Electric heating method for reduction pot and reduction pot used for the same

A reduction tank and electric heating technology, applied in furnace heating elements and other directions, can solve the problems of large heat radiation and other heat losses, difficult to reduce production costs, and large energy consumption, so as to reduce heat energy loss, simplify production costs, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

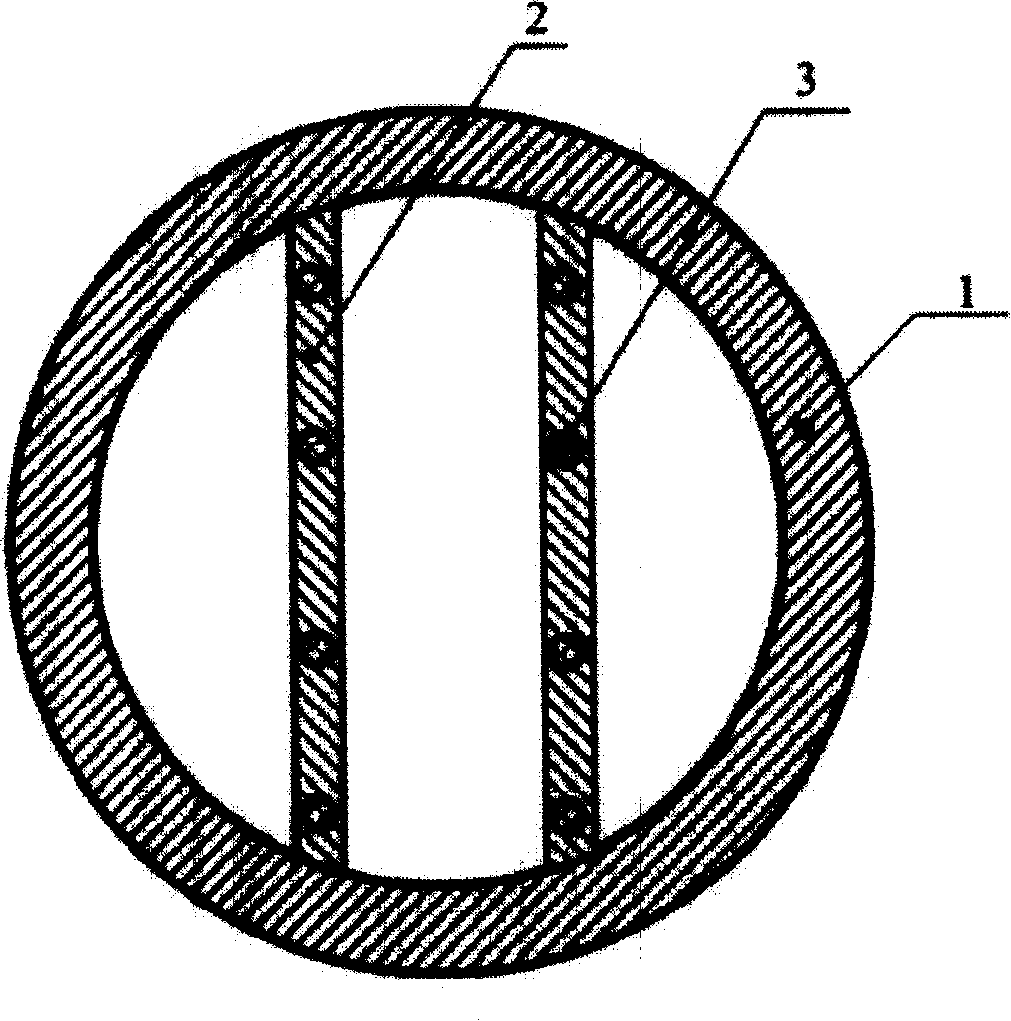

[0025] Embodiment: the electric heating method of reduction tank, as figure 1 As shown, a heat conductor 2 is arranged in the tank body of the reduction tank 1, and an electric heating rod 3 is embedded in the heat conductor. heating.

