Desulfurization waste liquid treatment and reuse system and method

A technology of desulfurization waste liquid and desulfurization agent, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of large amount of desulfurization agent, troublesome desulfurization waste liquid treatment and reuse, poor desulfurization effect, etc., and achieve desulfurization The dosage is small, the reduction reaction efficiency is improved, and the effect and speed are improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings. It should be understood that the implementation of the present invention is not limited to the following examples, and any modifications and / or changes made to the present invention will fall within the protection scope of the present invention.

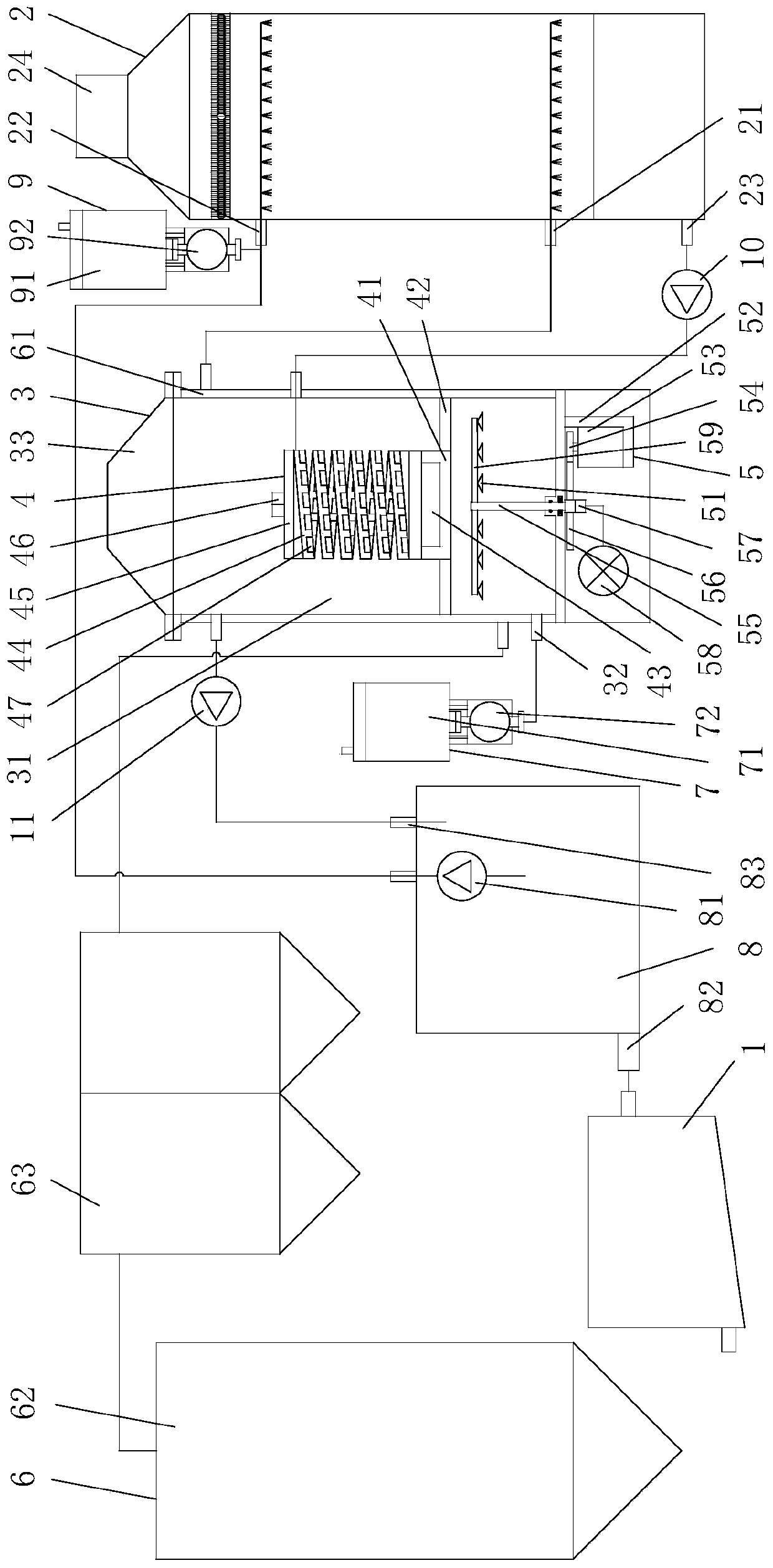

[0016] as attached figure 1 Shown: a desulfurization waste liquid treatment and reuse system, including: a desulfurization tower 2 with a flue gas inlet 21, a desulfurizer inlet 22, a desulfurization waste liquid outlet 23 and an exhaust port 24, a filter press device 1, and a tower body 31 The lower part of the side wall is provided with a reduction tower 3 with a flocculant inlet 32, a desulfurization waste liquid distributing device 4 located in the tower body 31, and an aeration nozzle group 51 located at the lower side of the desulfurization waste liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com