Filtering magnetic core with high magnetic conductivity

A technology with high magnetic permeability and magnetic core, which is applied in the field of filtering and can solve the problems of electromagnetic field influence and affecting filter filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

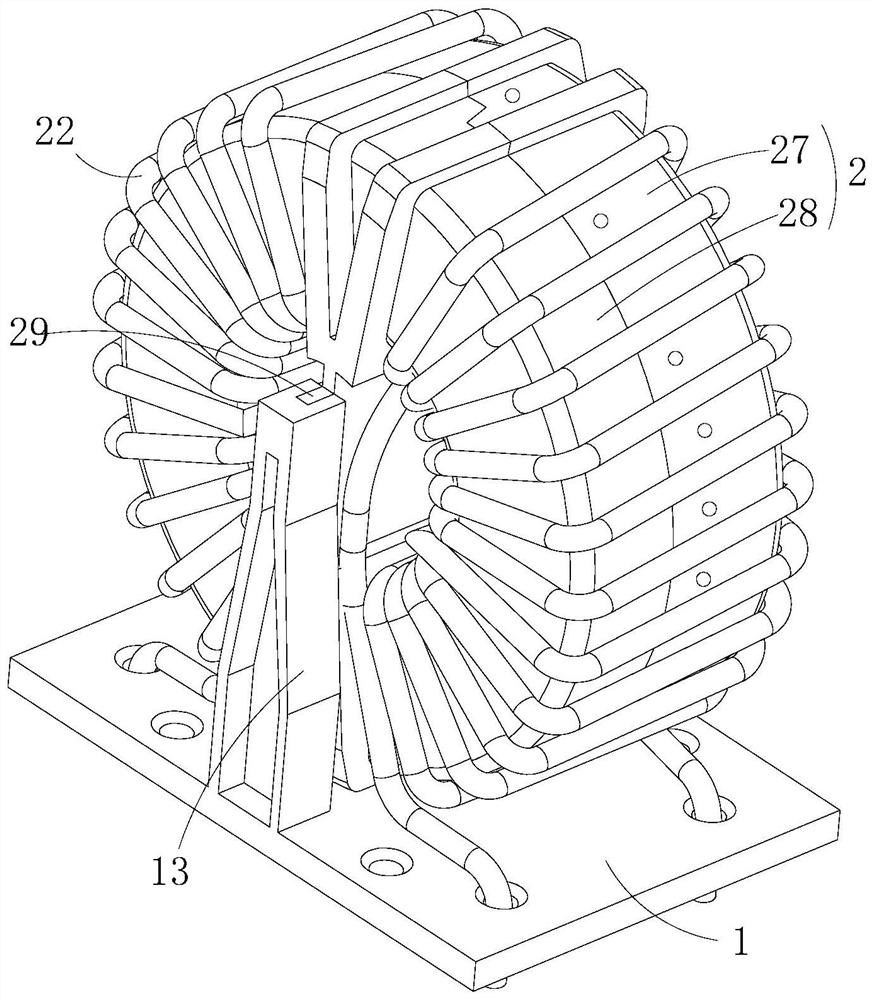

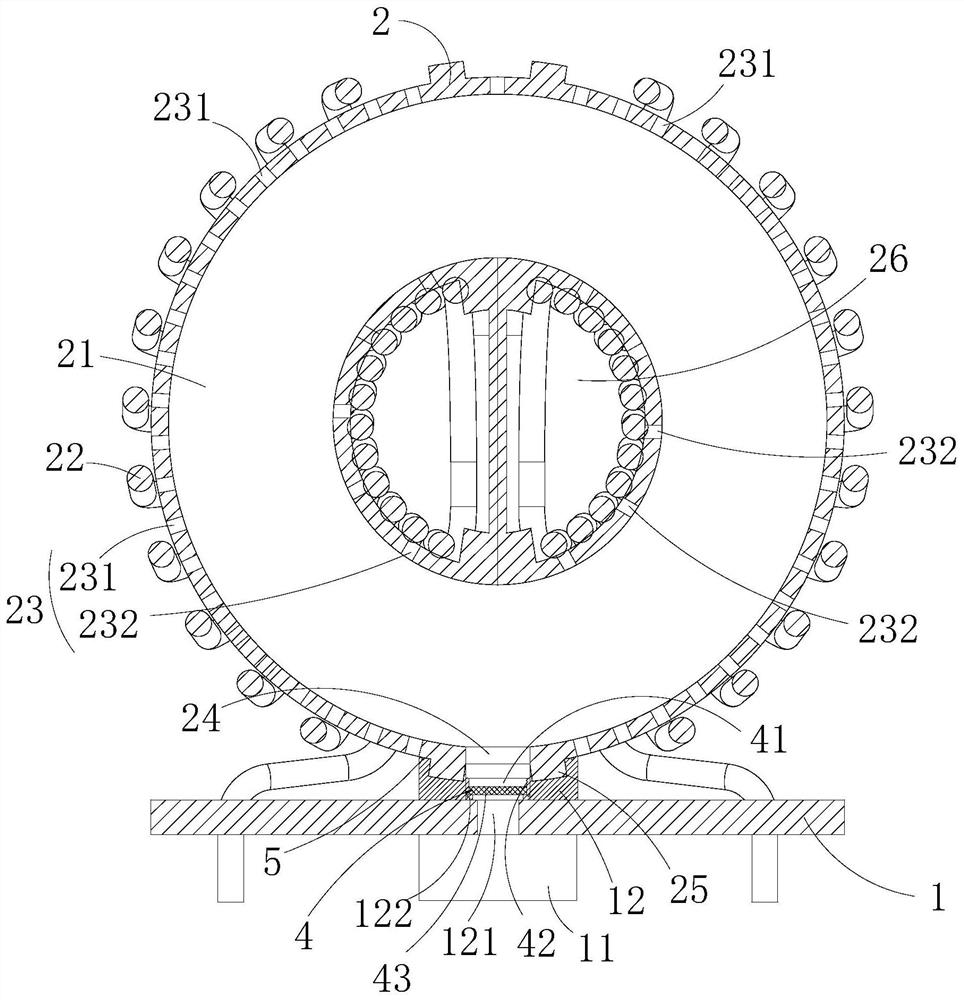

[0037] Such as Figure 1 to Figure 3 As shown, the present invention provides a filter core with high magnetic permeability, including: a base 1, on which a cooling fan 11 is arranged; a housing 2, which is detachably connected to the base 1, the housing 2 is provided with a heat dissipation chamber 21, and a coil 22 is wound on the outside of the housing 2, and the housing 2 is provided with an air inlet 23 and an air vent communicating with the heat dissipation chamber 21 24, the vent 24 communicates with the air intake of the heat dissipation fan 11; the filter element 4, the filter element 4 is detachably arranged between the air intake 24 and the air intake, the The filter element 4 is provided with a dust collection groove 41 with an opening facing the air vent 24 .

[0038] It can be understood that, by making the air suction port of the heat dissipation fan 11 communicate with the heat dissipation chamber 21, when the heat dissipation fan 11 is running, under the acti...

Embodiment 2

[0041] The difference between this embodiment and the foregoing embodiments is that;

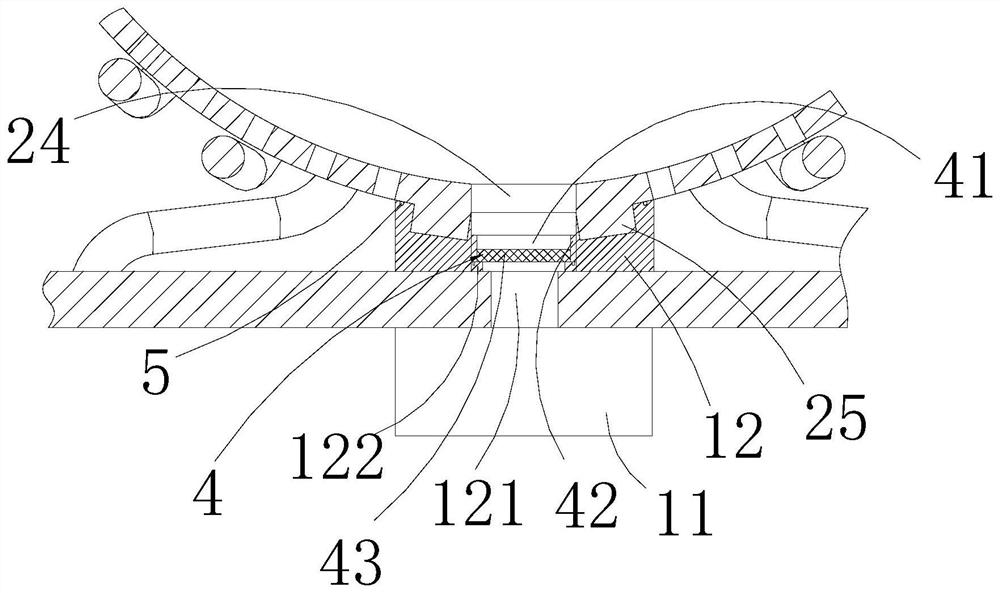

