Horizontal type measuring apparatus for Young's modulus

A Young's modulus and measuring instrument technology, which is applied in the field of horizontal Young's modulus measuring instruments, can solve the problems of shaking of the measuring frame, large error of measurement results, and heavy instrument, so as to improve the accuracy of measurement and simplify the error. Calculation, the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

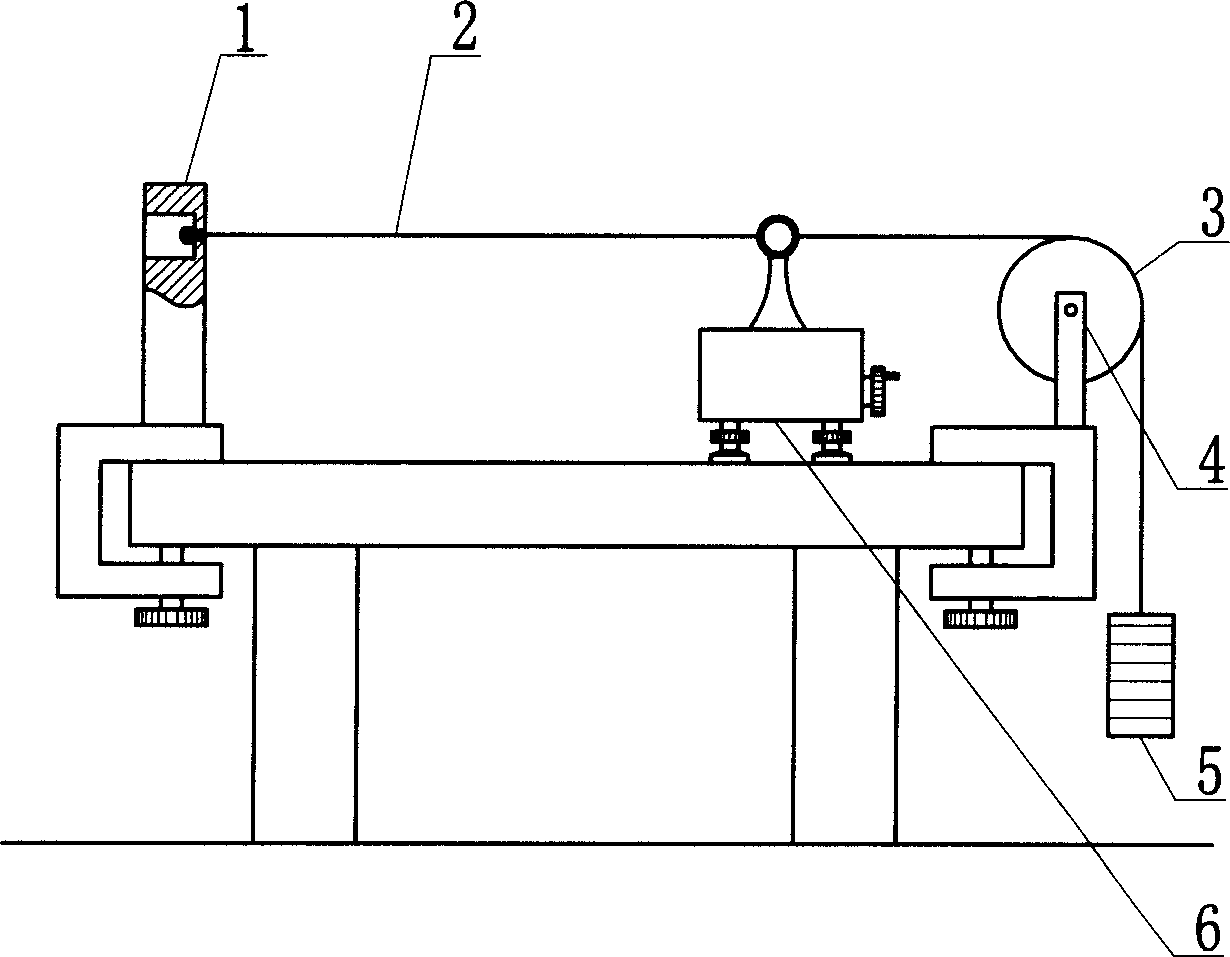

[0016] Embodiment: The wire head fixing plate and the pulley fixing plate are casted, and the wire head fixing plate is fixed on one end of the desktop through the clamping bolts that come with it, and then the pulley frame with the pulleys is fixed through the clamping bolts that come with it After the other end of the desktop, take a section of steel wire to be tested whose length is 1.2 times the length of the desktop, tie a knot at one end, let the other end pass through the wire head fixing plate, go around the pulley and connect the weight plate, so that the weight plate Hanging down from the end of the table, the weight plate must be pre-loaded with 1kg of weight to straighten the steel wire. Then use a light-colored pen to draw a horizontal mark on the steel wire to be tested. The color of the mark is white, the width of the mark is 1mm, and the position of the mark is set at 0.2m from the pulley. Make the steel wire to be tested parallel to the edge of the table on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com