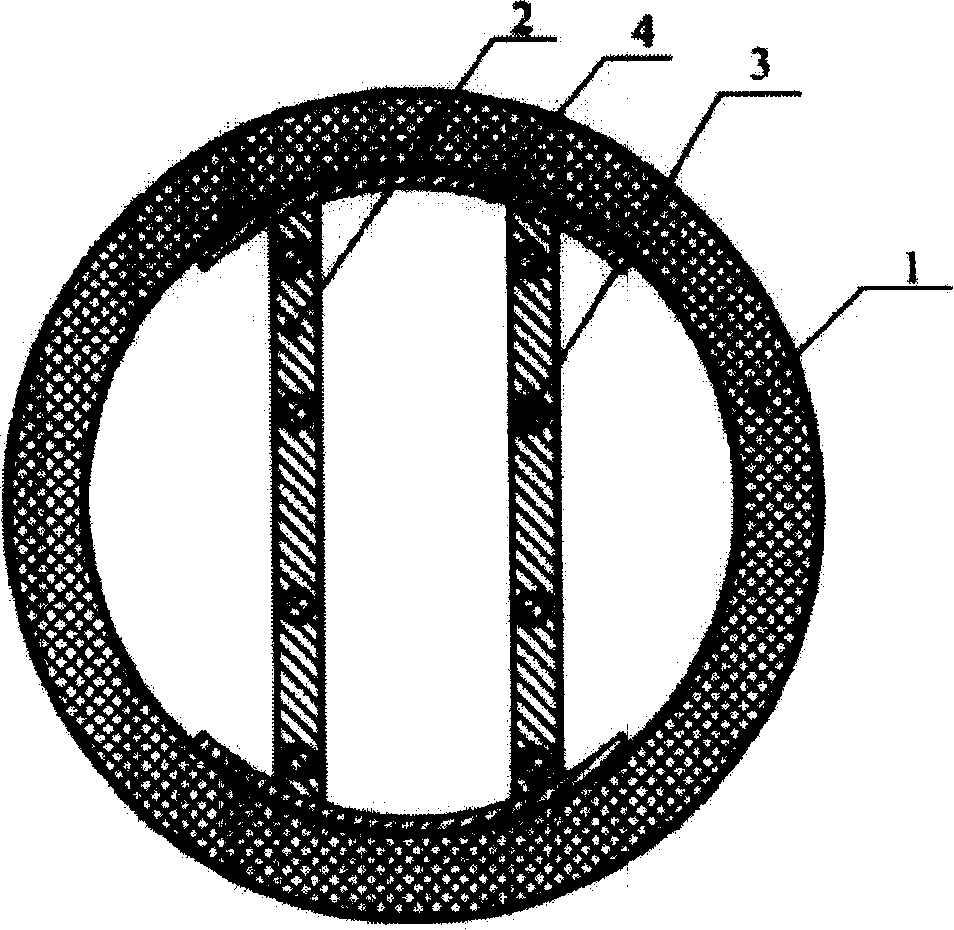

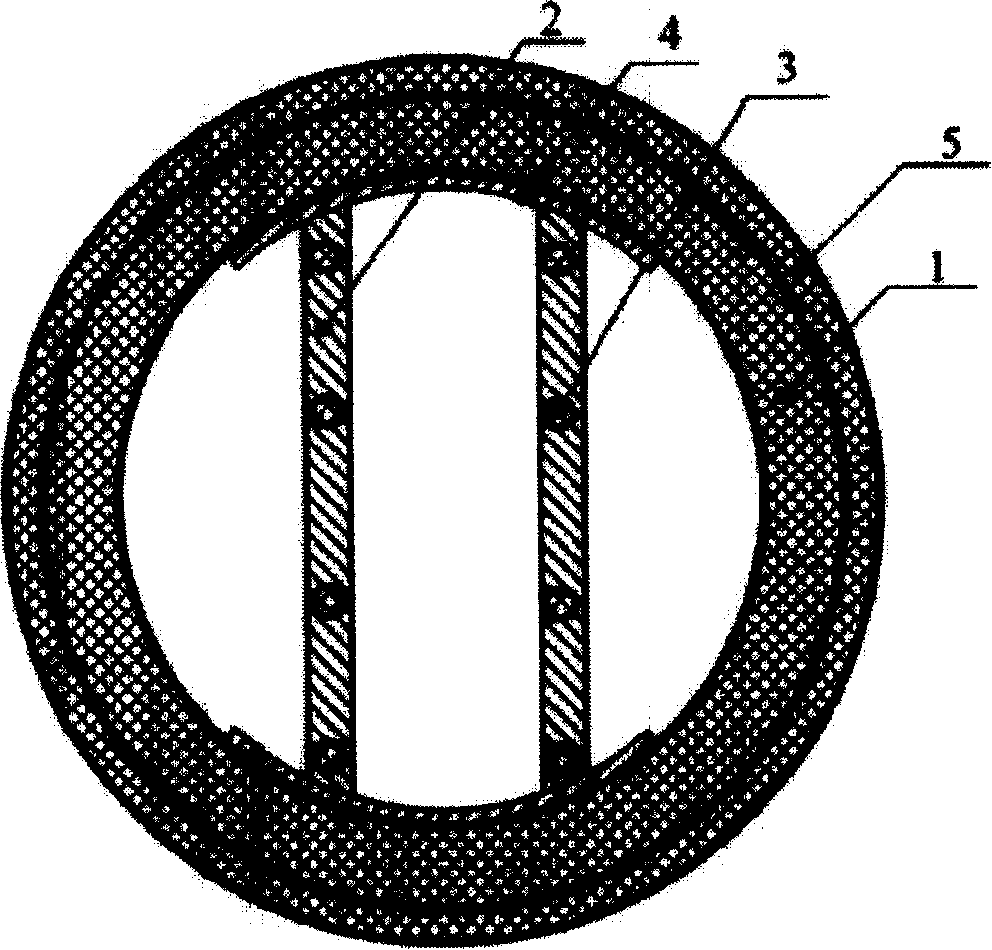

[0026] The reduction tank used in the above-mentioned reduction tank electric heating method, such as Figure 1 to Figure 9 As shown, the reduction tank 1 is a cylindrical, rectangular or arbitrary cylindrical structure. One end of the reduction tank 1 is provided with a charging port, and the other end is closed or provided with a slag discharge port; It is an integrated structure connected with the inner wall of the reduction tank, or the heat conductor is a movable structure tightly nested in the reduction tank; the shape and setting method of the heat conductor 2 are arbitrary, and the heat conductor 2 is embedded with an electric heating rod 3. The connecting terminal on the bar is connected with a lead, and the lead passes through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com