Vacuum metal smelting heat accumulation reducing furnace system

A metal smelting and reduction furnace technology, applied in the field of vacuum metal smelting regenerative reduction furnace system, can solve the problems of limited production capacity, slow temperature rise, low thermal conductivity, etc., and achieve low smoke pollution, complete combustion, and high heat utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

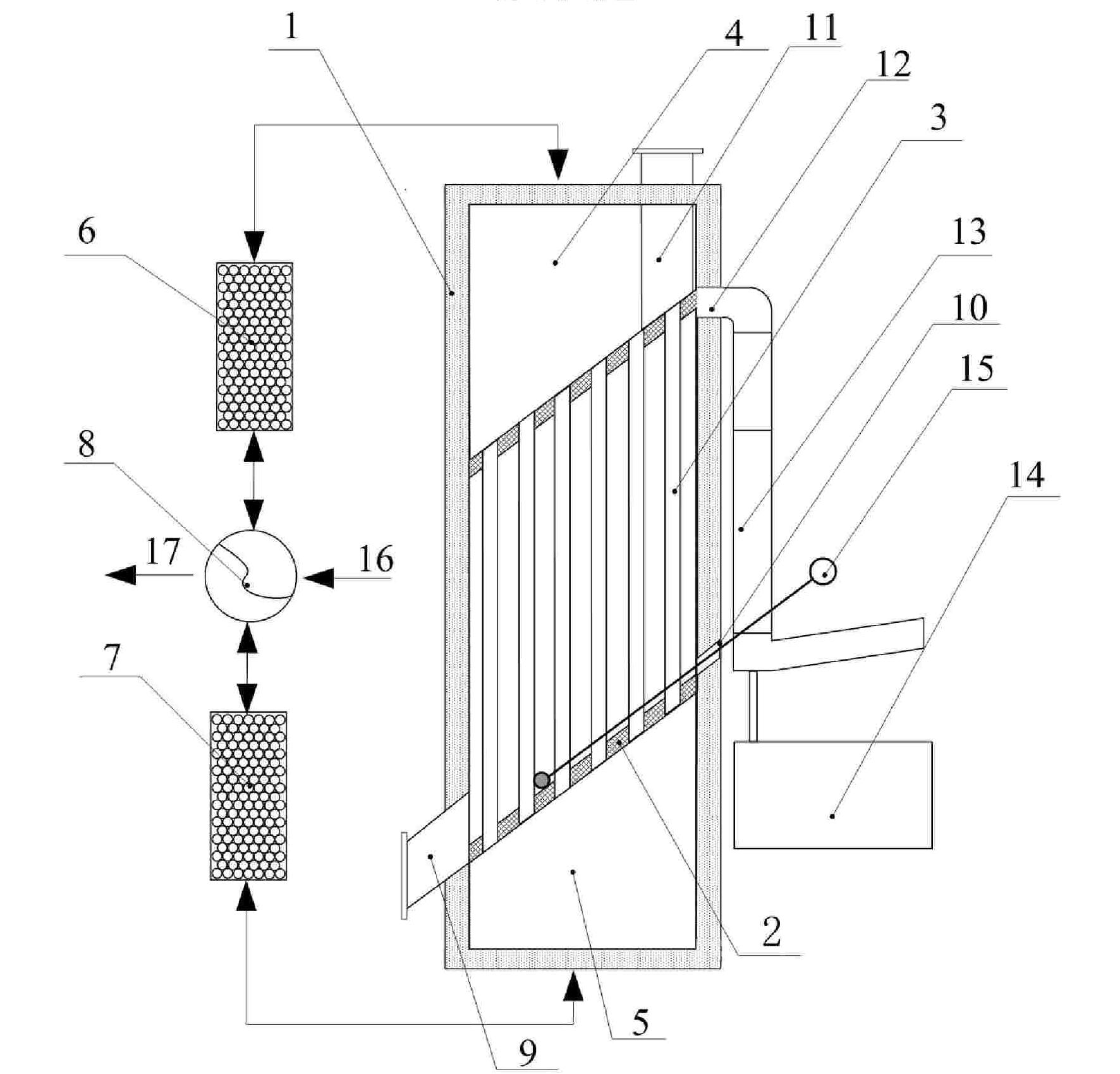

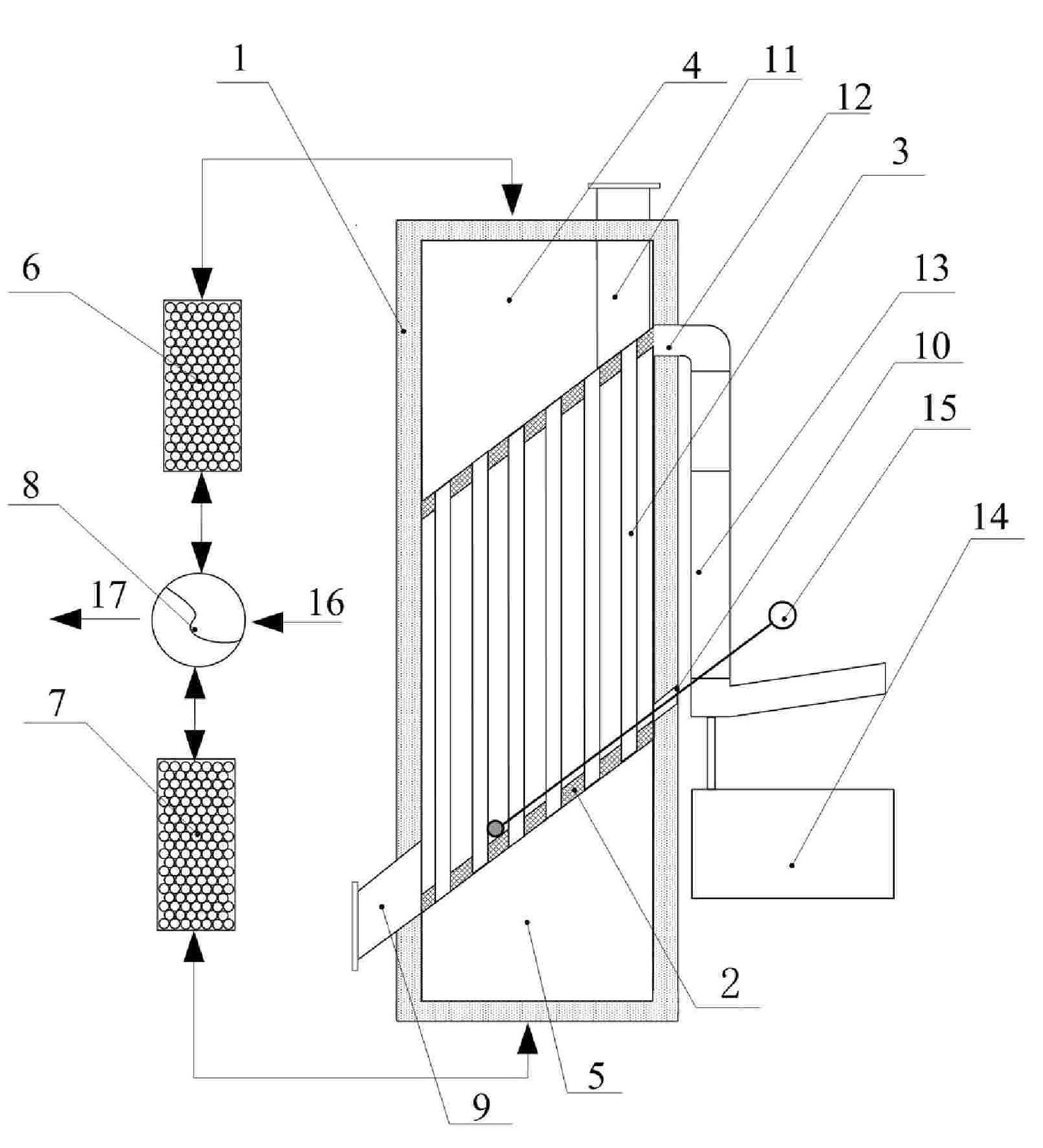

[0016] Example. A vacuum metal smelting regenerative reduction furnace system, such as figure 1 As shown, it includes a reduction furnace 1, a reduction kettle 2, a regenerative combustion system and a liquid metal collection system. The reduction kettle is provided with a group of radiant tubes 3 arranged in an array and running through the reduction kettle. The radiant tubes can be arranged parallel to the front and rear side walls of the reduction kettle, or can be arranged horizontally. When the radiant tubes are arranged in parallel with the front and back side walls of the reduction kettle, the reduction kettle is arranged in the middle of the reduction furnace so that the upper combustion chamber 4 and the lower combustion chamber 5 are formed in the reduction furnace; The furnace forms a left combustion chamber 4 and a right combustion chamber 5; the two combustion chambers are penetrated by a radiant tube, so that the hot flue gas in the combustion chamber can pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com