Patents

Literature

225results about "Drilling with mechanical conveying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

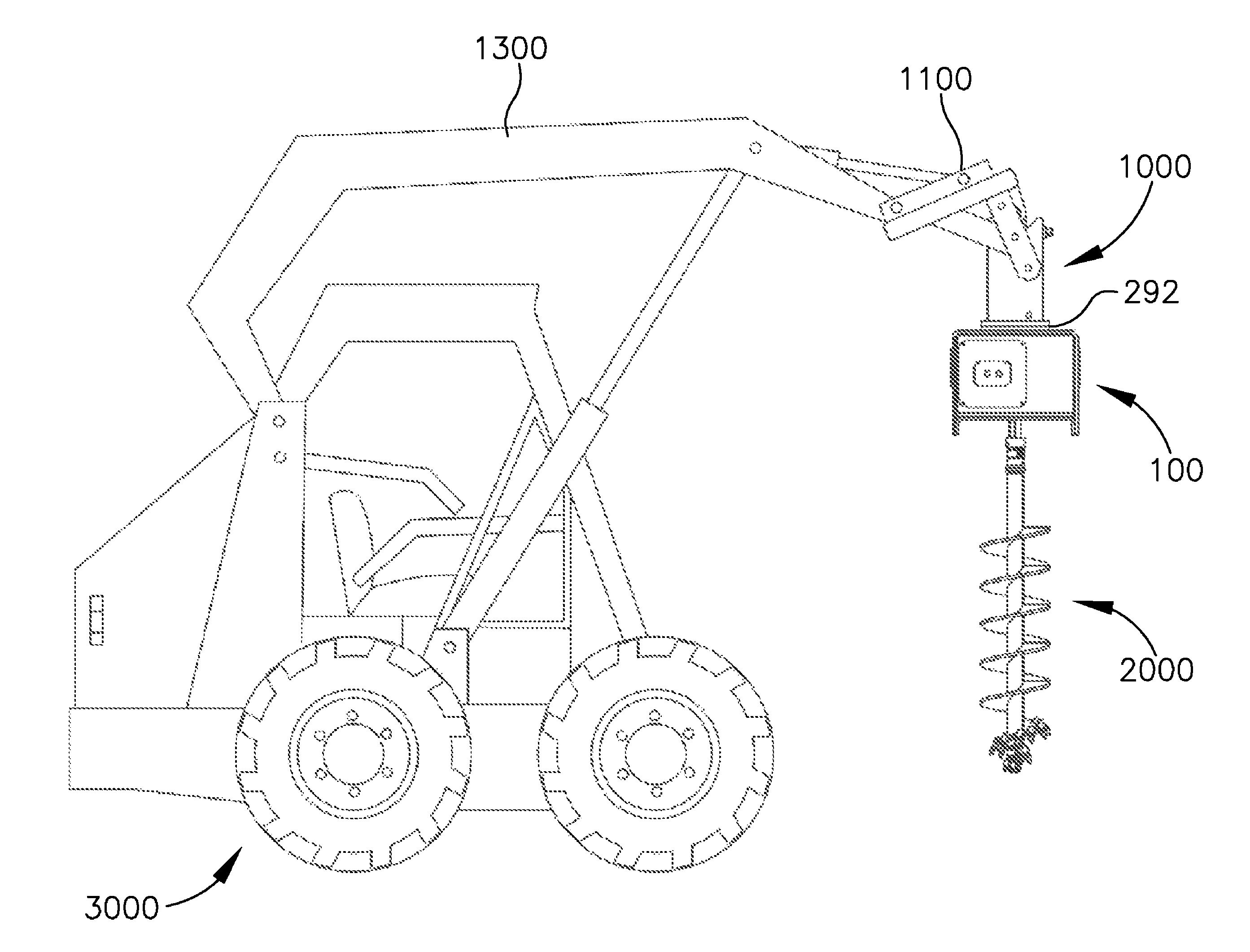

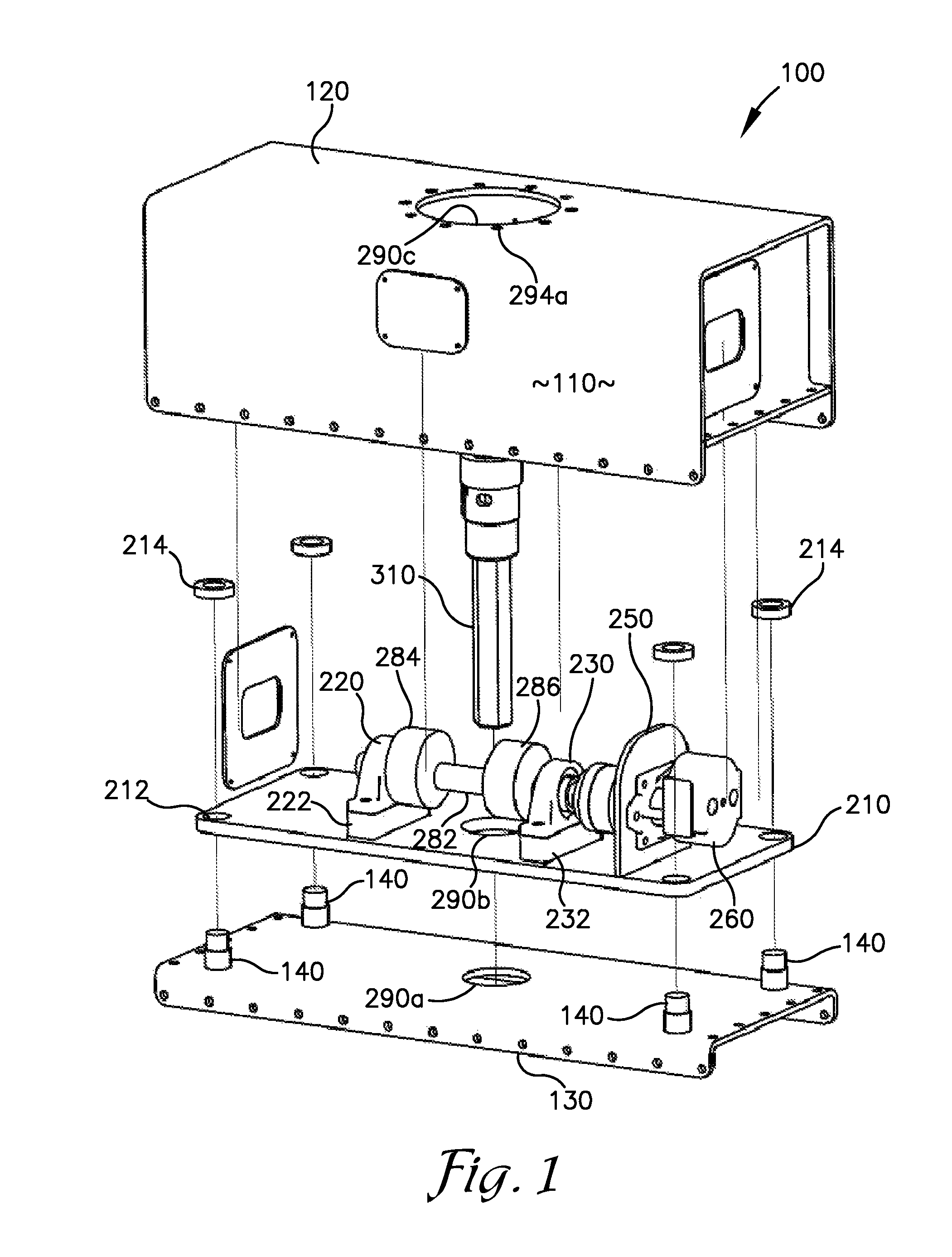

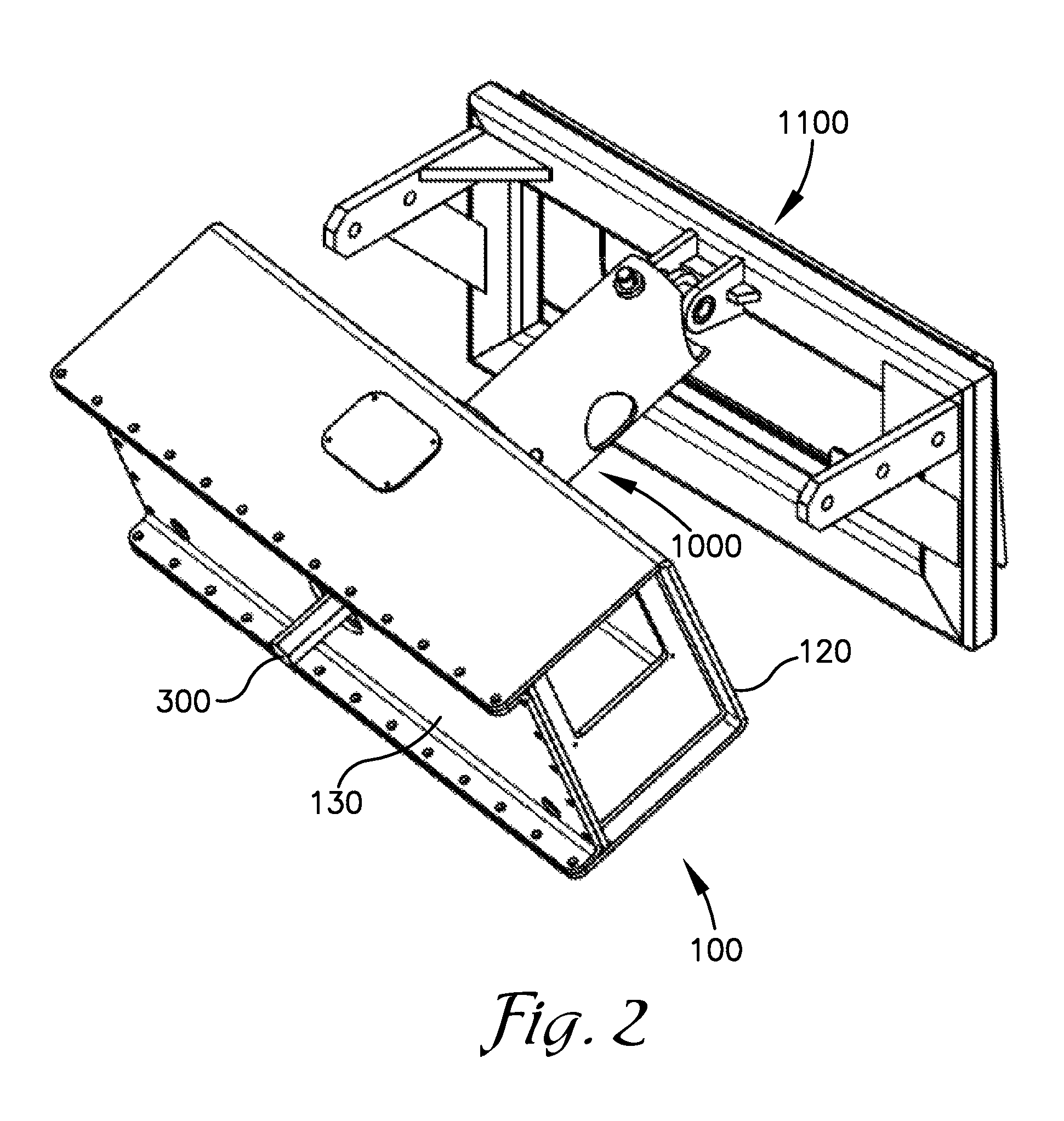

Vibratory drilling apparatus

A vibratory unit interposed between a planetary drive and earth-penetrating device, e.g., an auger, is powered by the hydraulic system of a tractor, skid loader or the like. The unit includes a housing having a base plate with a slidable striker plate mounted therein. A Kelly bar displaces the planetary drive from the auger and through the housing. A rotatable shaft with weights eccentrically mounted thereon produces vibratory forces and urges the striker plate into contact with the base plate to provide hammer-like forces on the auger.

Owner:HARLEMAN RONALD

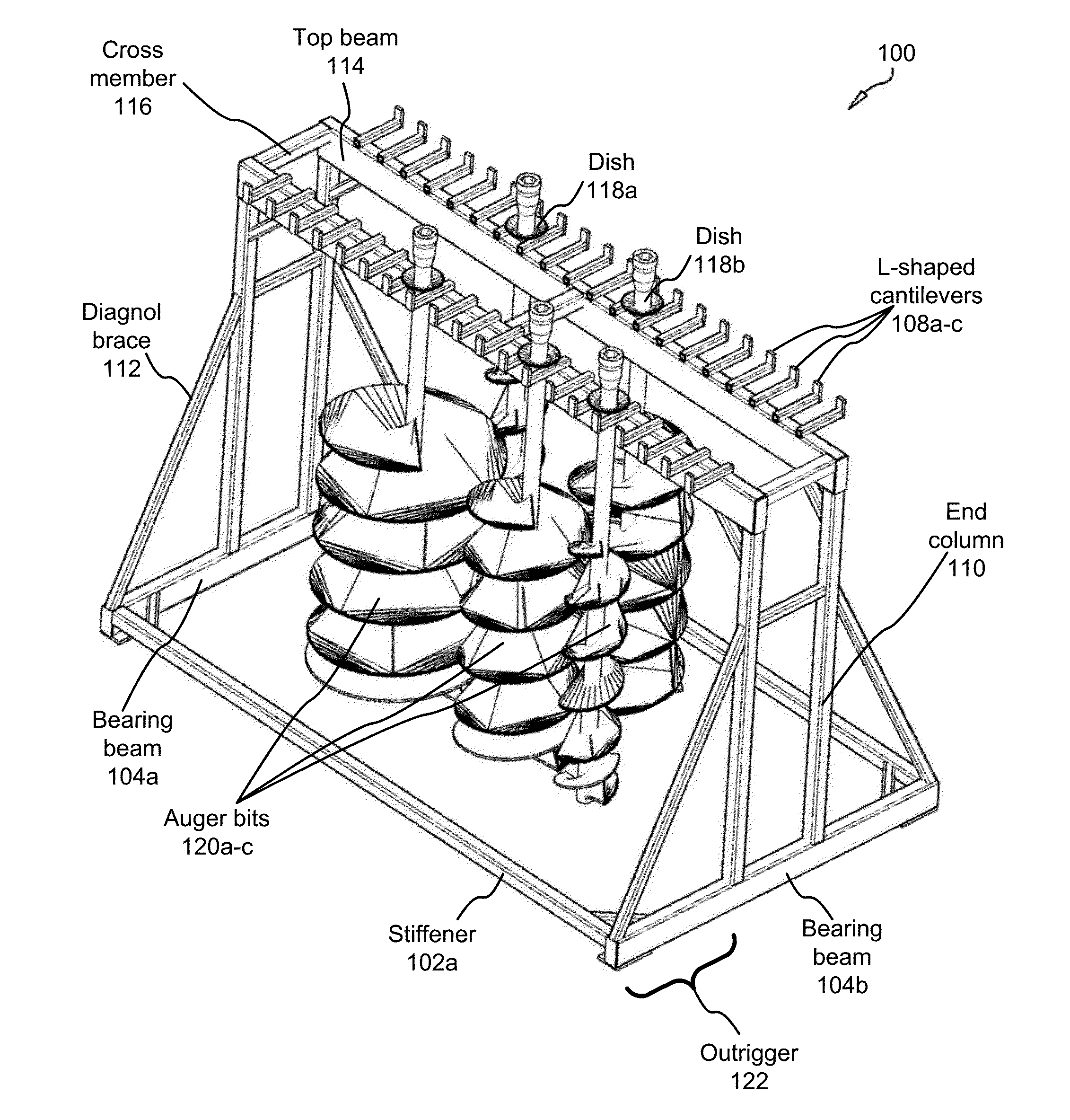

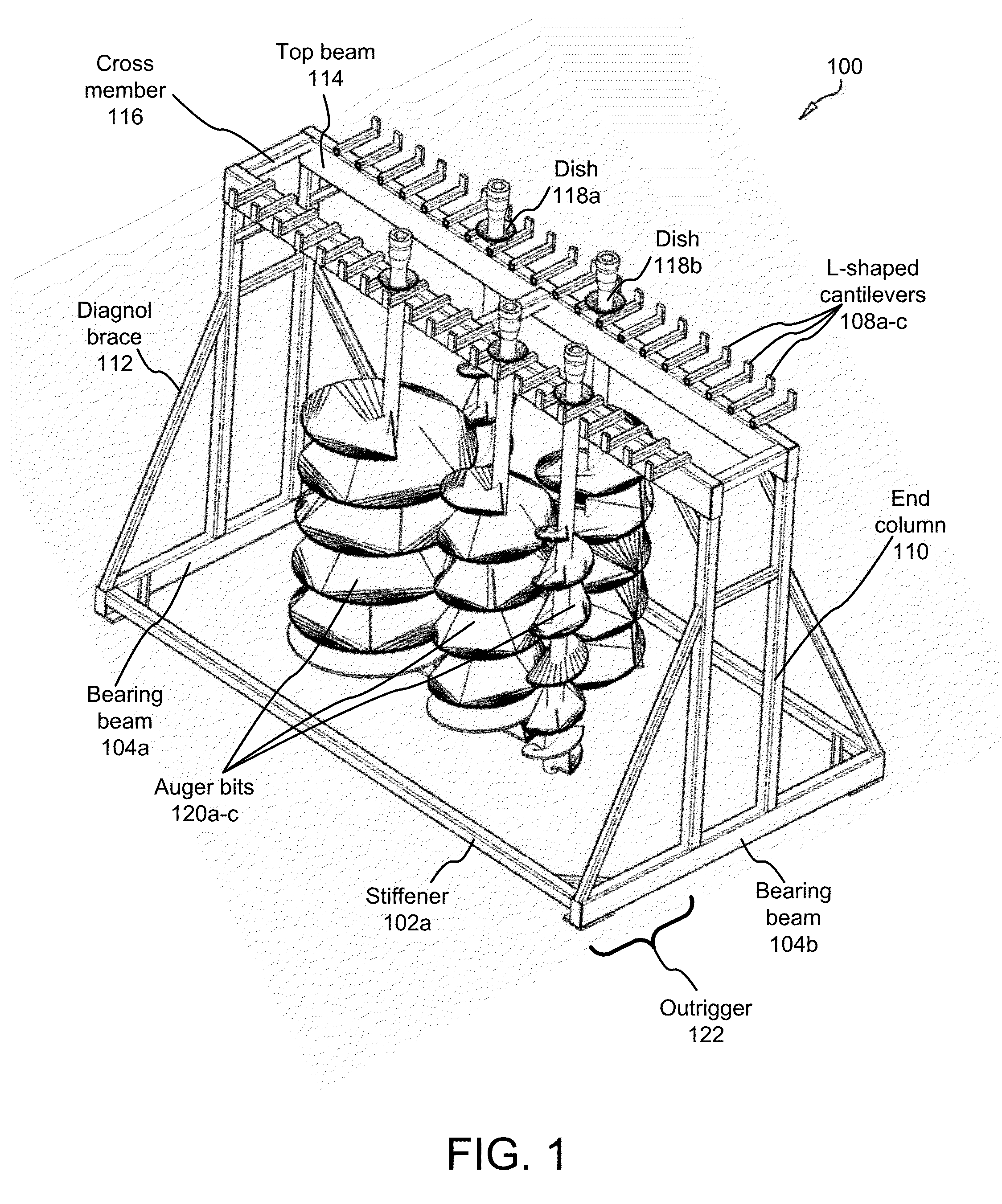

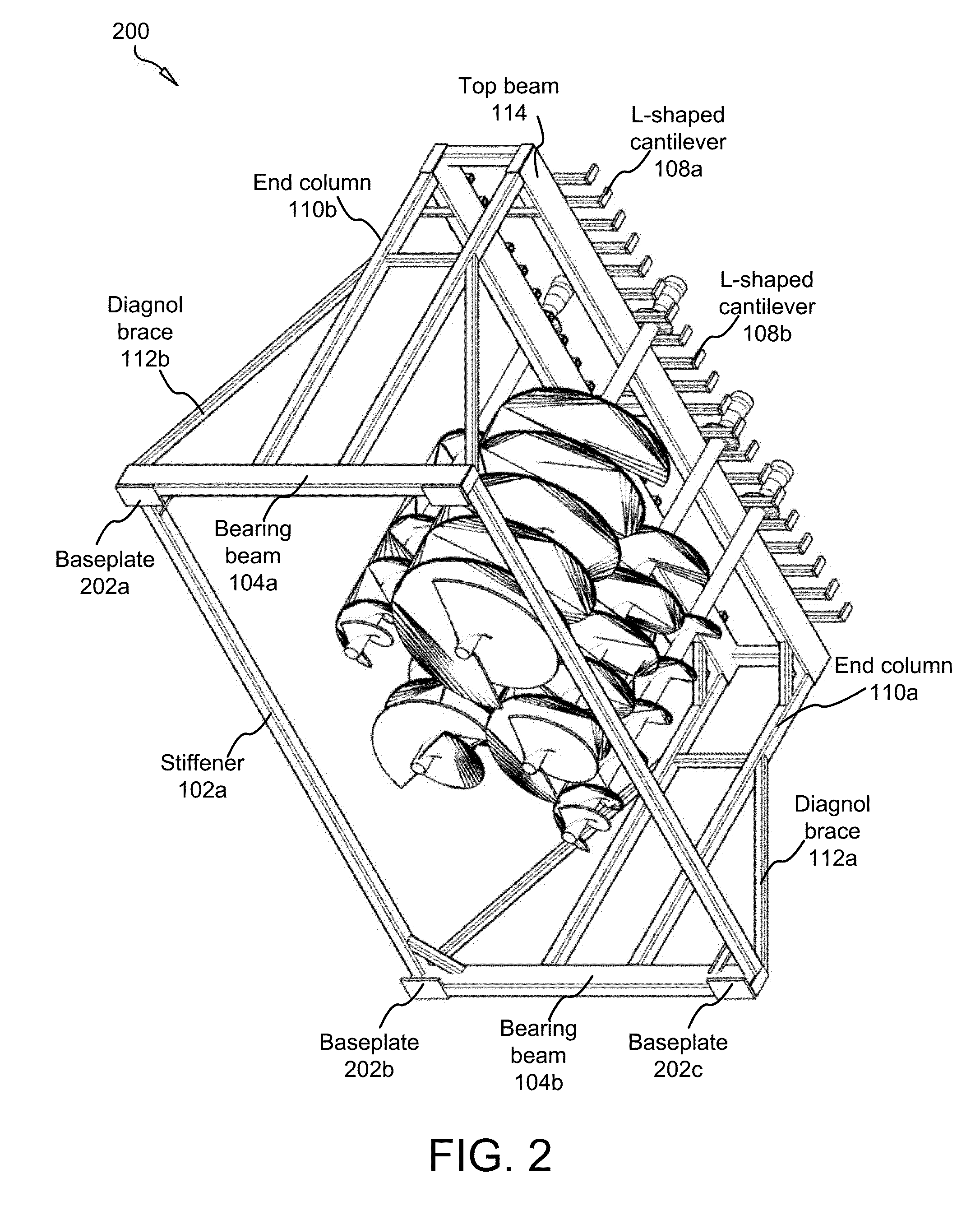

Auger rack with vertical securement means for suspended storage, use and/or transport of augers or drill bits

A rack is disclosed, adapted to facilitate efficient transport and interchange of augers and / or mining drill bits used in construction by either single operator or a plurality of operators. The rack comprises a plurality of elongated members affixed to one another; and, in some embodiments, a plurality of L-shaped, cantilevered brackets from which augers or drill bits are suspended during transport, storage, interchange, and the like.

