Process for preparing nano silicon carbide by sol-gel method

A sol-gel method, nano-silicon carbide technology, applied in the direction of silicon carbide, carbide, etc., can solve the problems of difficult dispersion, difficult mixing of carbon source and silicon source, etc., and achieves lower reduction temperature, good dispersion, and improved reduction. The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

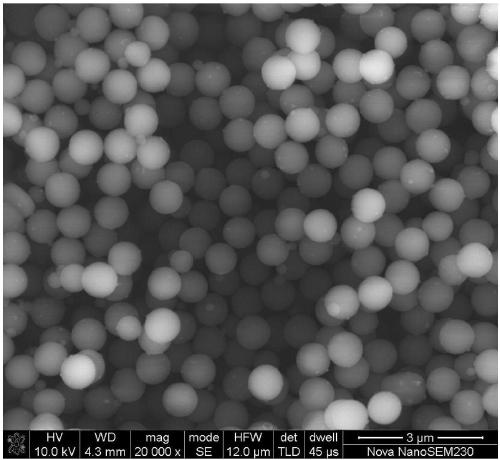

[0038] The silicon carbide powder prepared by the sol-gel method is homogeneously mixed, reduced at high temperature, and dispersed and classified, and the prepared silicon carbide powder has a narrow particle size distribution and high purity.

[0039] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings of the specification and specific implementations.

[0040] The embodiment of the present invention provides a process for preparing nano silicon carbide by a sol-gel method, which includes the following steps:

[0041] S1: Preparation of silica by sol-gel method;

[0042] S2: the silicon dioxide prepared in step S1 is homogeneously mixed with a homogenizer, a carbon source and a sintering reducing agent;

[0043] S3: high temperature reduction;

[0044] S4: Dispersed classification.

[0045] The invention prepares silica by a sol-gel method, and the prepared silica is we...

Embodiment 1

[0066] A process for preparing nano silicon carbide by sol-gel method includes the following steps:

[0067] S1: Preparation of silica by sol-gel method;

[0068] S1-1: Mix 1 part of ammonia, 2 parts of ethanol, and 10 parts of distilled water to obtain solution A;

[0069] S1-2: Mix 1 part of ethyl orthosilicate, 10 parts of ethanol, and 5 parts of distilled water to obtain solution B;

[0070] S1-3: Add solution B to solution A and react for 12 hours;

[0071] S1-4: Wash to obtain silica.

[0072] S2: The silica prepared in step S1 is homogeneously mixed with a homogenizer, a carbon source, and a sintering aid reducing agent;

[0073] S2-1: The silica obtained in S1 is dispersed in a liquid phase medium, a dispersant is added, and ultrasonic stirring is used to obtain a dispersion; the dispersant is one or more of an aqueous dispersant and an oily dispersant. The homogenizer is one or more of NaCl, KCl, ZnCl, and LiCl.

[0074] S2-2: The dispersion obtained in the step S2-1 is added wit...

Embodiment 2

[0080] A process for preparing nano silicon carbide by sol-gel method includes the following steps:

[0081] S1: Preparation of silica by sol-gel method;

[0082] S1-1: Mix 1 part of ammonia, 2 parts of ethanol, and 10 parts of distilled water to obtain solution A;

[0083] S1-2: Mix 1 part of ethyl orthosilicate, 10 parts of ethanol, and 5 parts of distilled water to obtain solution B;

[0084] S1-3: Add solution B to solution A and react for 12 hours;

[0085] S1-4: Wash to obtain silica.

[0086] S2: The silica prepared in step S1 is homogeneously mixed with a homogenizer, a carbon source, and a sintering aid reducing agent;

[0087] S2-1: The silica obtained in S1 is dispersed in a liquid phase medium, a dispersant is added, and ultrasonic stirring is used to obtain a dispersion; the dispersant is one or more of an aqueous dispersant and an oily dispersant. The homogenizer is one or more of NaCl, KCl, ZnCl, and LiCl.

[0088] S2-2: The dispersion obtained in the step S2-1 is added wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com