Method for solving looseness of connecting parts of engineering machines

A technology for connecting parts and construction machinery, applied in the direction of connecting components, mechanical equipment, threaded fasteners, etc., can solve the problems of unstable connection parts of construction machinery, and achieve the effect of solving loosening, reducing maintenance frequency and avoiding engineering accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

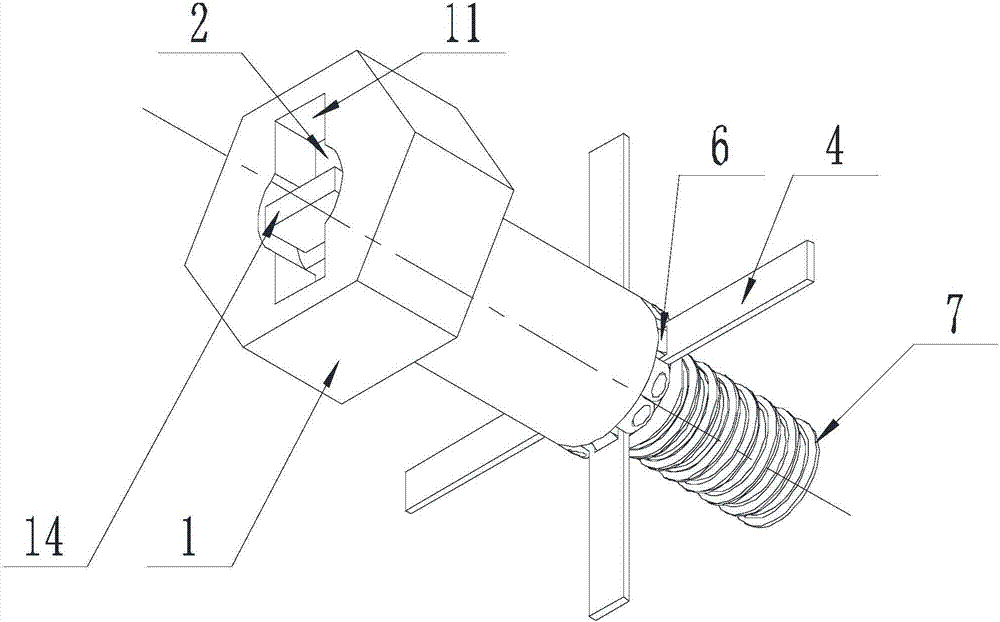

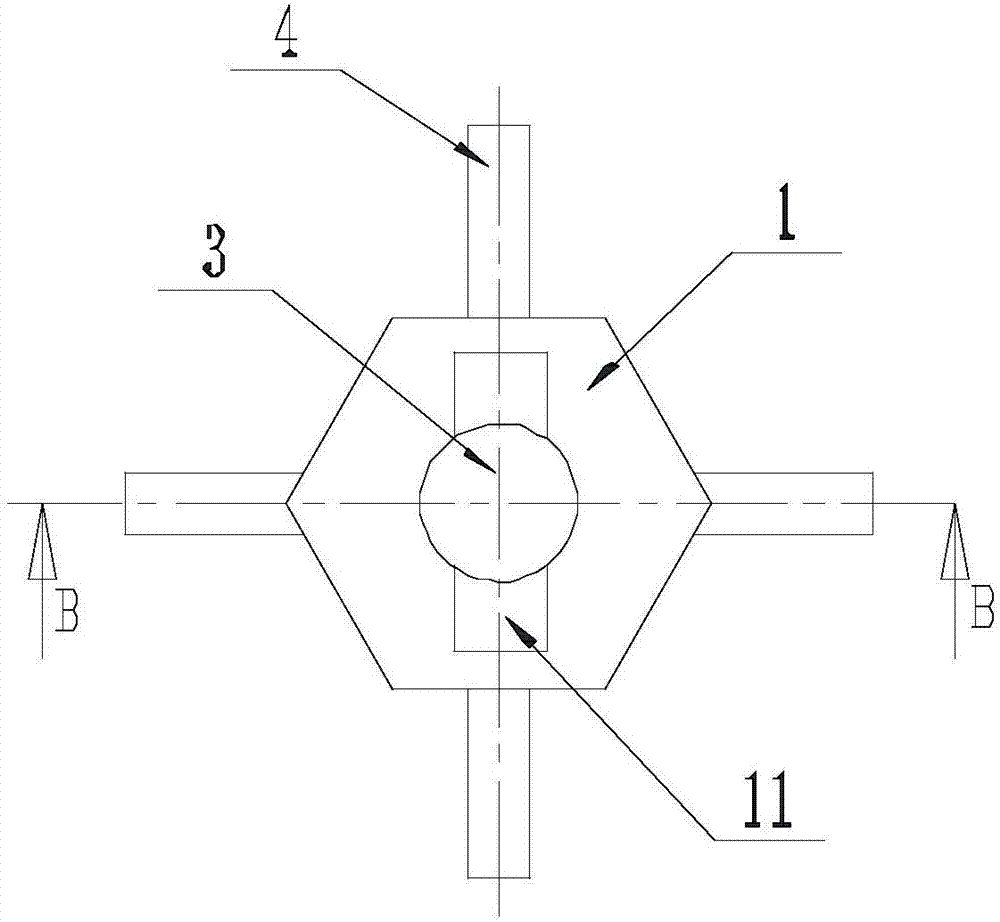

[0039] Such as Figure 1-Figure 8 As shown, the present invention solves the method for unloading of construction machinery connection parts, comprising the following steps:

[0040] Step A Installation: Put the pin shaft 5 through the gear 6 from the axis of the gear 6, fix the gear 6 on the pin shaft 5, and connect one end of the anti-loosening plate 4 to the side wall of the pin shaft 5, and then install the pin shaft 5 It is hinged with the end surface of the screw rod of the bolt 1 away from the head of the bolt, so that the pin shaft 5 can rotate around its own axis;

[0041] Step B Fixing for the first time: first put the parts to be connected and fixed, and align the threaded holes on them, then insert the anti-loosening plate 4 and the end of the bolt 1 close to the anti-loosening plate 4 into the threaded holes in turn, and then Rotate the bolt 1 to thread the bolt 1 to the threaded hole, and fix the parts to be connected and fixed to each other;

[0042] Step C Se...

Embodiment 2

[0045] The present invention is based on embodiment 1, and the present invention is further described.

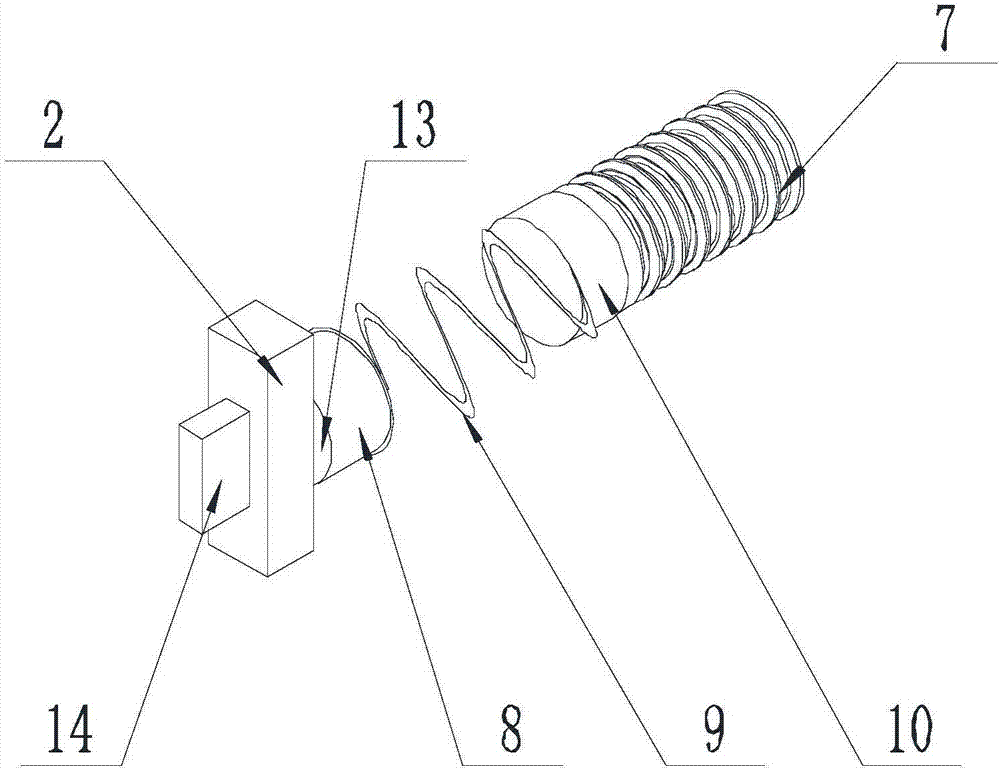

[0046] Such as Figure 1-Figure 8 As shown, the present invention solves the method for loosening and unloading the connection parts of construction machinery. The push rod assembly includes the stopper 2, the installation shaft 8, the spring 9 and the connection shaft 10 connected in sequence, and the installation shaft 8, the spring 9 and the connection shaft 10 are coaxial with each other, and the end surface of the connecting shaft 10 away from the spring 9 is hinged with the anti-loosening plate 4;

[0047] A relief groove 11 is provided at the head of the bolt 1, and the projected dimension of the relief groove 11 along the axis of the bolt 1 is consistent with the projected dimension of the stopper 2 along the axis of the installation shaft 8;

[0048] One end of the relief groove 11 close to the screw rod is provided with a mounting hole 12 communicating with the b...

Embodiment 3

[0050] The present invention is based on embodiment 2, and the present invention is further described.

[0051] Such as Figure 1-Figure 8 As shown, the method of the present invention to solve the loosening of the connection parts of construction machinery also includes step D and step E which are sequentially arranged after step C;

[0052] Step D pushing: when the surface of the anti-loosening plate 4 away from the axis of the bolt 1 is in contact with the parts to be connected, continue to push the push rod assembly along the axis of the bolt 1, and the spring 9 is compressed until the stopper 2 moves to the installation hole 12 in;

[0053] Step E rotation: when the block 2 moves into the mounting hole 12, turn the block 2 so that the projection of the block 2 along the axis of the bolt 1 does not completely fall on the relief groove 11, that is, the block 2 is installed in the hole 12 Block the end face away from the end of the screw.

[0054] When the push rod assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com