Owner:HOKANSON CRAIG RICHARD

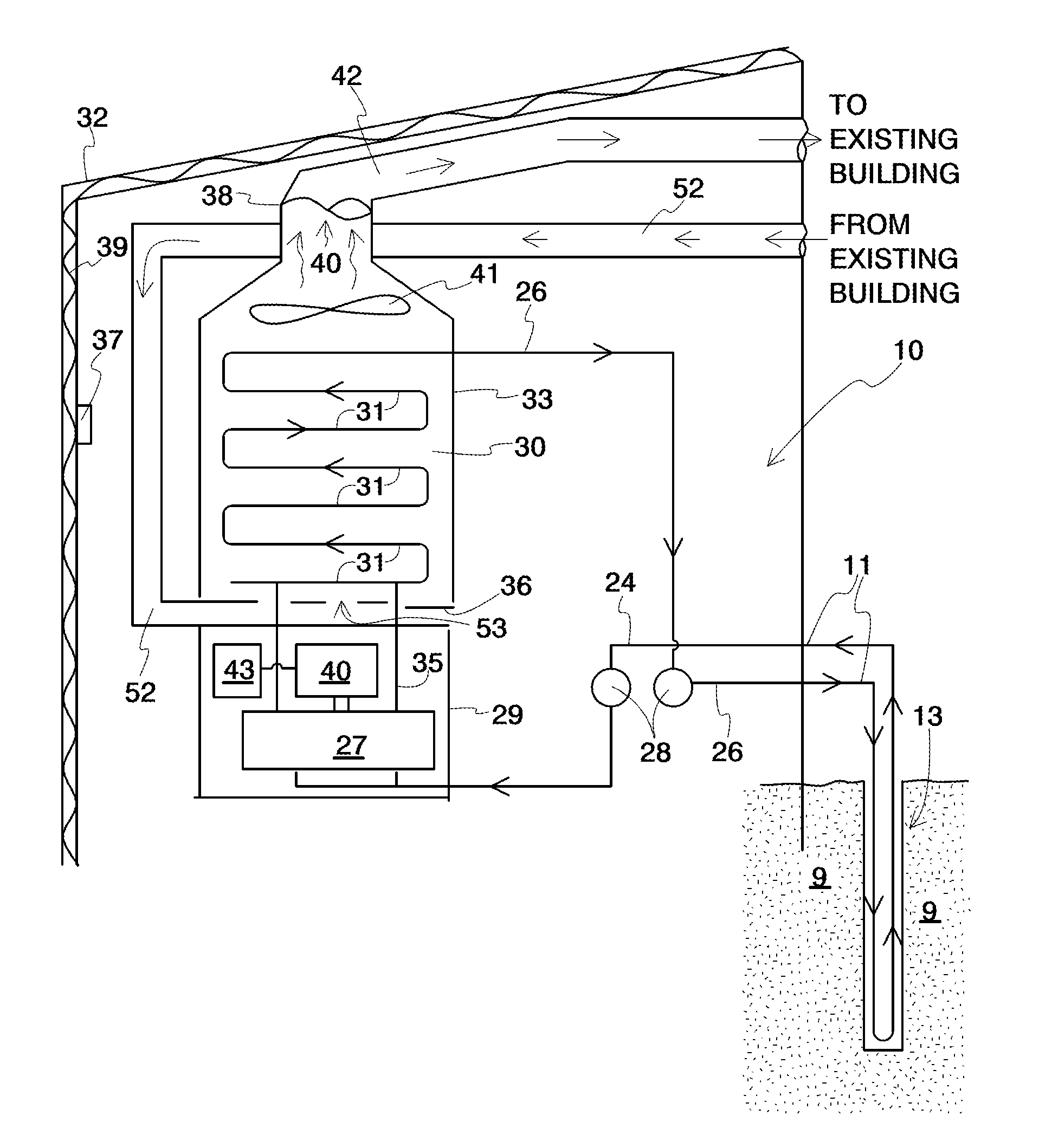

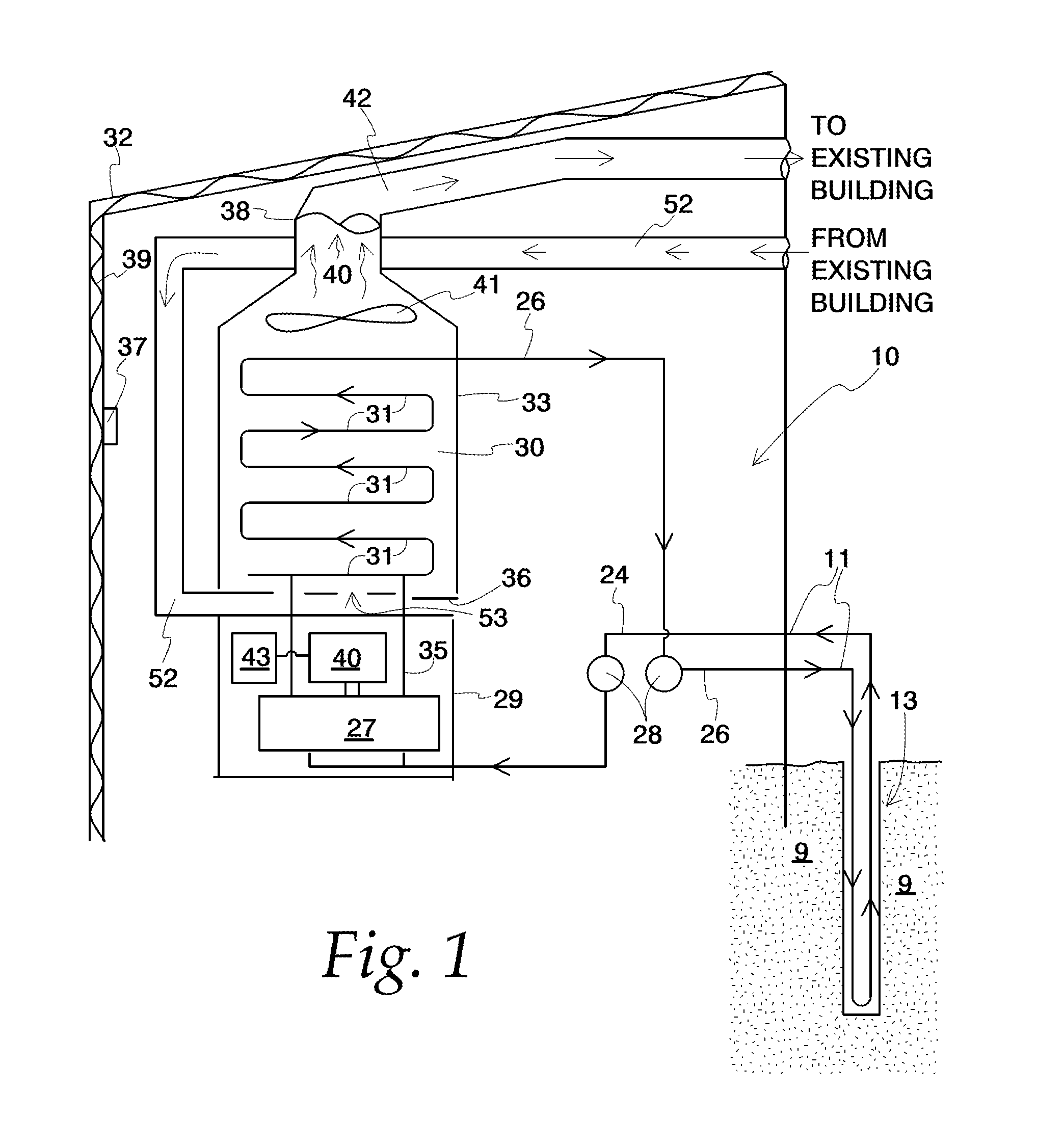

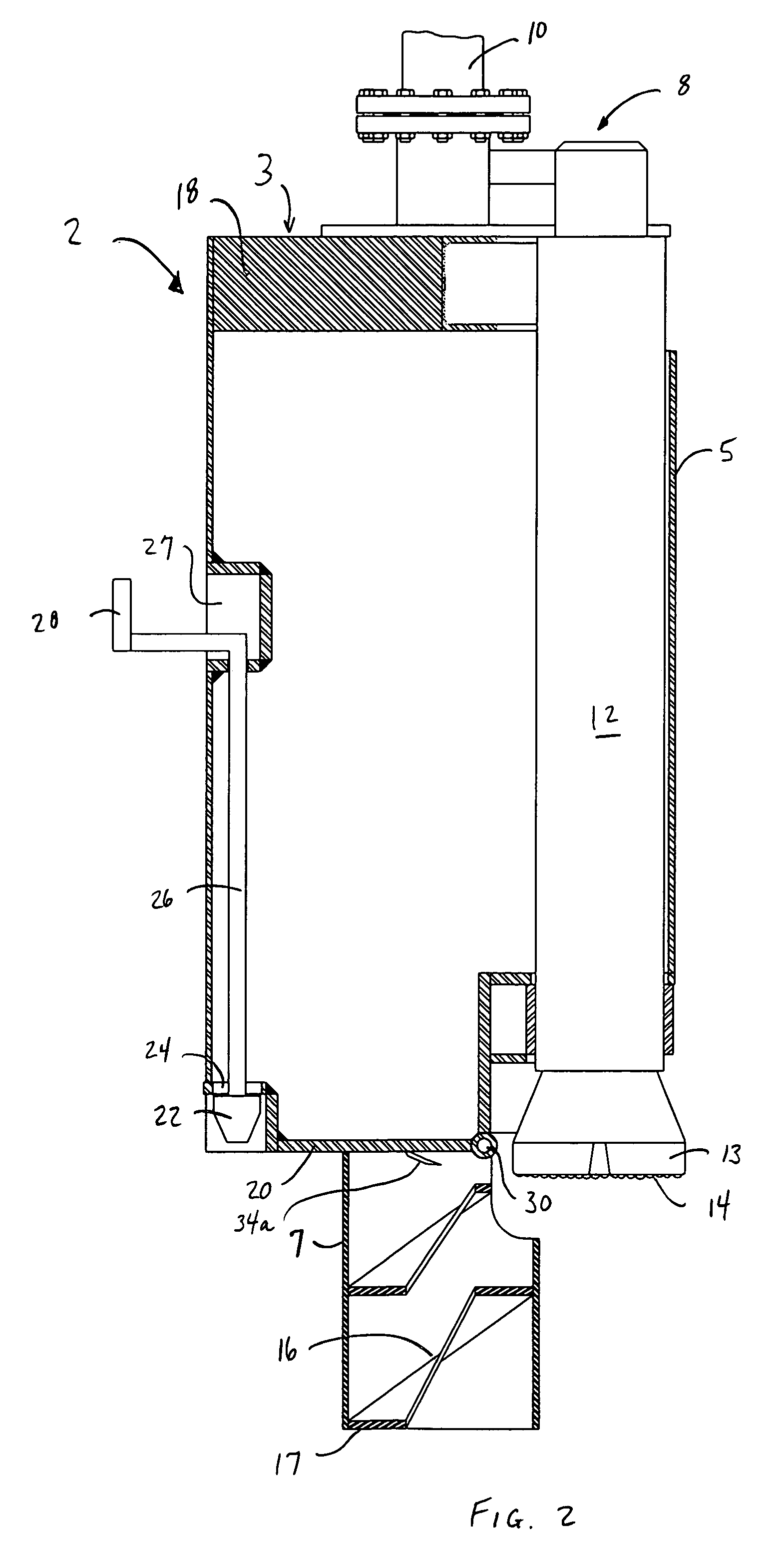

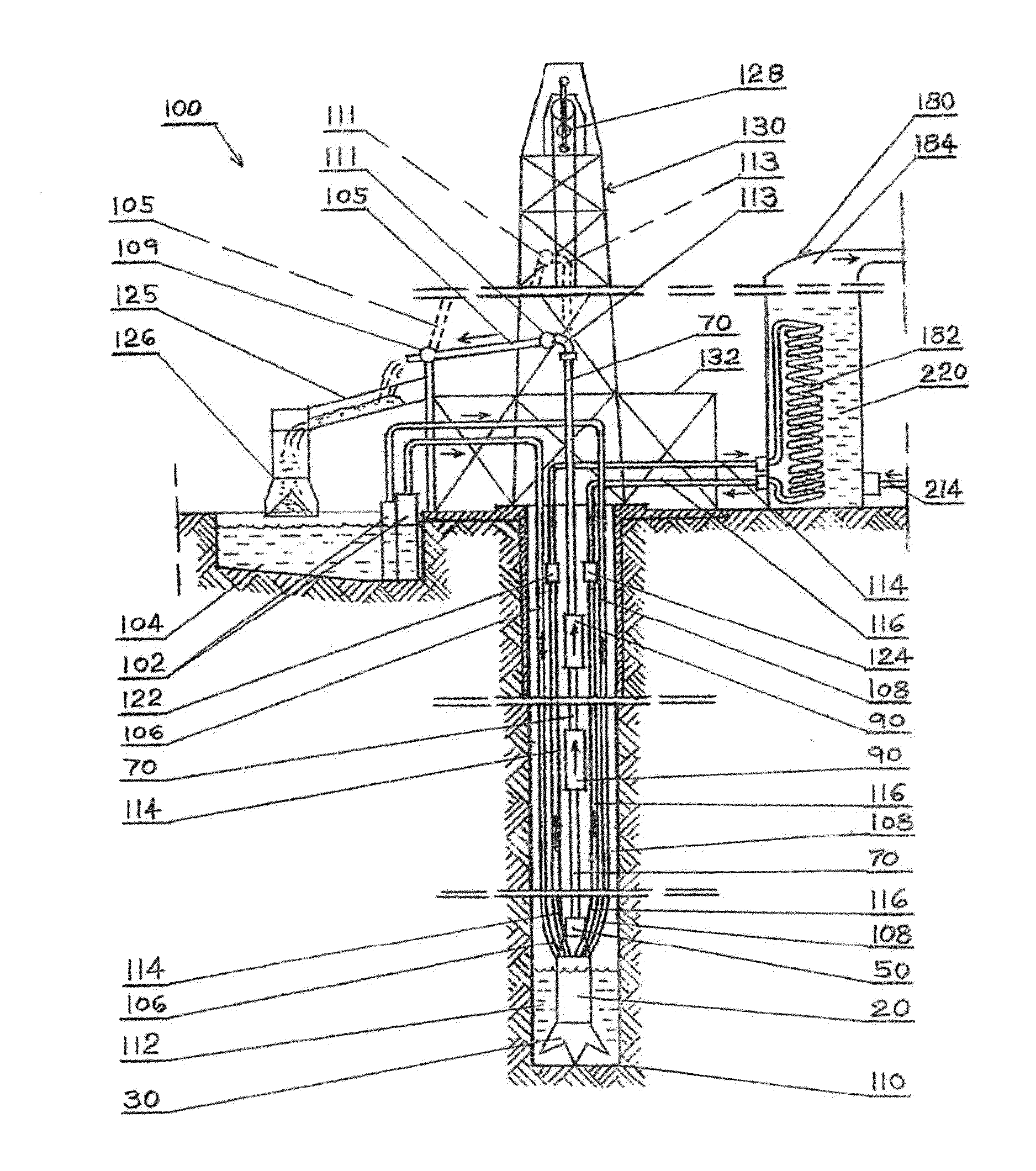

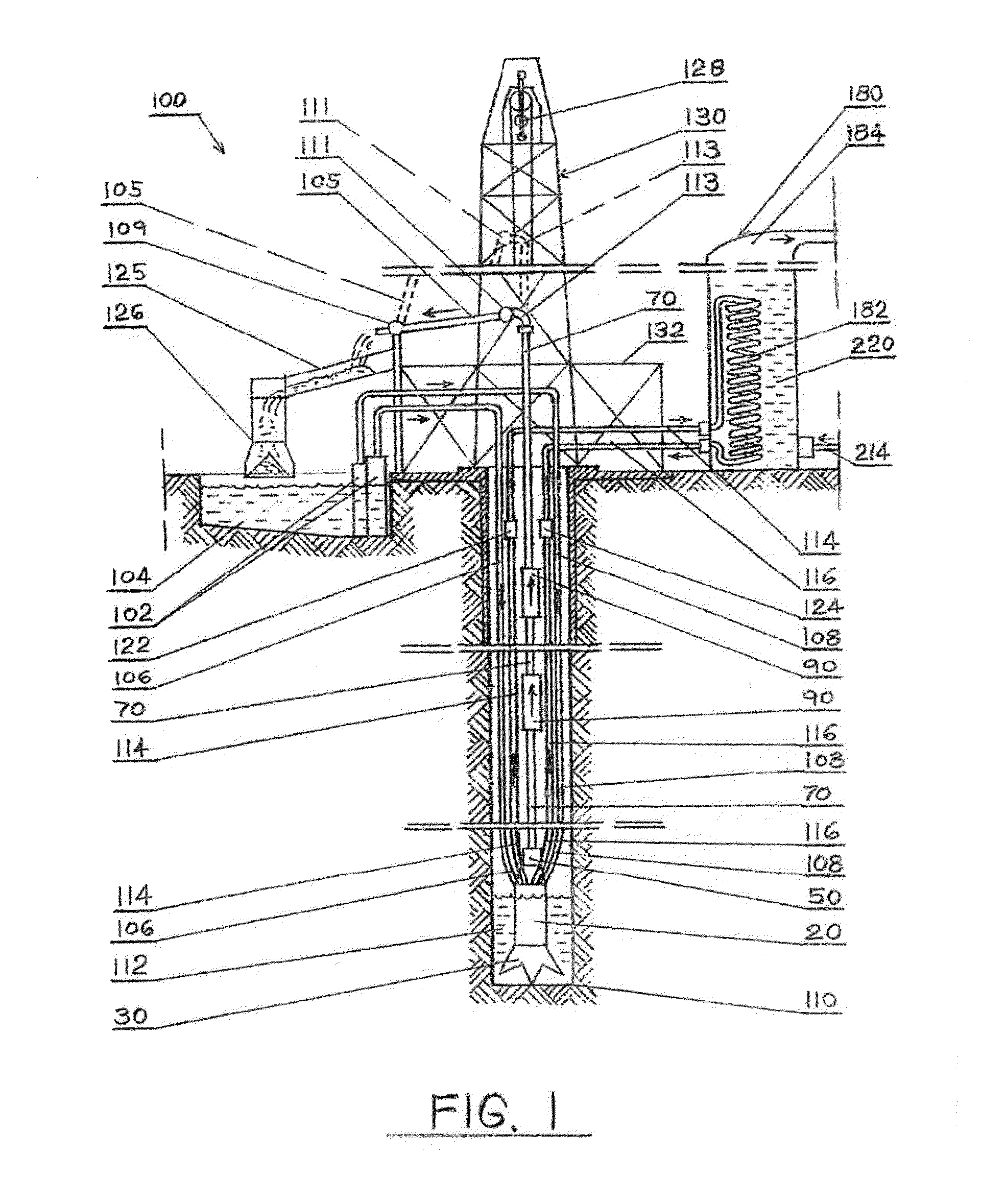

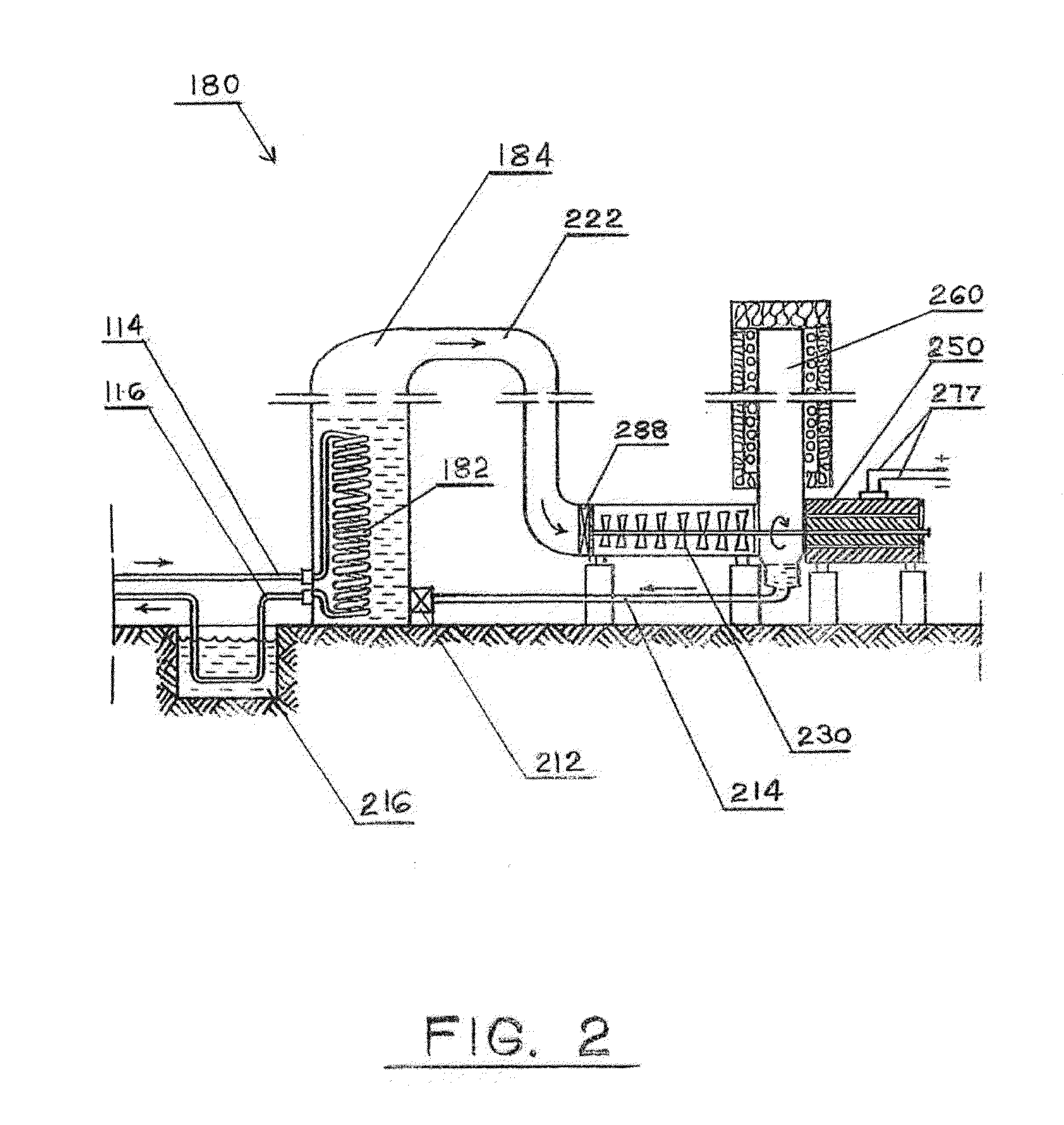

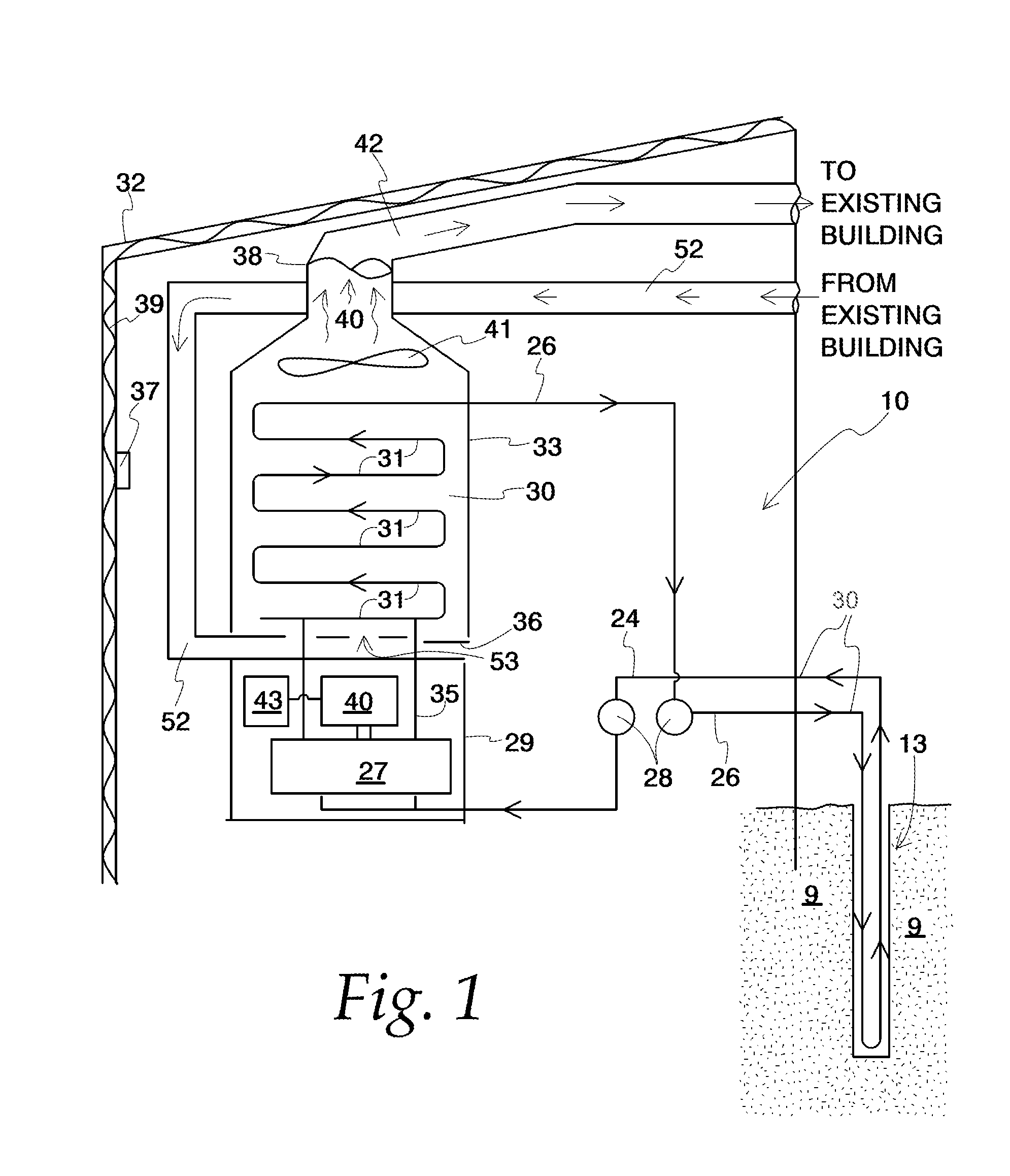

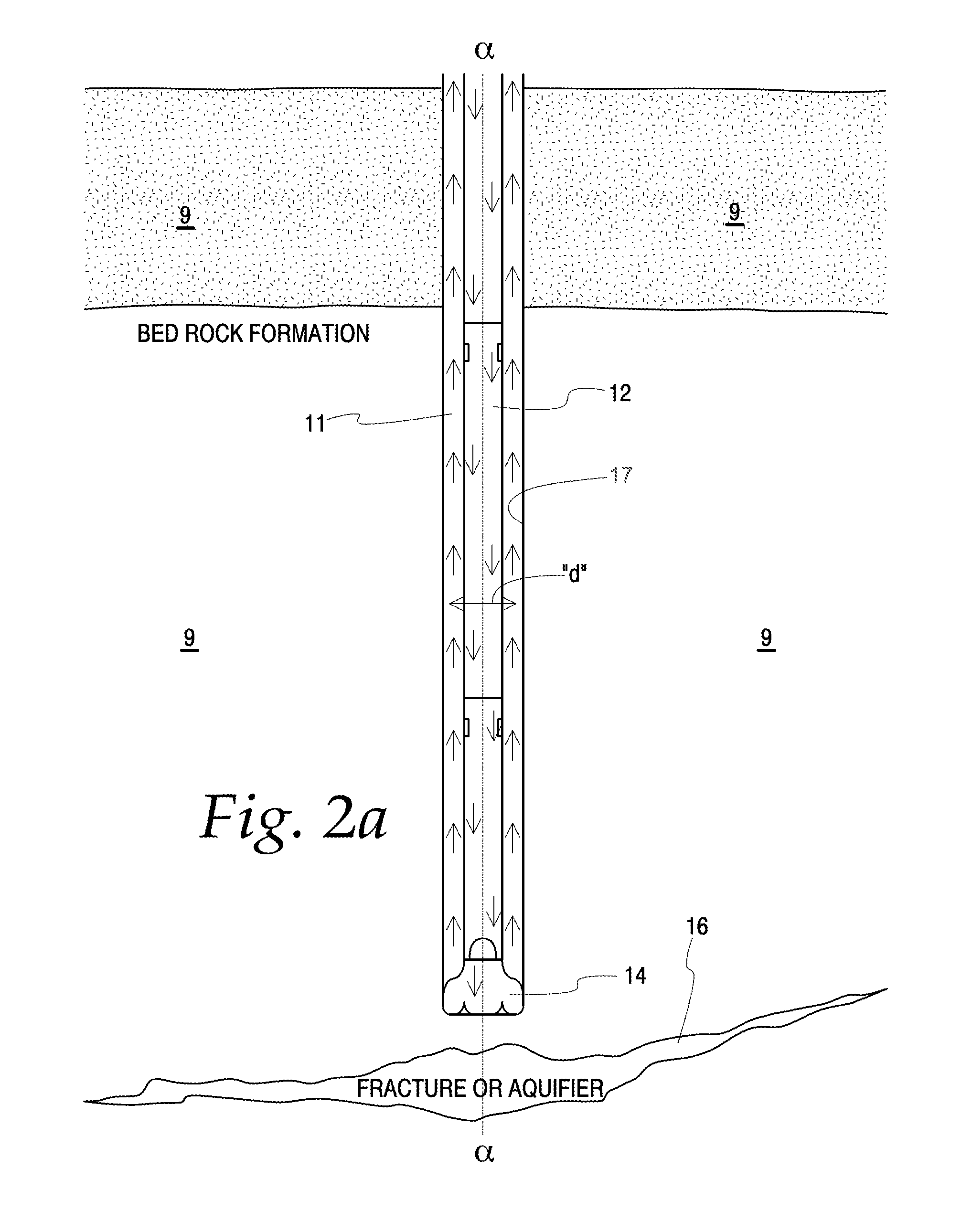

System to enable geothermal field interaction with existing HVAC systems, method to enable geothermal field interaction with existing HVAC system

InactiveUS20110011557A1Increase capacityAdd depthCollector components/accessoriesDrilling rodsThermodynamicsAuger

The invention provides a system for adapting an HVAC system in an existing building for utilizing geothermal energy, the system comprising an incoming flux of geothermal energy; a plurality of heat exchange surfaces adapted to receive the incoming flux of geothermal energy; and an interface between the HVAC system and the heat exchange surfaces, said interface adapted to transfer the geothermal energy to the system. Also provided is a method for repairing aberrations in drill borings, the method comprising using a rotary mud drill system to produce a drill hole up to the location of the aberrations; removing the rotary mud drill from the drill hole; inserting an auger into the drill hole to a point directly above the location of the aberrations; actuating the auger; introducing loose substrate into the drill hole; allowing the substrate to contact the auger; and lifting and lowering the auger along longitudinally extending regions of the drill hole defining the aberrations for a time and in substrate amounts sufficient to fill the aberrations. The invention also provides a system which facilitates rotating drill bits at an rpm which are multiples faster than their associated drill strings.

Owner:GEOTHERMAL TECH

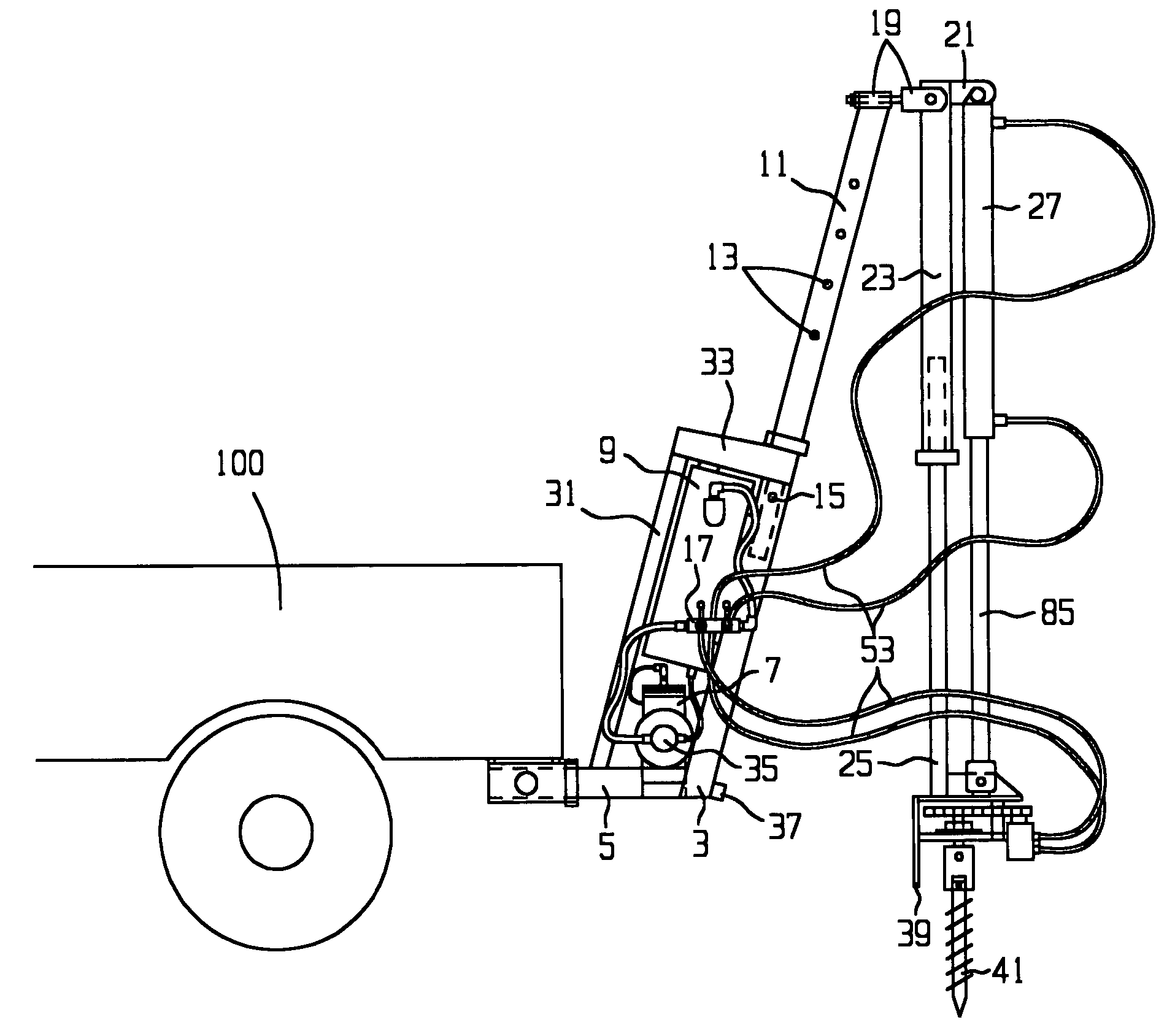

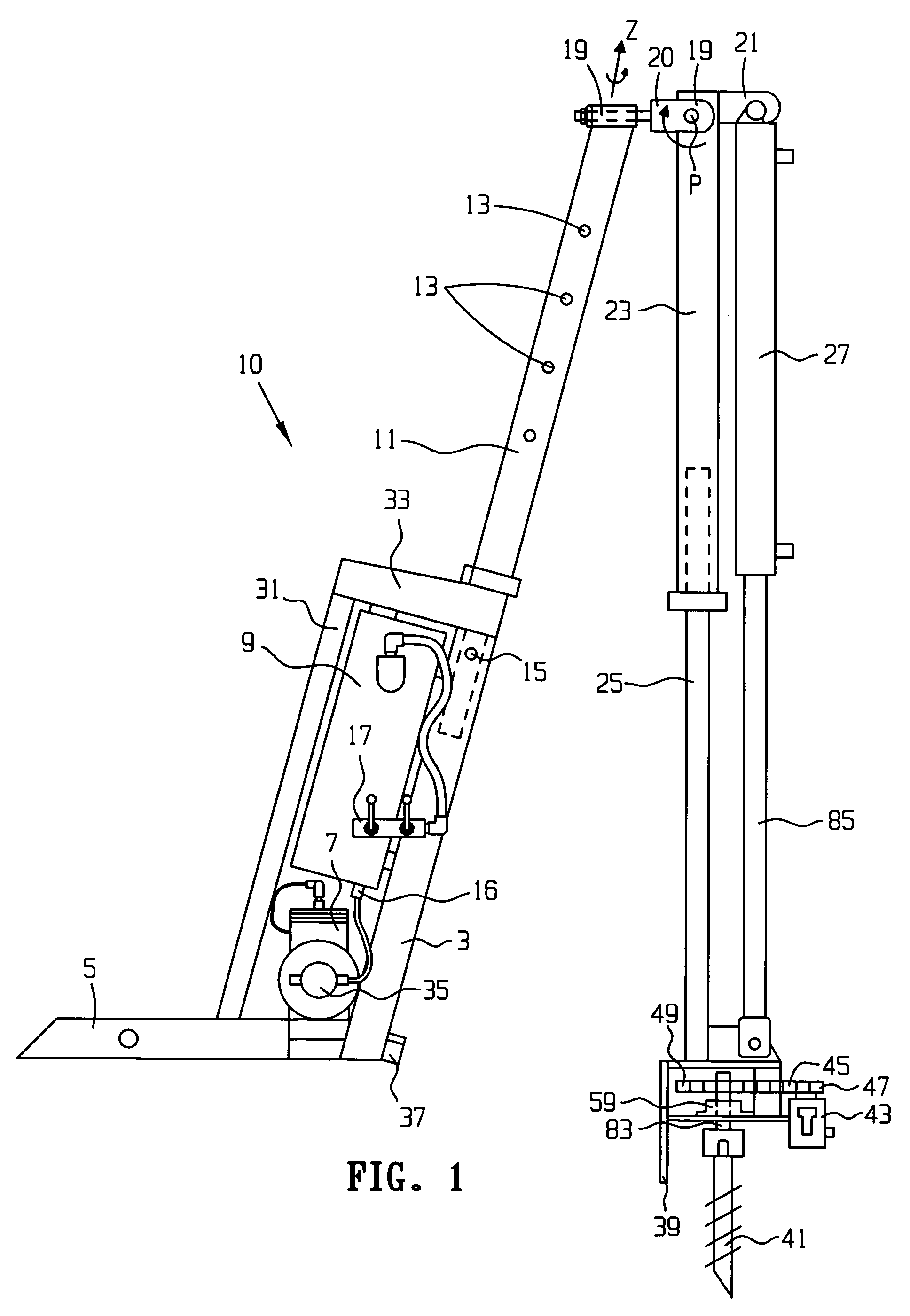

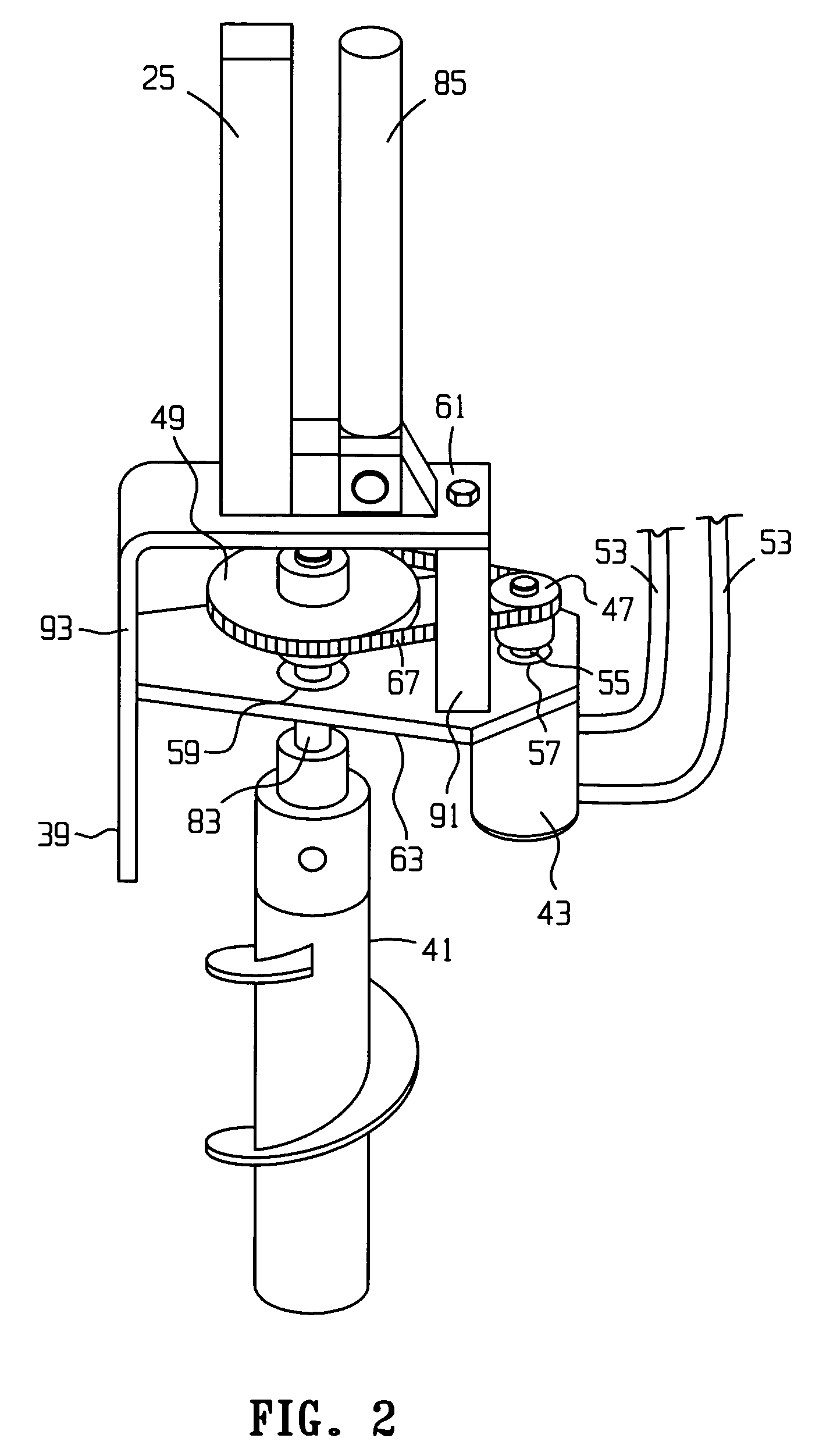

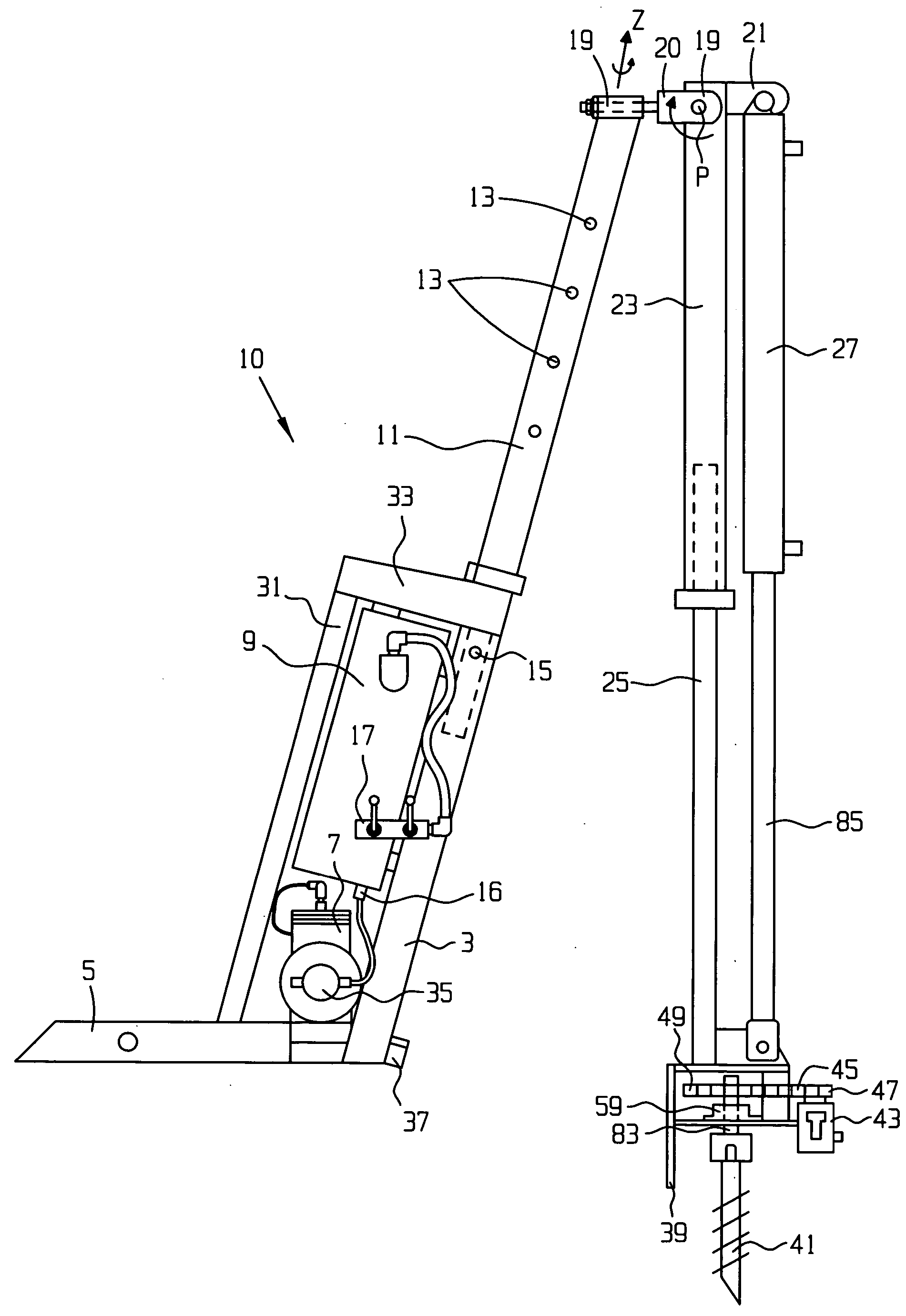

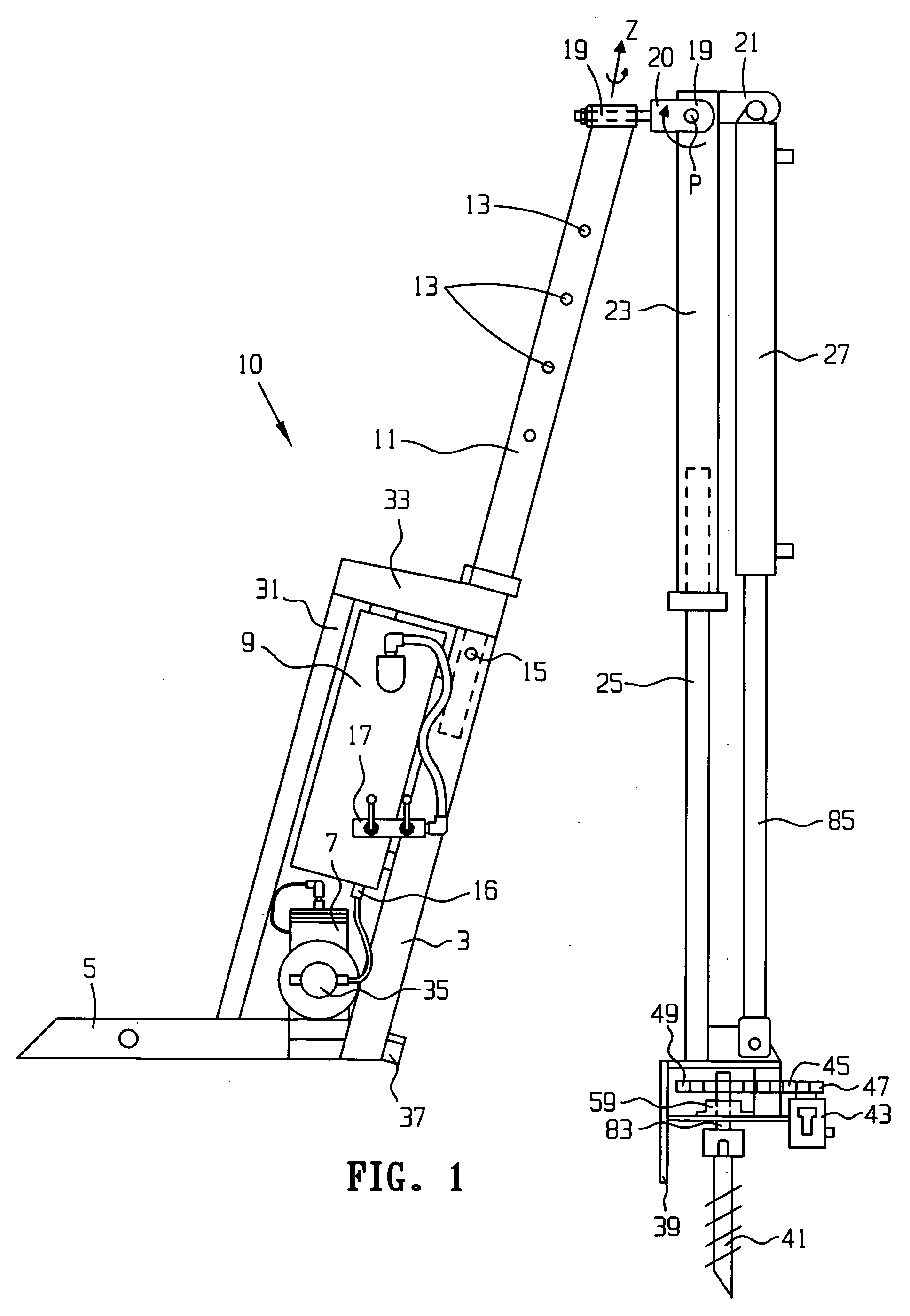

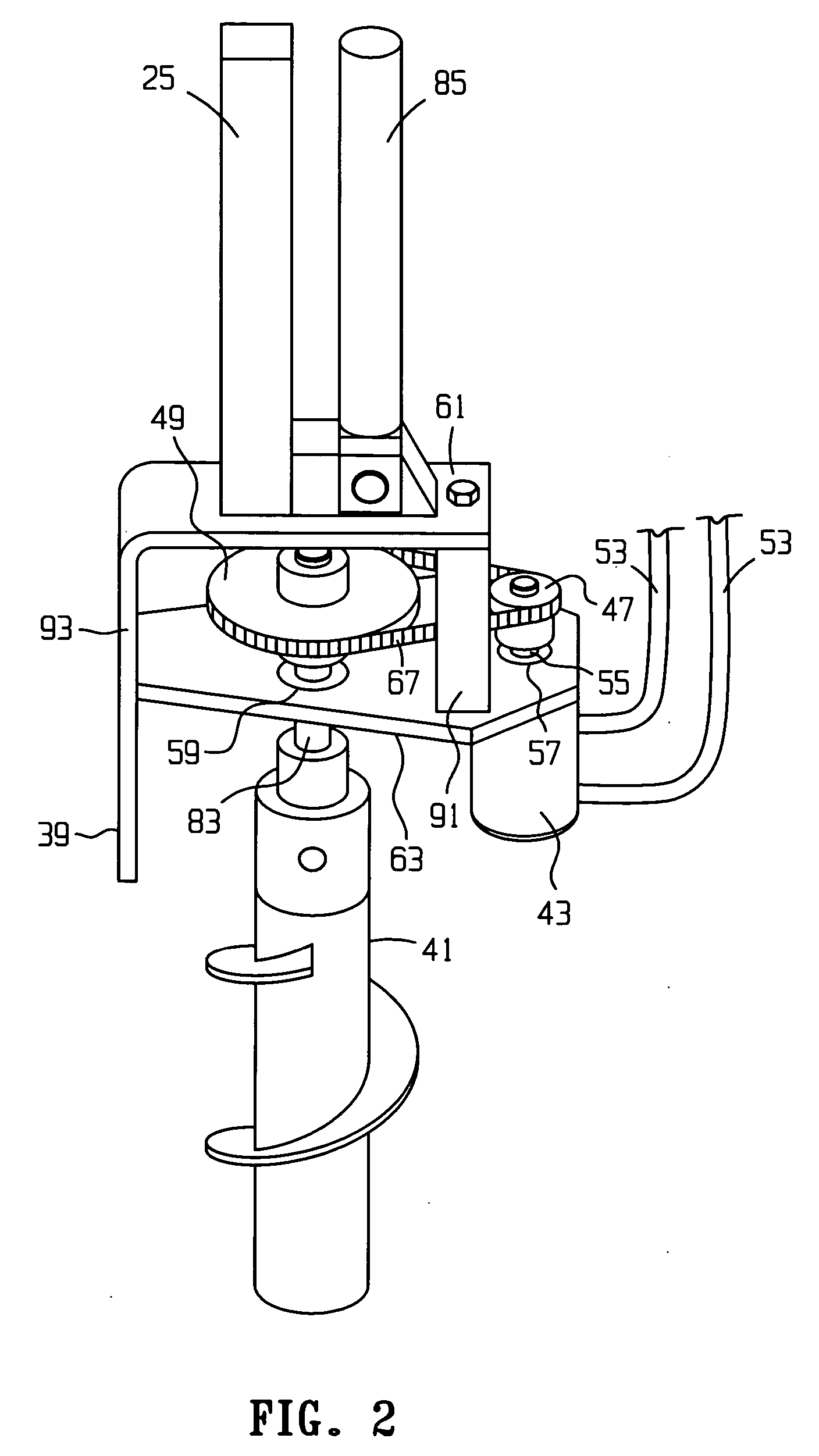

Quick-detach vehicle-mounted auger driver

The present invention provides a device useful for boring holes into the earth, and is especially useful for drilling holes in which fence posts are to be placed. A device according to the invention is completely self-powered, having its own on-board engine which supplies all of the power necessary for the boring operation and other movements of the device associated therewith. A device according to the invention is readily removable from and attachable to a motorized vehicle equipped with a trailer hitch, and is adapted to configure itself in a retracted position for ease in storage and transportation.

