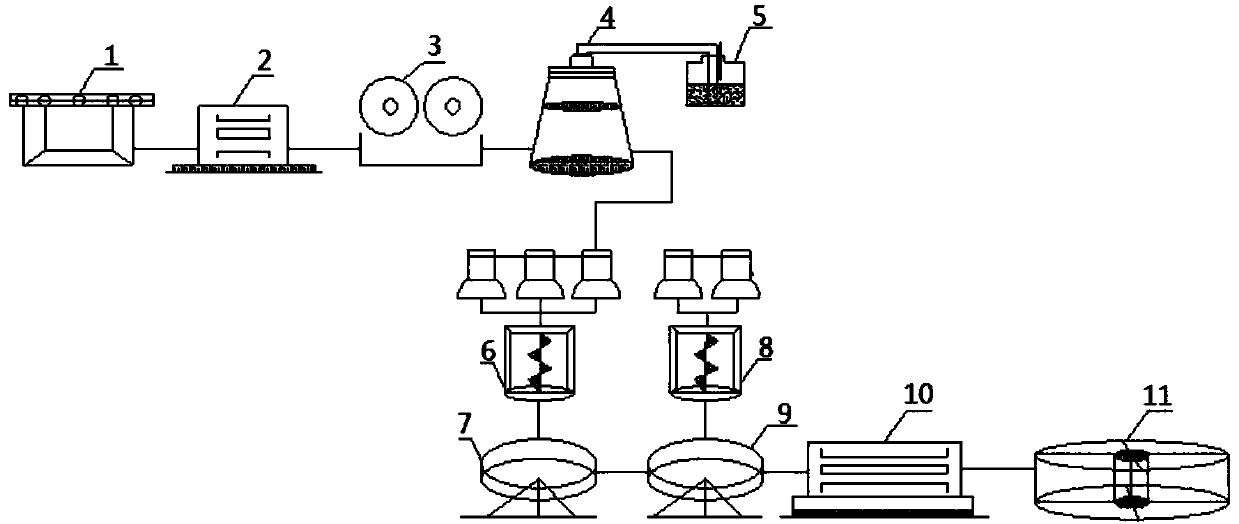

Carbon-containing pellet reducing system and method

A technology of carbon pellets and pellets, which is applied in the field of metallurgy, can solve problems such as pellet melting, achieve the effects of reducing the amount of coal powder, inhibiting the production of dioxins and other harmful substances, and improving the metallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

