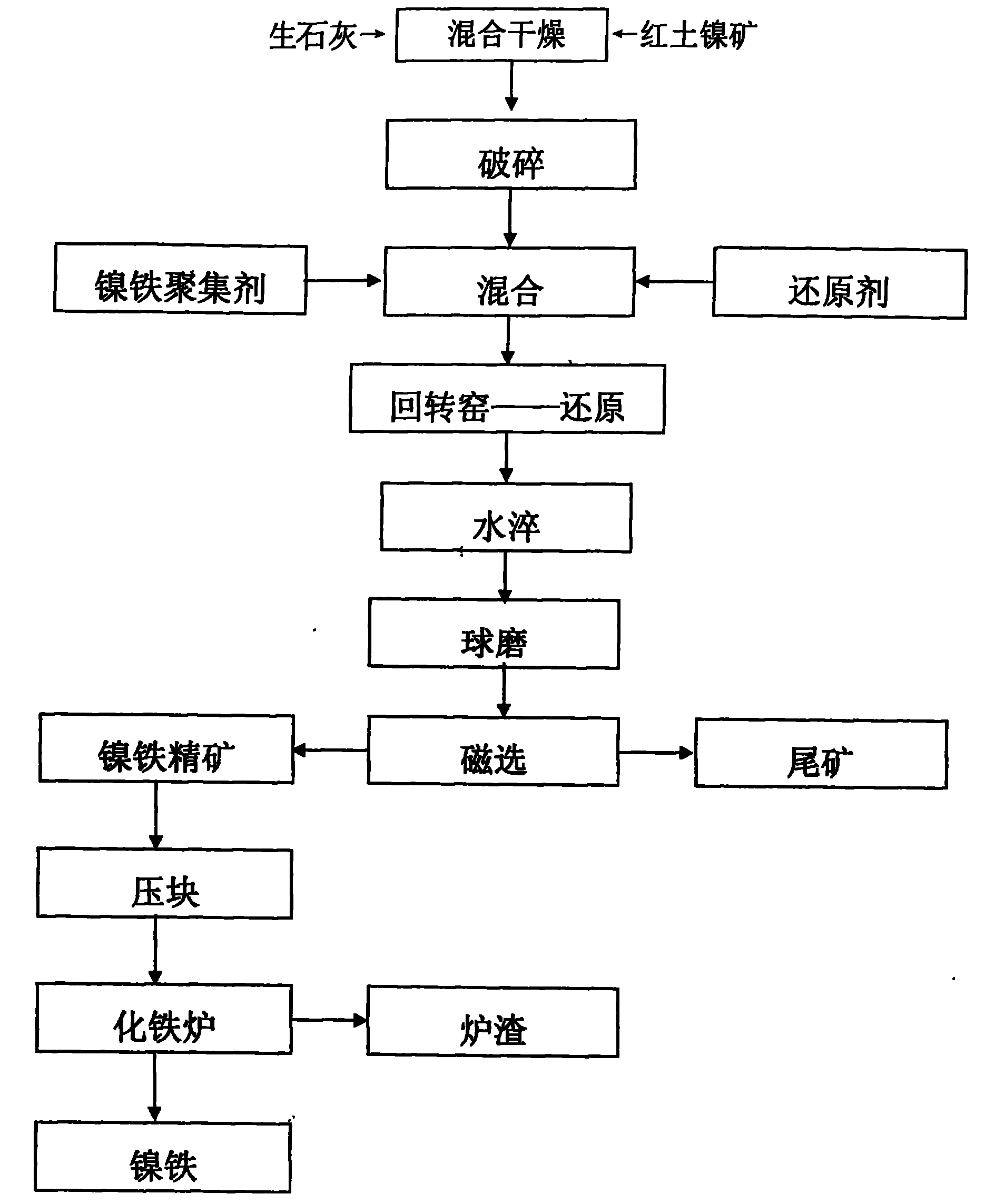

Process for producing nickel iron in rotary kiln-blast furnace by using laterite nickle mine

A laterite nickel ore and rotary kiln technology, applied in the field of iron and steel metallurgy, can solve problems affecting normal production, complex processing equipment, complex processing technology, etc., and achieve the effects of improving nickel grade, reducing production process, and increasing reduction reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the laterite nickel ore (Ni1.01, Tfe8.8%) containing water is mixed with 5% calcareous quicklime and dried, broken to below 5mm, adding the carbonaceous reductant of raw ore weight 8%, the nickel of 7% Mix the iron aggregating agent evenly, put it directly into the rotary kiln for reduction and roasting, the temperature is controlled at 980°C, after reduction and roasting, it is cooled by water quenching, crushed, ball milled, and then magnetically separated by a 1500 Gauss magnetic separator to obtain ferronickel concentrate powder, its nickel The grade can reach 10.2%, and the nickel recovery rate is 90.1%. Then the ferronickel concentrate powder is pressed into blocks and put into the iron furnace for smelting; 30% of the weight of the nickel-iron concentrate block is added with coke, and the temperature is controlled at 1400-1420°C. It takes 1 hour to smelt nickel-iron alloy, the nickel grade can reach 15.2%, and the nickel recovery rate is 93%.

Embodiment 2

[0018] Embodiment 2: the laterite nickel ore (Ni1.14, Tfe10.2) containing water is mixed with 7% calcareous quicklime and dried, broken to below 5mm, adding the carbonaceous reductant of 9% of raw ore weight, 8% of ferronickel The aggregating agent is mixed evenly, directly put into the rotary kiln for reduction roasting, the temperature is controlled at 970°C, after reduction roasting, it is cooled by water quenching, crushed, ball milled, and then magnetically separated by a 2500 Gauss magnetic separator to obtain ferronickel concentrate powder. The grade can reach 12.1%, the nickel recovery rate is 90.5%, and then the ferronickel concentrate powder is pressed into blocks, and then enters the iron furnace for smelting; 35% of the weight of the nickel-iron concentrate block is added with coke, and the temperature is controlled at 1400-1500°C. It takes 1.5 hours to obtain high-grade nickel-iron alloy, the nickel grade can reach 17.6%, and the nickel recovery rate is 94%.

Embodiment 3

[0019] Embodiment 3: the laterite nickel ore (Ni1.2, Tfe11.0%) containing water is mixed thoroughly with 6% magnesia quicklime and dried, broken to below 5mm, adding the carbonaceous reductant of raw ore weight 7%, the nickel of 6% The iron aggregation agent is mixed evenly, and it is directly put into the rotary kiln for reduction and roasting. The temperature is controlled at 1000°C. After reduction and roasting, it is cooled by water quenching, crushed, ball milled, and then magnetically separated by a 2000 Gauss magnetic separator to obtain ferronickel concentrate powder. The grade can reach 12.4%, the nickel recovery rate is 92%, and then the ferronickel concentrate powder is pressed into blocks, and then enters the iron furnace for smelting; 40% of the weight of the nickel-iron concentrate block is added with coke, the temperature is 1400-1480 ℃, the time After 1.2 hours, a high-grade nickel-iron alloy is obtained, and the nickel grade can reach 18.0%. The nickel recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com