Owner:ROSSI FR W

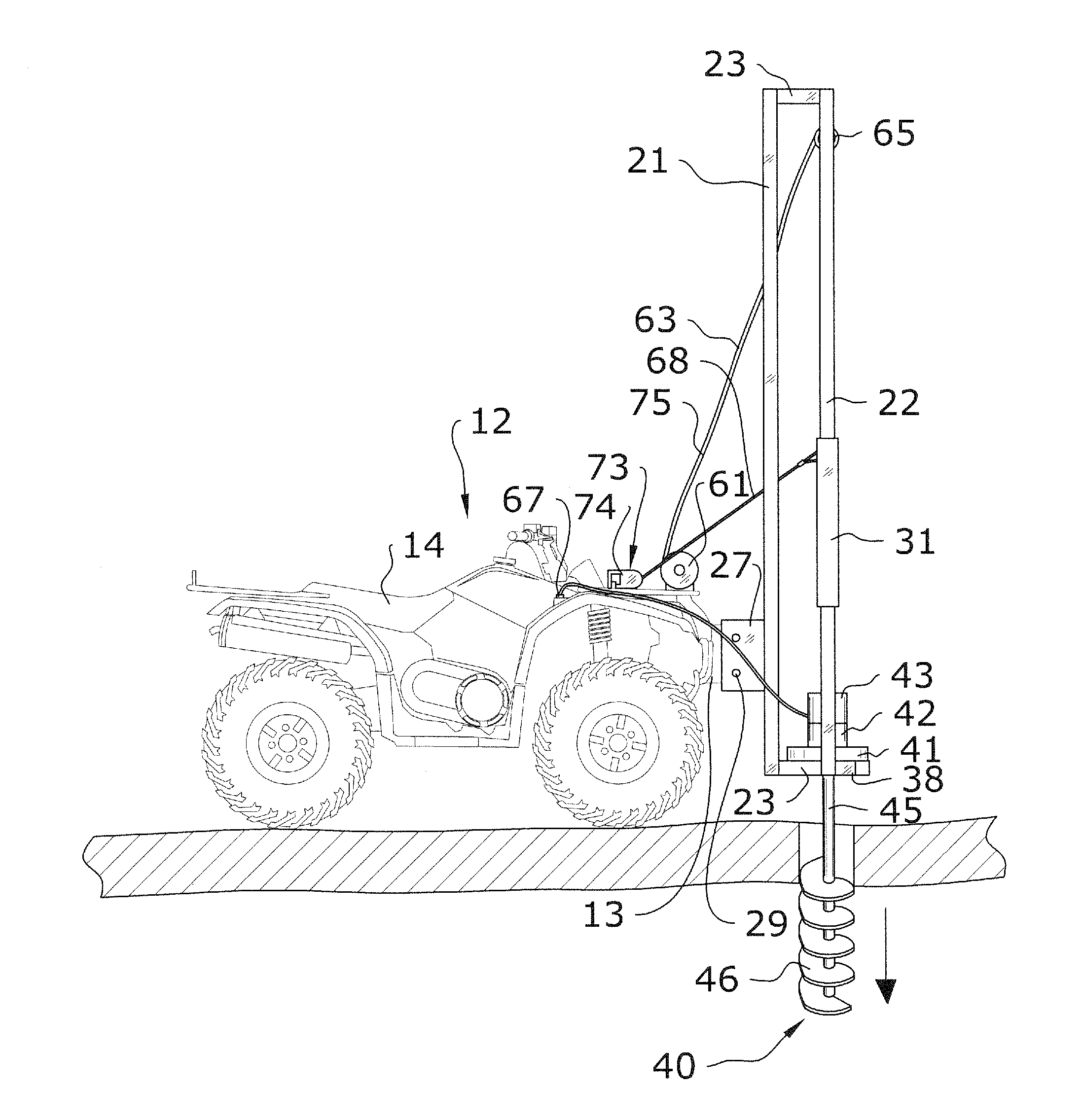

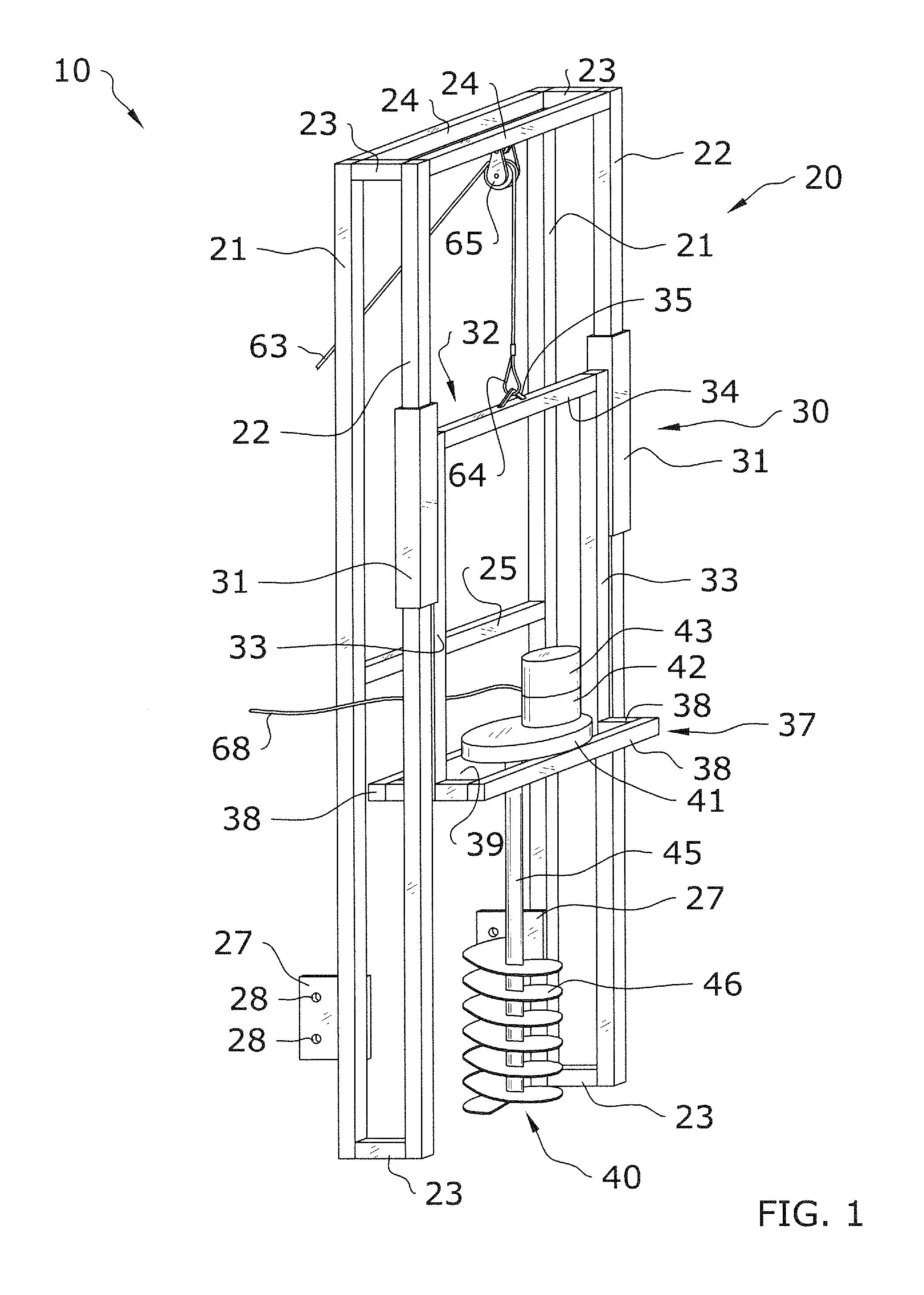

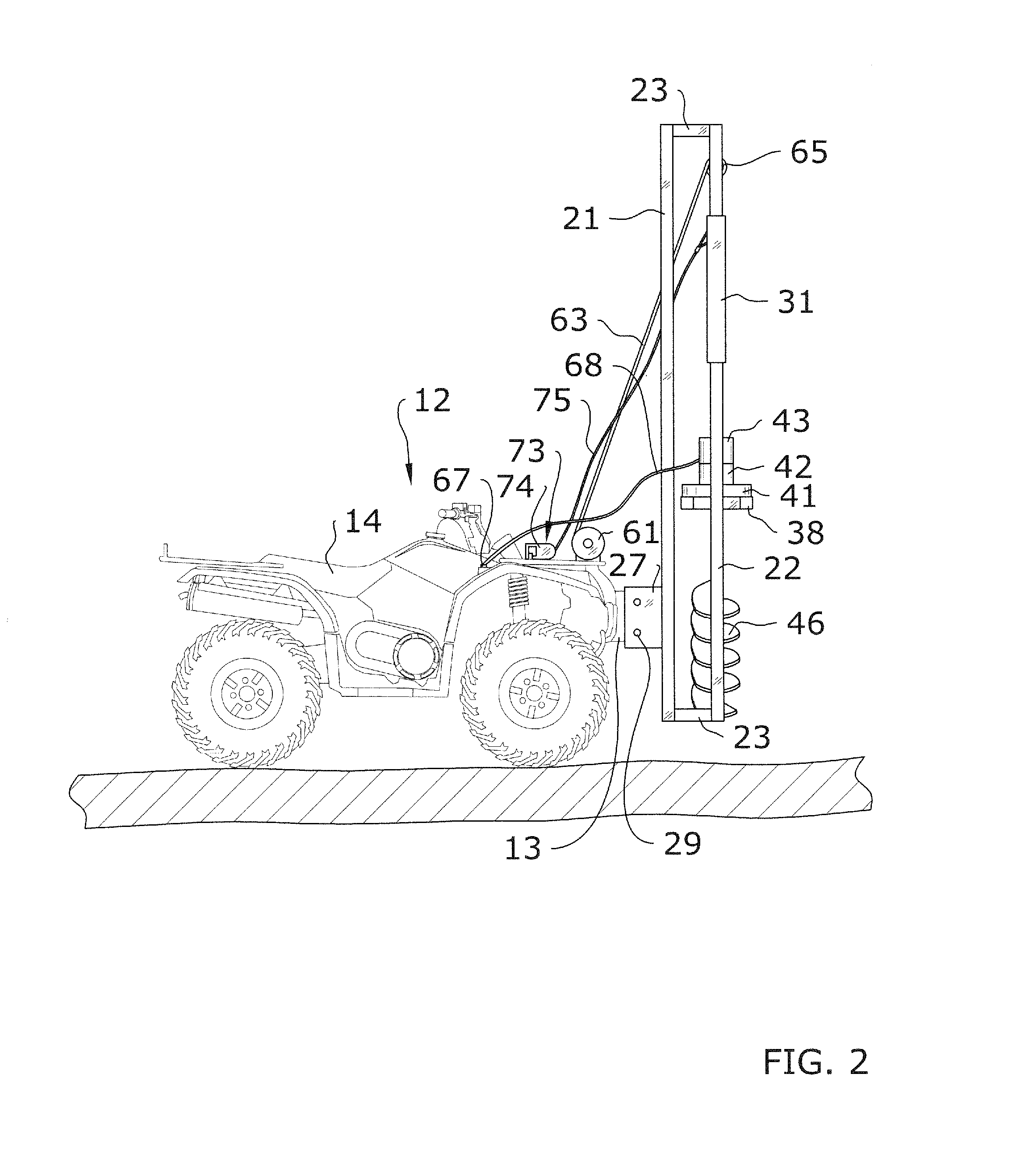

Ice auger attachment for a vehicle

An ice auger attachment for attaching an ice auger to and operating the ice auger from a vehicle, such as an ATV. The ice auger attachment generally includes a support frame attached to a front end of the vehicle, a carriage assembly movable vertically along the support frame, and a motorized ice auger supported by the carriage assembly in a vertical orientation, the ice auger adapted to move vertically along the support frame with the carriage assembly. The carriage assembly and ice auger are generally raised and lowered via a winch, cable, and pulley operable from the seat of the vehicle. The ice auger may also be operated from the seat of the vehicle via a control unit that engages the motor of the ice auger. Various structures may be utilized to apply downward pressure structures upon the carriage assembly to ensure proper functioning of the ice auger.

Owner:LYNGAAS JAMES L

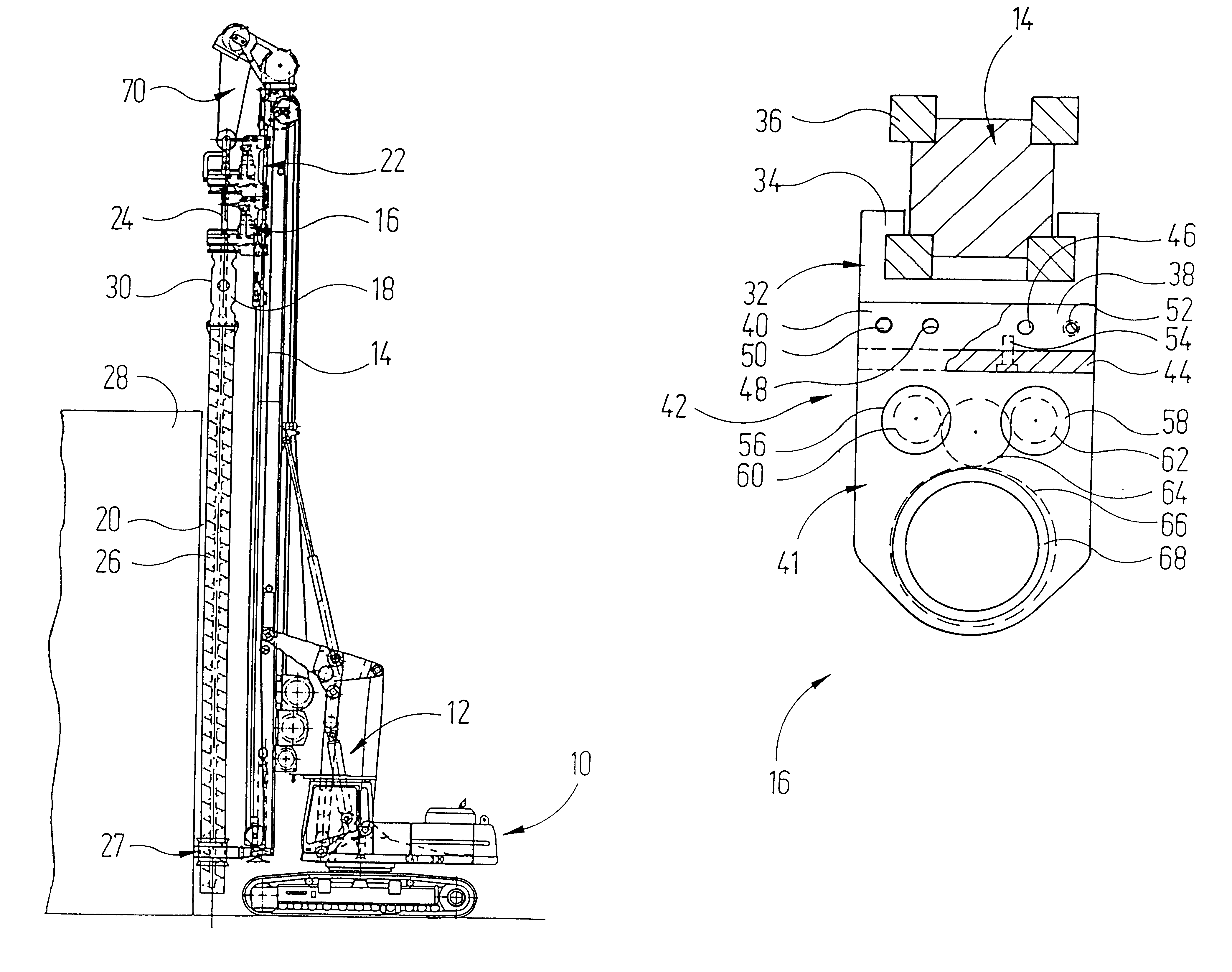

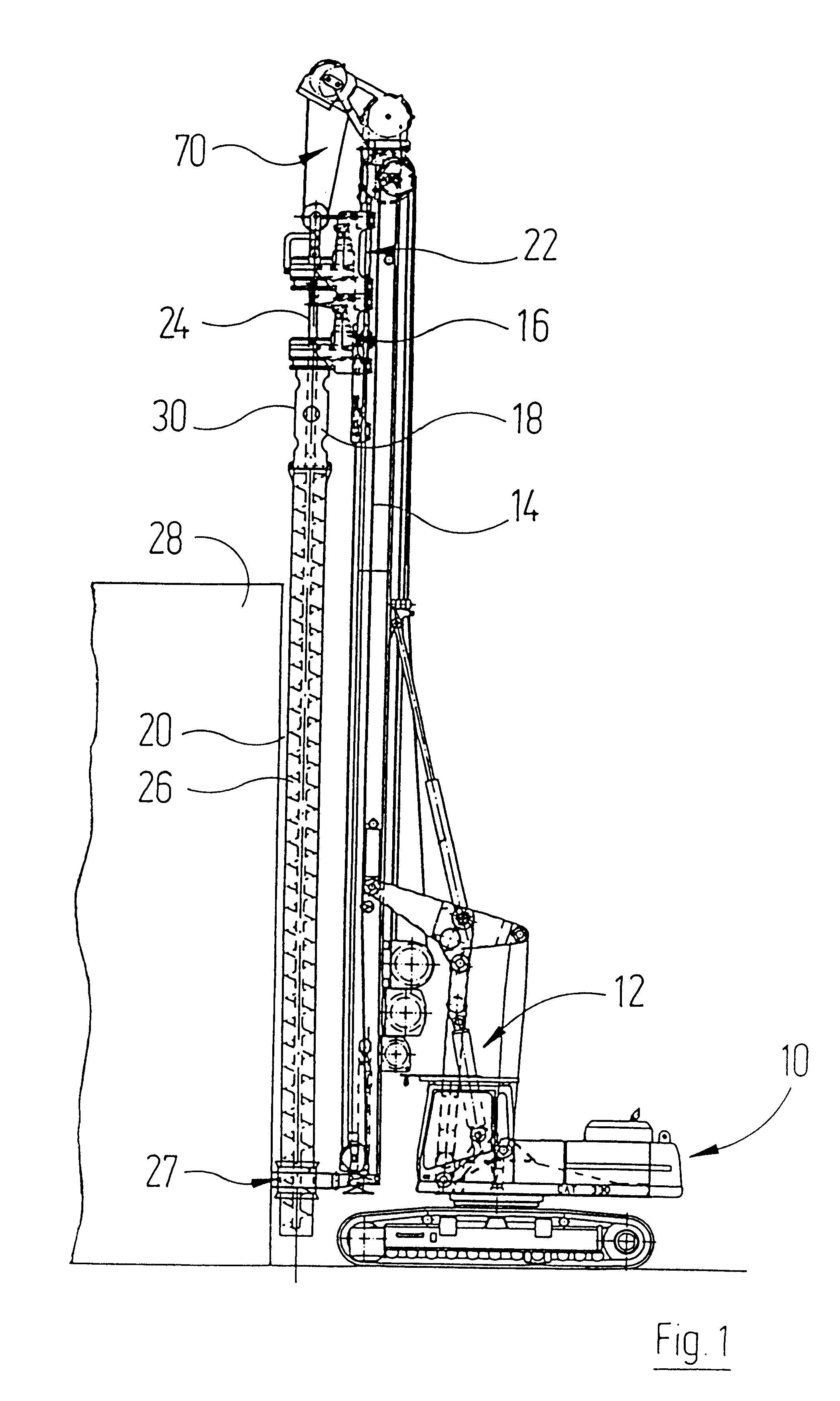

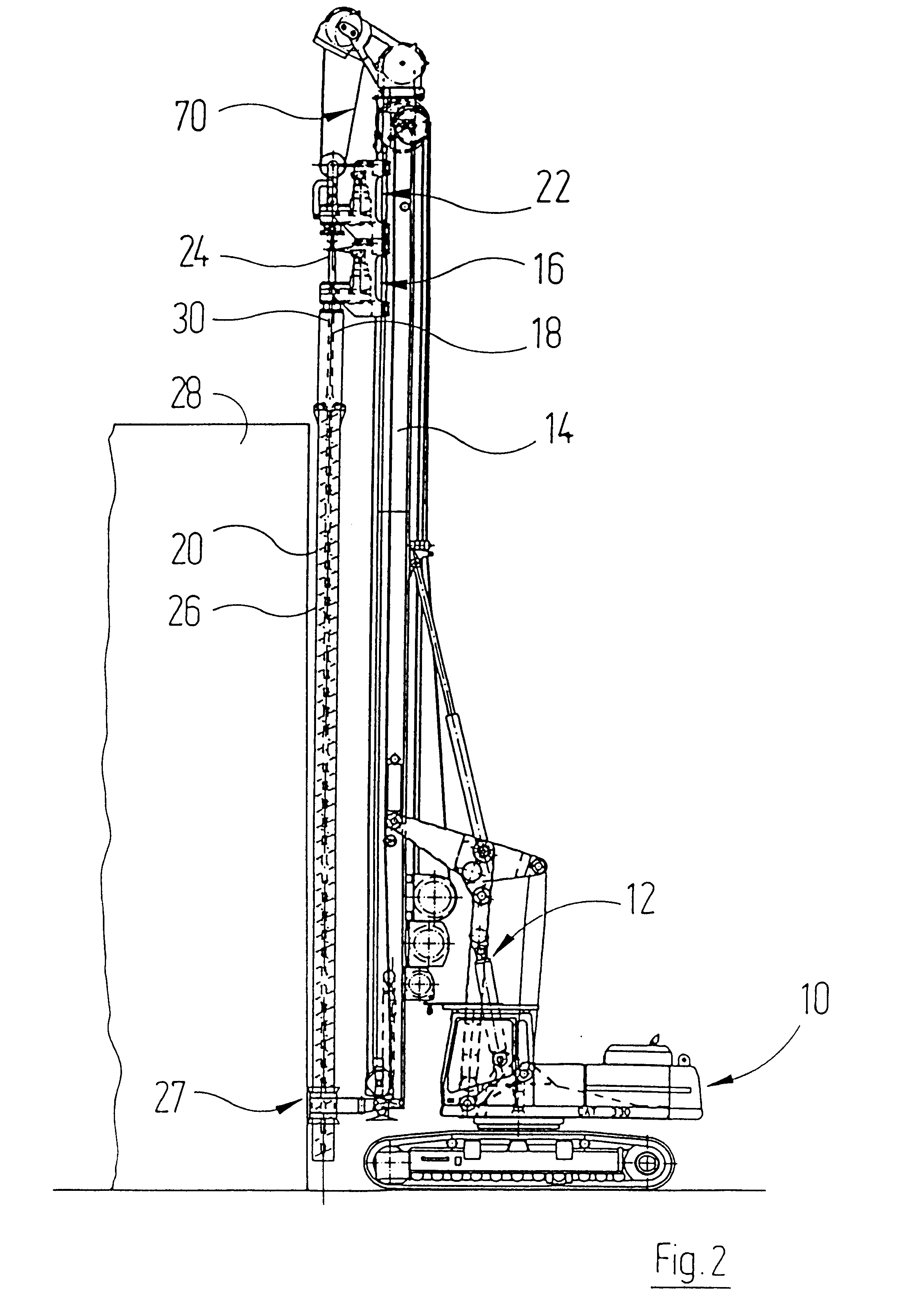

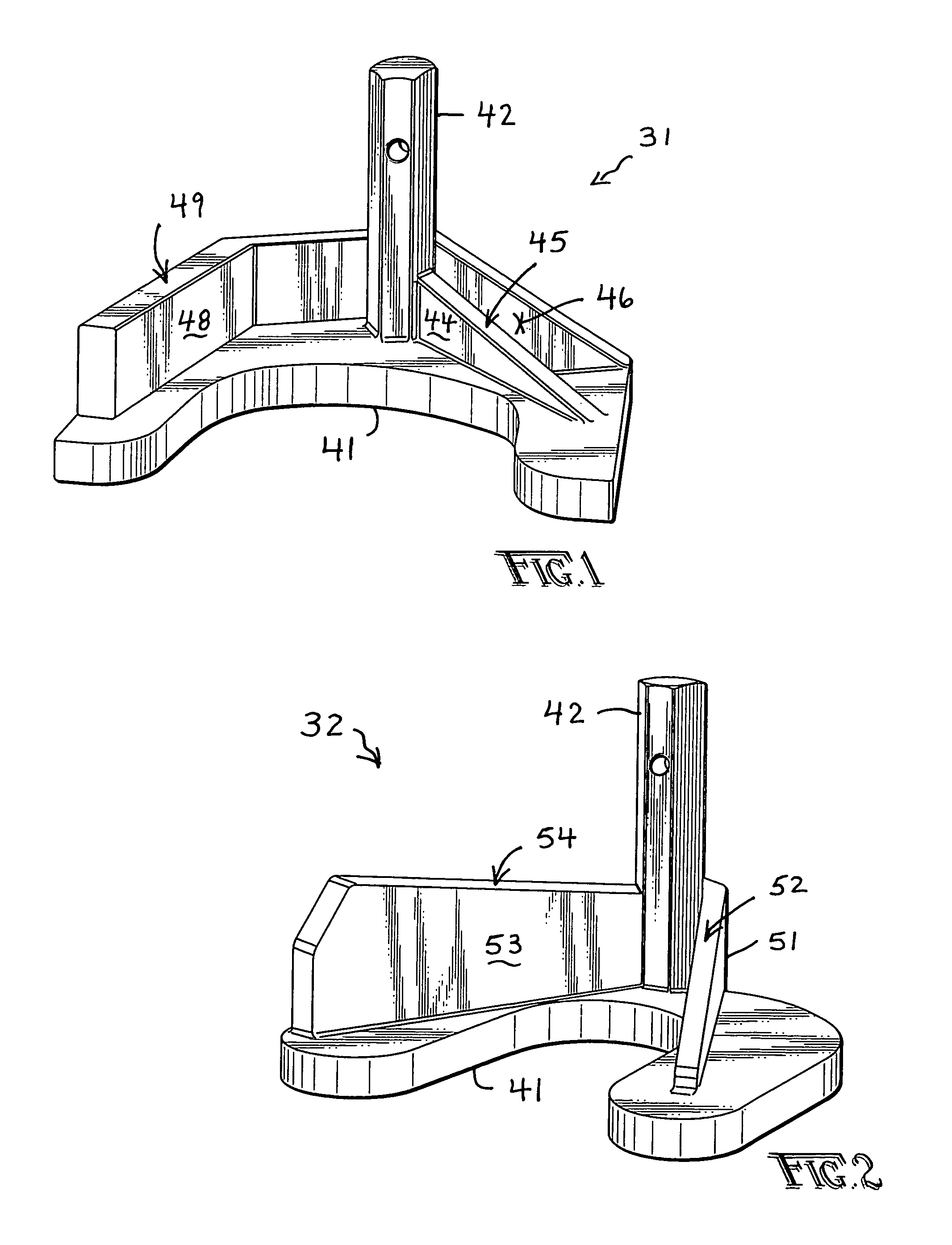

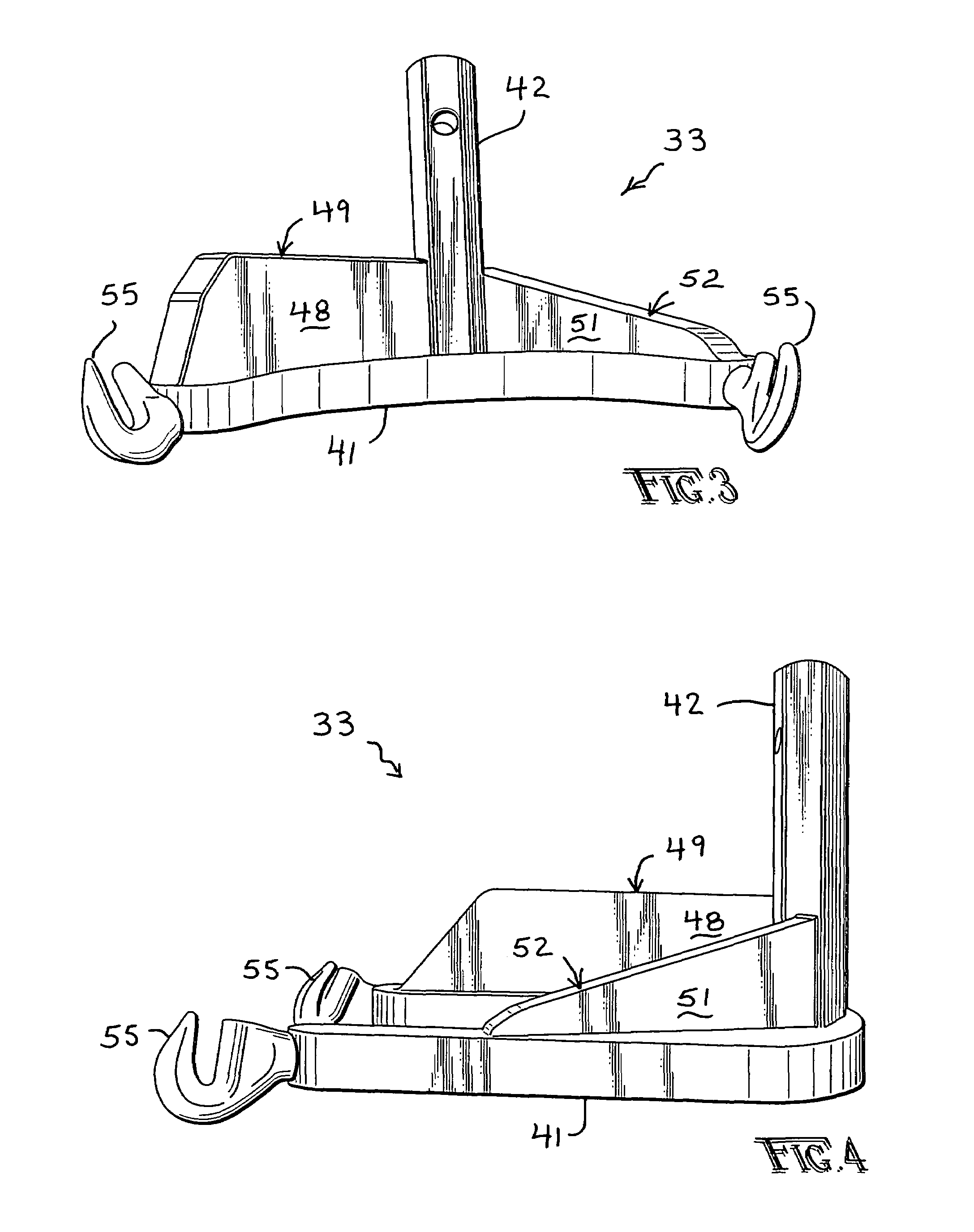

Drilling machine with changeable drive unit

A double-head drilling machine is disclosed, which by changing over or converting small component units can cooperate with drill or drill pipes of different diameters. To this end, drive carriages (16) operating on drills or drill pipes, for example, comprise a carriage base element (32), to which a drive unit (42) is releasably fitted. The drive unit (42) can thus be replaced by a different drive unit having essentially the same geometry, which is designed for operating with a drill or drill pipe having a different diameter.

Owner:DELMAG MASCHFAB REINHOLD DORNFELD

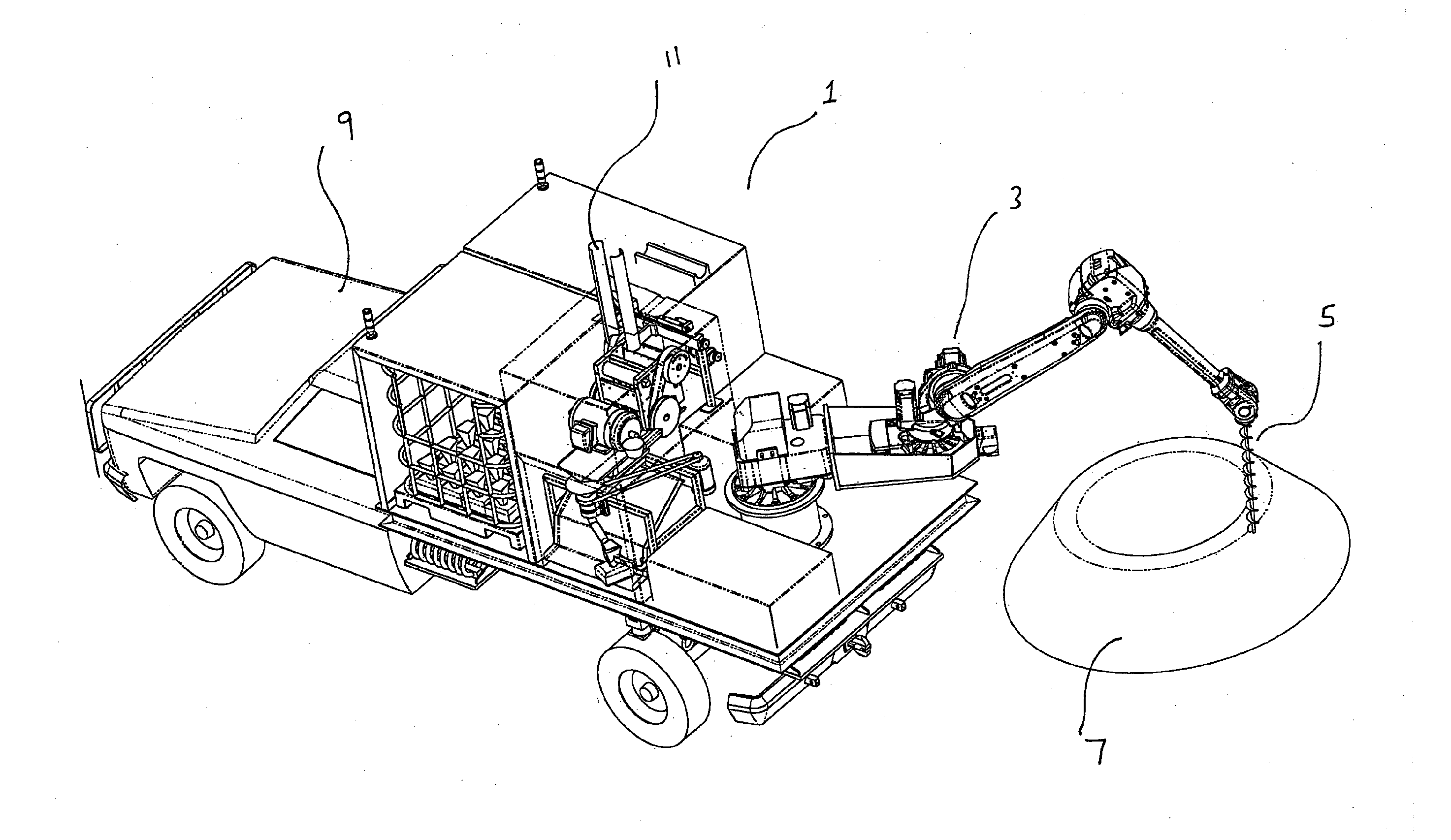

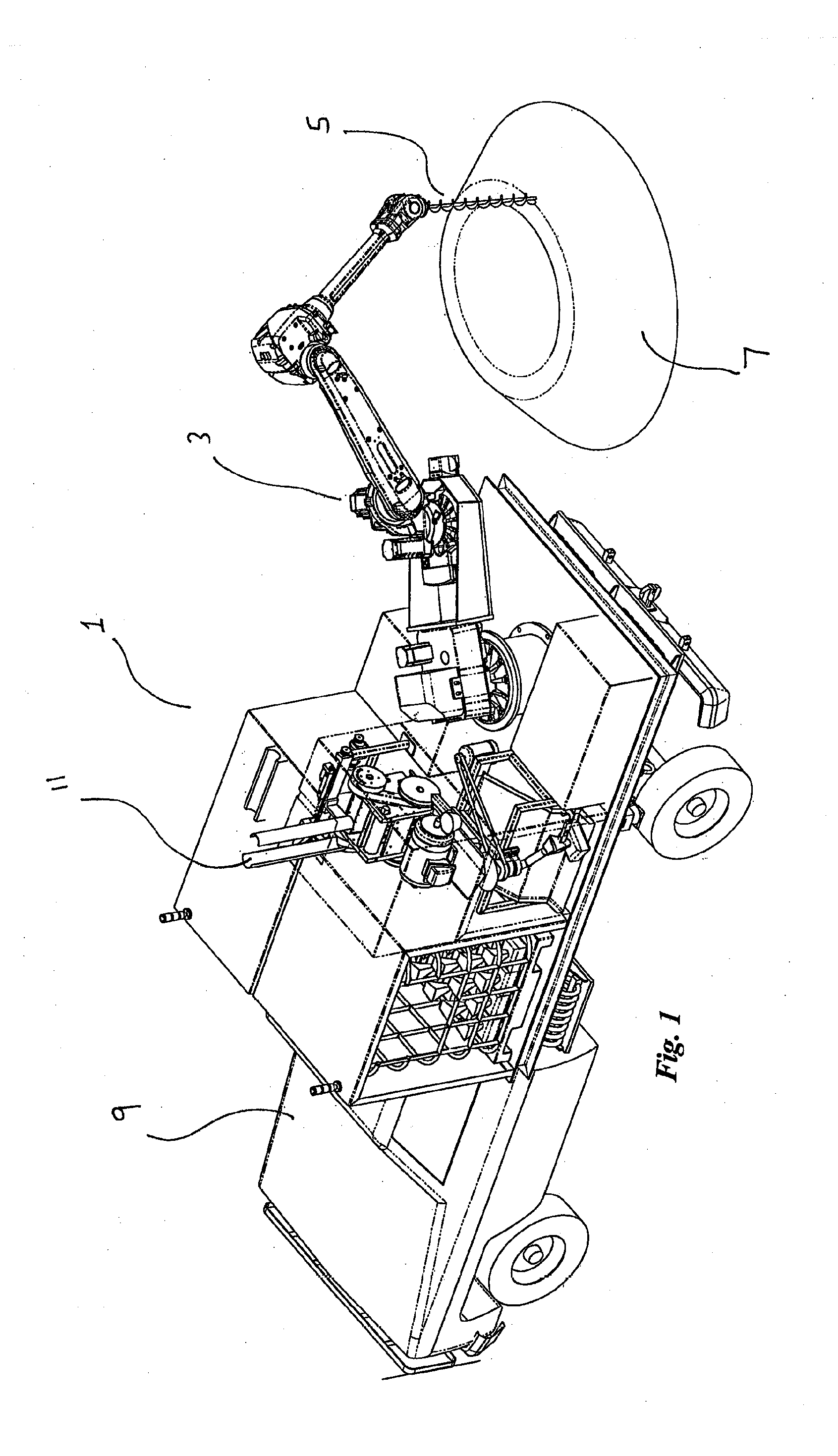

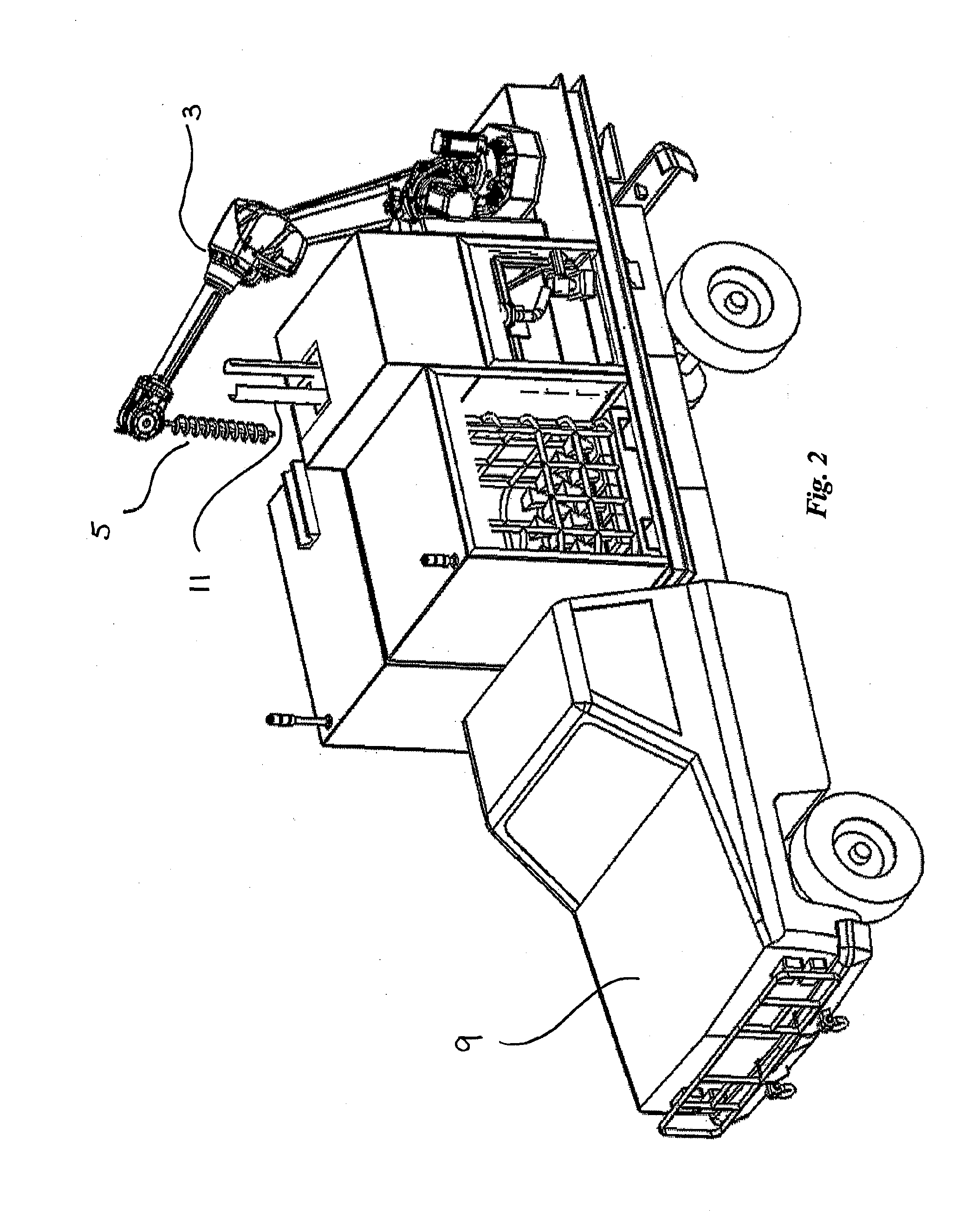

Self Contained Sampling and Processing Facility

ActiveUS20130327159A1Easy to identifyImprove mobilityDrilling with mechanical conveyingWithdrawing sample devicesRobotic armControl theory