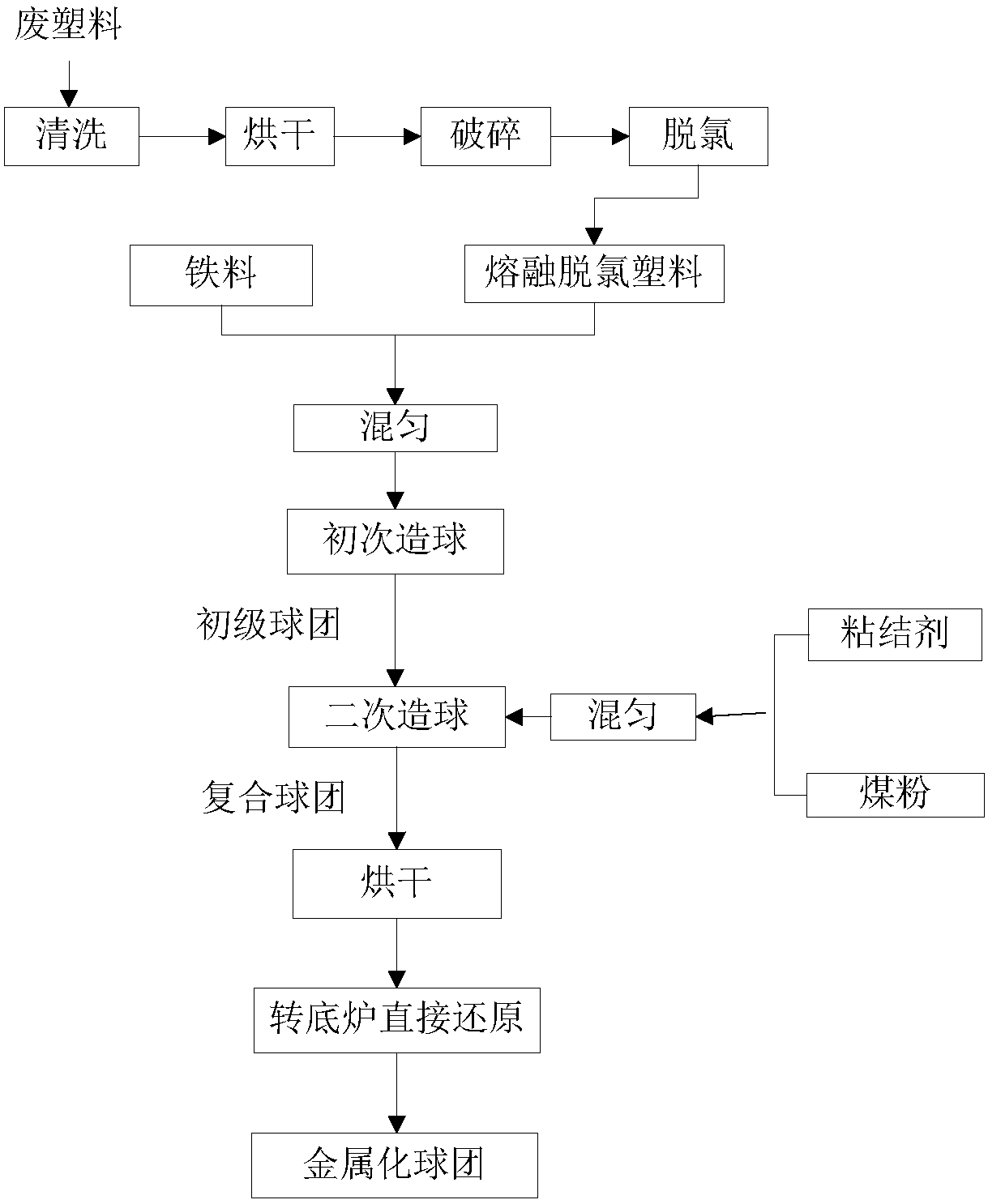

Method used

Image

Examples

Embodiment 1

[0062] In this embodiment, copper slag is used as iron material, and the process of preparing carbon-containing pellets and reducing them is as follows:

[0063] 1. Send waste plastics to the cleaning device for cleaning to obtain clean plastics.

[0064] 2. Send the clean plastic to the plastic dryer for drying to obtain the dried plastic. The drying temperature is 80°C and the drying time is 15 minutes.

[0065] 3. Send the dried plastic to a crusher for crushing to obtain waste plastic particles, the particle size of which is 1mm.

[0066] 4. Send the waste plastic particles to the dechlorination device for dechlorination. The dechlorination temperature is 300°C to obtain molten dechlorinated plastics; the generated hydrogen chloride is passed into the absorption tank for treatment.

[0067] 5. Send copper slag and molten dechlorinated plastic to the first mixer and mix evenly to obtain the first mixture; the mass ratio of iron material to molten dechlorinated plastic is 1...

Embodiment 2

[0074] In this embodiment, lead-zinc slag is used as iron material, and the process of preparing carbon-containing pellets and reducing them is as follows:

[0075] 1. Send waste plastics to the cleaning device for cleaning to obtain clean plastics.

[0076] 2. Put the clean plastic into the plastic dryer for drying to obtain the dried plastic. The drying temperature is 150°C and the drying time is 5 minutes.

[0077] 3. Send the dried plastic to a crusher for crushing to obtain waste plastic particles, the particle size of which is 2mm.

[0078] 4. The waste plastic particles are sent to the dechlorination device for dechlorination. The dechlorination temperature is 250°C to obtain molten dechlorinated plastics; the generated hydrogen chloride is passed into the absorption tank for treatment.

[0079] 5. Send lead-zinc slag and molten dechlorinated plastic into the first mixer and mix evenly to obtain the first mixture; the mass ratio of lead-zinc slag to molten dechlorinate...

Embodiment 3

[0086] In this embodiment, iron vanadium slag is used as iron material, and the process of preparing carbon-containing pellets and reducing them is as follows:

[0087] 1. Send waste plastics to the cleaning device for cleaning to obtain clean plastics.

[0088] 2. Send the clean plastic to the plastic dryer for drying to obtain the dried plastic. The drying temperature is 100°C and the drying time is 10 minutes.

[0089] 3. Send the dried plastic to a crusher for crushing to obtain waste plastic particles, the particle size of which is 3mm.

[0090] 4. Send the waste plastic particles into the dechlorination device for dechlorination. The dechlorination temperature is 350°C to obtain molten dechlorinated plastics; the generated hydrogen chloride is passed into the absorption tank for treatment.

[0091] 5. Feed the iron vanadium slag and molten dechlorinated plastic into the first mixer and mix evenly to obtain the first mixture; the mass ratio of iron material to molten dechl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com