Drilling device for water conservancy project construction

A technology of water conservancy engineering and perforating device, which is applied in the agricultural field, can solve the problems of easy backfilling of soil into holes and poor stability, and achieve the effects of improving strength, improving stability and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

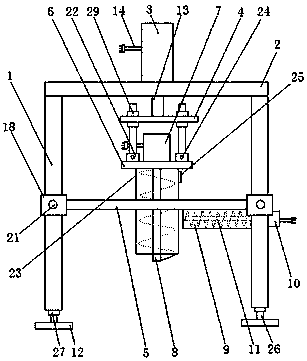

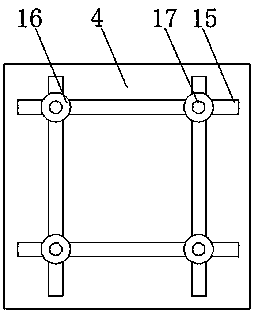

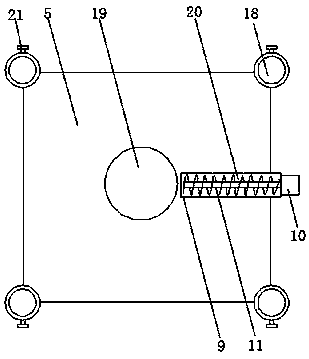

[0018] as attached Figure 1-3 Shown: a drilling device for water conservancy construction, including a vertical bar 1, a top plate 2, a cylinder 3, an adjustment plate 4, a limit plate 5, a fixed plate 6, a motor 7, a drilling column 8, and a soil discharge tank 9 , motor two 10, auger 11 and backing plate 12, it is characterized in that: described top plate 2 is arranged on the vertical bar 1, and described cylinder 3 is arranged on the top plate 2, and is provided with power line 14 on cylinder 3 , Piston rod 13, described adjusting plate 4 is arranged on the piston rod 13, and is provided with positioning groove 15 on adjusting plate 4, is provided with connecting rod 17 by positioning nut 16 in described positioning groove 15, described Limiting ring 18 is set on the limiting plate 5, limiting groove 19 is set at the center of limiting plate 5, soil falling groove 20 is arranged on one side of limiting groove 19, and limiting ring 18 is arranged on On the vertical rod 1,...

Embodiment 2

[0024] as attached Figure 4 Shown: a drilling device for water conservancy construction, including a vertical bar 1, a top plate 2, a cylinder 3, an adjustment plate 4, a limit plate 5, a fixed plate 6, a motor 7, a drilling column 8, and a soil discharge tank 9 , motor two 10, auger 11 and backing plate 12, it is characterized in that: described top plate 2 is arranged on the vertical bar 1, and described cylinder 3 is arranged on the top plate 2, and is provided with power line 14 on cylinder 3 , Piston rod 13, described adjusting plate 4 is arranged on the piston rod 13, and is provided with positioning groove 15 on adjusting plate 4, is provided with connecting rod 17 by positioning nut 16 in described positioning groove 15, described Limiting ring 18 is set on the limiting plate 5, limiting groove 19 is set at the center of limiting plate 5, soil falling groove 20 is arranged on one side of limiting groove 19, and limiting ring 18 is arranged on On the vertical rod 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com