A self-contained mobile sampling and processing facility for use at a mine having at least one blast-hole that forms a blast-hole cone wherein the sampling and processing facility includes at least one primary robotic arm that carries at least one sampling tool, and the primary robotic arm and sampling tool is controlled by robotic arm and sampling tool movement controller means, and the primary robotic arm is capable of self-determining the direction, distance and shape of a nearby blast-hole cone, then subsequently positioning itself so that the sampling tool is able to engage with the blast-hole cone and retrieve a sample from it without significant mixing or stirring the cone, or a localised region of the cone, and then the sample is deposited into the processing facility.

Owner:LEWIS AUSTRALIA

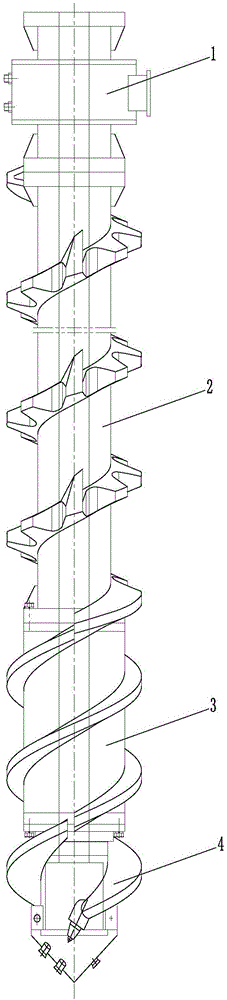

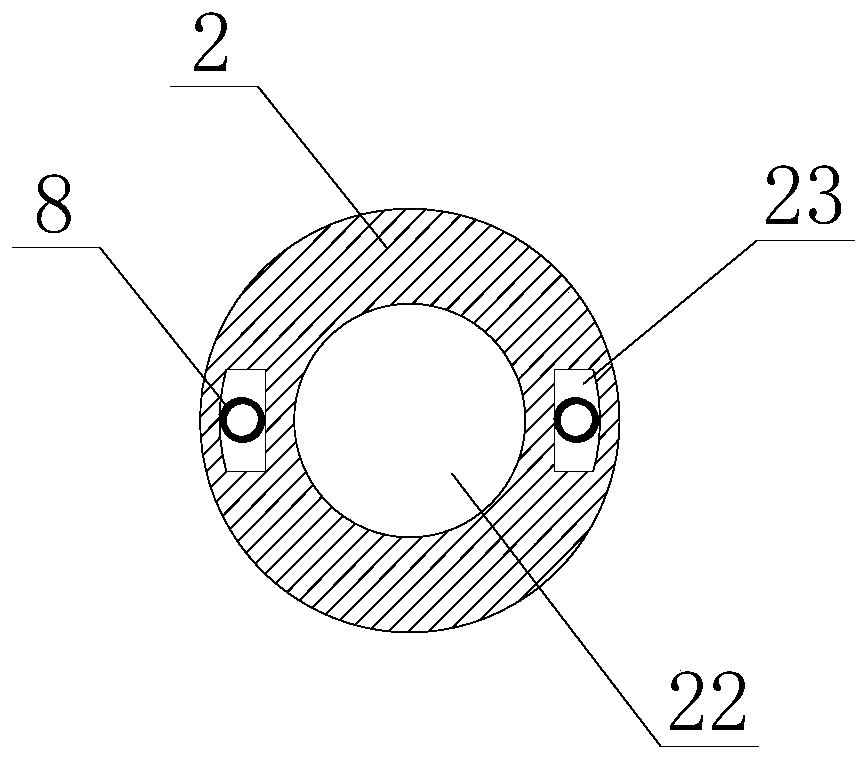

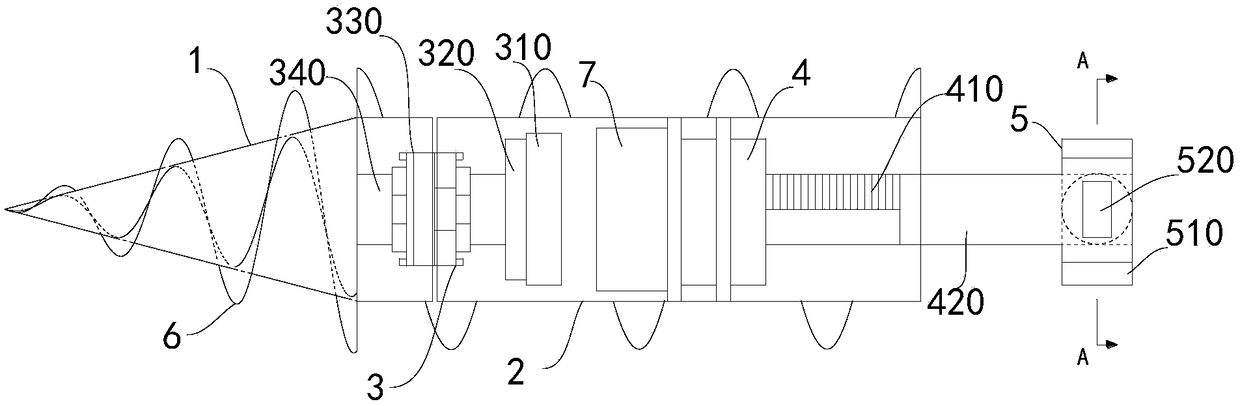

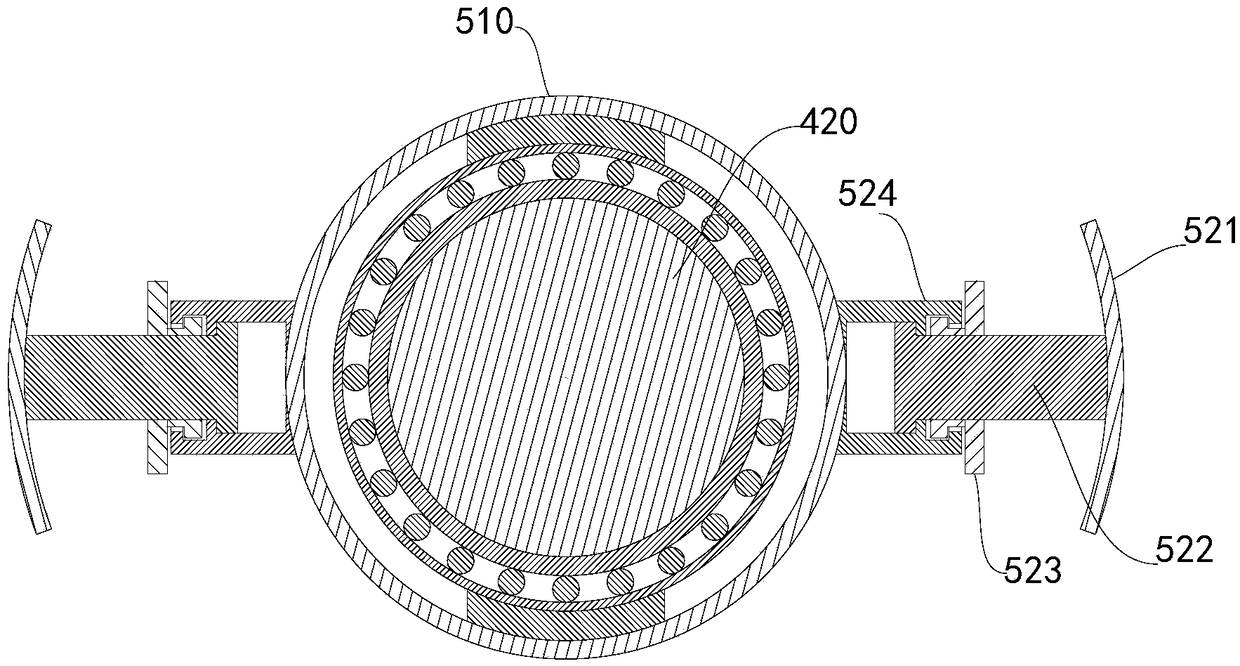

Spiral soil-squeezing downhole rock embedding device and pile forming method

ActiveCN106246099AImprove construction efficiencyReduce construction costsDrill bitsDrilling rodsFlangeDrill bit

The invention relates to a spiral soil-squeezing downhole rock embedding device and a pile forming method. The spiral soil-squeezing downhole rock embedding device is composed of a rotating unit, a standard soil squeezing drill rig, an impactor and a drill bit. The rotating unit is mounted at the upper end of the standard soil squeezing drill rig. The standard soil squeezing drill rig and the impactor are connected with an upper connecting plate through a standard flange. The impactor and the drill bit are positioned through a guiding spline between a lower body and an upper body, and the lower body, a pile casing and the upper body are connected into a whole through bolts and flanges. An impacting unit mounted in the impactor is movably connected with the upper body, and an inner tube II penetrates through the impactor and the drill bit. By means of the pile forming method, a rock-embedded pile with the rock bearing capacity larger than 500 Kpa is constructed, the construction quality is guaranteed, construction efficiency is improved, and the requirements for energy saving and environmental protection are met.

Owner:东营正诺技术服务有限公司

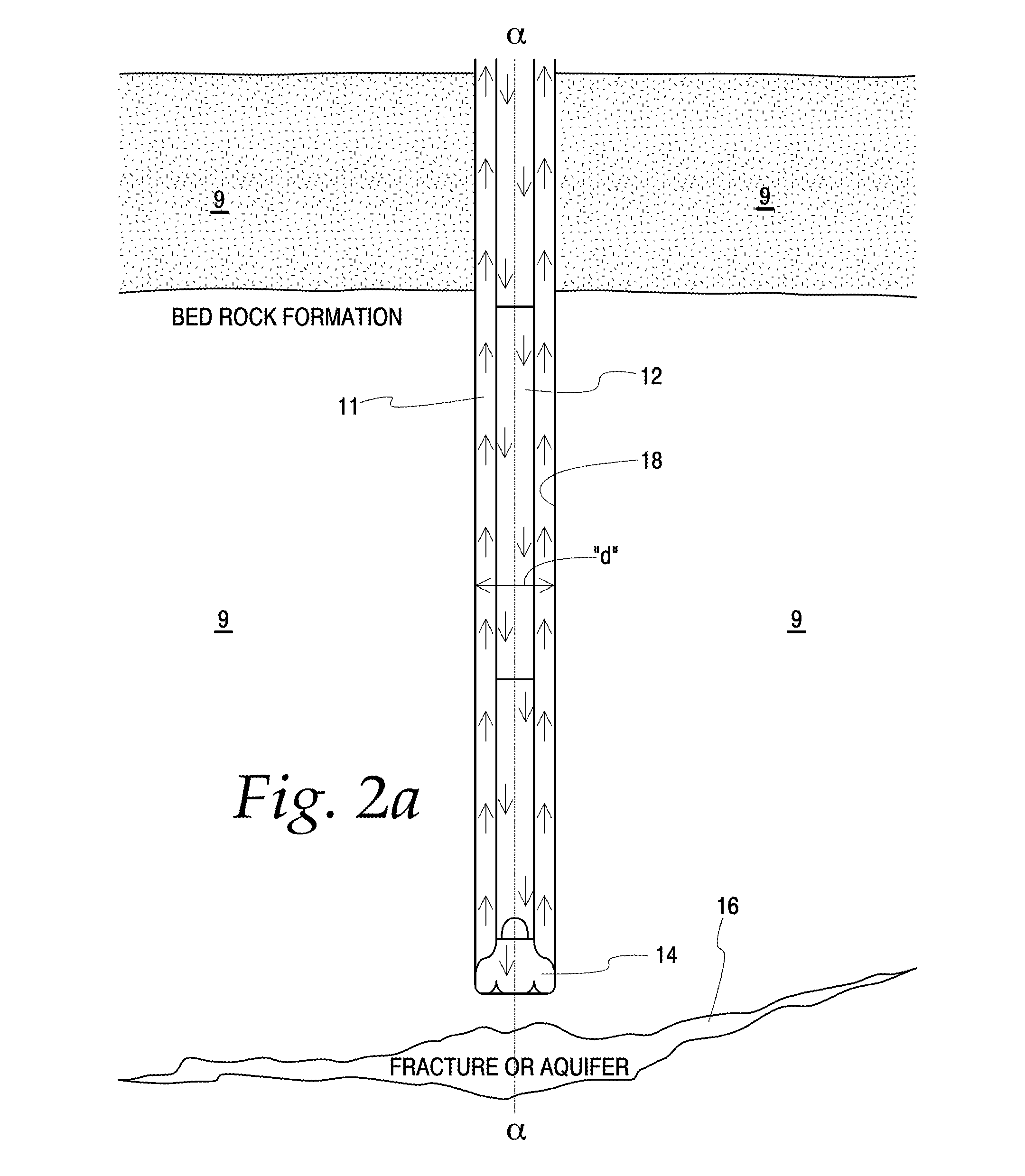

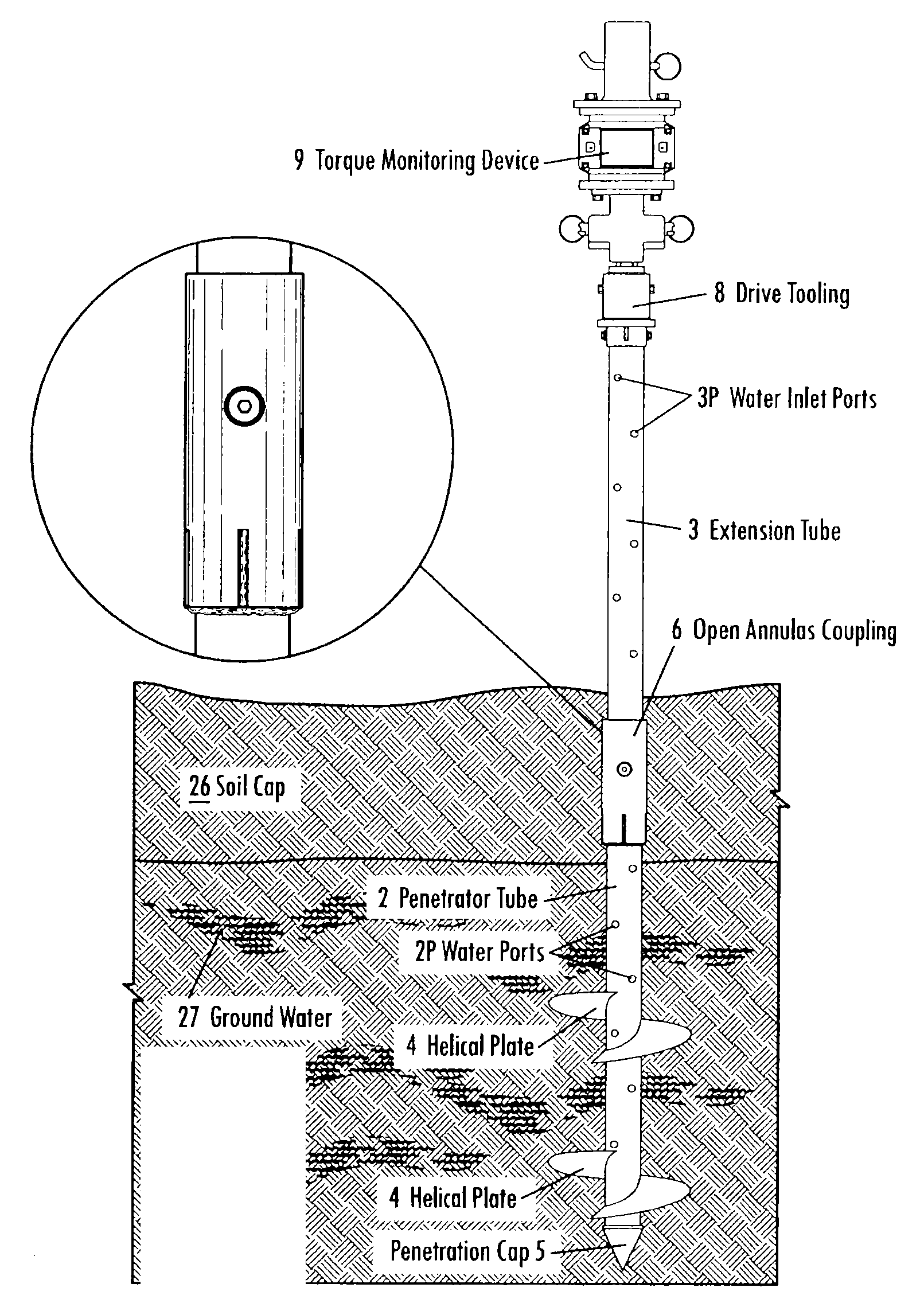

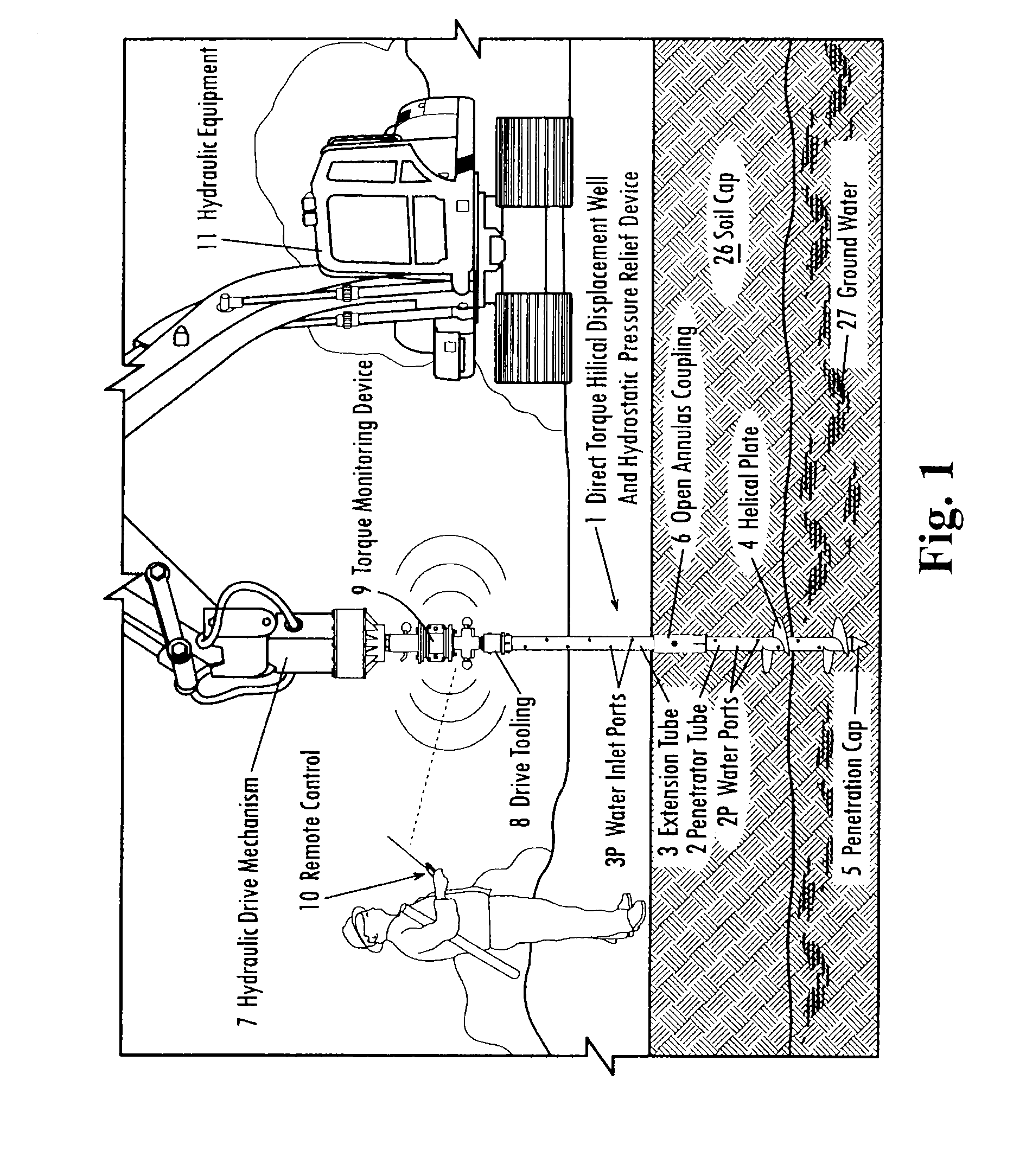

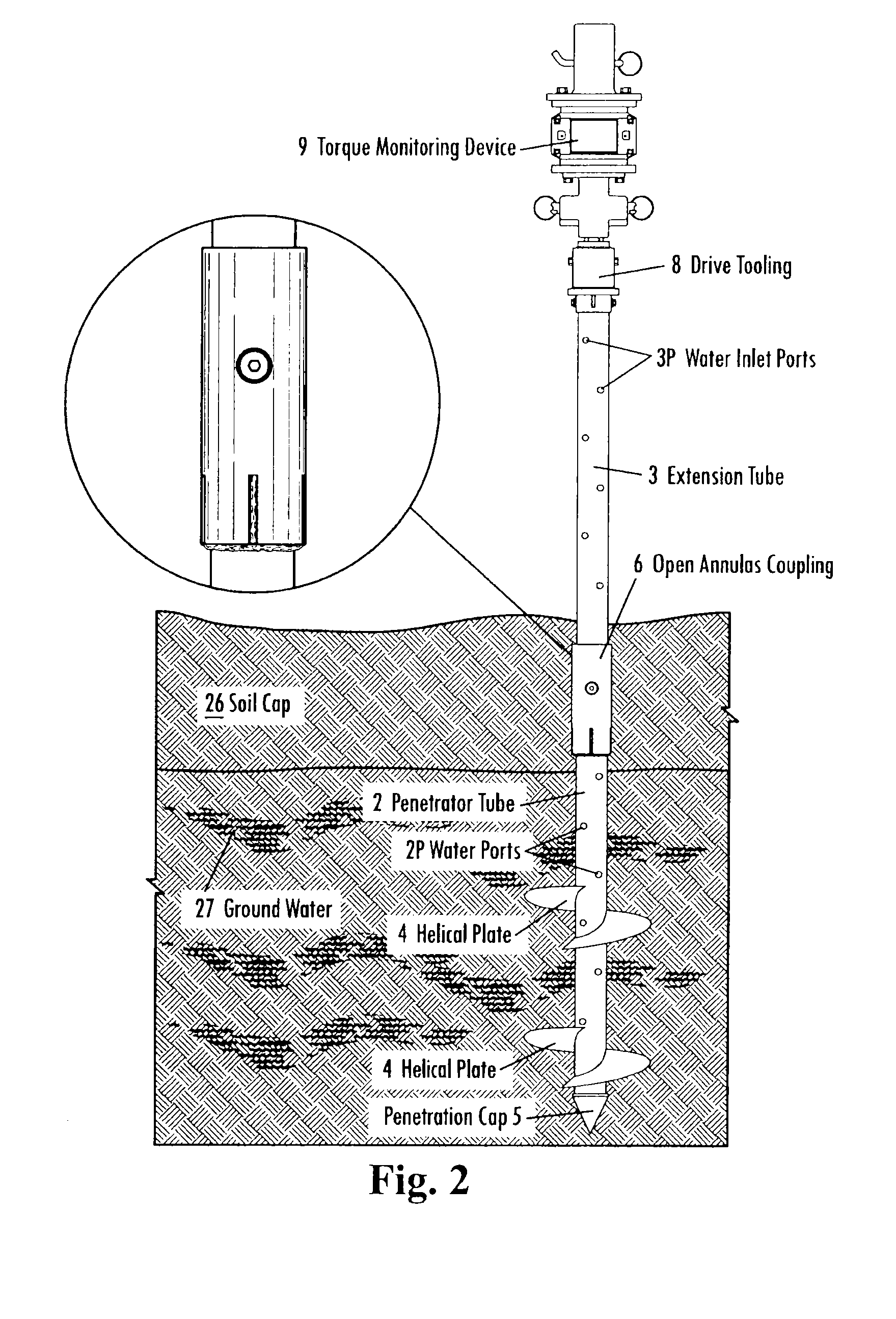

Direct Torque Helical Displacement Well and Hydrostatic Liquid Pressure Relief Device