[0042] Such as Figure 1 to Figure 3 As shown, in some embodiments of the present invention, the heat dissipation fan 11 is arranged at the lower end of the base 1, and the upper end of the base 1 is provided with a boss 12, and the boss 12 is provided with an overflow channel 121 , the upper port of the flow passage 121 communicates with the vent 24, and the suction port communicates with the lower port of the flow passage 121; wherein, the filter element 4 is arranged in the flow passage Inside Road 121. Thereby, communication between the air intake port and the vent port 24 is facilitated.

[0043] In some embodiments of the present invention, the filter element 4 includes a dust collection cylinder 42 and a filter screen 43 connected to the lower end of the dust collection cylinder 42 , the inner cavity of the dust collection cylinder 42 and the filter screen 43 The dust collection gr...

Embodiment 3

[0047] The difference between this embodiment and the foregoing embodiments is that;

[0048] Such as Figure 1 to Figure 3 As shown, in some embodiments of the present invention, the housing 2 is provided with a central hole 26, the coil 22 is passed through the central hole 26, and the air inlet 23 includes a plurality of The first air inlet hole 231 on the side wall of the housing 2 and a plurality of second air inlet holes 232 arranged at intervals on the side wall of the central hole 26 . Thus, it is ensured that the airflow from all places can enter into the cooling chamber 21 to improve the cooling effect.

[0049] In some embodiments of the present invention, at least a part of the first air inlet hole 231 is located between two adjacent coils 22 . Thus, the heat dissipation effect is improved. It should be noted that the coil 22 is composed of wires, and the first air inlet hole 231 may be located between two adjacent wires.

[0050] In some embodiments of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com