Coal gasification method using oxygen-rich air, CO2 flue gas and steam as gasifying agents

An oxygen-enriched air and CO2 technology, applied in the field of coal gasification, can solve problems affecting global climate change and increase, and achieve the effects of improving thermal efficiency, reducing CO2 emissions, and increasing the calorific value of coal gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

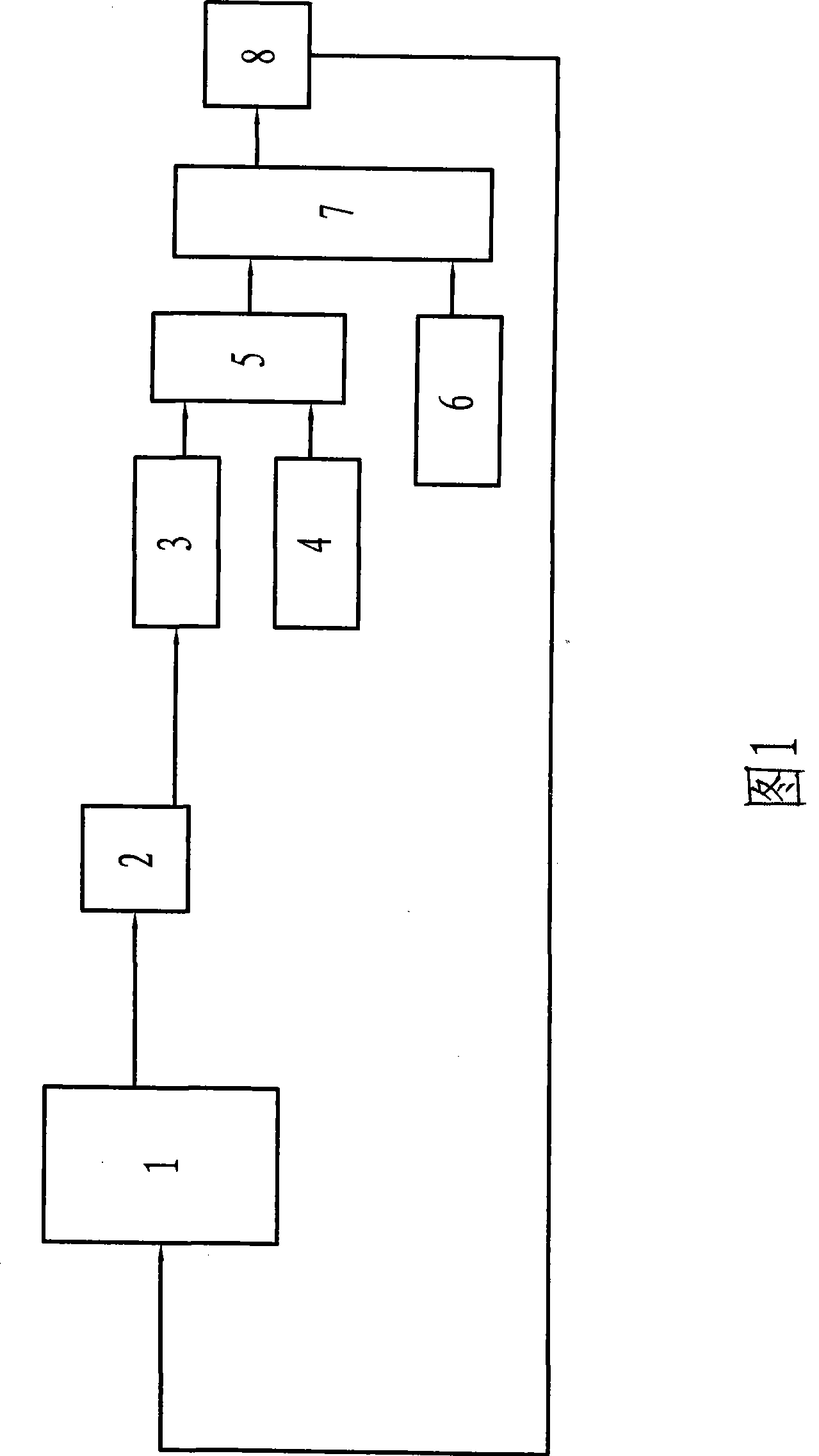

[0017] The present invention is described in detail below in conjunction with accompanying drawing.

[0018] As shown in the figure: First, part of the flue gas in the gas-fired kiln 1 is led to the flue gas purification device 2 for purification treatment, and the purified flue gas is pressurized by the flue gas pressurization device 3 and then sent to the gas mixing device 5. In this device, it is mixed with oxygen-enriched air 4 in a certain proportion to make it O 2 and CO 2 The content is a certain concentration of mixed gas, in which O 2 content reaches 30-50%, CO 2 The content reaches 5-25%; then, the mixed gas is mixed with water vapor 6 as a gasification agent for coal gasification device 7 to gasify coal; finally, in the coal gasification device 7, the mixed gas is mixed with water vapor to form The gasification agent undergoes a redox reaction with coal to generate CO and H 2 The coal gas is the main combustible component. After the gas is purified by the gas pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com