Owner:QUEEN FRIE A R

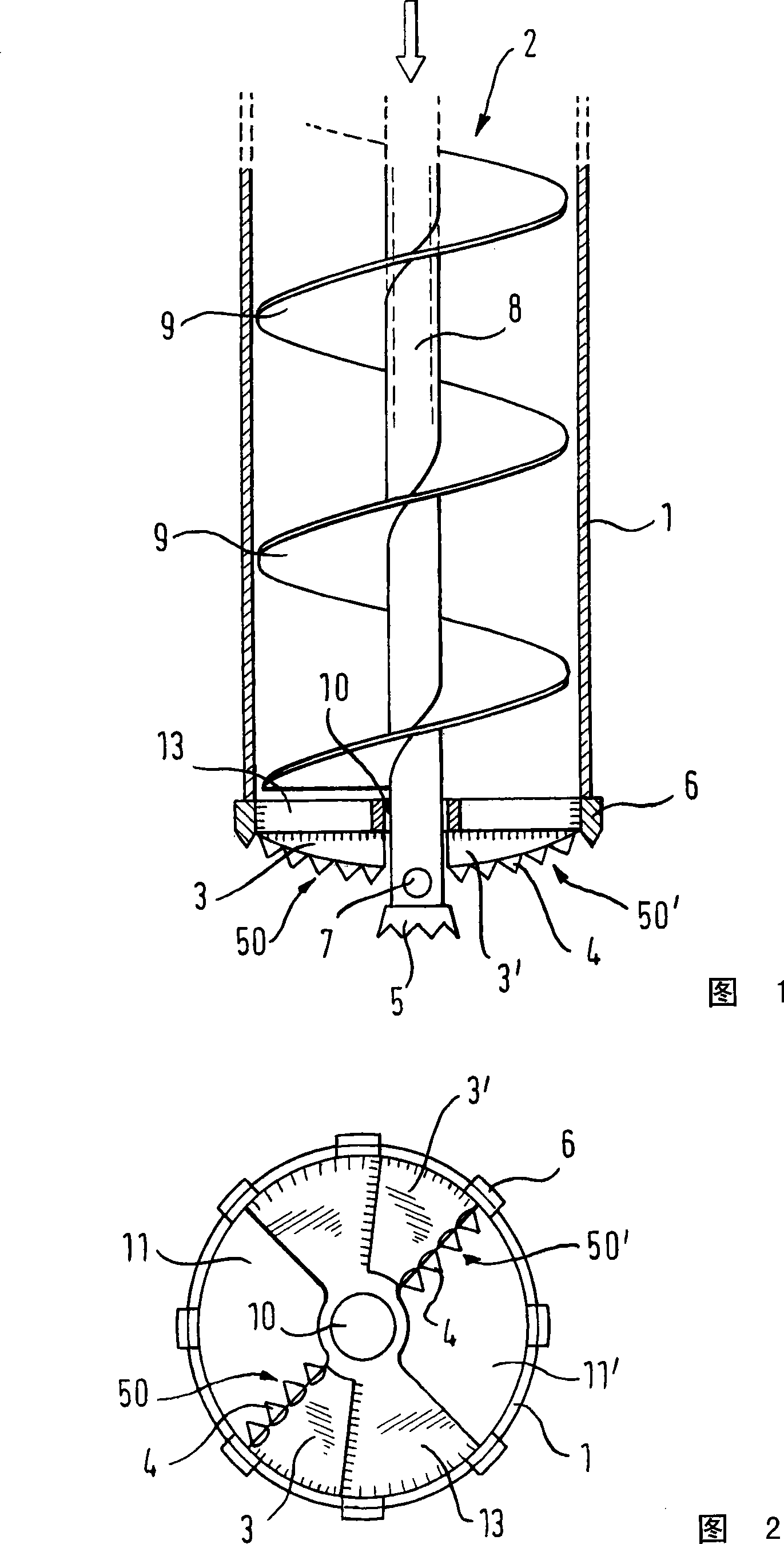

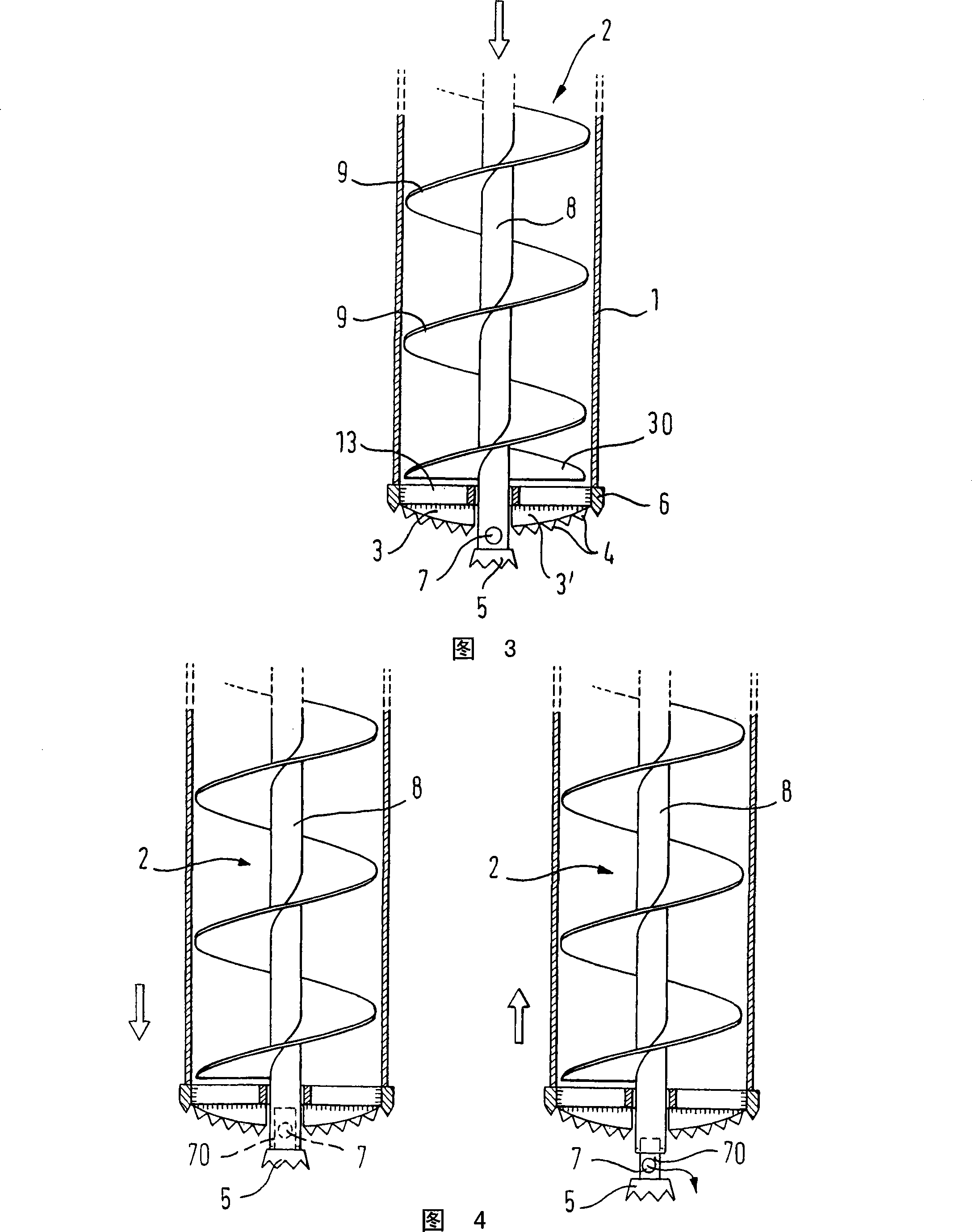

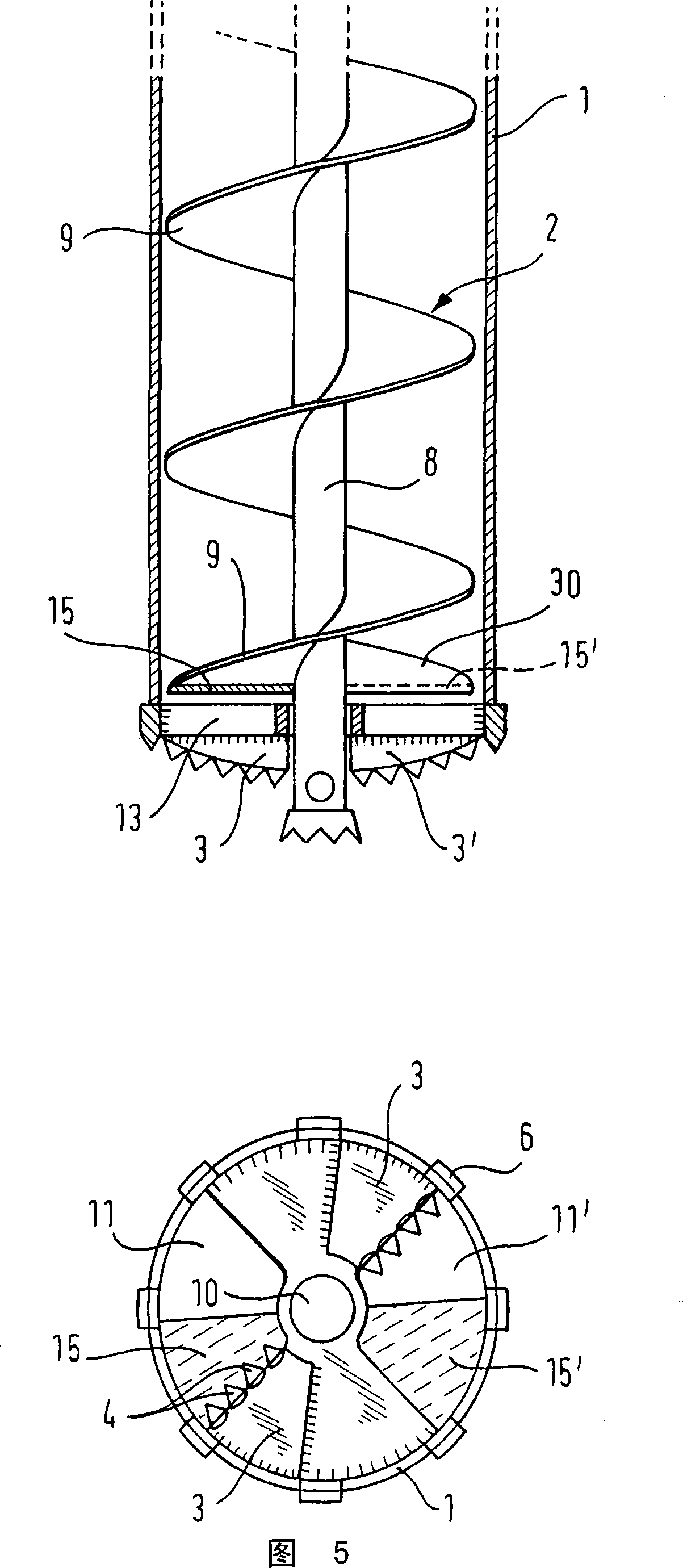

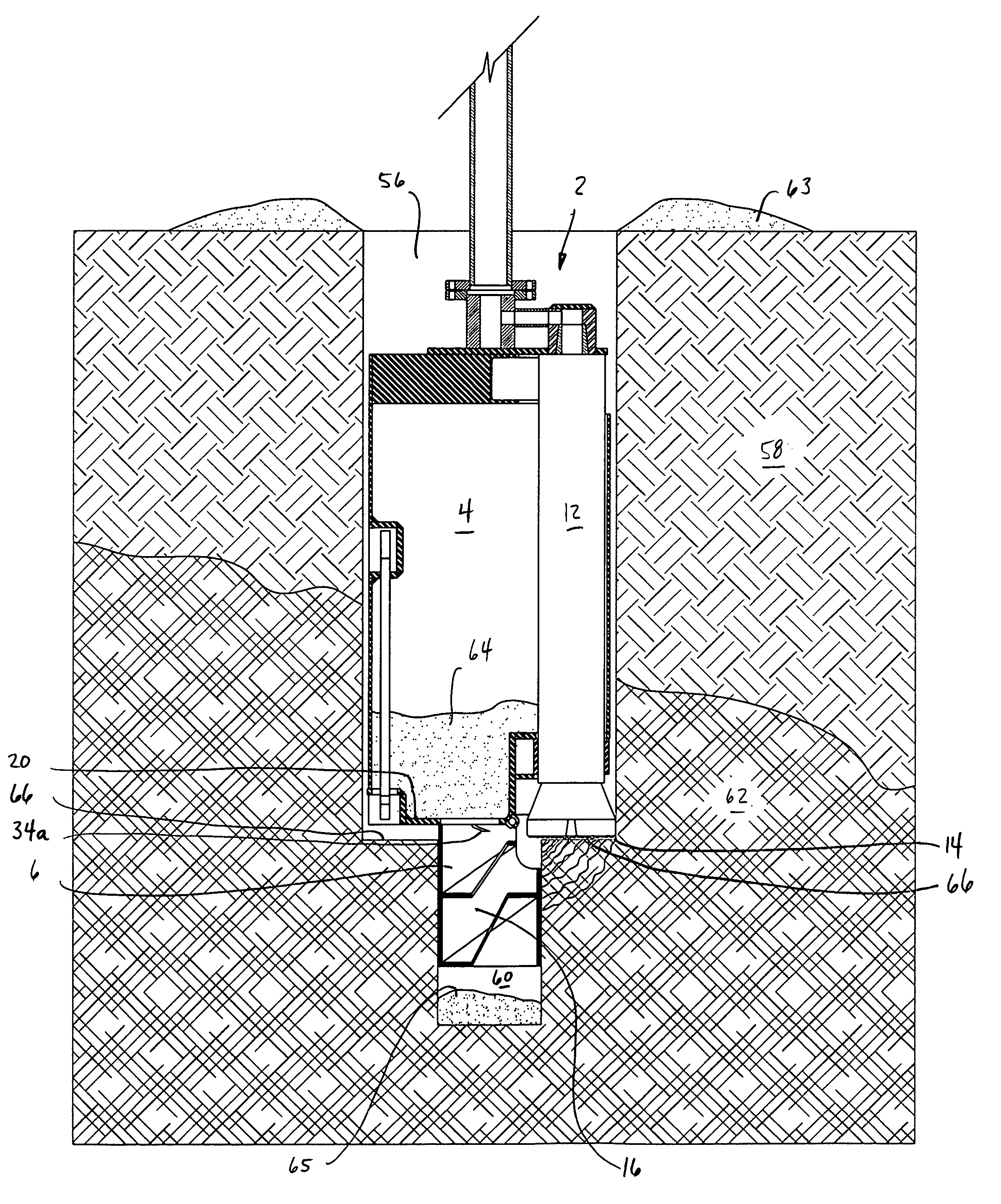

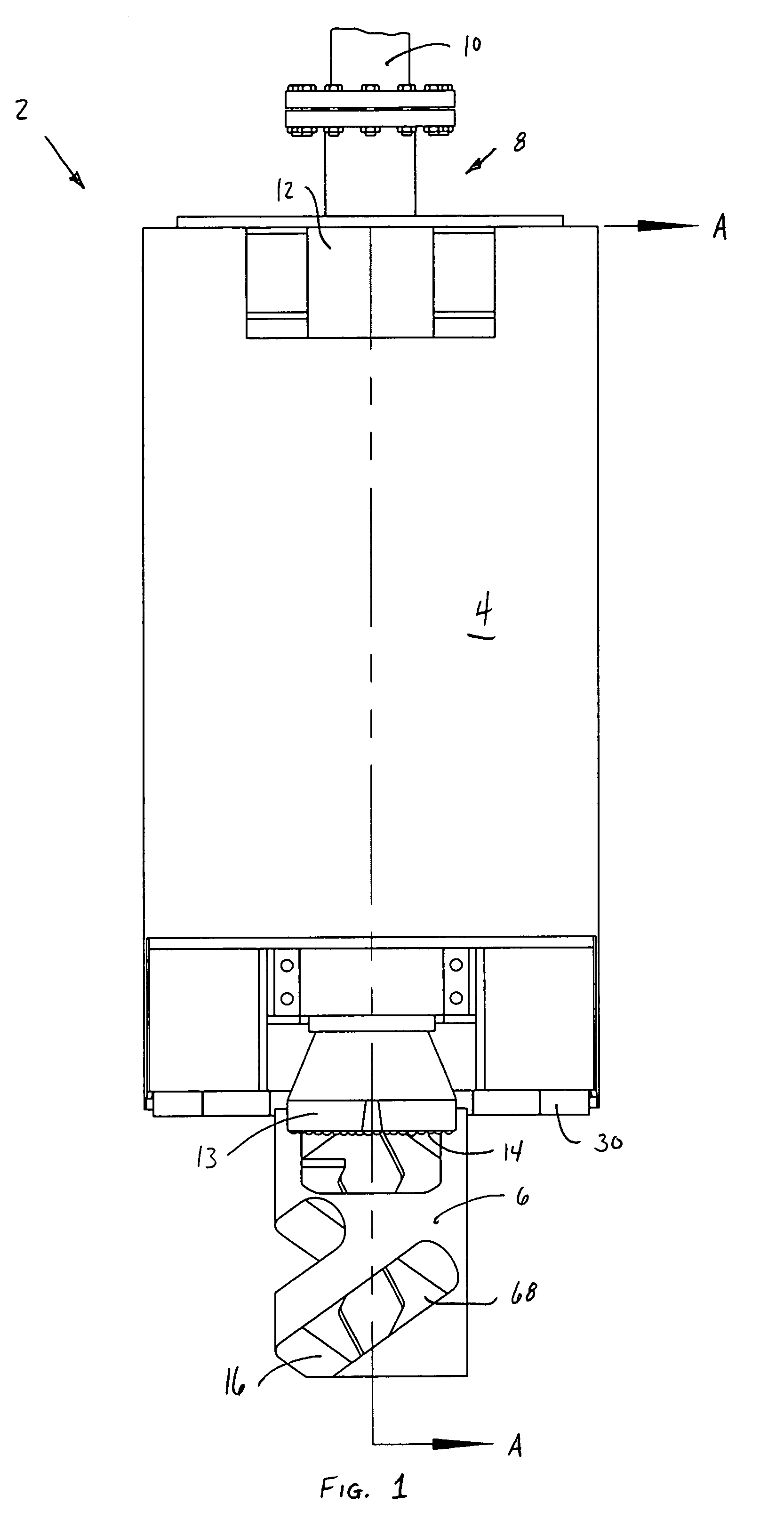

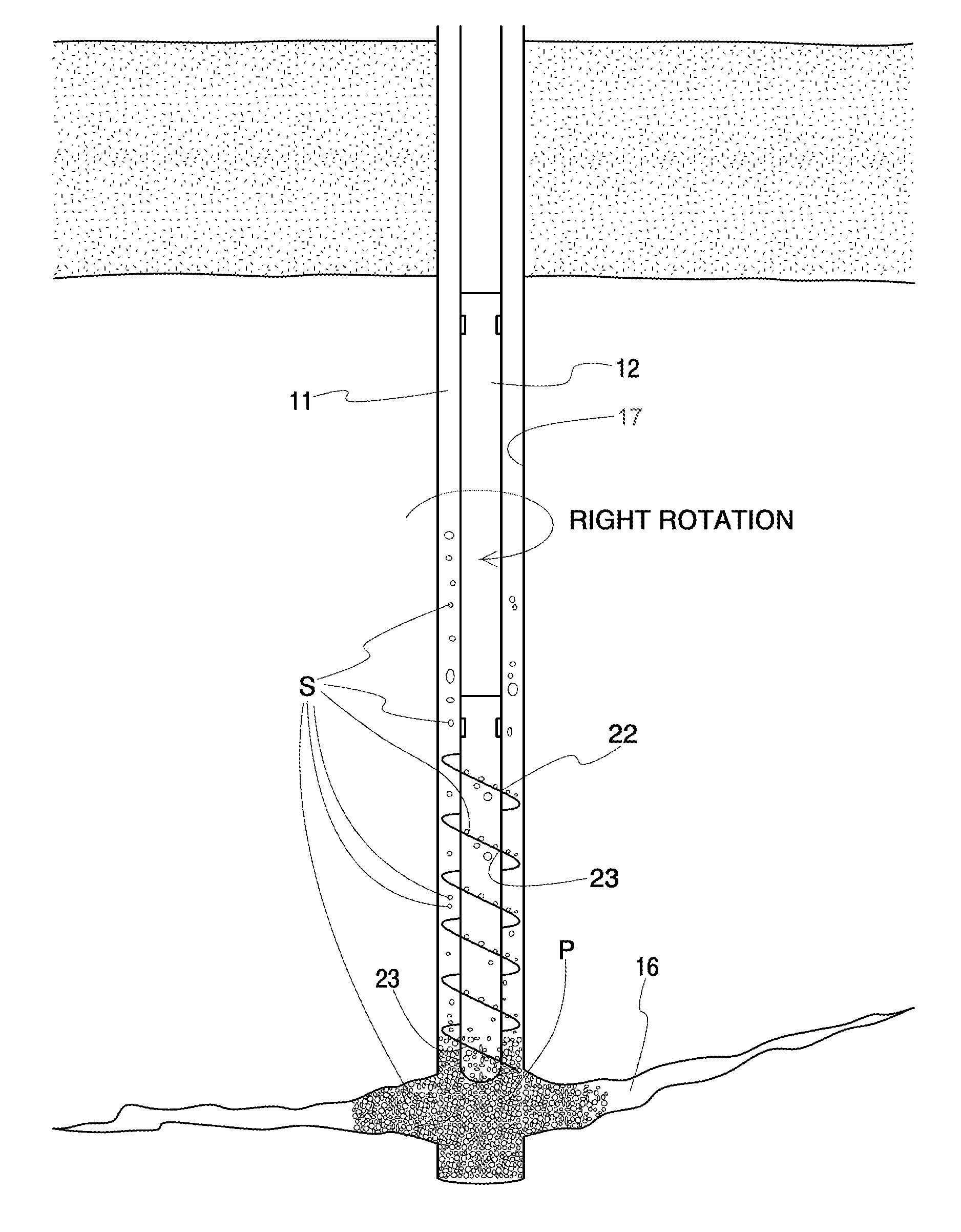

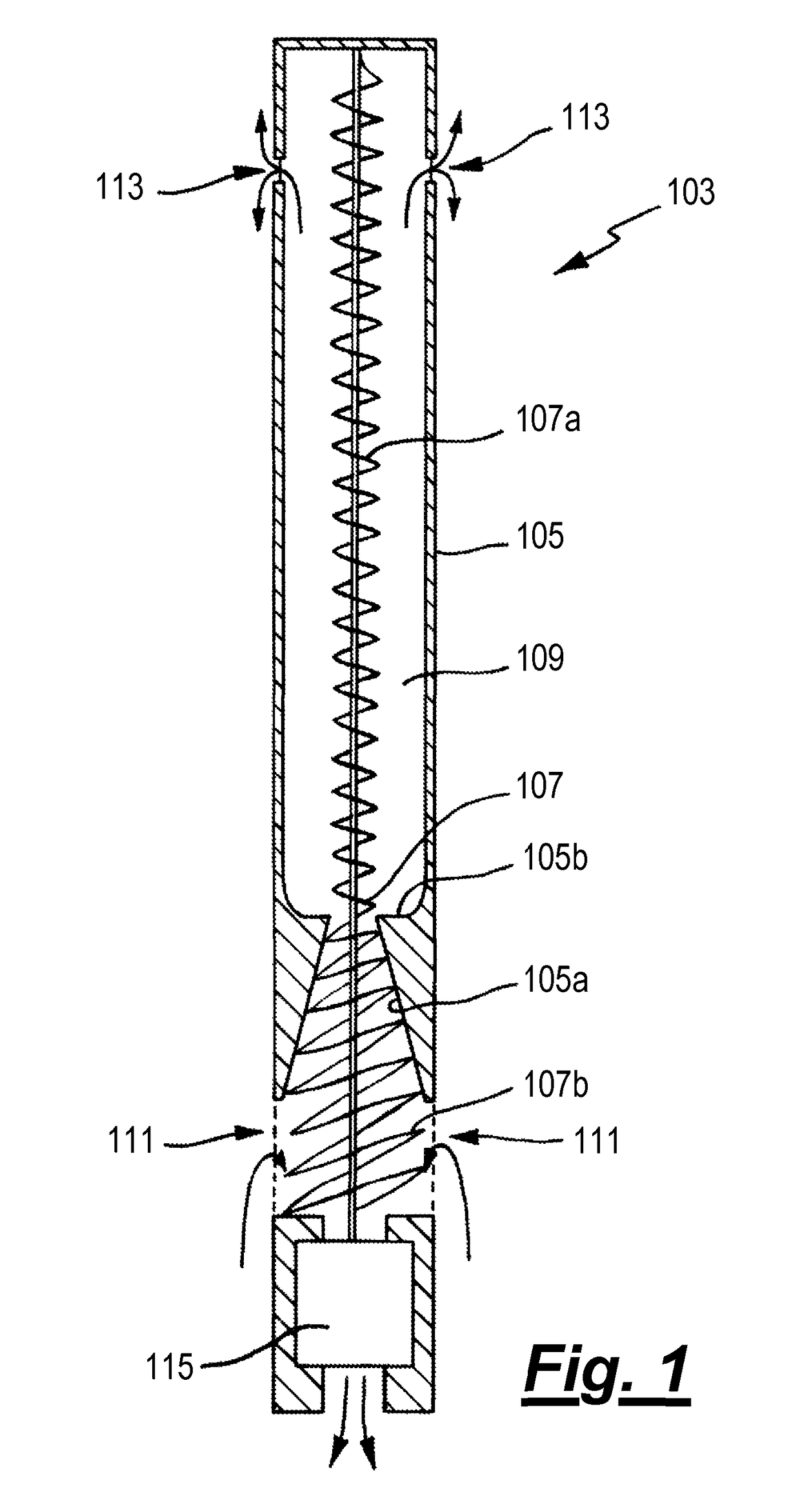

Method and apparatus for creating a borehole in the ground

The invention relates to a method for producing a borehole in the soil, in which a drill pipe and a conveyor screw arranged inside the drill pipe are set into rotation and introduced into the soil, and in which outcropping soil material is loosened by means of at least one main cutting edge, which is positioned axially in front of the conveyor screw, and is conveyed by means of the conveyor screw in the inside of the drill pipe. In accordance with the invention provision is made for the main cutting edge to be arranged on the drill pipe and to be rotated therewith. The invention further relates to a device for producing a borehole in the soil which can be employed in the method according to the invention.

Owner:BAUER MASCH GMBH

Piloted drill barrel and method of using same

A hard rock drill barrel has a barrel portion with a downhole hammer drill disposed therein at the barrel's periphery. A pilot portion, in substantial axial alignment with the barrel but having a smaller diameter, extends distally from the barrel for inserting into a pilot shaft of slightly larger diameter than the pilot portion. In operation, the hammer drill excavates a collar around the pilot shaft when the drill barrel is rotated and supplied with pressurized air, thereby excavating a relative large diameter shaft. The drill barrel is hollow and open at its proximal end to receive and collect cuttings flushed into the shaft above the drill barrel. The piloted drill barrel is adjustable to excavate variable diameter shaft portions, enabling the placement of casing within a larger diameter shaft portion. After adjustment of the drill barrel, smaller-diameter shaft excavation proceeds beyond the casing.

Owner:BECK III AUGUST H

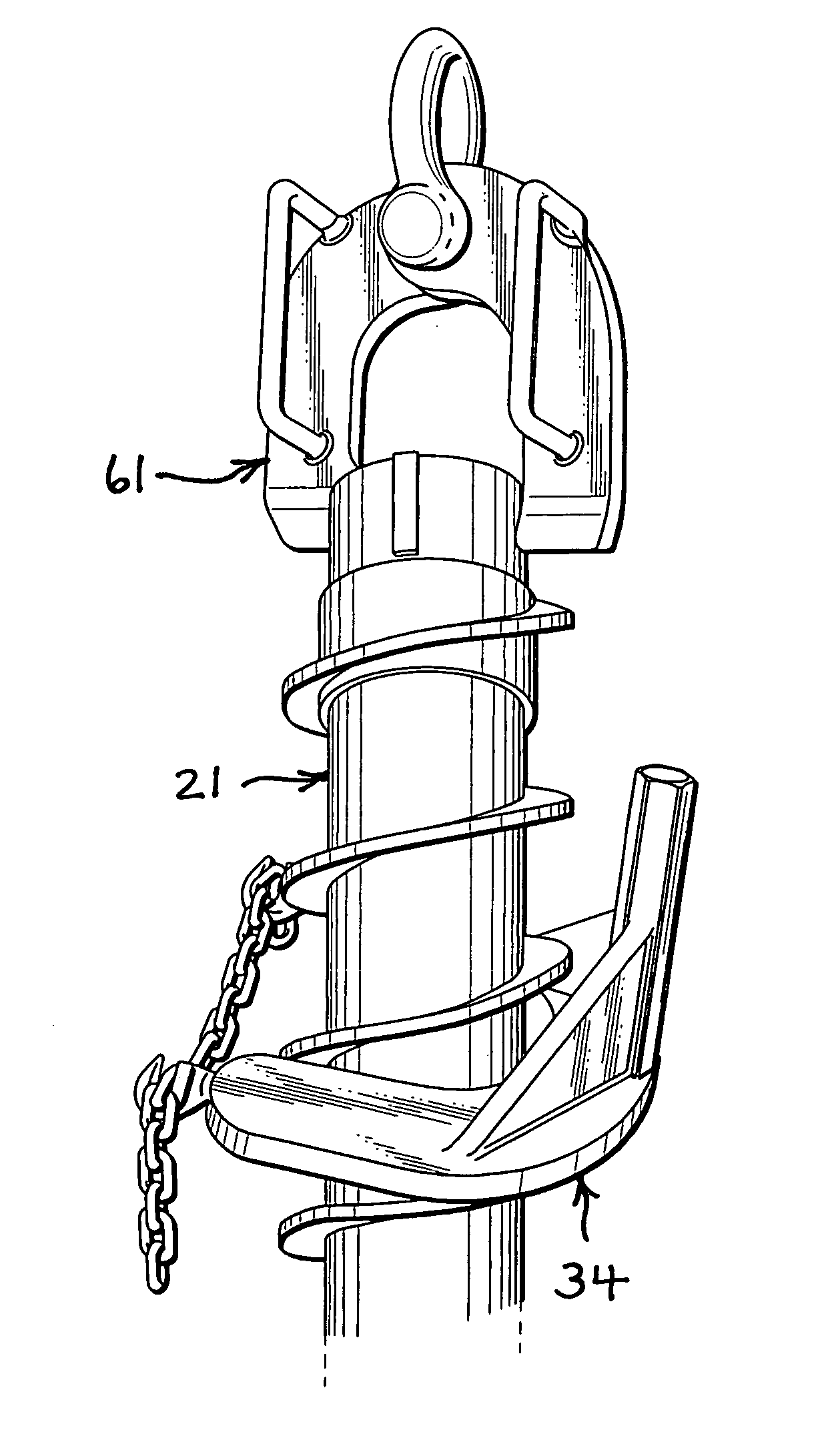

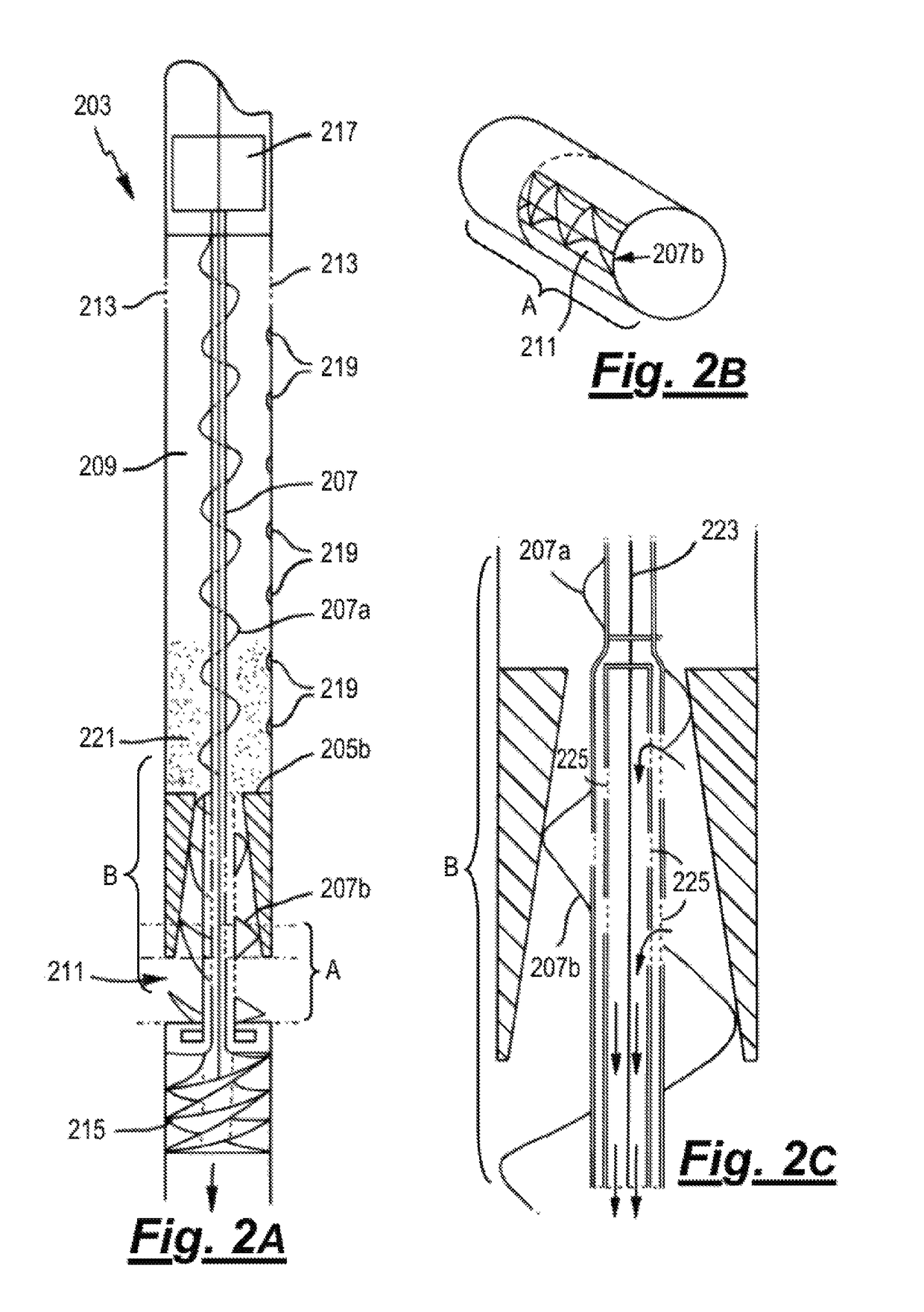

Accessories and method for hollow stem auger retraction

InactiveUS7708072B1Easy to controlDrilling rodsDrilling with mechanical conveyingHydraulic cylinderEngineering

Withdrawing a hollow stem auger string from a well includes a retractor having C-shaped inter-coil insertions and a hoist having tong-arms, one which terminates in an inwardly disposed pin. The retractor connects to a drilling rig's hydraulic cylinder vertical drive system, the hoist to a winch system thereof. The retractor engages the string by the C-shaped inter-coil insertion disposed between one coil of the helical flight of the topmost section of the string. The hoist engaged the top collar of the topmost section by the at least one pin inserting into a pin hole thereof. The string is lifted about the height of one section by the retractor, which is promptly disengaged. The topmost section is detached, and carried by the hoist to elsewhere to be dropped. The method repeats by re-engaging the retractor and hoist and then returning to the activity of lifting.

Owner:HUNZIKER DAVID G

Apparatus for drilling deeper and wider well bore with casing

An apparatus and method for drilling deeper and wider well bores is provided. The apparatus includes a motorized drill head for cutting and shredding ground material; a separate excavation line; a separate fluid delivery line; a separate close loop engine cooling line; and a casing system. Excavation line includes repetitive stationary segments of the main pipe with periodical segments of an in-line excavation pump. The close loop cooling line includes a heat exchanger in the motorized drill head and in the in-line excavation pump and one on the ground surface in the binary unit where fluid is cooled and in process electricity produced. The diameter of the excavation line and rate of flow of mud and cuttings through it and the diameter of the fluid delivery line and rate of fluid flow through it are in balance requiring only limited fluid column at the bottom of the well bore.

Owner:LAKIC NIKOLA

Method for repairing aberrations along a drill bore wall

InactiveUS8672058B2Increase capacityAdd depthEarth drilling toolsCollector components/accessoriesEngineeringDrill bit

The invention provides a system for adapting an HVAC system in an existing building for utilizing geothermal energy, the system comprising an incoming flux of geothermal energy; a plurality of heat exchange surfaces adapted to receive the incoming flux of geothermal energy; and an interface between the HVAC system and the heat exchange surfaces, said interface adapted to transfer the geothermal energy to the system. Also provided is a method for repairing aberrations in drill borings, the method comprising using a rotary mud drill system to produce a drill hole up to the location of the aberrations; removing the rotary mud drill from the drill hole; inserting an auger into the drill hole to a point directly above the location of the aberrations; actuating the auger; introducing loose substrate into the drill hole; allowing the substrate to contact the auger; and lifting and lowering the auger along longitudinally extending regions of the drill hole defining the aberrations for a time and in substrate amounts sufficient to fill the aberrations. The invention also provides a system which facilitates rotating drill bits at an rpm which are multiples faster than their associated drill strings.

