A kind of aluminum-barium wire and its production process

A technology of barium wire and aluminum powder, which is applied in the field of aluminum-barium wire and its production process, can solve problems such as unsatisfactory demand and lack of attention to aluminum utilization, and achieve the elimination of phosphorus back phenomenon, improvement of effective utilization rate, and increase of free oxygen The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

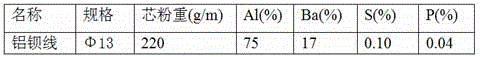

[0035] The production technology of aluminum-barium wire of the present invention is:

[0036] ① core material preparation: weigh 70 parts of aluminum powder, 5 parts of aluminum granules, and 25 parts of barium carbonate according to the core powder raw material, and use a mixer to mix evenly, and the obtained core material enters the powder silo;

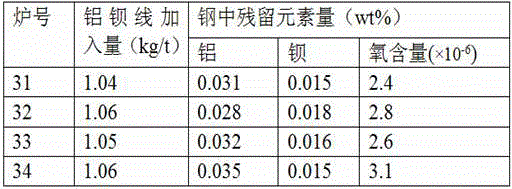

[0037] ② Coating: Manually inspect the quality of the strip steel without rotten edges and holes, and then use the edge folding machine to coat the strip steel with the core material to obtain aluminum-barium wire. The physical and chemical properties of the test are as follows:

[0038]

Embodiment 2

[0040] The production technology of aluminum-barium wire of the present invention is:

[0041] ① Preparation of core material: Take 75 parts of aluminum powder, 5 parts of aluminum granules, and 20 parts of barium carbonate according to the core powder raw material, and use a mixer to mix evenly, and the obtained core material enters the powder silo;

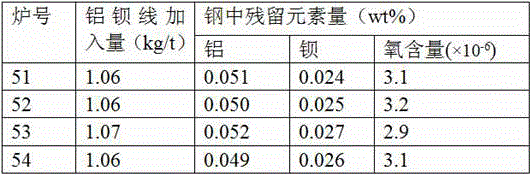

[0042] ② Coating: Manually inspect the quality of the strip steel without rotten edges and holes, and then use the edge folding machine to coat the strip steel with the core material to obtain aluminum-barium wire. The physical and chemical properties of the test are as follows:

[0043]

Embodiment 3

[0045] The production technology of aluminum-barium wire of the present invention is:

[0046] ① Preparation of core material: Take 70 parts of aluminum powder, 10 parts of aluminum granules, and 20 parts of barium carbonate according to the core powder raw material, and use a mixer to mix evenly, and the obtained core material enters the powder silo;

[0047] ② Coating: Manually inspect the quality of the strip steel without rotten edges and holes, and then use the edge folding machine to coat the strip steel with the core material to obtain aluminum-barium wire. The physical and chemical properties of the test are as follows:

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com