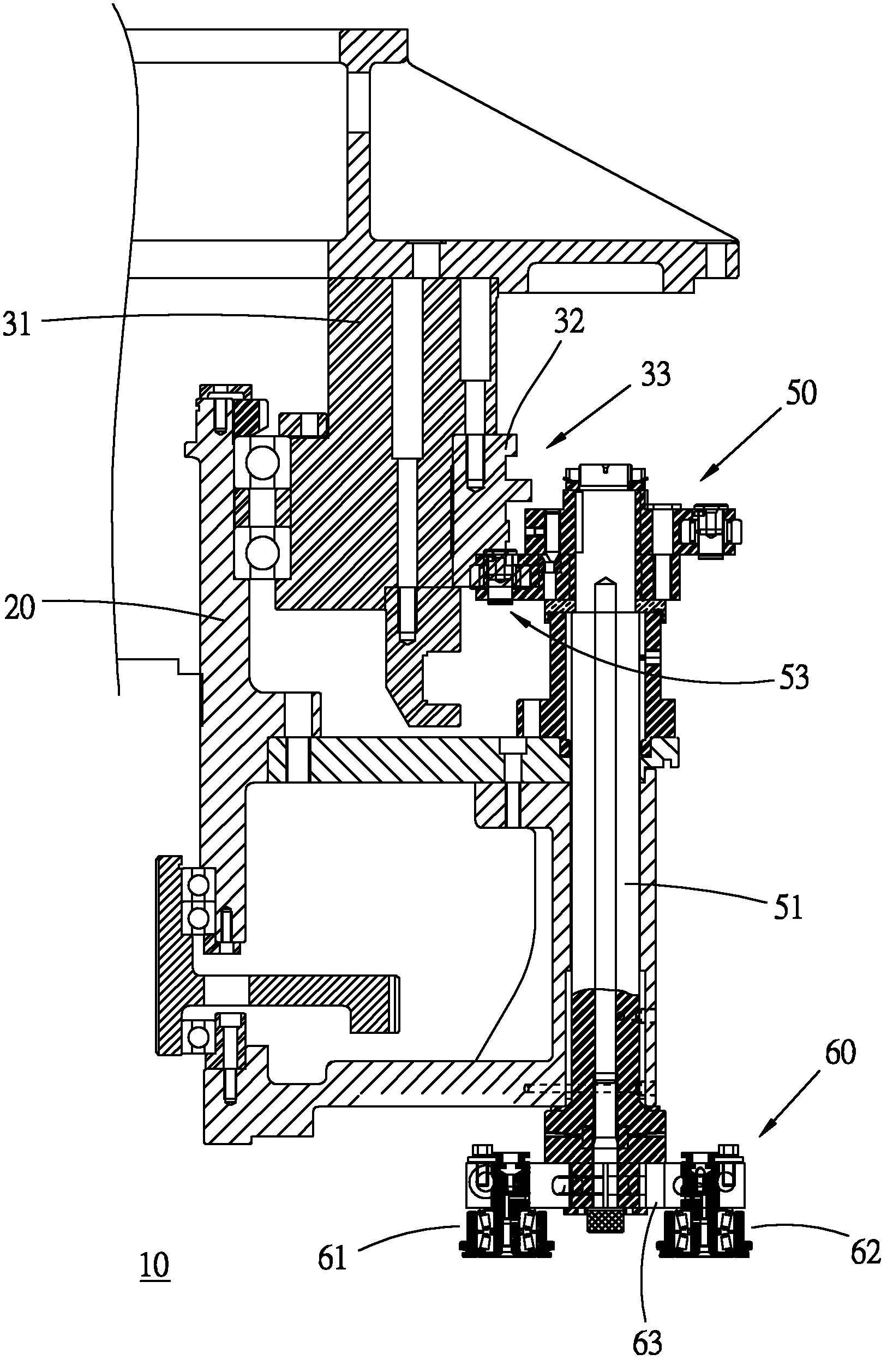

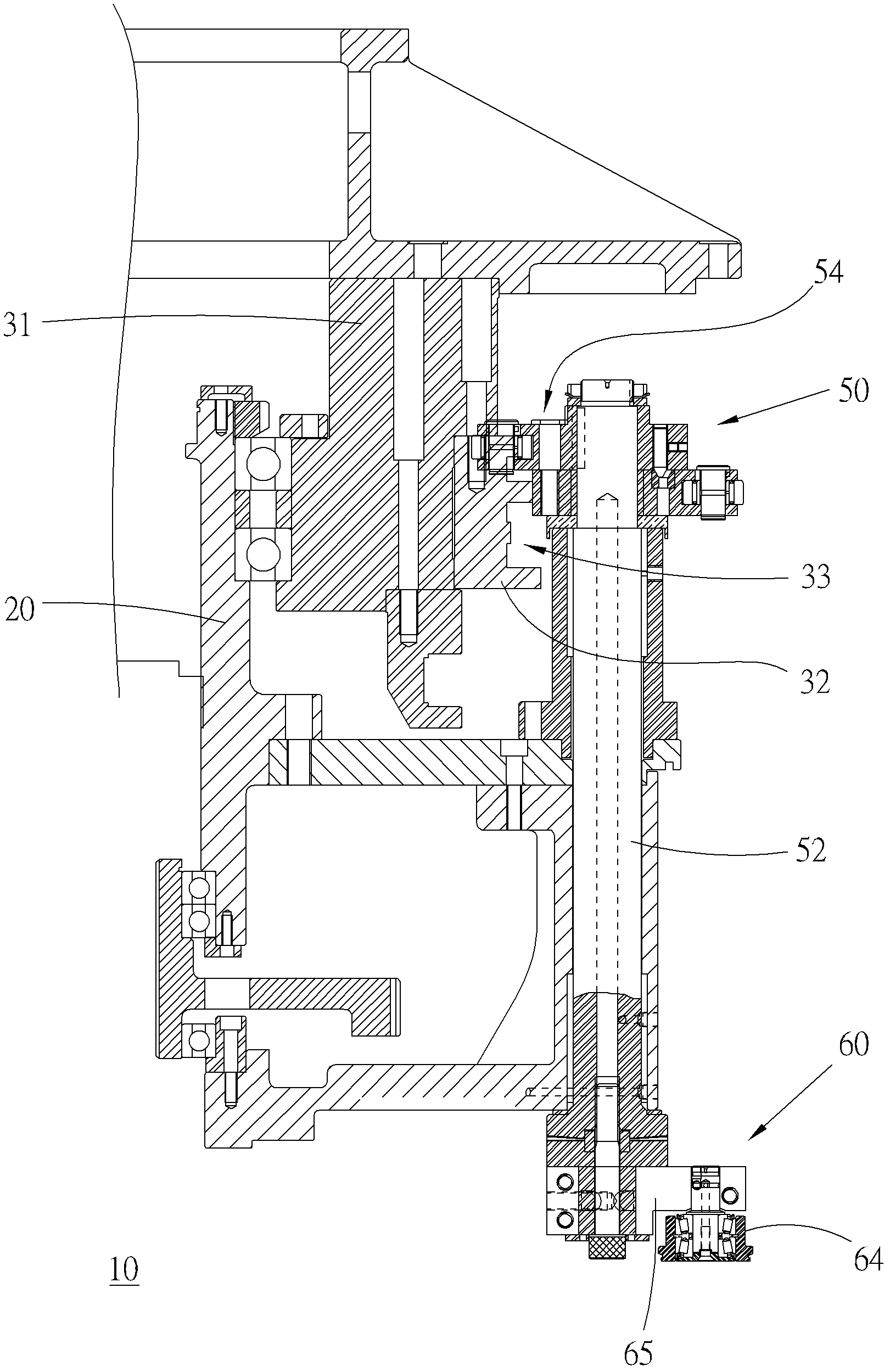

[0028] Please refer to shown in each figure, the seaming mechanism 10 of can making machine provided in a preferred embodiment of the present invention, it mainly consists of a main shaft 20, a guide 30, some rolling groups 40, some seaming shaft groups 50 And several seaming modules 60 are formed.

[0029] The main shaft 20 is in the shape of an upright tube for the guide member 30 to pivot on it, and each of the rolling group 40, the seaming shaft group 50 and the seaming module 60 are arranged equidistantly around the main shaft 20. Circumferential side, and can move around the axial direction of the main shaft 20 under the drive of external force.

[0030] The guide 30 has an annular body 31 coaxially pivoted on the top of the main shaft 20, an annular cam 32 coaxially fixed on the peripheral side of the body 31, and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com