Owner:GEOTHERMAL TECH

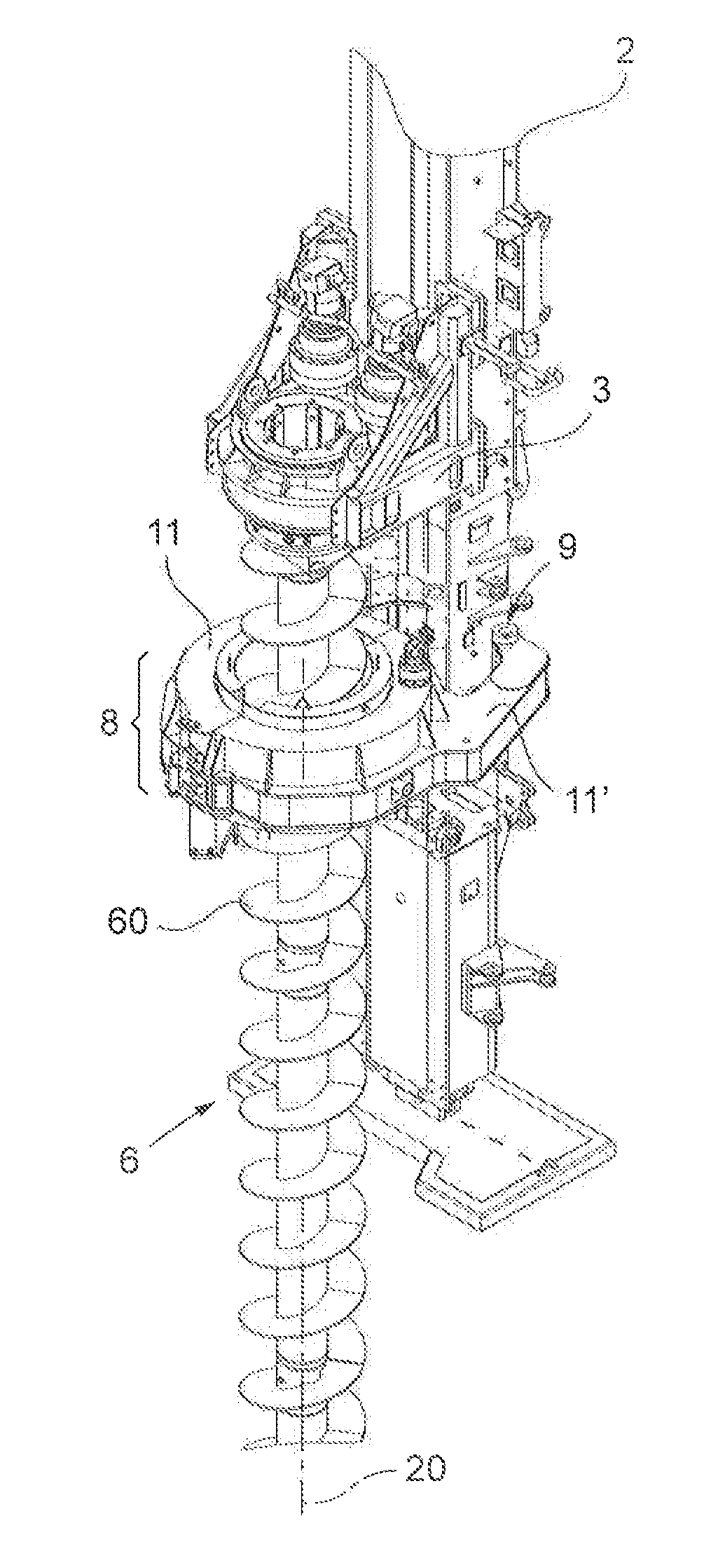

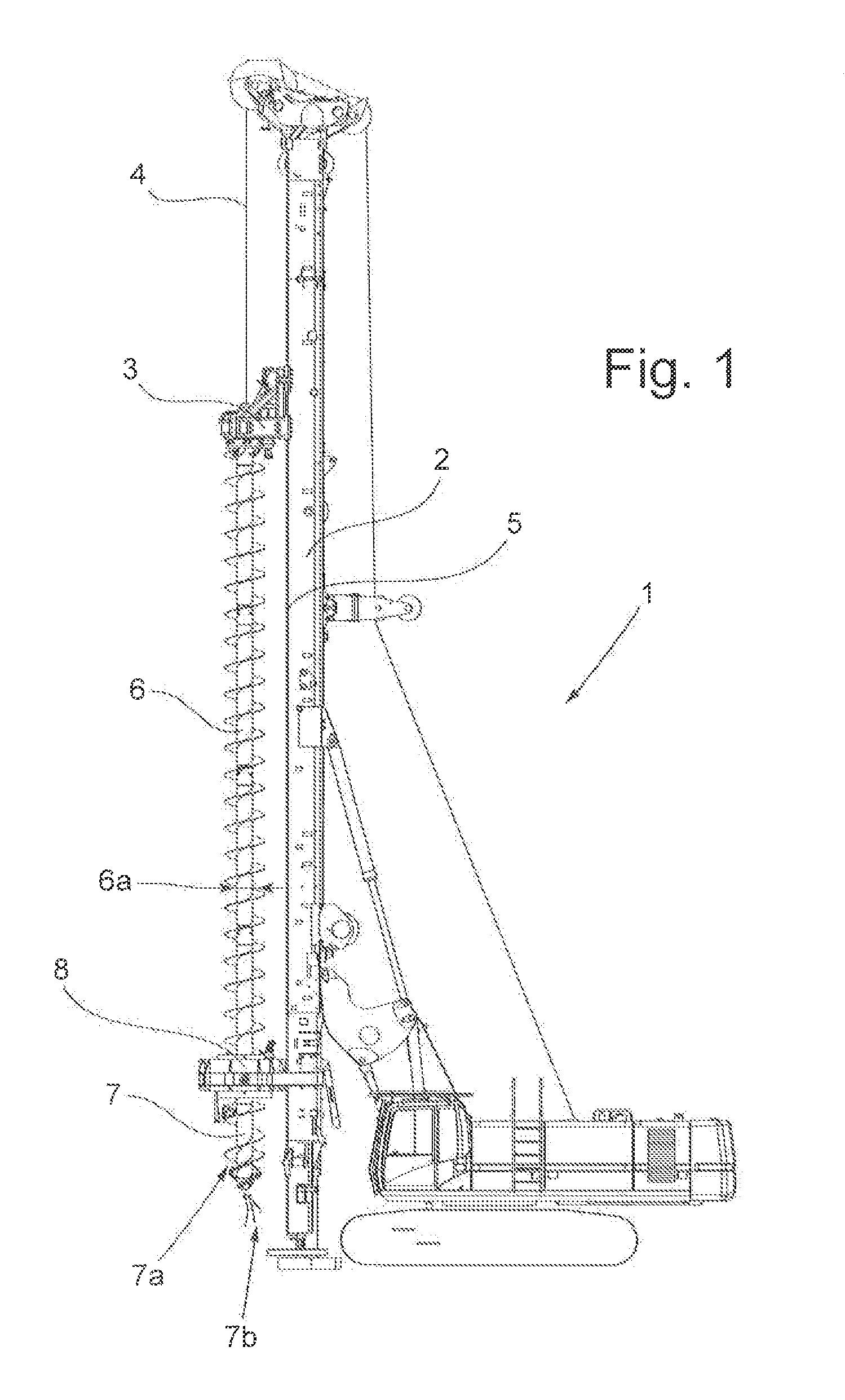

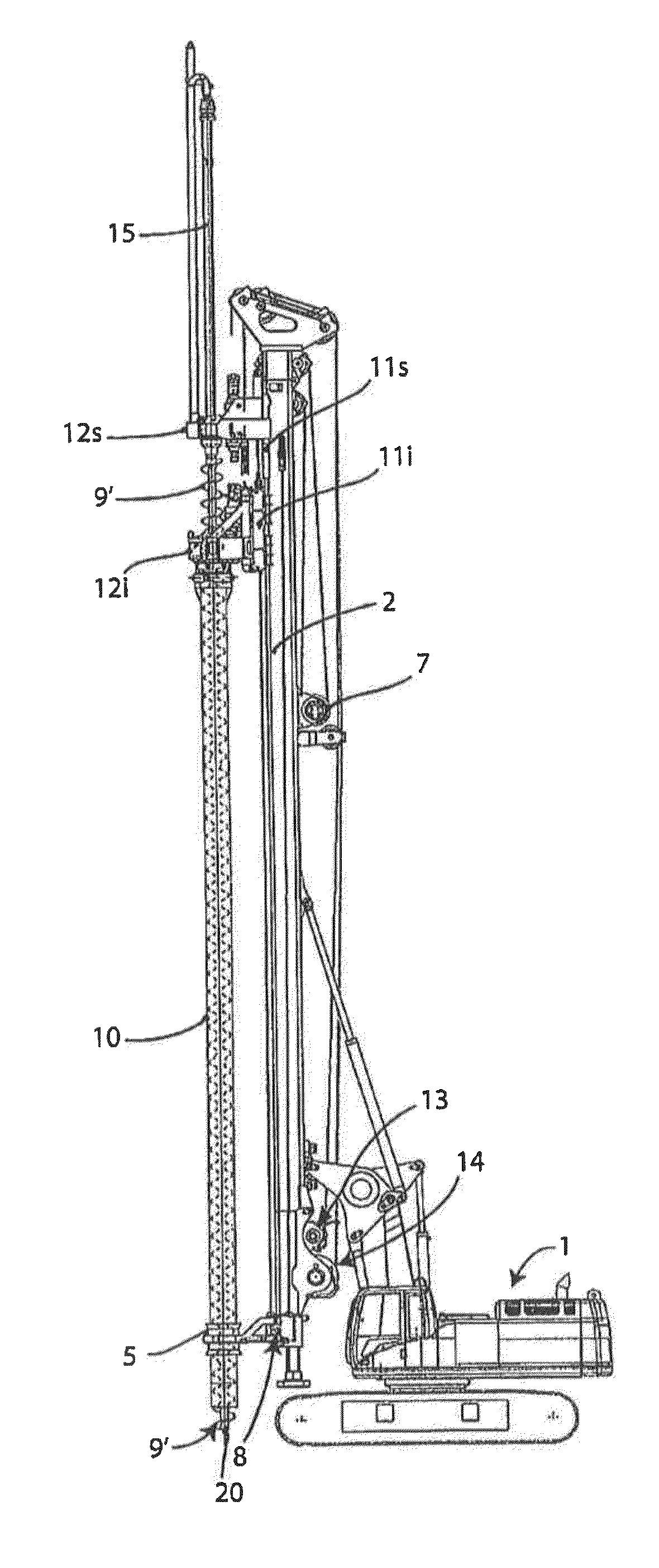

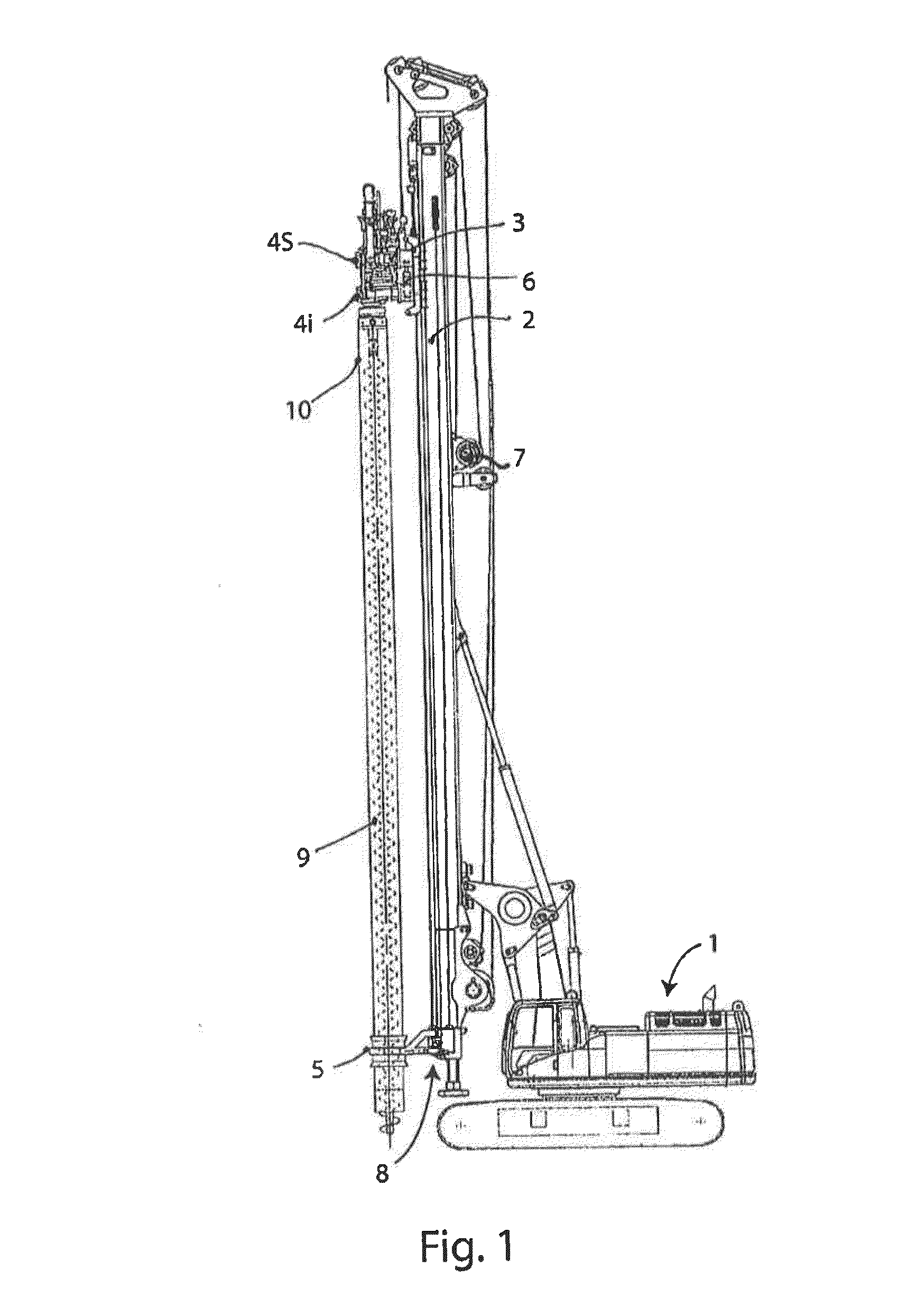

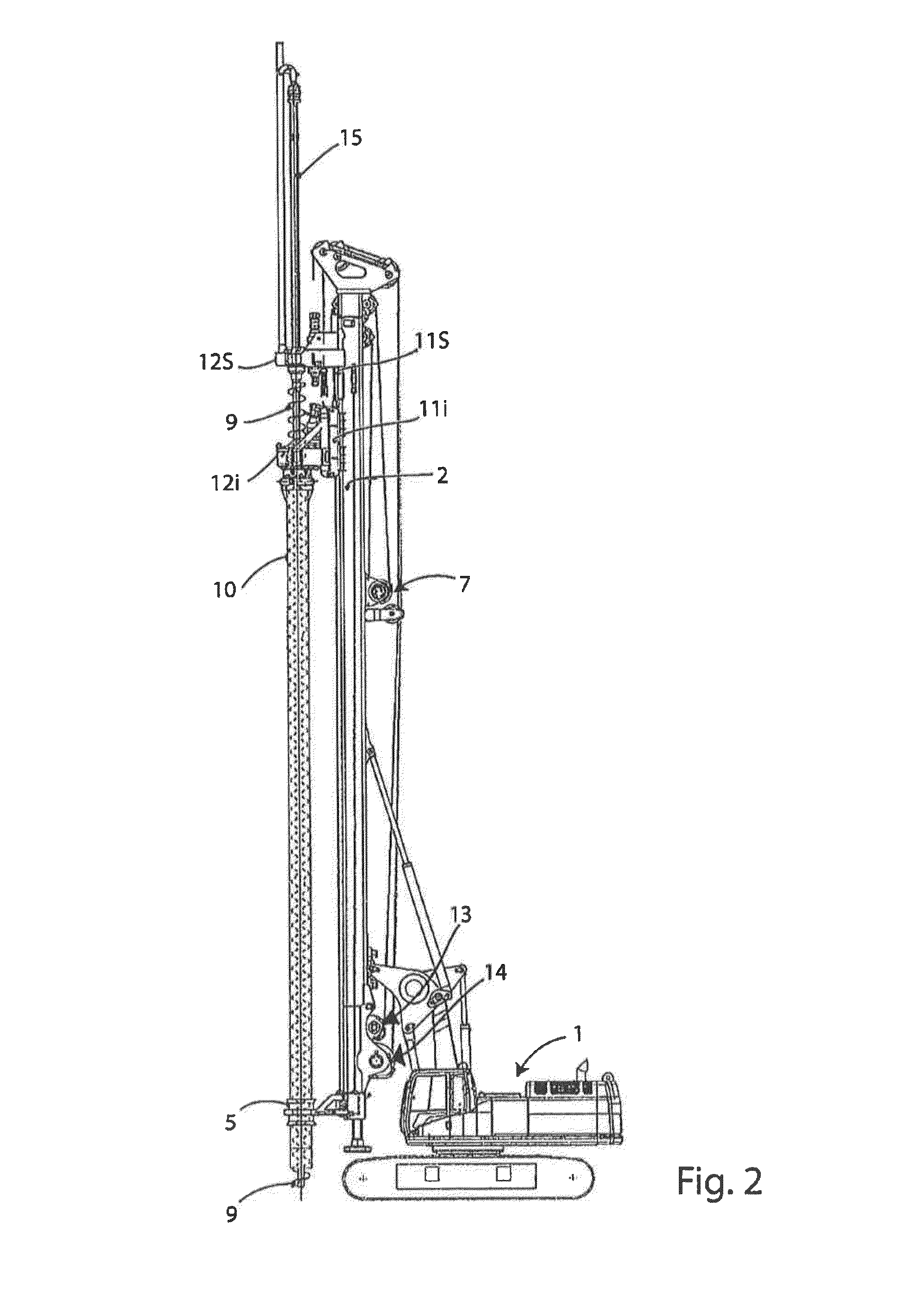

Auger cleaning device for removing debris from a helical drilling tool, drilling machine provided with said cleaning device and use of said drilling machine

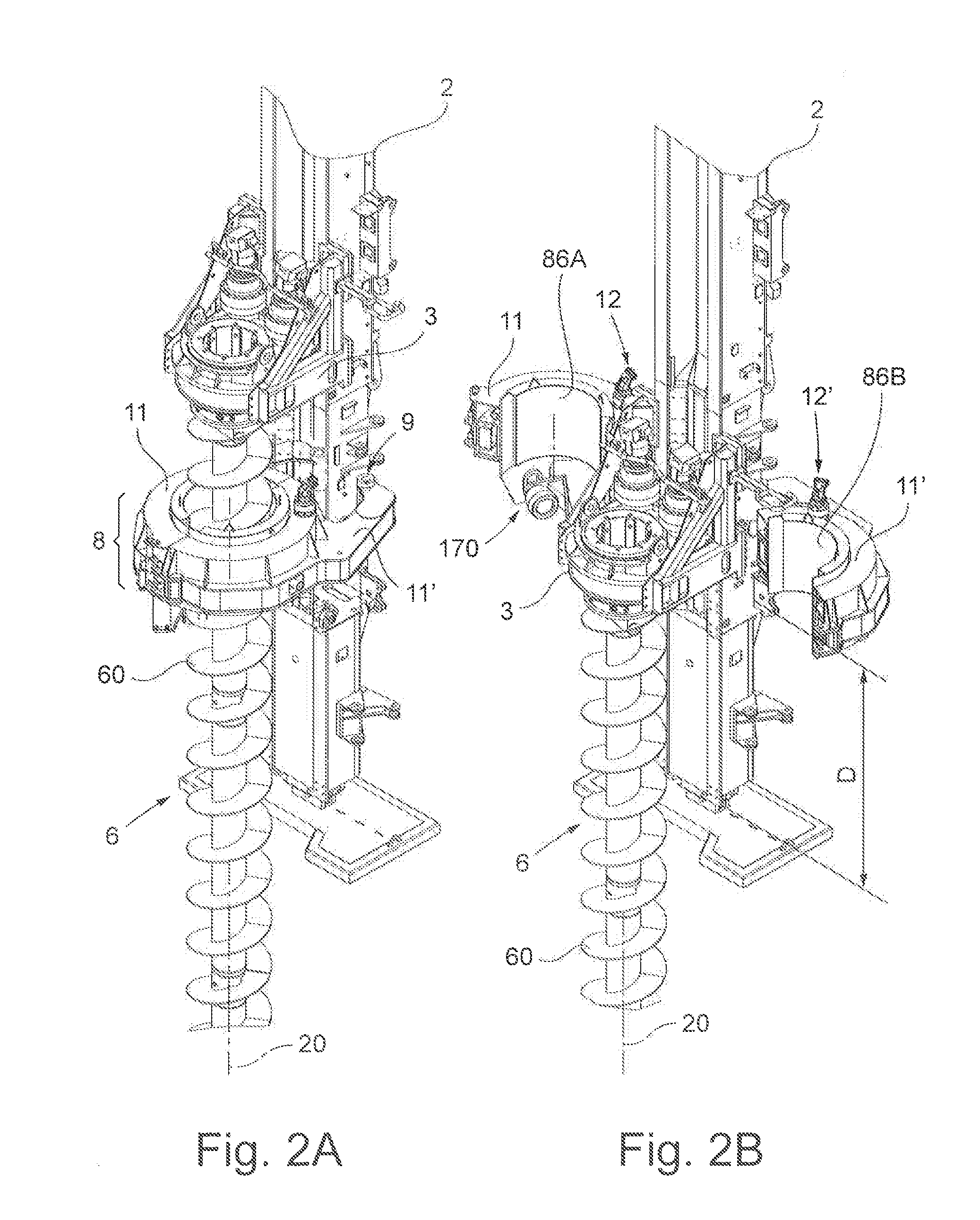

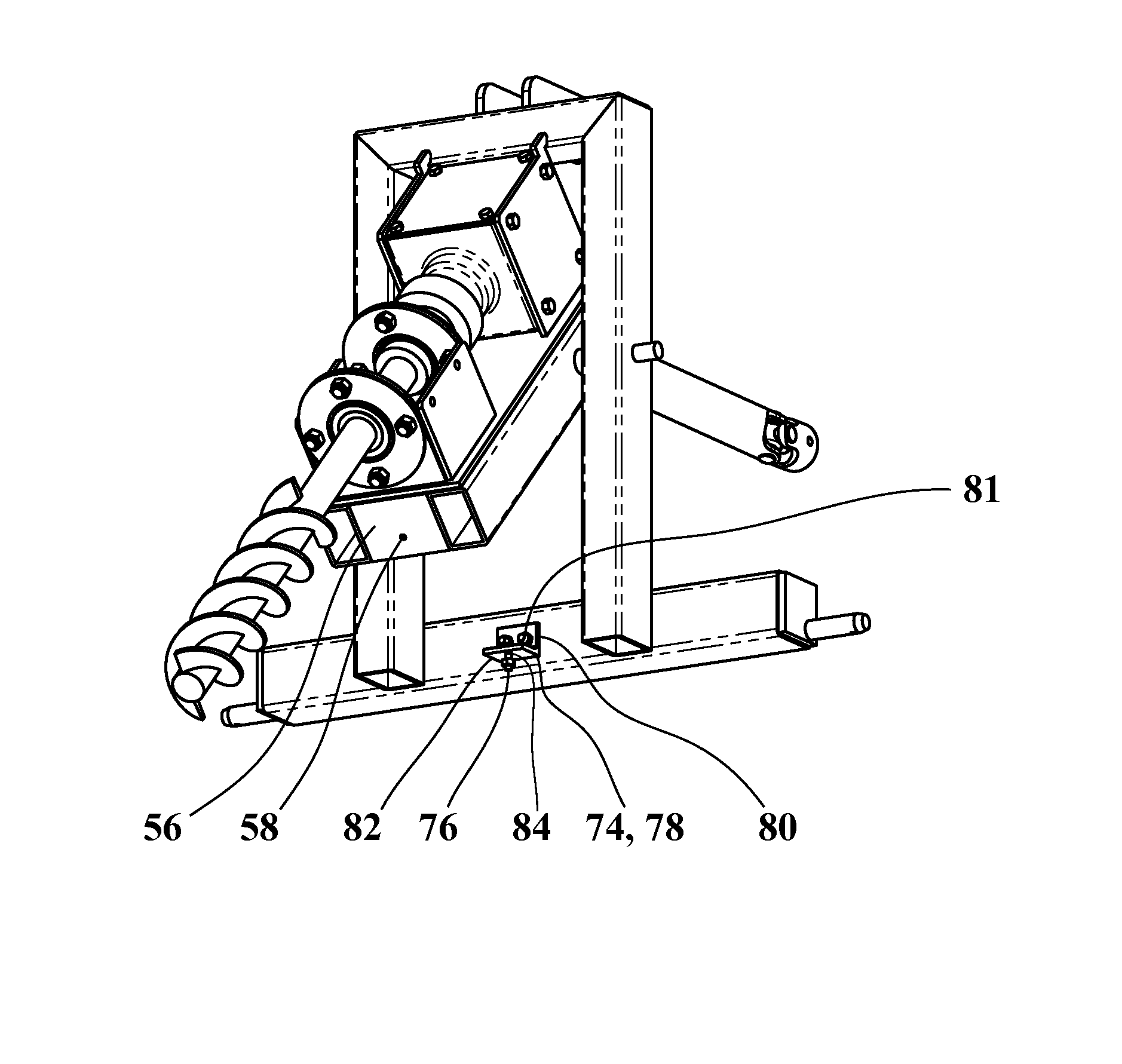

In the auger cleaning device (8) according to the invention, in the closed configuration the tool-holder support forms a pass-through opening (82) arranged for allowing the passage of a helical drilling tool (6), the cleaning tool (170) engaging with the screw of the drilling tool (6) and, actuated by the actuation system (12, 12′, 12″, 4), is arranged for rotating around the drilling tool (6) following at least one of its threads (60) so as to remove the debris lying on the drilling tool (6). In the open configuration the cleaning tool (170) is disengaged from the drilling tool (6) and preferably farther from it, with respect to when it is in the closed configuration.

Owner:SOILMEC

Horizontal auger garden tilling apparatus and method of use

InactiveUS8910400B1Promote root growthGuaranteed safety and longevitySpadesDrilling rodsHorizontal forceEngineering

A horizontal auger garden tilling apparatus and method of use having an outer frame, an inner frame which pivots with said outer frame, and a rotating auger capable of tilling soil to depth which conventional tillers cannot begin to reach. The apparatus is moved and the method of use is performed via attachment with a tractor or other movable carriage which provides enough horizontal force to move the auger through the soil and provides auger rotational power. A trencher attachment prevents auger soil refilling and allows the apparatus and method of use to be utilized and performed in conjunction with trenching operations.

Owner:PROVINES WYNN

Helical drill bit for an auger of a ground excavation assembly, in particular for building excavated piles, and drilling method that uses such a bit

ActiveUS20130294843A1Simple and safe and effective and cost-effectiveDrawback can be solvedDrill bitsDrilling rodsEngineeringHole drilling method

The helical drill bit defines a helical end section of a helical structure formed at its periphery by an auger of an excavation assembly, and it is associated or associate with a support portion of the auger. Such a support portion defines a proximal section of the helical structure, which has an extension substantially centred around a longitudinal axis (X-X). The helical drill bit is adapted to rotate about the longitudinal axis (X-X) together with the support portion so as to drill a hole in the ground. The helical end section extends around an extremity axis (Y-Y; Ψ-Ψ) that is not aligned relative to the longitudinal axis (X-X).

Owner:SOILMEC

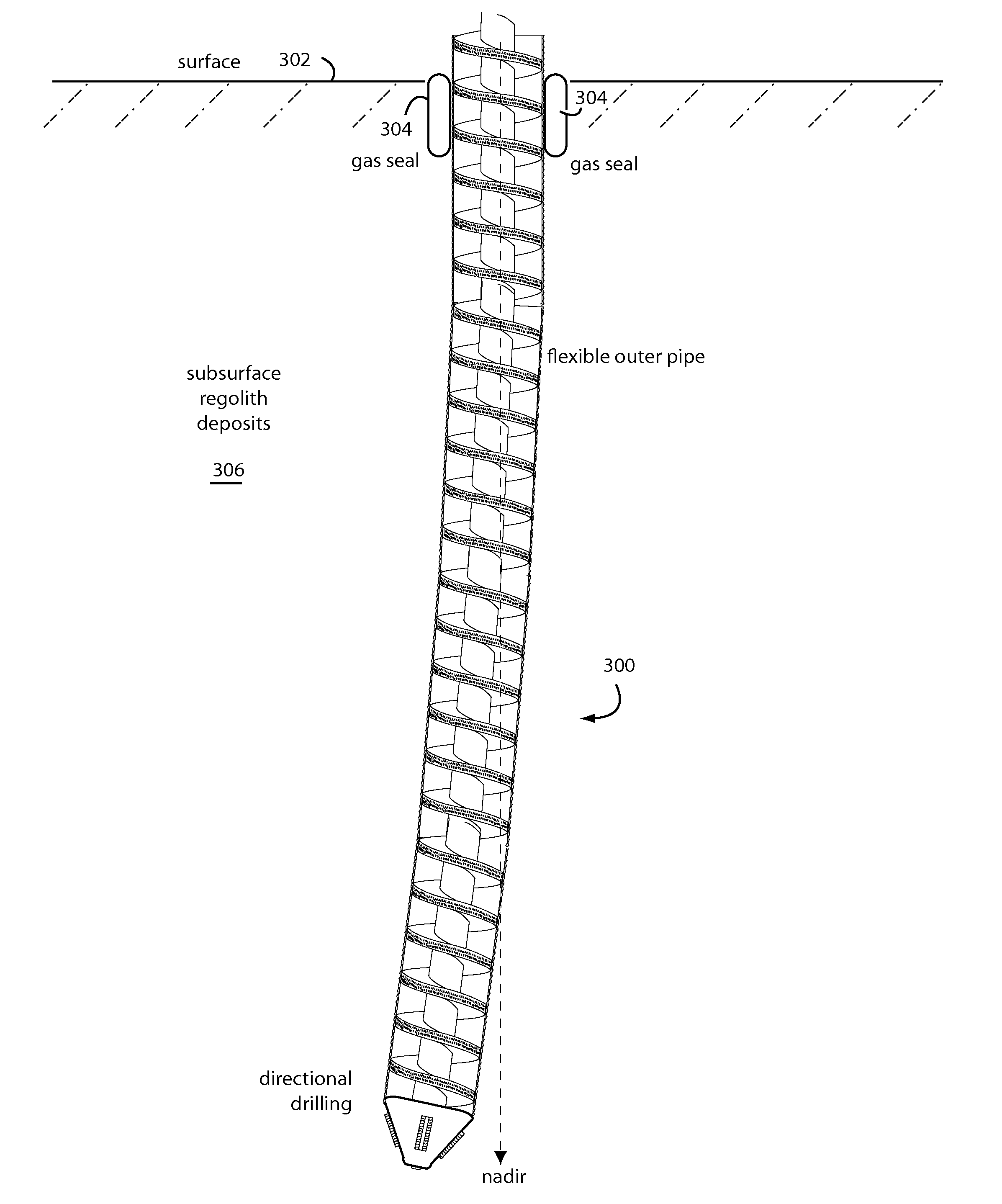

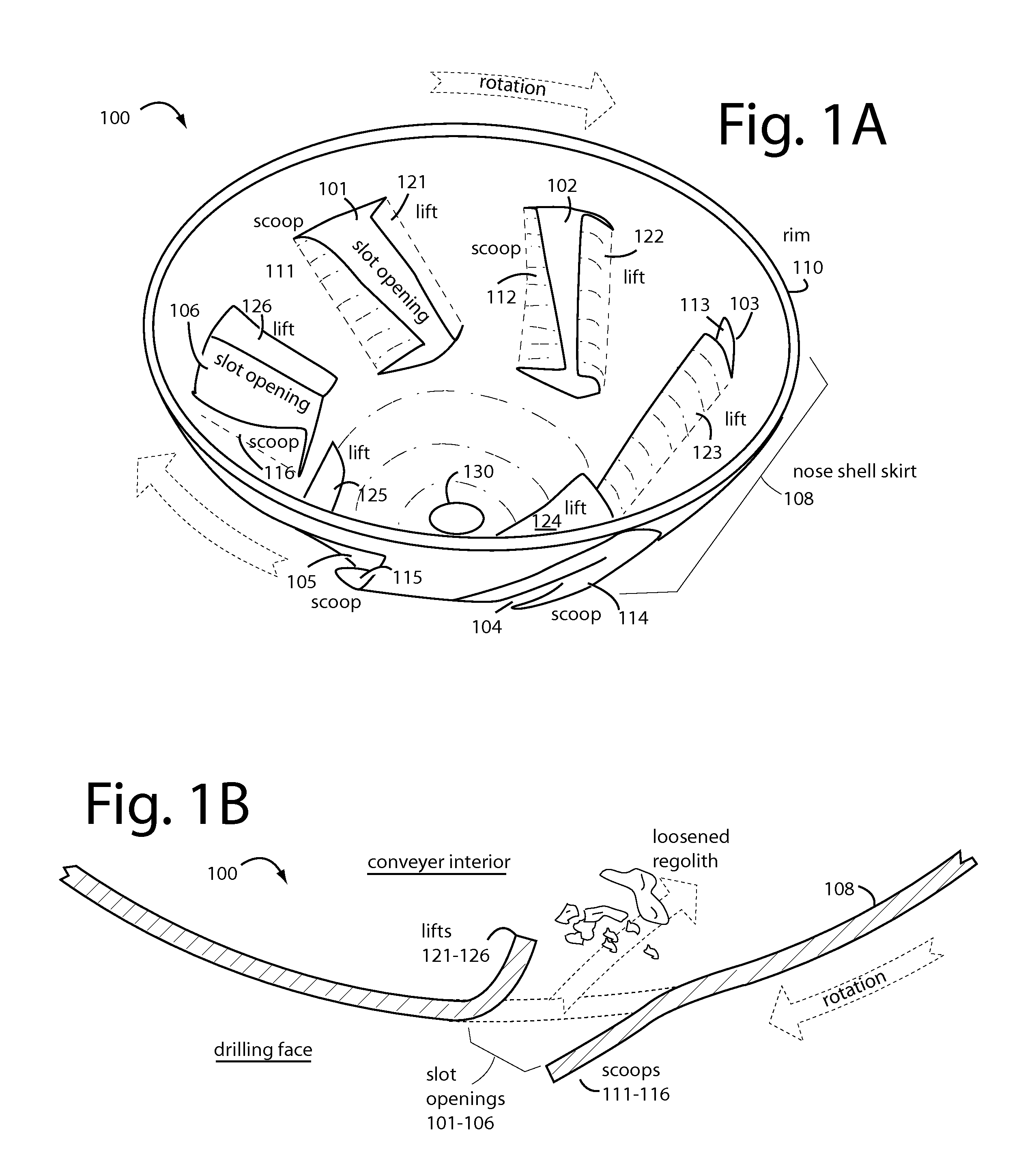

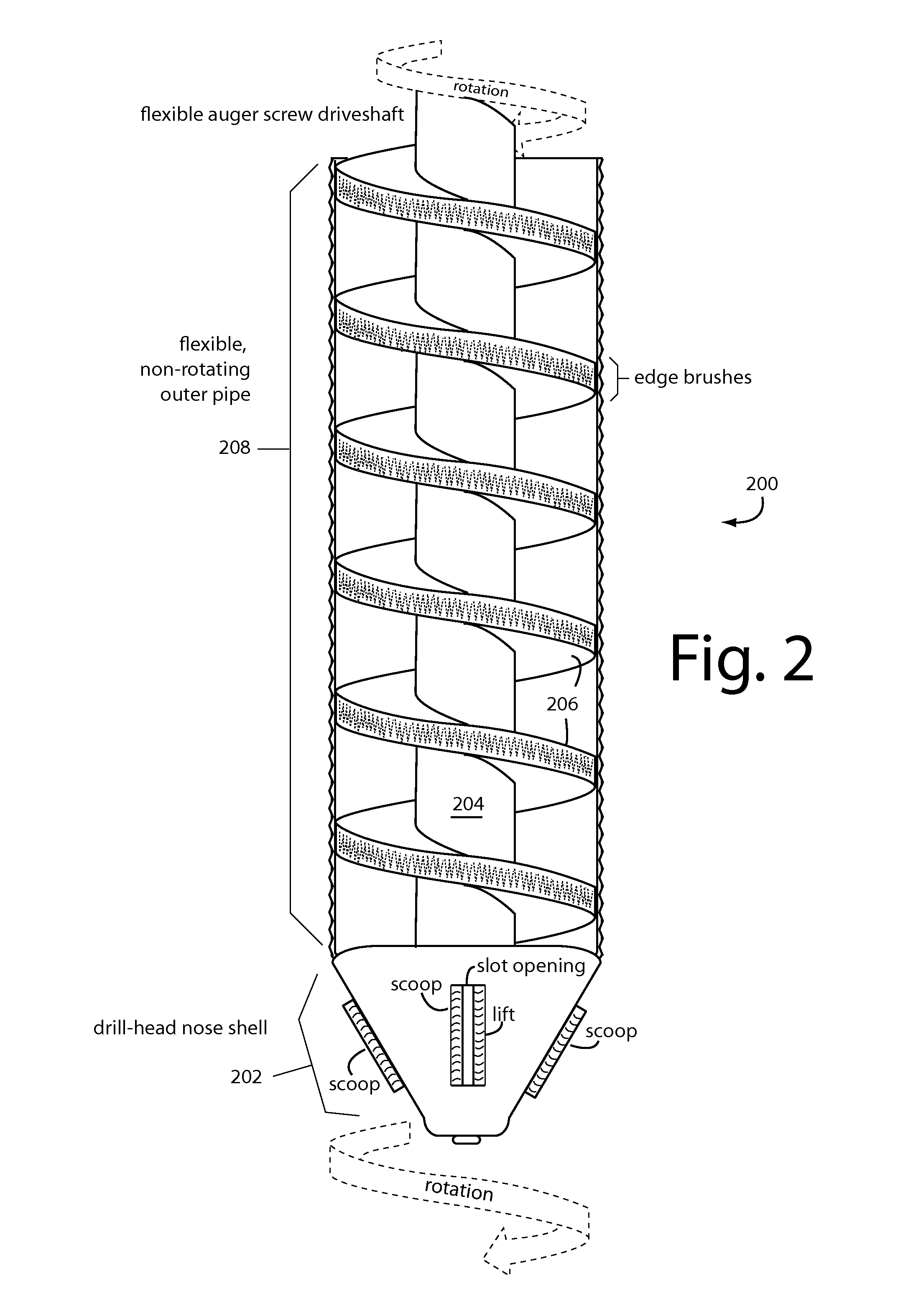

Vertical-screw-auger conveyer feeder

A conical feeder is attached to a vertically conveying screw auger. The feeder is equipped with scoops and rotated from the surface to force-feed regolith the auger. Additional scoops are possible by adding a cylindrical section above the conical funnel section. Such then allows the unit to collect material from swaths larger in diameter than the enclosing casing pipe of the screw auger. A third element includes a flexible screw auger. All three can be used in combination in microgravity and zero atmosphere environments to drill and recover a wide area of subsurface regolith and entrained volatiles through a single access point on the surface.

Owner:WALTON OTIS +1

Earth boring bit

InactiveUS6533048B2Reduce frictionProlong lifeEarth drilling toolsDrill bitsMechanical engineeringDrill bit

An earth boring bit for boring a hole having a predetermined depth into the earth. The earth boring bit includes a cylindrical drum for being mounted for rotation on the end of a boom of a mobile machine and connected to and rotated by a power supply mounted on the boom. The drum includes an exterior for defining the diameter of the hole being bored and an interior adapted for receiving upturned earth therein as the hole is being bored. A plate is mounted in the drum adjacent a lower end thereof for movement between a closed position for cooperating with the interior of the drum for retaining the upturned earth therein and an open position for dispensing the upturned earth out of the interior of the drum at a predetermined location away from the hole being bored. At least one cutting member is carried on the plate for cutting the earth in a progressive slice and directing the earth into the drum, thereby boring the hole into the earth.

