Composite fabric with built-in drug powder and its production method and application

A composite fabric and production method technology, applied in the field of medical supplies and textiles, can solve the problems of secondary damage, poor anti-virus effect, etc., achieve the effect of reducing the damage of secondary inhalation, high porosity, and solving the problem of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

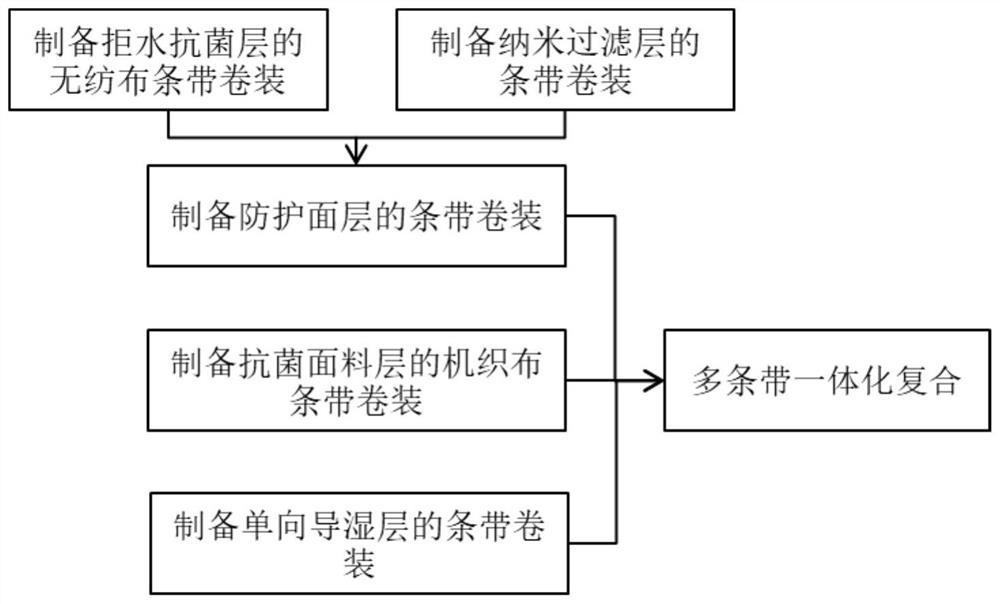

Method used

Image

Examples

Embodiment 1

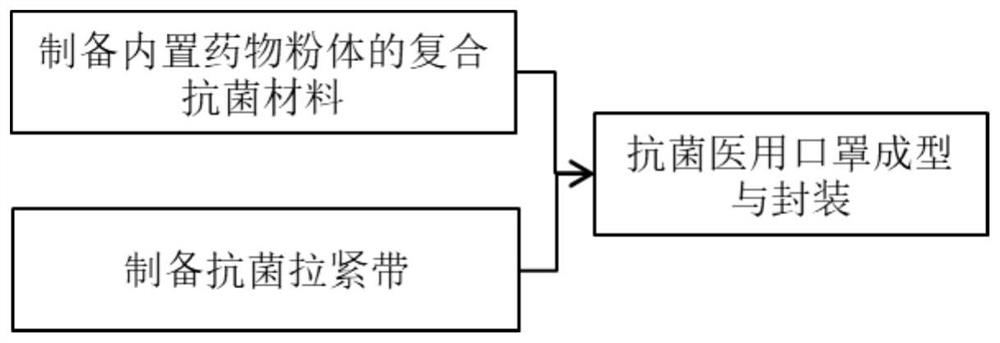

[0064] Composite fabric and medical mask with built-in ZnO drug powder and its application practice

[0065] A composite fabric with built-in ZnO drug powder, the preparation method is as follows:

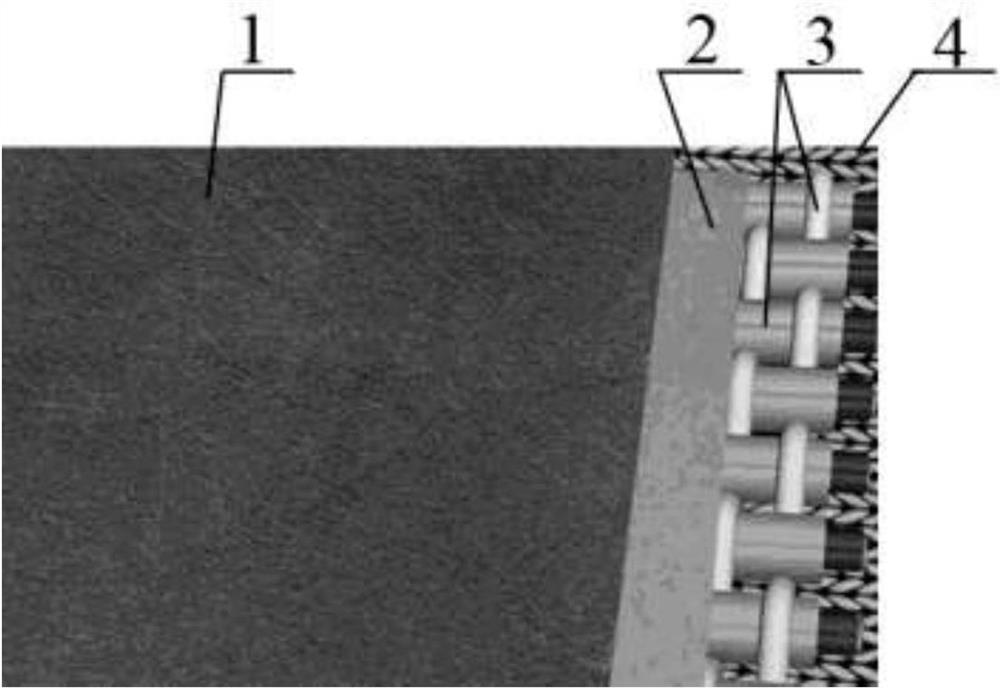

[0066] (1) Prepare the non-woven tape package of water-repellent and antibacterial layer 1

[0067] Use a silicone water-repellent finishing solution with a mass concentration of 10g / L and an opposite surface density of 30g / m 2 The 50 / 50 viscose / hemp medical antibacterial non-woven fabric is padded, and the cloth passing speed is 20m / min during padding; the cloth strips after padding are dried by SWA801-100 dryer, The drying temperature is 160°C, and then the BS-5300 fabric setting machine is used for steam setting treatment. The setting temperature is 150°C, and the setting time is 1min. The shaped fabric is cut into The 13cm wide non-woven fabric strip is wound in parallel on the cylindrical paper tube at a linear speed of 120m / min to obtain the non-woven fabric strip package o...

Embodiment 2

[0077] Composite fabrics and medical masks with built-in nano-silver nitrate powder and its application practice

[0078] A kind of composite fabric with built-in nano-silver nitrate powder, compared with embodiment 1, the difference is that, in step (3) preparation built-in anti-virus powder yarn woven fabric layer's strip wrapping process, adopts built-in The silver nitrate powder mass fraction is 40%, and the fineness is 40tex PP non-woven fabric strip coated silver nitrate powder composite yarn as the weft yarn, and the fineness is 21tex polyester sewing thread as the warp yarn, on the rapier loom The woven fabric with built-in powder material is made, and the woven fabric is cut into 10cm wide woven fabric strips by a strip cutting machine, and the edges of the woven fabric strips are sealed by thermal bonding to form a drug medical layer fabric cloth strips in rolls.

[0079] The rest of the steps are basically the same as those in Embodiment 1, and will not be repeated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com