Heat conductive thermoplastic resin composite material and preparation method thereof

A thermoplastic resin and composite material technology, applied in the field of composite materials and their preparation, can solve the problems of heavy weight, difficult disassembly and transfer, difficult processing of thermally conductive materials, unsatisfactory insulation requirements, etc., so as to improve mechanical properties, save consumption, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

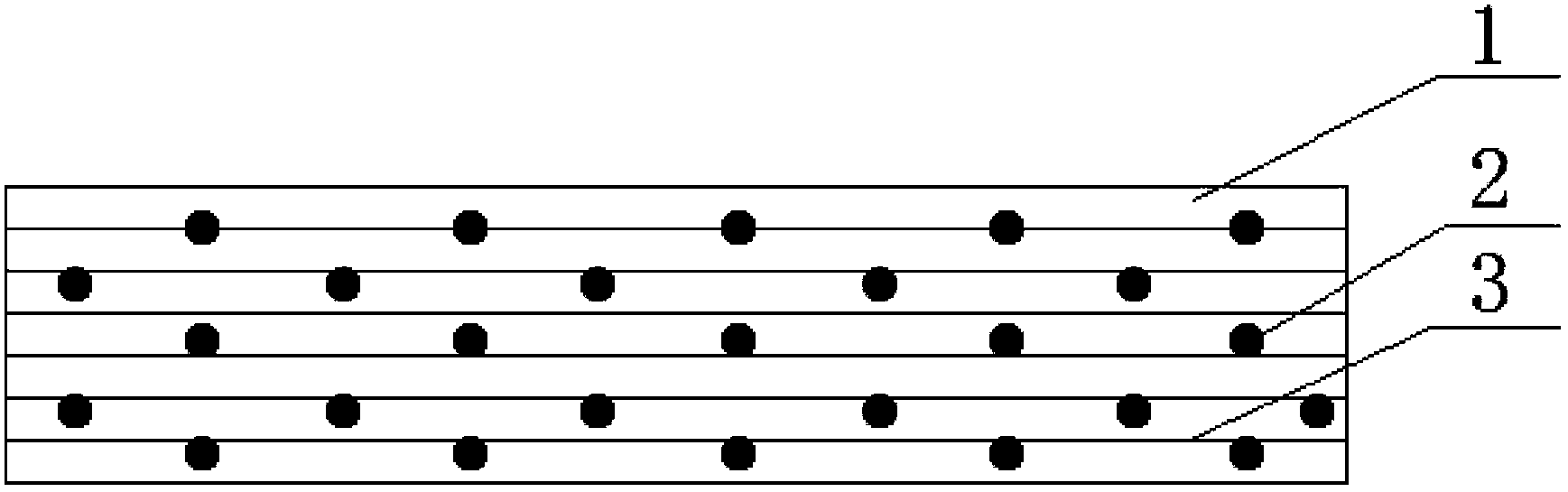

Image

Examples

Embodiment 1

[0029] (1), thermoplastic resin, glass fiber and magnesia, aluminum oxide, graphite and antioxidant are mixed uniformly by following parts by weight;

[0030] Polypropylene resin 40,

[0031] E-glass roving 32,

[0033] Aluminum oxide 30,

[0034] Graphite 3.8,

[0035] Antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.267,

[0036] Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.133;

[0037] After the extruder is heated and melted, the coating is plasticized, and the coating temperature is set. The coating temperature of the polypropylene resin is 240°C, and the leached film is compounded with the continuous glass fiber; the glass fiber needs to be stretched in parallel before the compounding, so that After the fibers are evenly spread, enter the oven for preheating, the preheating temperature is 200°C; the compounding process is carried out in the compounding roll; during the compounding ...

Embodiment 2

[0048] (1), mix nylon 6, glass fiber, magnesium oxide, aluminum oxide, graphite and antioxidant according to the following ratio evenly;

[0049] Nylon 6 30,

[0050] E-glass roving 29,

[0052] Aluminum oxide 33,

[0053] Graphite 3.8,

[0054] Antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.133,

[0055] Antioxidant tris (2,4-di-tert-butylphenyl) phosphite 0.267;

[0056] Spread multiple bundles of continuous fibers (non-alkali glass roving) in parallel to make the fibers spread evenly and then enter the oven for preheating, the preheating temperature is 200°C; then the mixed raw materials are heated and melted, and then passed through the extruder The die head coats the resin, and the coating temperature is set at 300°C. If the coating state is not uniform, it is necessary to increase the coating temperature and extruder screw frequency appropriately to make the film reach a uniform and continu...

Embodiment 3

[0067] (1), mix thermoplastic resin, glass fiber, magnesium oxide, aluminum oxide, graphite and antioxidant according to the following proportions;

[0068] Polypropylene resin 30,

[0069] E-glass roving 20,

[0071] Aluminum oxide 43.6,

[0072] graphite 3,

[0073] Antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.267,

[0074] Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.133;

[0075] After the extruder is heated and melted, the coating is plasticized, and the coating temperature is set. The coating temperature of the polypropylene resin is 240°C. Composite the leached film with continuous glass fiber; before compounding, the glass fiber needs to be stretched in parallel, so that the fibers are spread evenly and then enter the oven for preheating. The preheating temperature is 200°C. The compounding process is carried out in the compounding roller; There is 20°C room temperature water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com