Owner:GOLD DIGGER ENTERPRISES INC +2

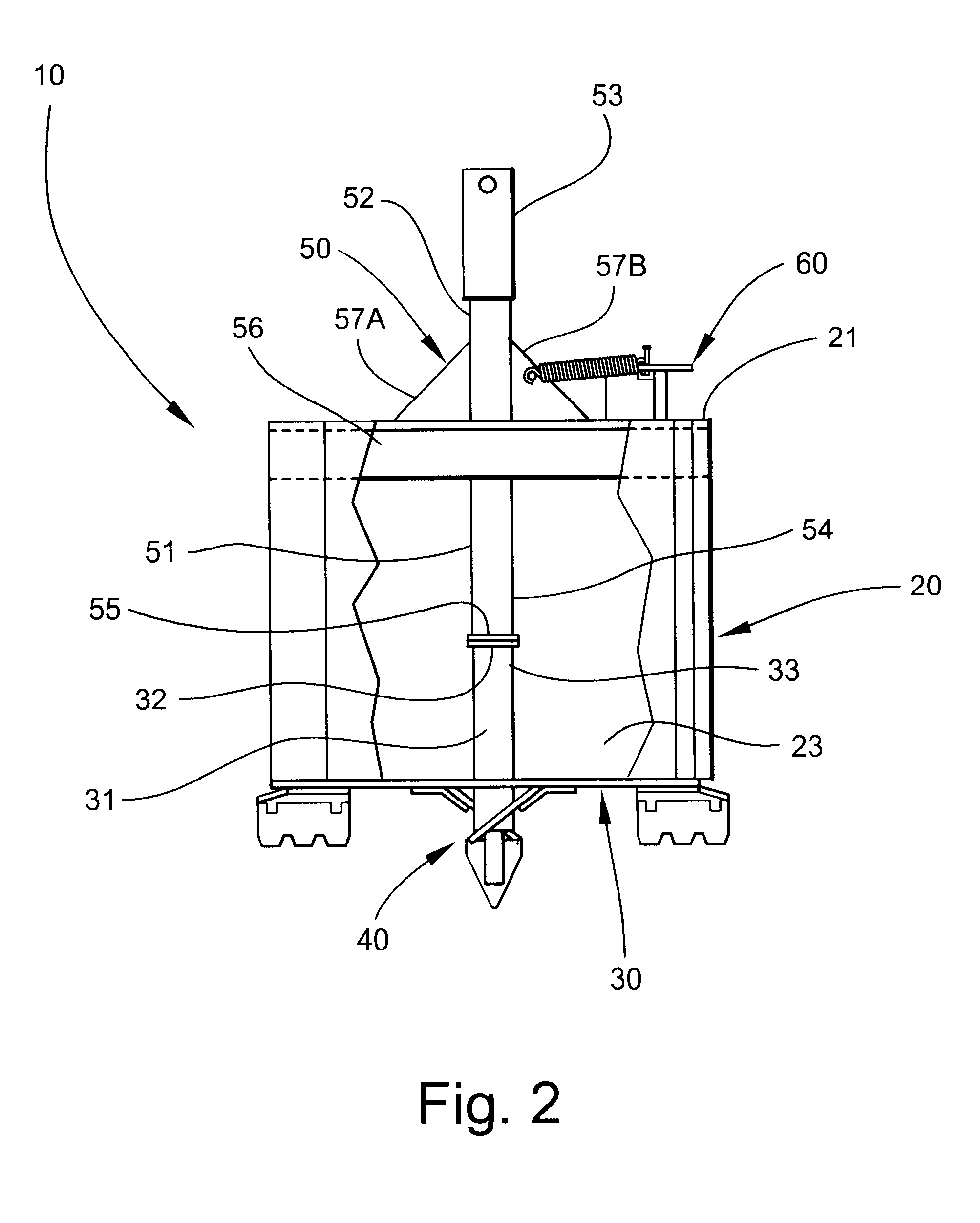

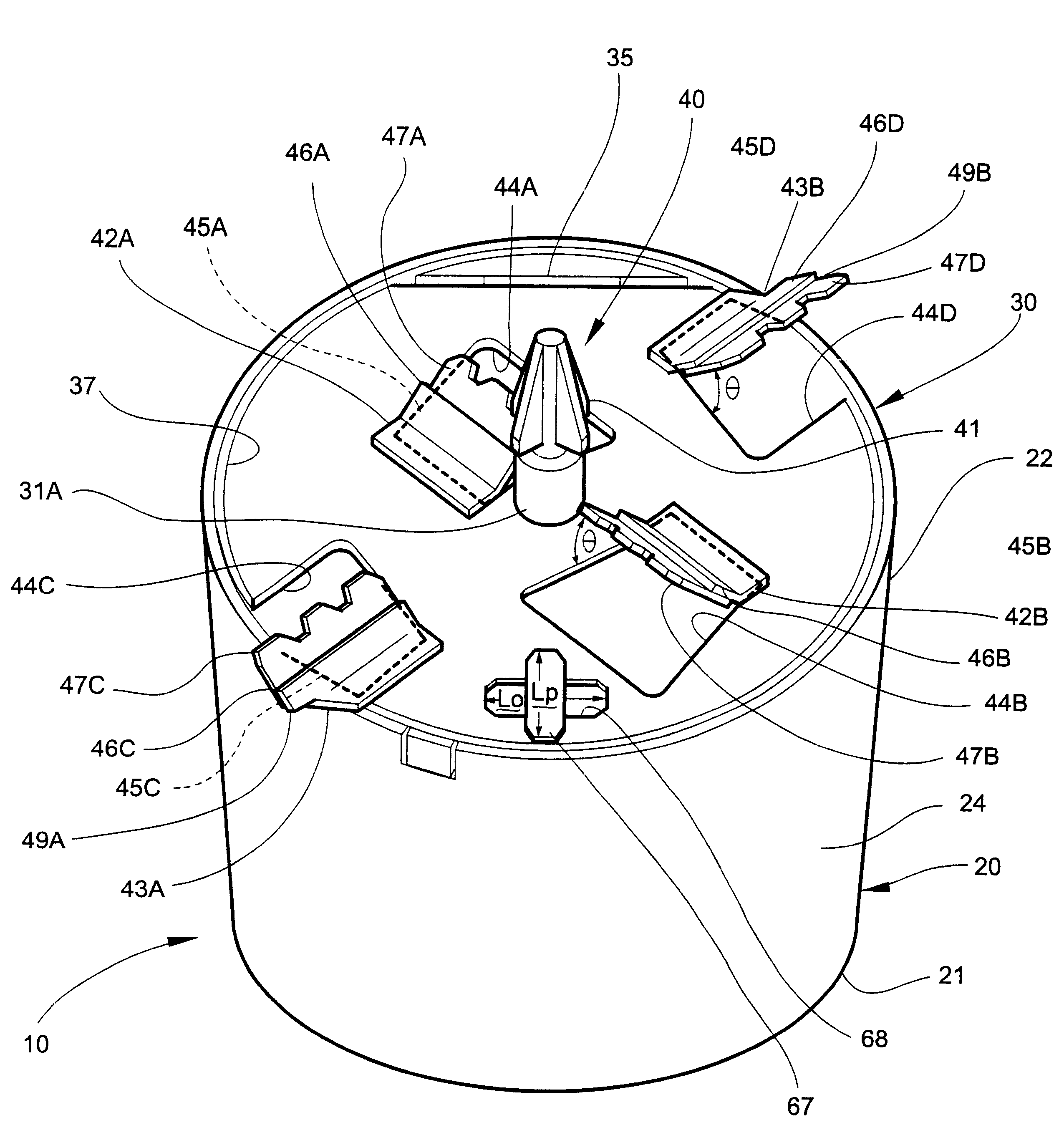

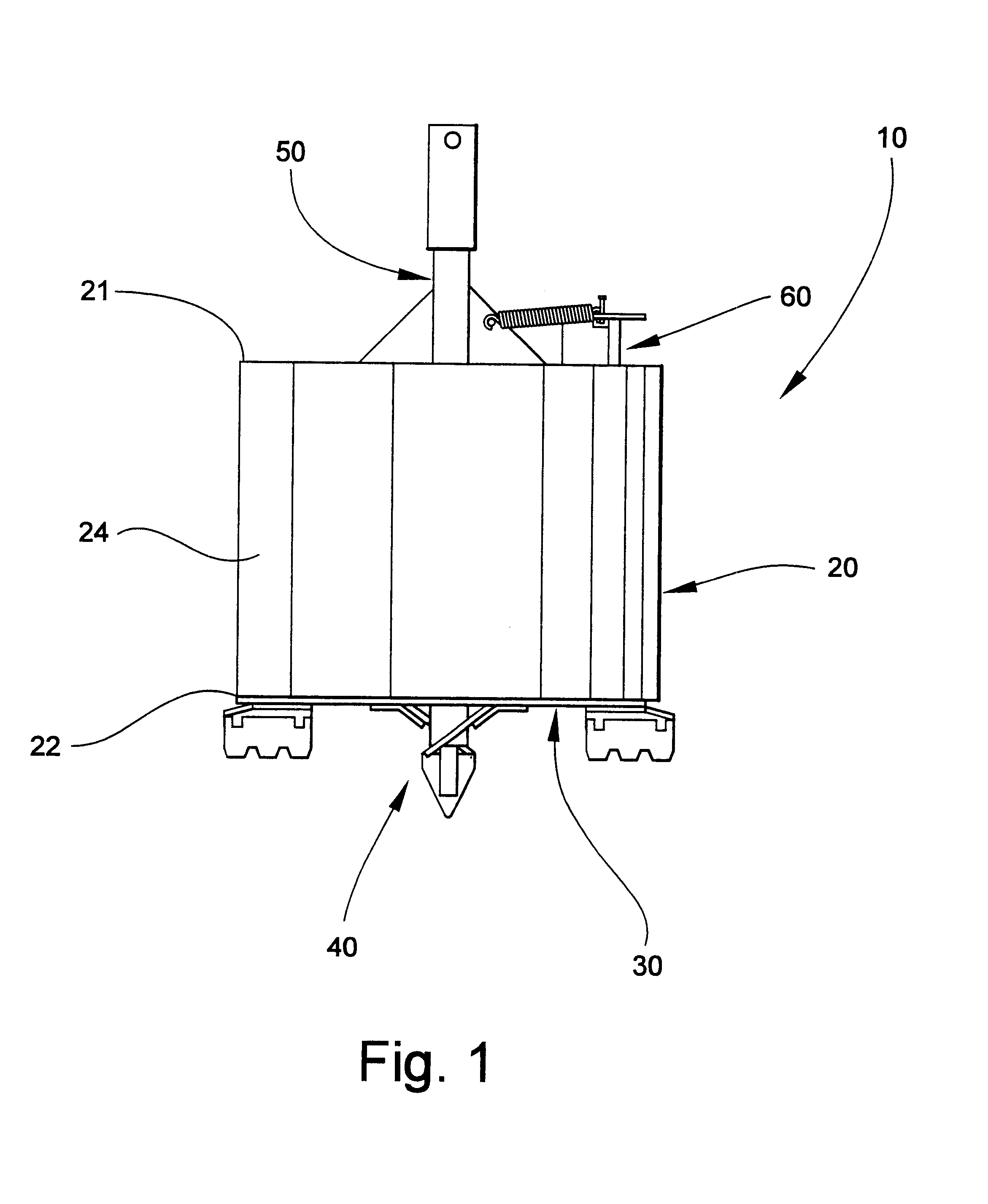

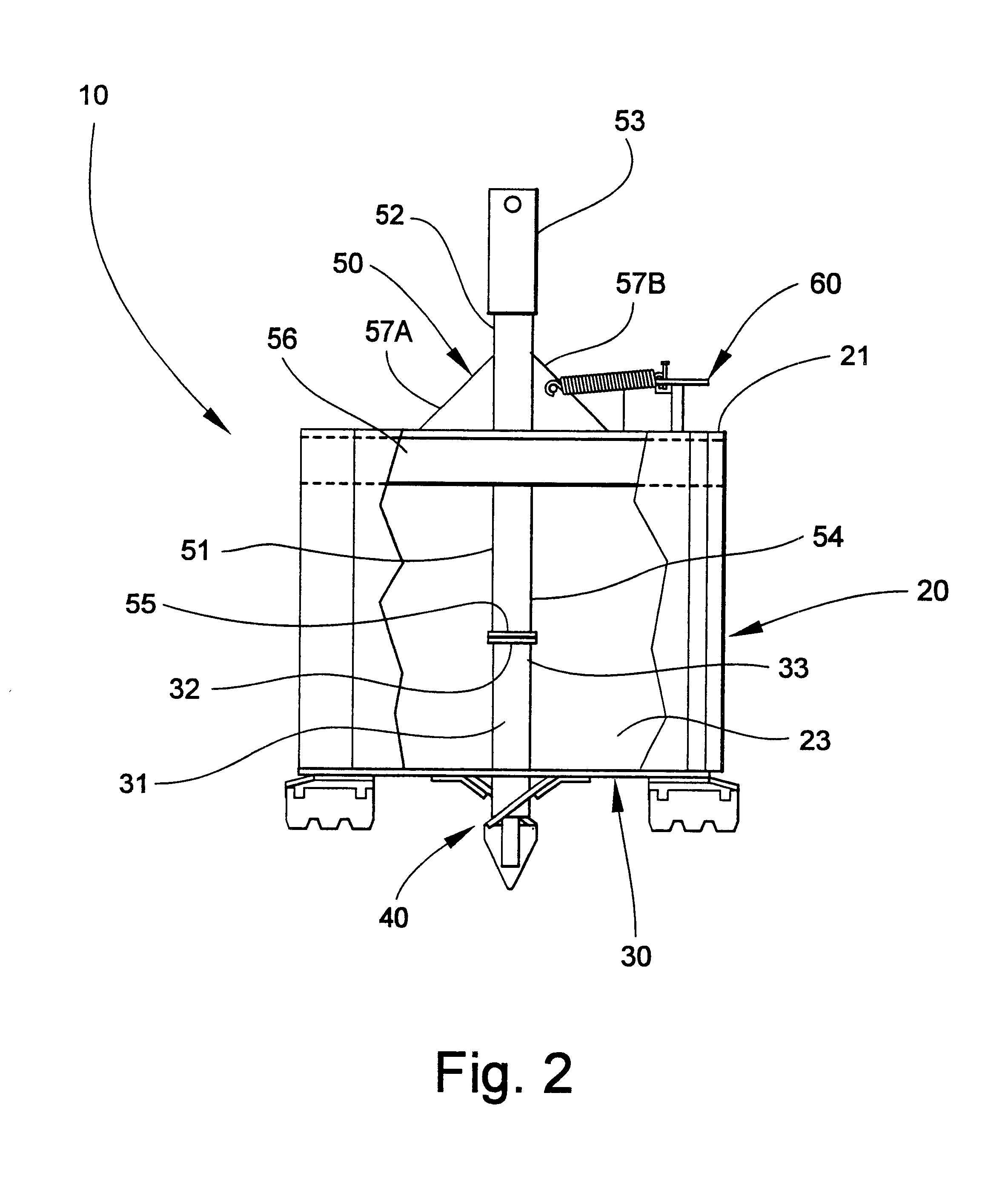

Earth boring bit

InactiveUS6655476B2Reduce frictionProlong lifeEarth drilling toolsDrill bitsEngineeringMechanical engineering

An earth boring bit for boring a hole having a predetermined depth into the earth. The earth boring bit includes a cylindrical drum for being mounted for rotation on the end of a boom of a mobile machine and connected to and rotated by a power supply mounted on the boom. The drum includes an exterior for defining the diameter of the hole being bored and an interior adapted for receiving upturned earth therein as the hole is being bored. A plate is carried by the drum adjacent a lower end thereof for movement between a closed position for cooperating with the interior of the drum for retaining the upturned earth therein and an open position for dispensing the upturned earth out of the interior of the drum at a predetermined location away from the hole being bored. A cutting member is carried on the plate for cutting the earth in a progressive slice and directing the earth into the drum, thereby boring the hole into the earth.

