Method for smelting high-phosphorus molten iron to produce steel with converter end point P less than or equal to 0.01% by adopting slagless material

A converter end point, slag material technology, applied in the direction of manufacturing converters, improving process efficiency, etc., can solve the problems of reduced metal yield, increased dephosphorization difficulty, poor dephosphorization effect, etc. Set and produce fast-paced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

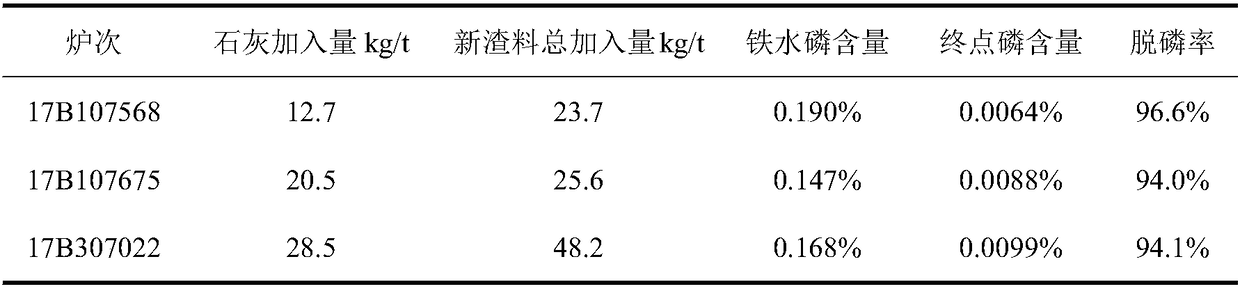

Embodiment 1

[0034] Load 109.8t of low-silicon and high-phosphorus hot metal and 16t of scrap steel into the 120t converter with a nominal tonnage of 120t. Among them, the weight percentage of elements in the molten iron is P: 0.190%, Si: 0.148% , C: 4.296%, the molten iron temperature is 1260℃, and the amount of slag remaining is 100%.

[0035] Within 4 minutes of the blowing process, the primary slag material mixed with lime, dolomite and returned slag is added to the converter. The primary slag material added is: lime 8.5kg / t molten steel, dolomite 8.5kg / t Liquid steel; After blowing oxygen for about 4 minutes, according to the slagging situation, add lime 4.2kg / t molten steel and pellets 2.5kg / t molten steel; add new slag material 23.7kg / t molten steel in total;

[0036] In the blowing process, the high-low-high-low gun position control mode is specifically as follows: the gun position is first reduced to 1.9m within 3 minutes of blowing, and the slag is rapidly reduced, and then about 1.6m...

Embodiment 2

[0042] Load 115.4t of low-silicon and high-phosphorus hot metal and 21t of scrap steel into the 120t converter with a nominal tonnage of 120t. Among them, the weight percentage of elements in the molten iron is P: 0.147% and Si: 0.198%. , C: 4.289%, molten iron temperature is 1270℃, slag retention is 50% half slag.

[0043] Within 4 minutes of the blowing process, the primary slag material mixed with lime, dolomite, and returned slag is added to the converter. The primary slag material added is: 11.9kg / t molten steel lime and 5.1kg / t dolomite Molten steel, return slag 4.5kg / t molten steel; after blowing oxygen for about 4 minutes, add 8.6kg / t molten steel with lime according to the slagging situation; add new slag material 25.6kg / t molten steel in total;

[0044] In the blowing process, the high-low-high-low gun position control mode is specifically as follows: the gun position is first reduced to 1.95m within 3 minutes of blowing, and the slag is quickly reduced, and then about 1....

Embodiment 3

[0050] The 120t nominal tonnage converter is charged with 120.0t of low-silicon and high-phosphorus hot metal and 20t of scrap steel without pre-treating treatment. The weight percentage of elements in the molten iron is P: 0.168% and Si: 0.258%. , C: 4.432%, the molten iron temperature is 1230℃, and the amount of slag remaining is 100%.

[0051] Within 4 minutes of the blowing process, a primary slag material mixed with lime, dolomite and returned slag is added to the converter. The primary slag material added is: lime 19.4kg / t molten steel and dolomite 16.5kg / t Liquid steel, return slag 4.7kg / t molten steel; after blowing oxygen for about 4 minutes, add 9.1kg / t molten steel with lime, 1.7kg / t molten steel with dolomite, and 1.5kg pellets according to the slagging situation. / t molten steel; a total of 48.2kg / t molten steel is added with new slag material;

[0052] The high-low-high-low gun position control mode used in the blowing process is specifically as follows: the gun posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com