Owner:GROCE BRIAN A +2

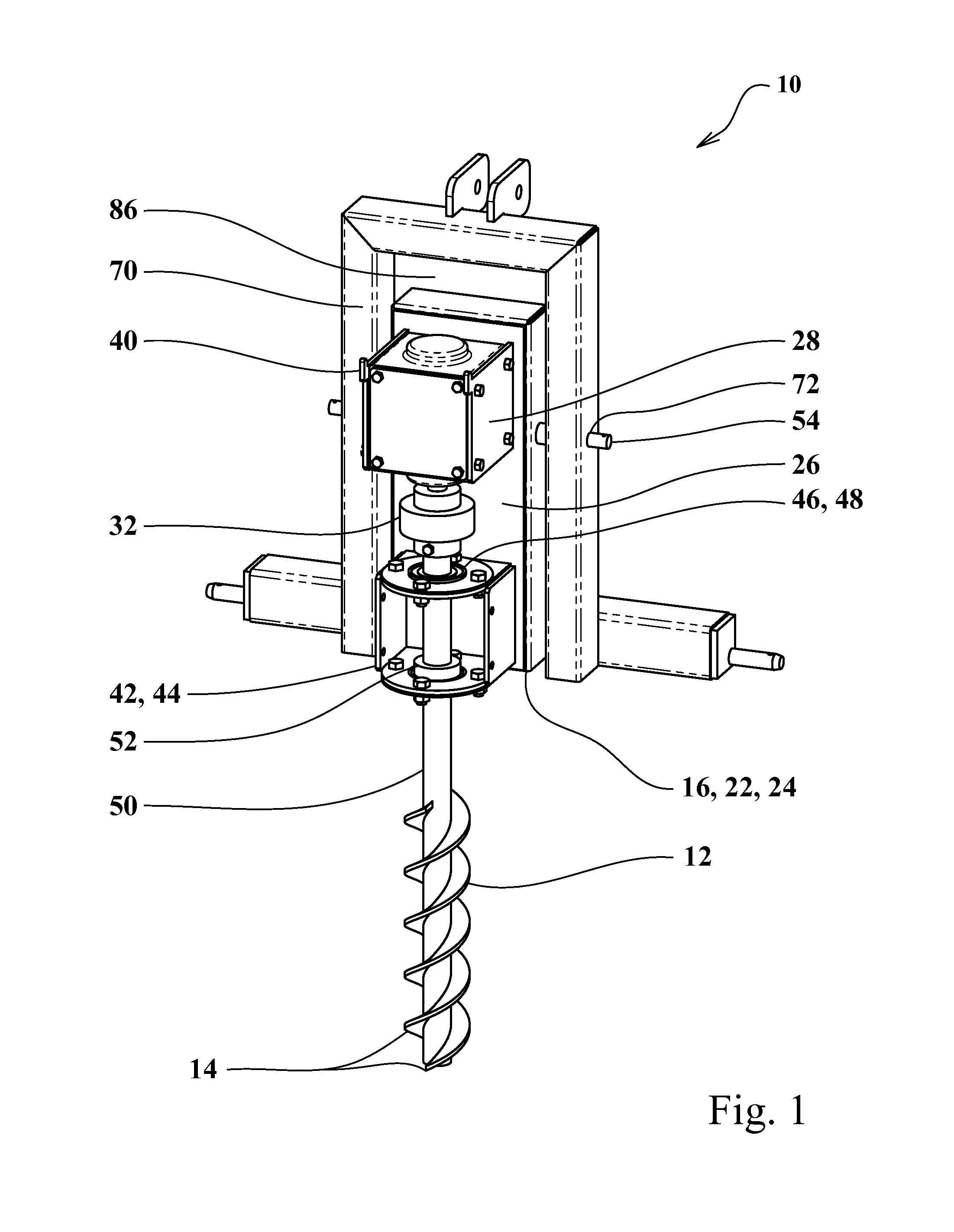

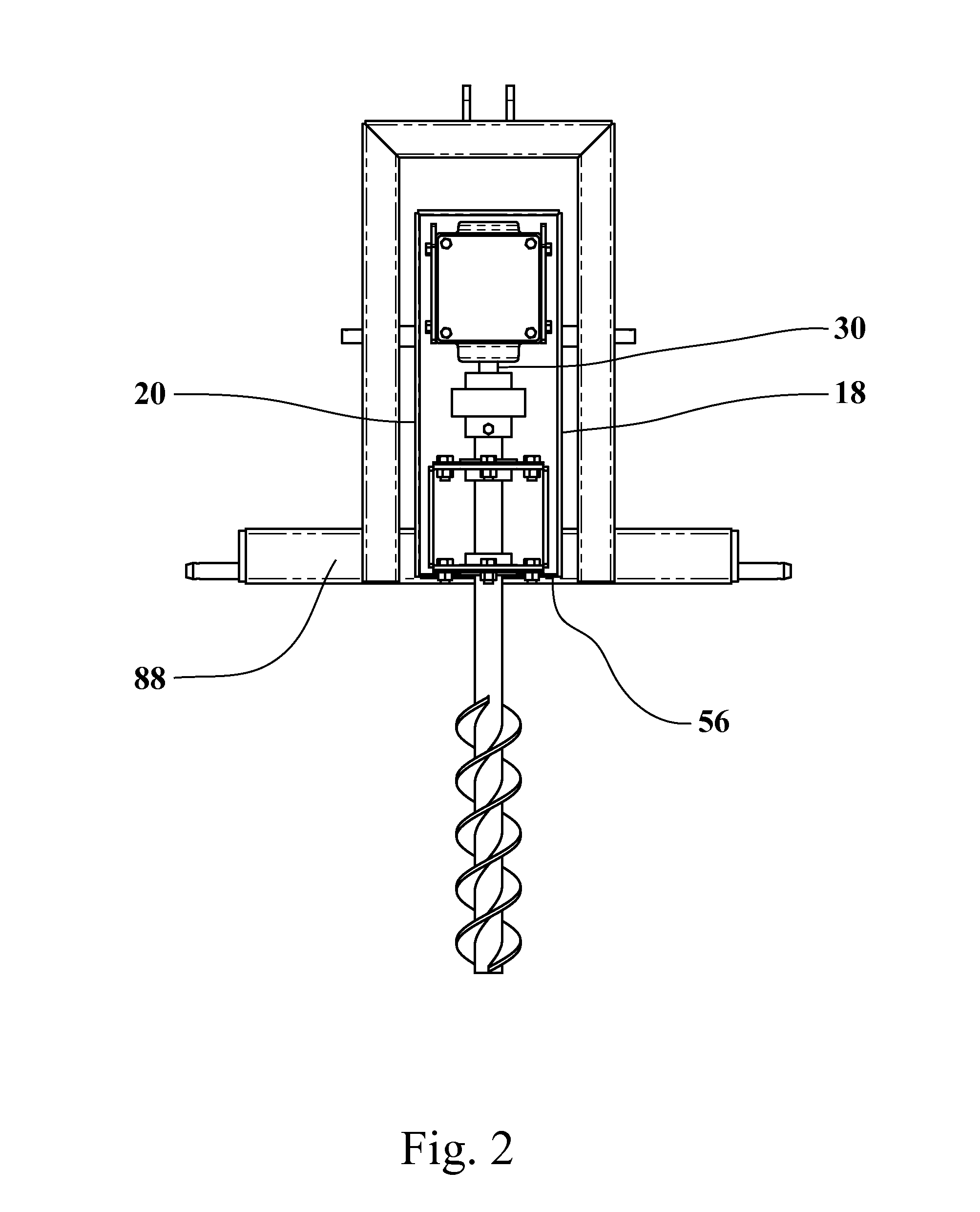

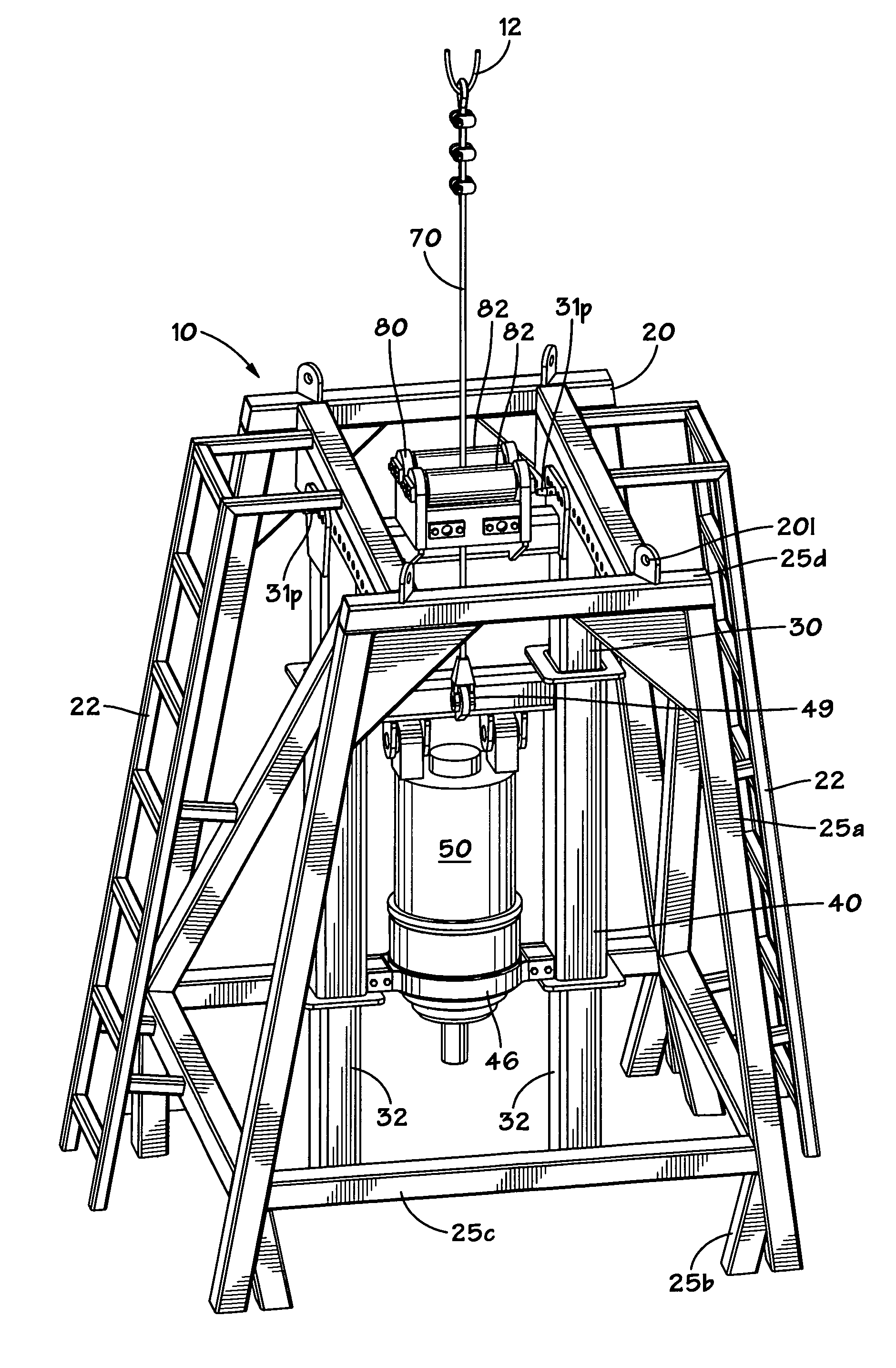

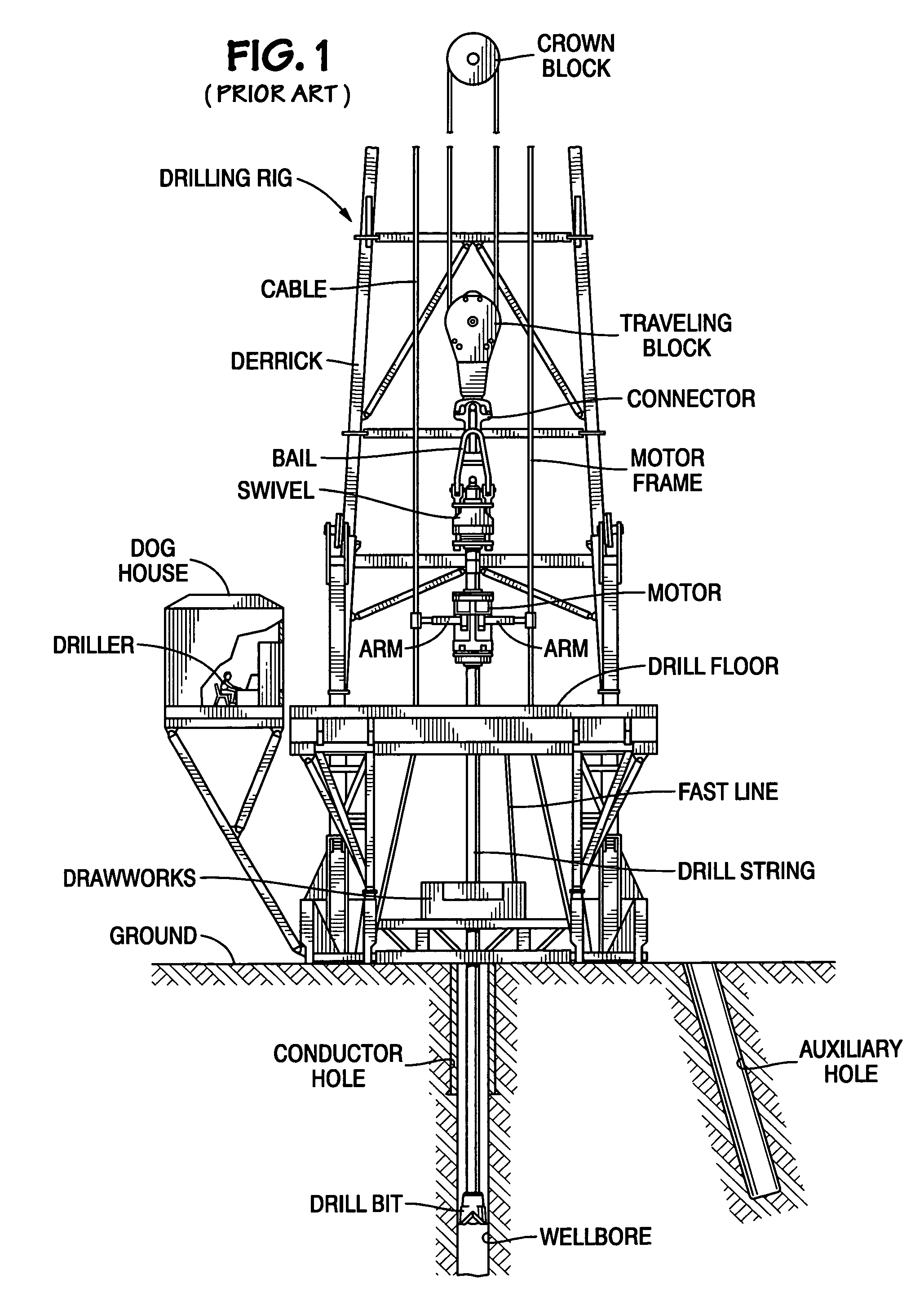

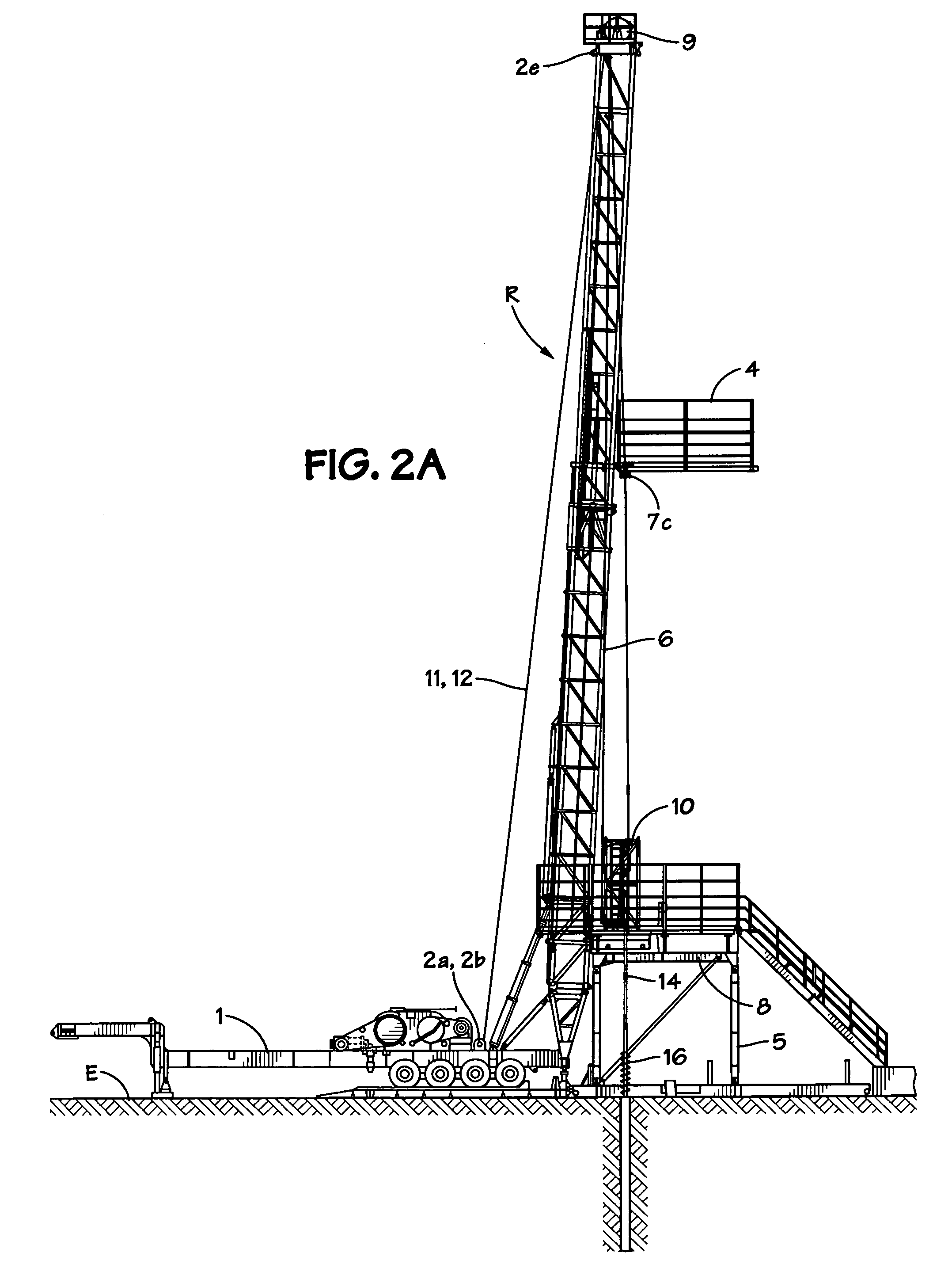

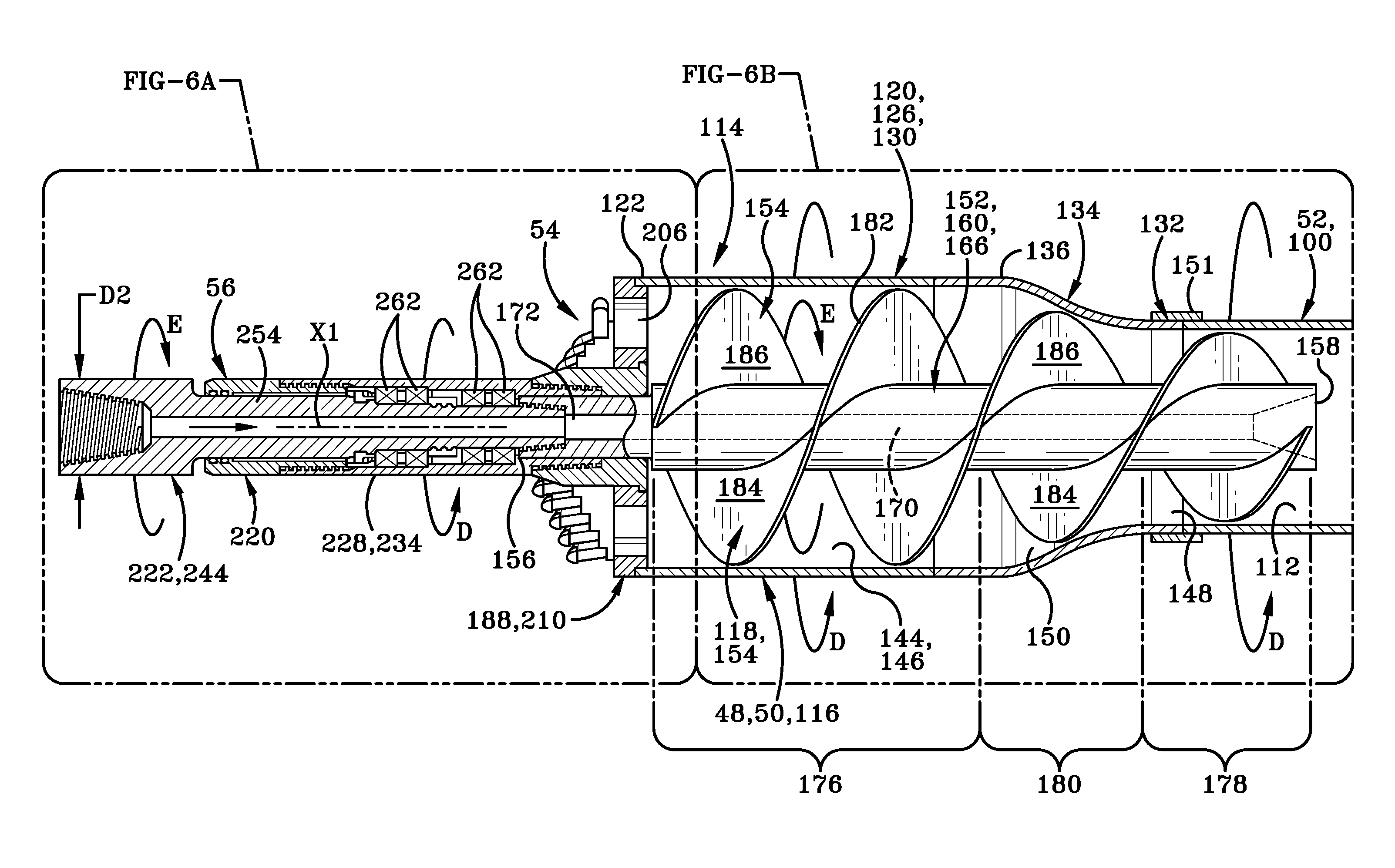

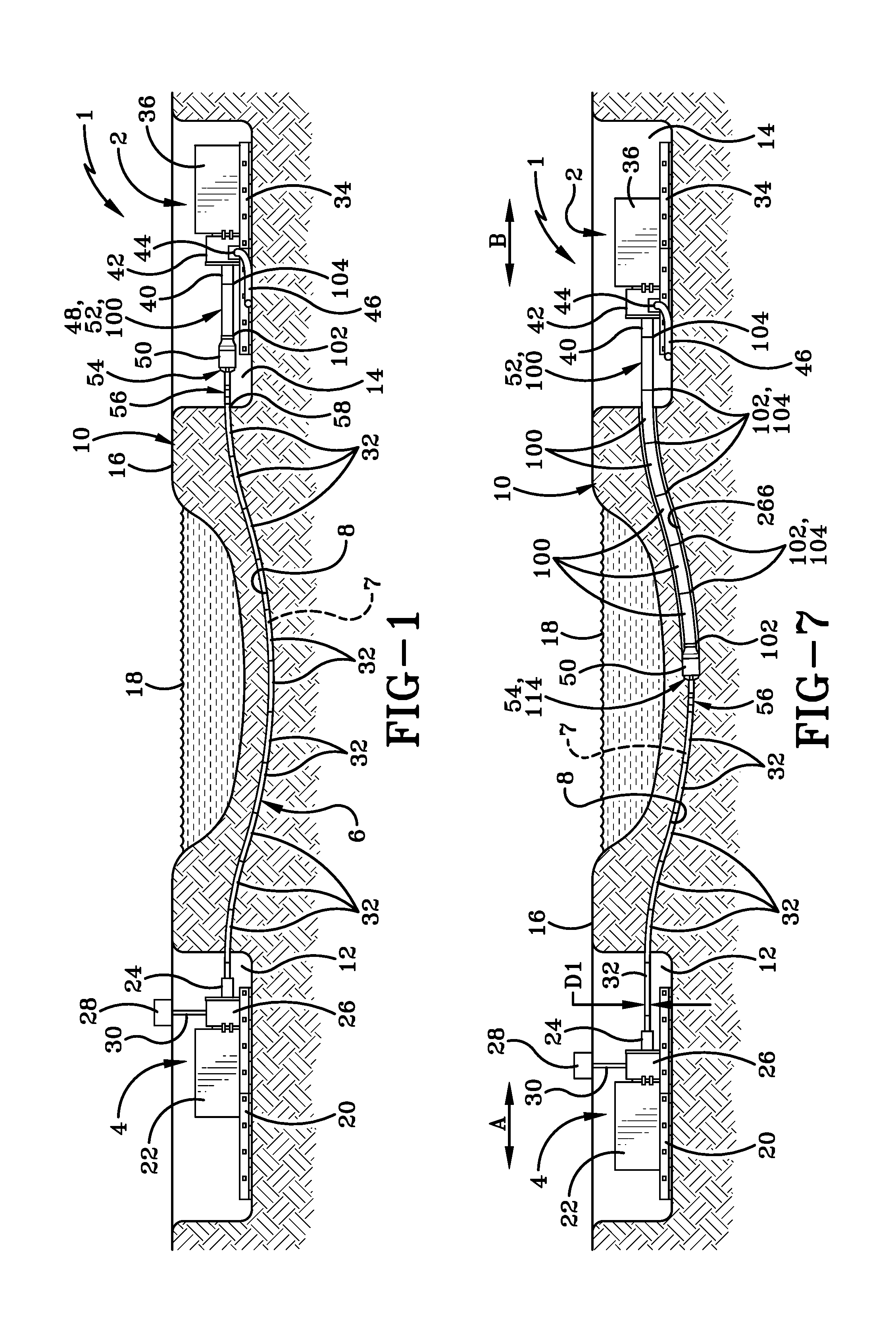

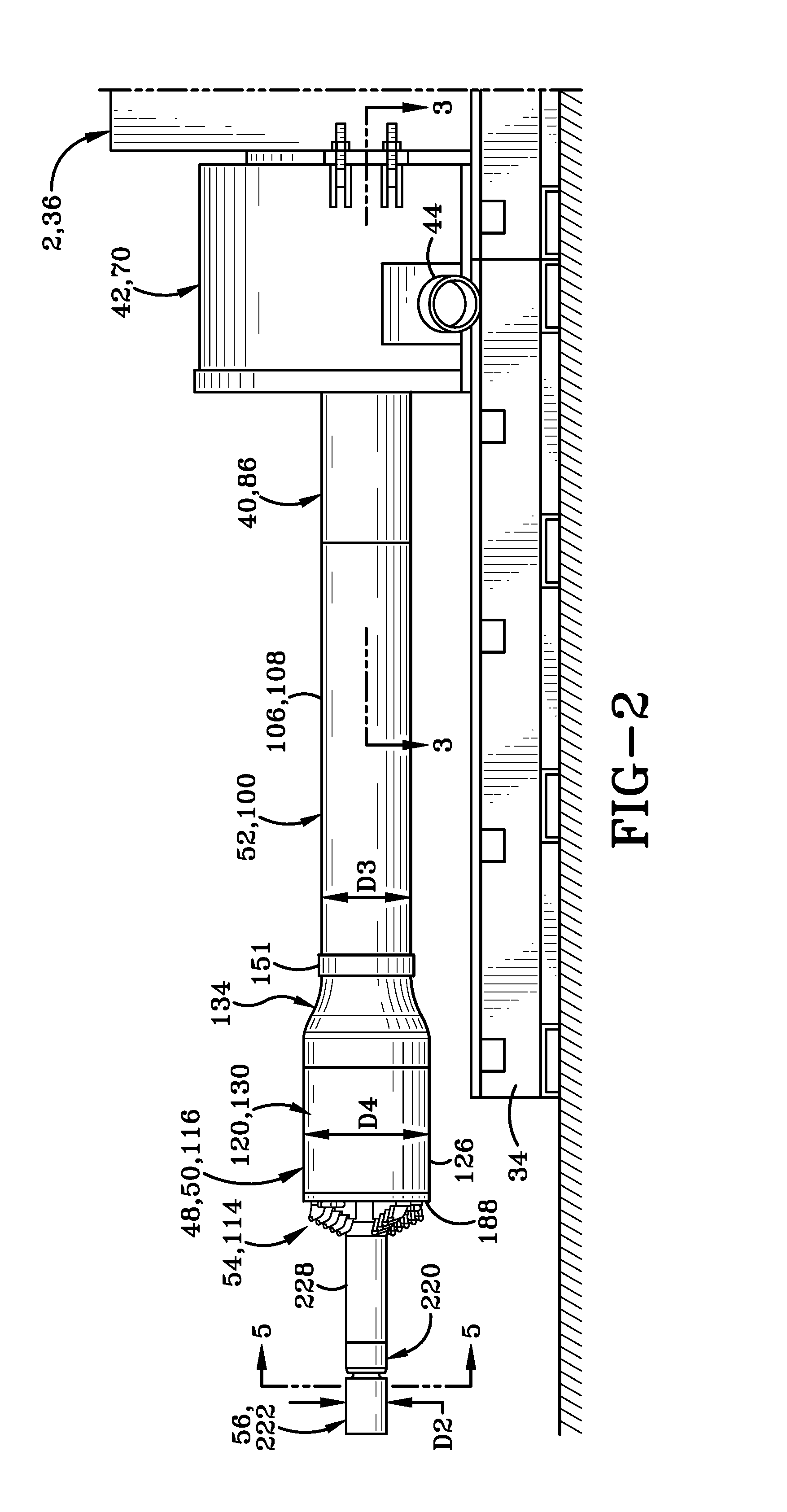

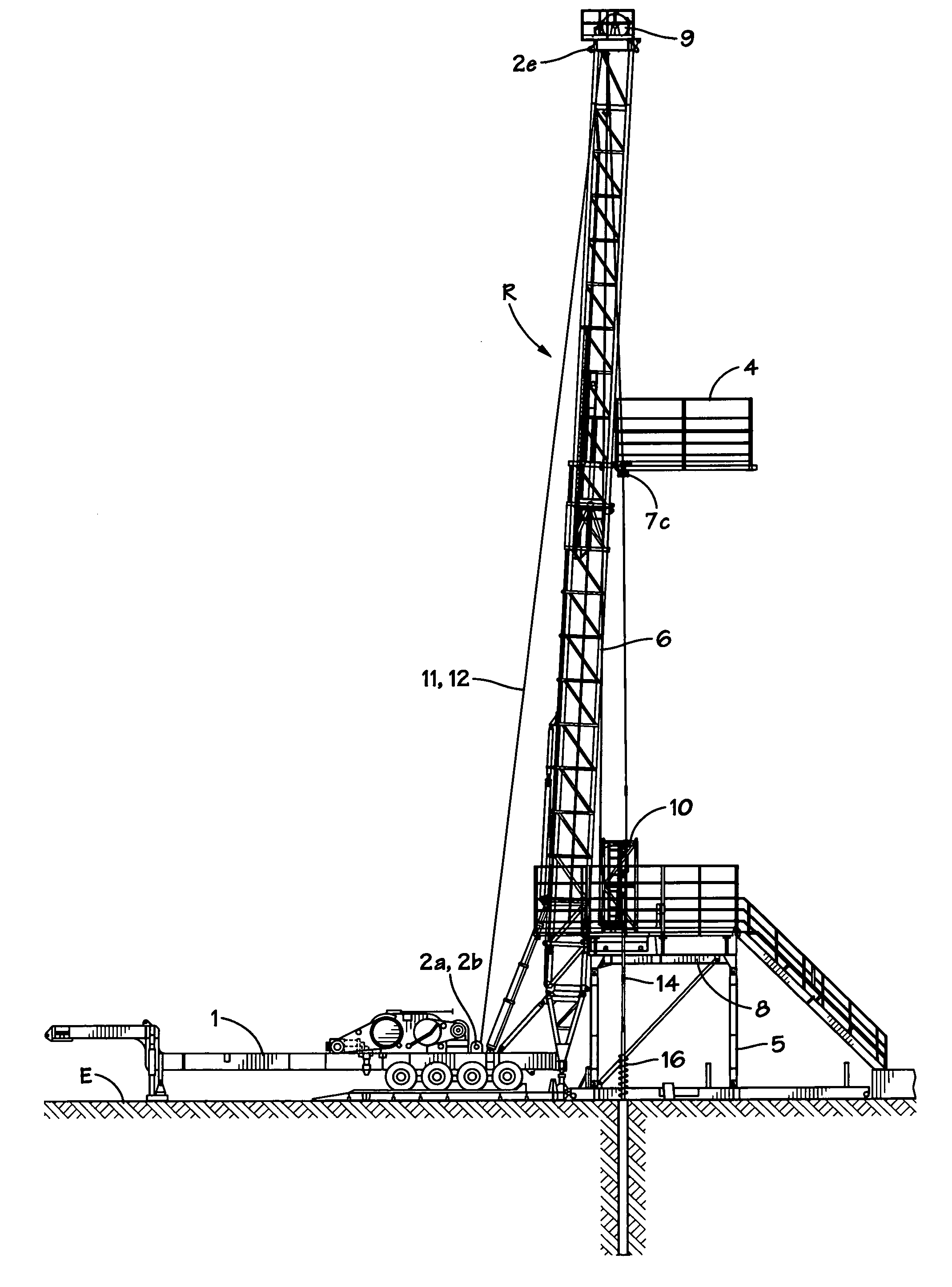

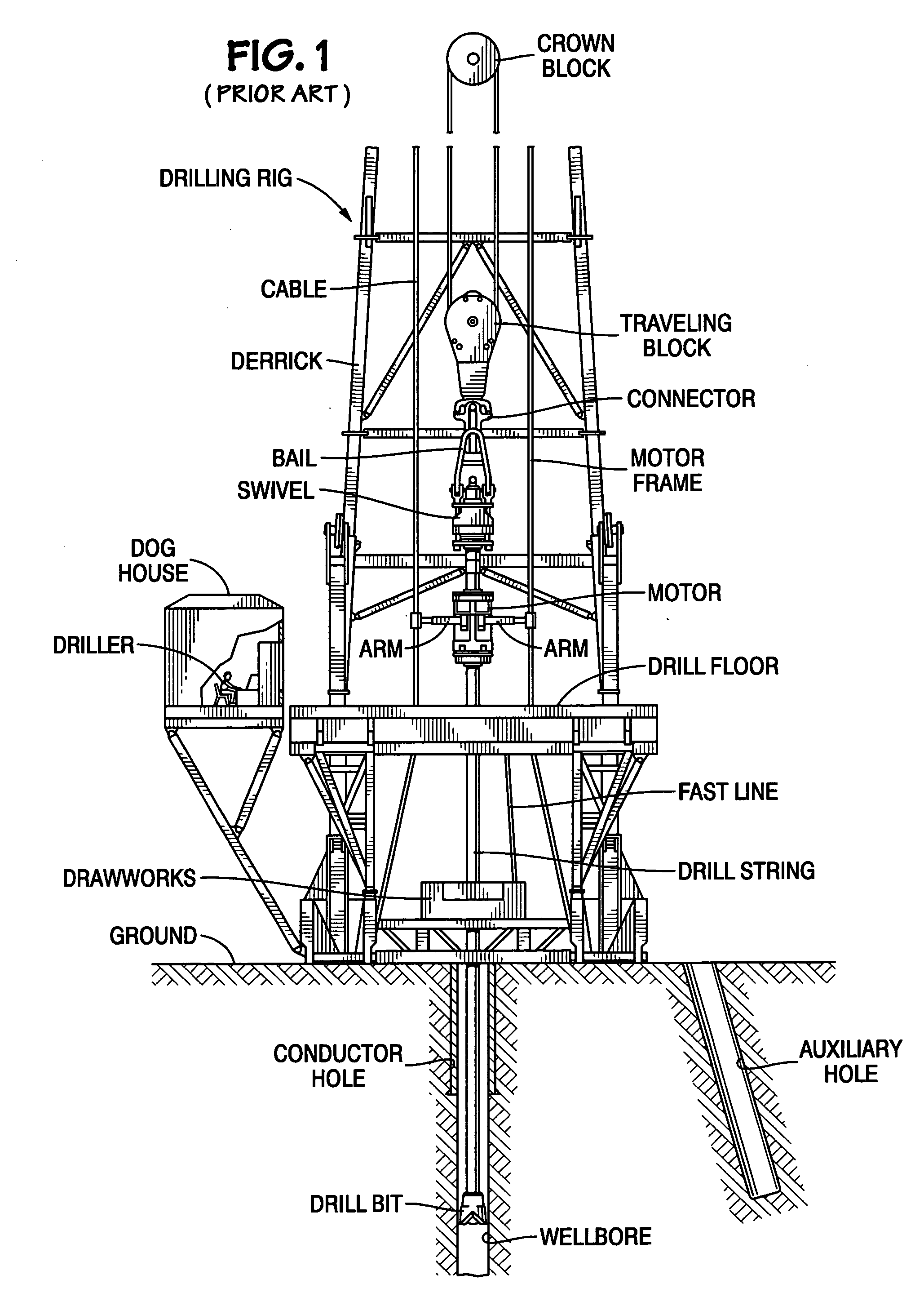

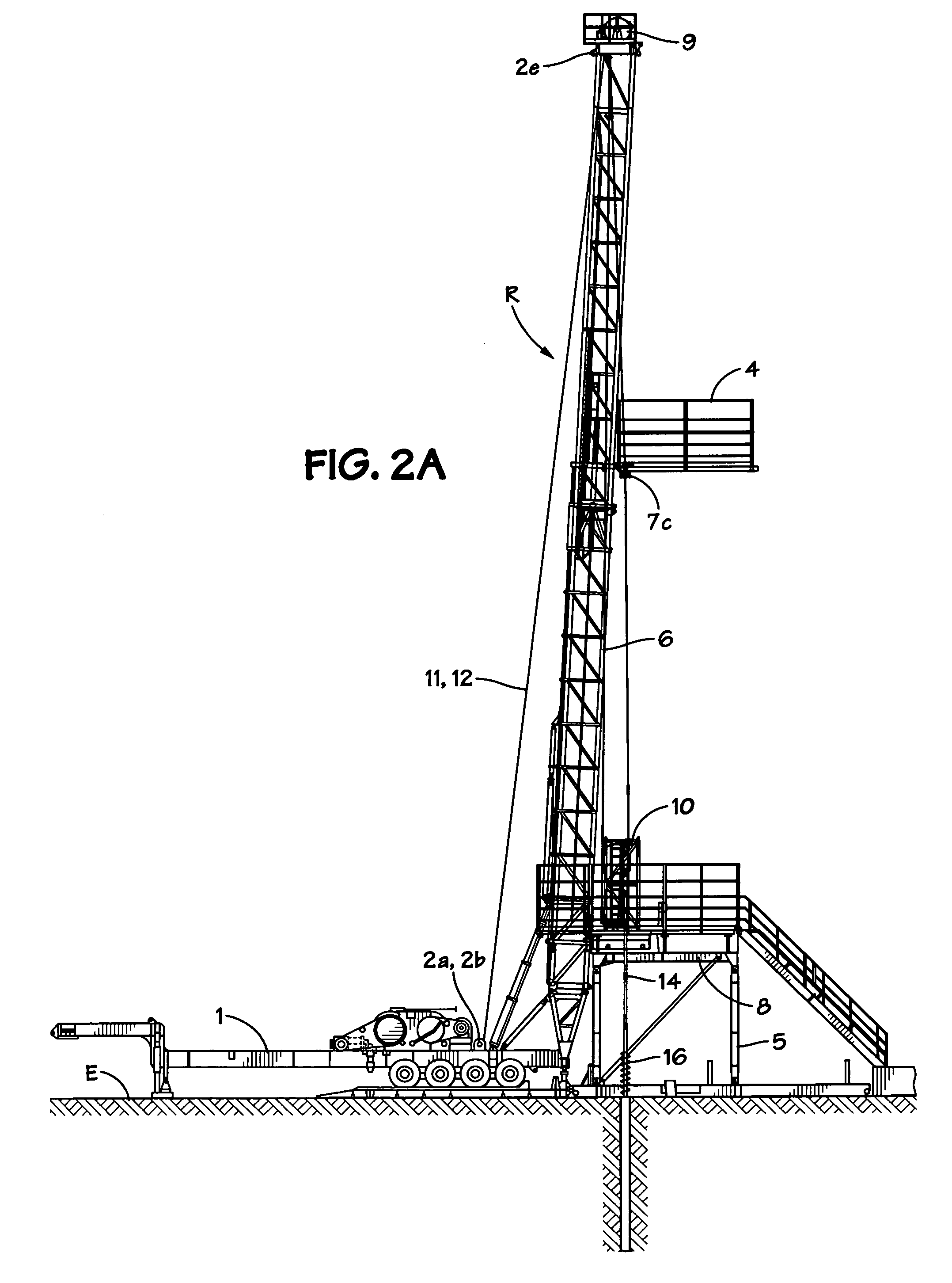

Methods and systems for drilling auxiliary holes

ActiveUS7637329B2Improve accuracyImprove efficiencyDrilling rodsConstructionsDrill floorPetroleum engineering

Systems and methods for drilling auxiliary holes such as conductor holes, ratholes, and mouseholes useful in drilling operations. The systems and methods include the use of a portable drilling apparatus that is selectively mountable on a rig's drill floor and is removable after an auxiliary hole has been drilled. A movable drive unit is pulled down by a cable system forcing the drive unit down and thereby facilitating drilling of the auxiliary hole.

Owner:NAT OILWELL VARCO LP

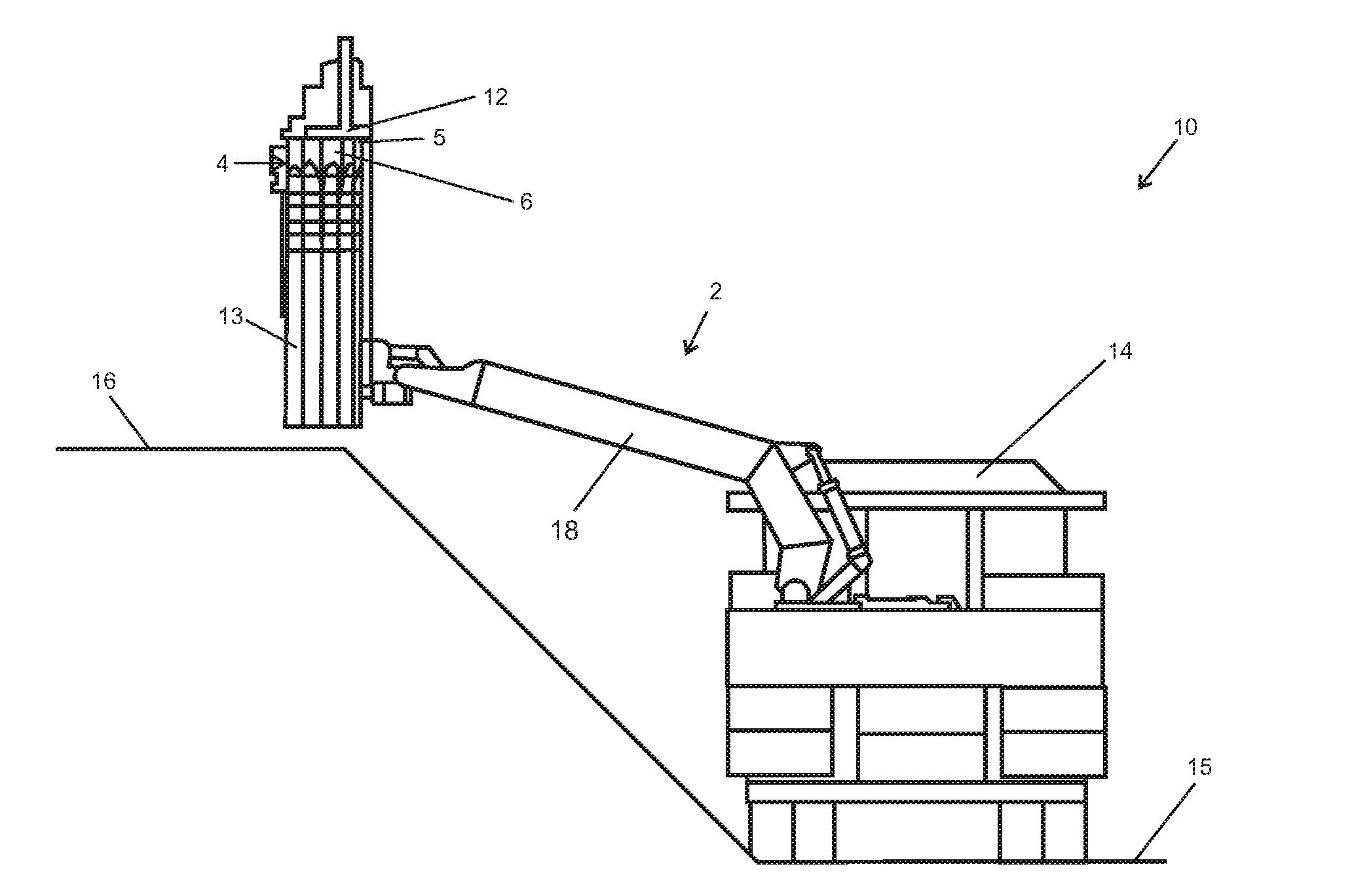

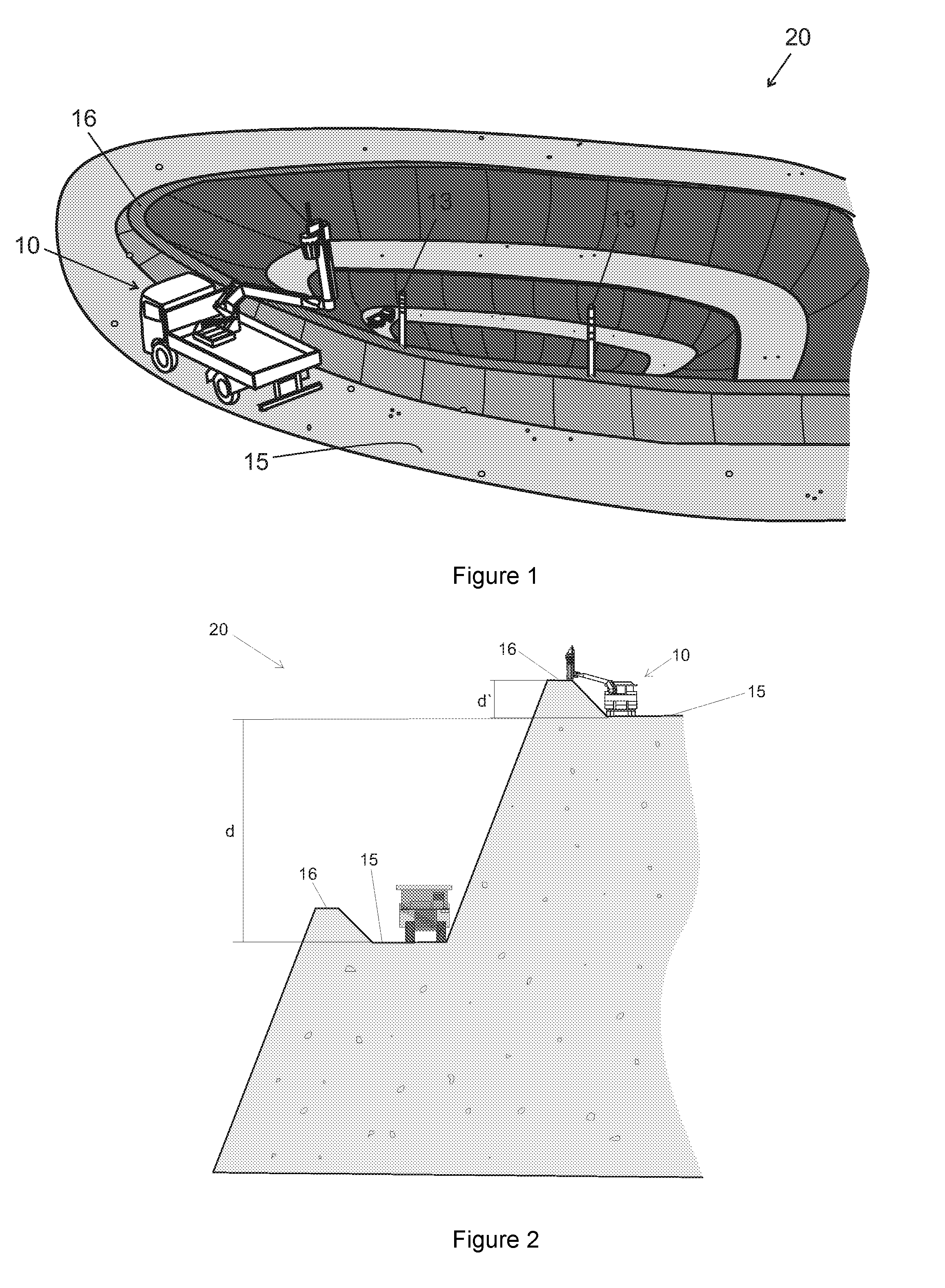

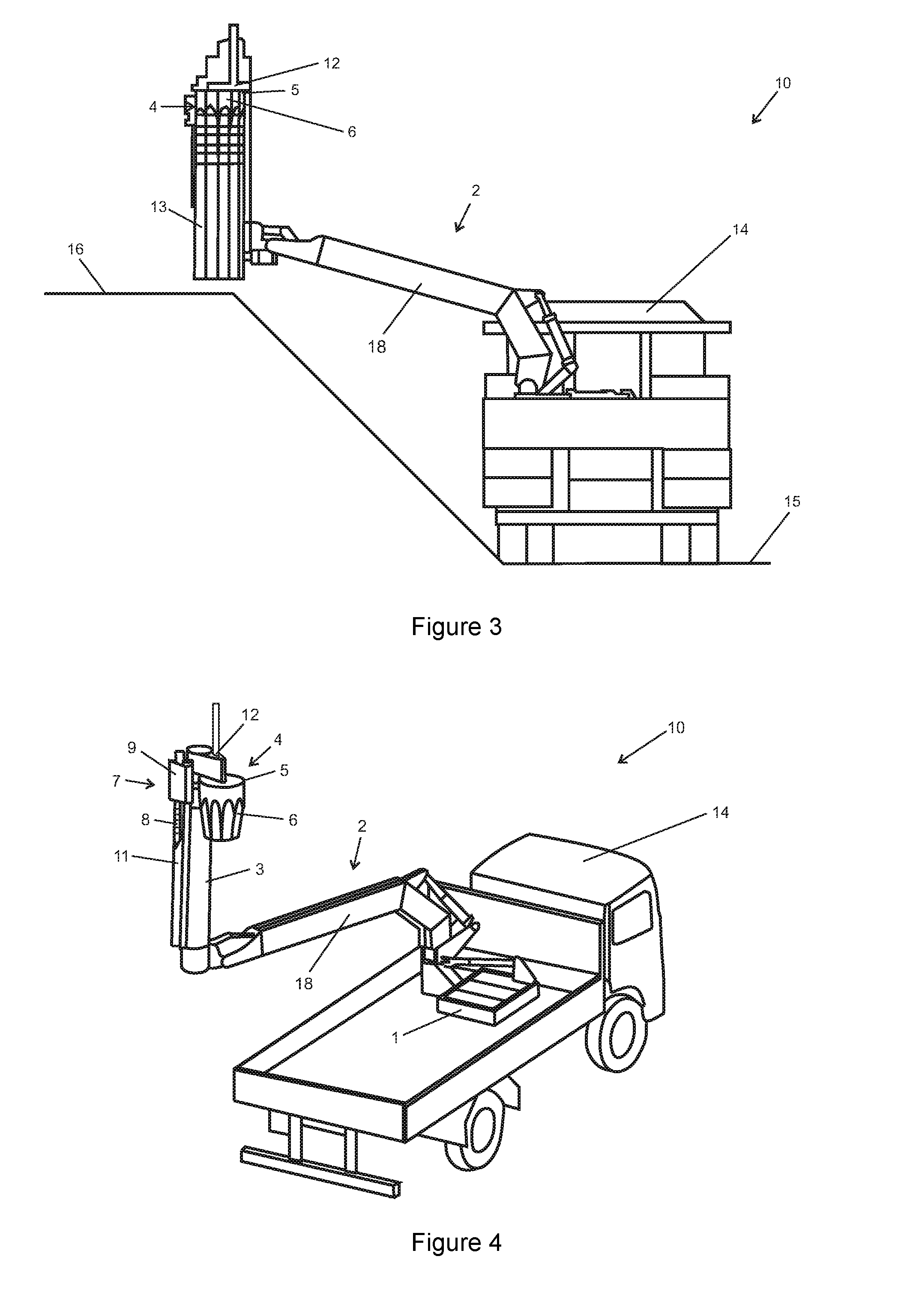

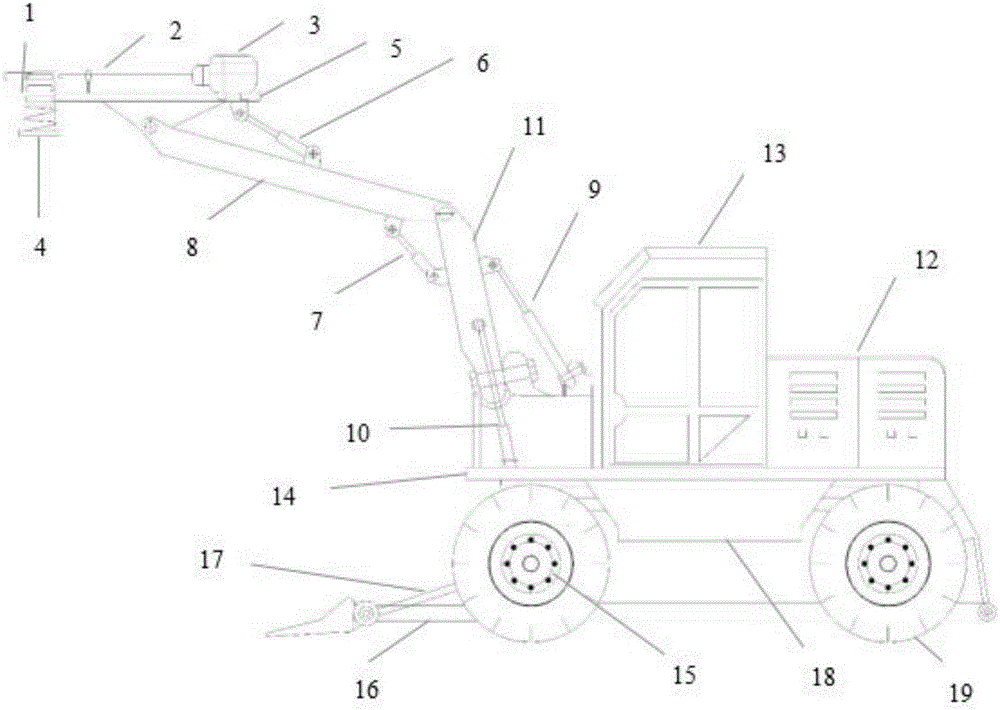

Earth auger and pole machine, and pole installation method

ActiveUS20160298355A1Low structural resistanceDrilling with mechanical conveyingMechanical machines/dredgersEngineering

Described herein is an earth auger and pole machine for automated installation of poles in earth banks of access roads to open-pit mines. The earth auger and pole machine is fitted with a mechanic boom comprised of a first link and a second link. The first link has an end attached to a base fixed to a conveyor vehicle, and the other end coupled to the second link. The second link comprises a magazine for loading the poles, an auger system to drill the ground, and an installer to place the poles into the hole. This document also describes a method for installing poles in sequence by using the earth auger and pole machine.

Owner:VALE LIMITED

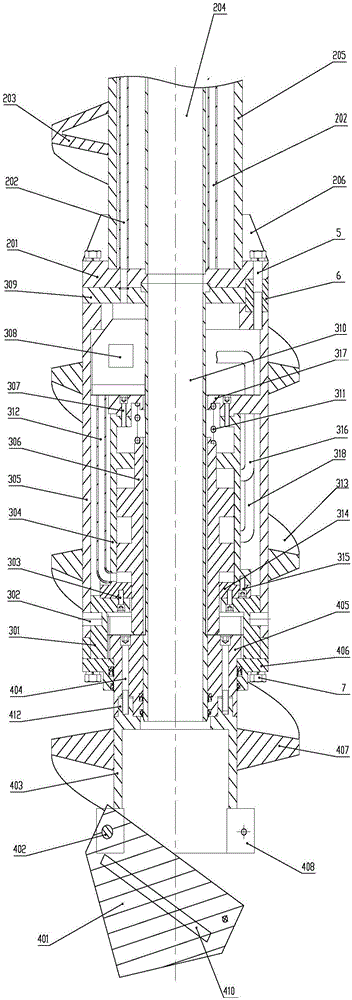

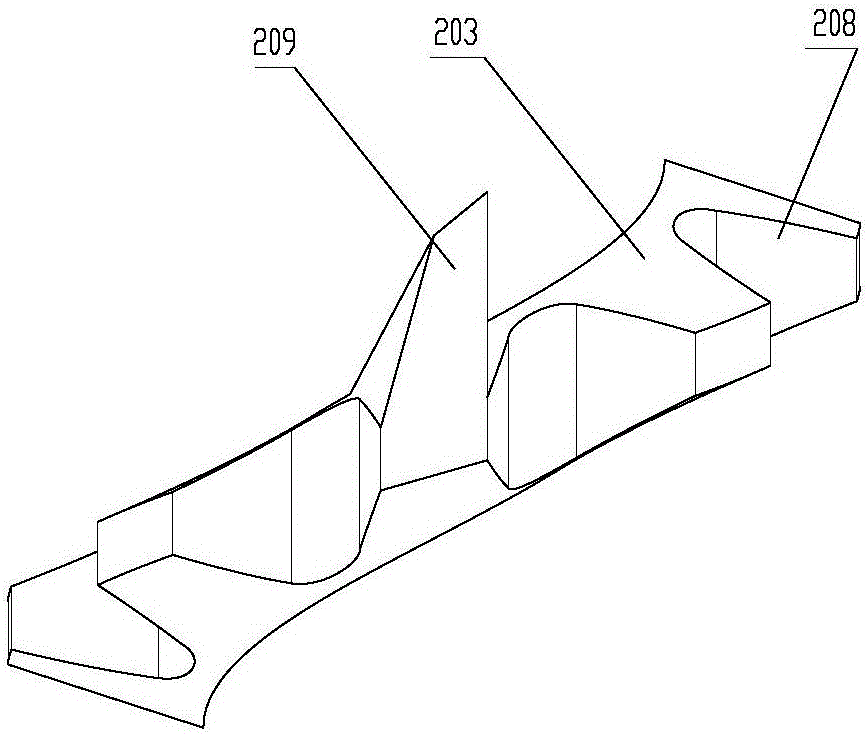

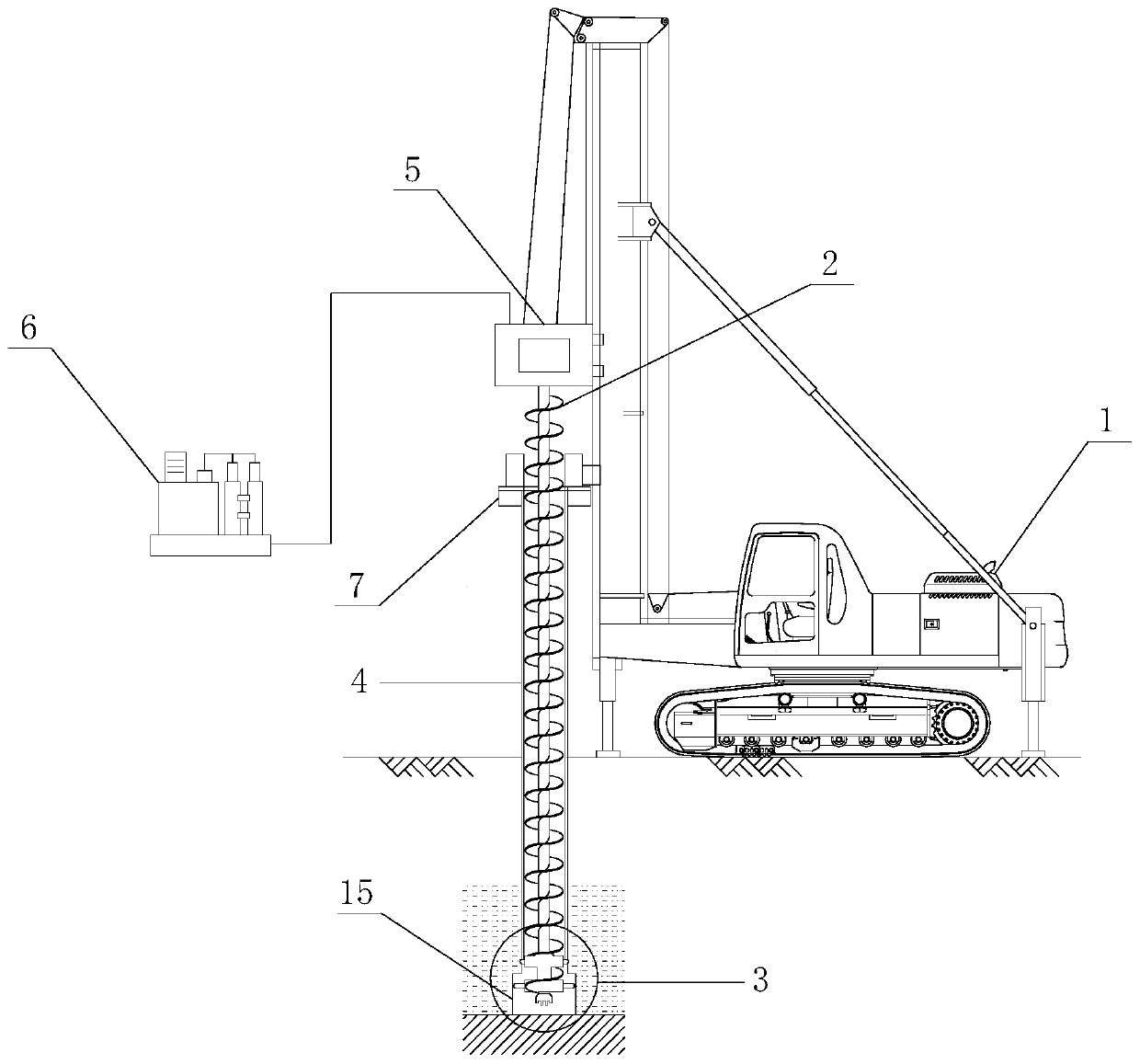

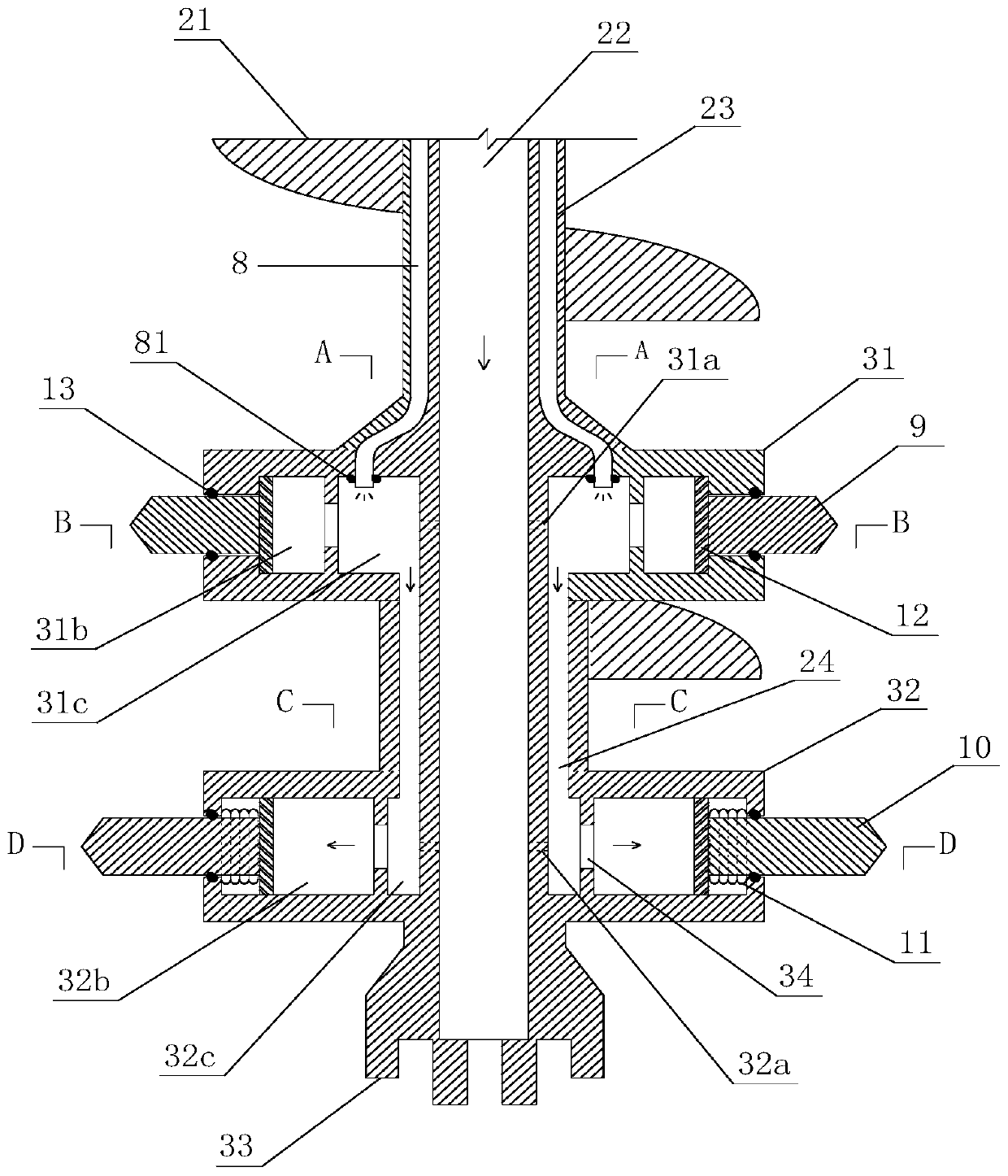

Hydraulic variable-diameter reamer drill bit of long spiral drilling machine and cast-in-place pile construction method

PendingCN110043187AIncrease side resistanceImprove pull resistanceDrilling rodsDrilling with mechanical conveyingEconomic benefitsReamer

The invention discloses a hydraulic variable-diameter reamer drill bit of a long spiral drilling machine and a cast-in-place pile construction method. The hydraulic variable-diameter reamer drill bitincludes the long spiral drilling machine, a detachable upper power head is mounted on the long spiral drilling machine, a spiral drilling rod can be made to rotate, a hydraulic system is arranged inthe upper power head, a drill bit system is fixedly arranged at the lower end of the spiral drilling rod, the drill bit system is provided with a first cavity and a second cavity, an outwardly movablefirst drill bit with a piston is mounted in the first cavity, an outwardly extensible and movable second drill bit with an a piston is mounted in the second cavity, a pouring channel, a first hole channel and a second hole channel are formed in the spiral drilling rod, a rotatable lower power head is arranged on the lower part of the upper power head, a detachable rotating sleeve is arranged at the lower end of the lower power head, and the sleeve wraps the outer side of the drill bit system and enables the drill bit system to move vertically. While sleeve pulling out and diameter expanding can be realized, meanwhile, concrete can be poured, the construction efficiency is high, economic benefits is good, and bearing capacity of the pile end and lateral resistance of a pile body can be effectively improved.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Apparatus and method for drilling generally horizontal underground boreholes

An apparatus and method for drilling an underground borehole is presented, wherein pressurized air may be used to discharge out of the borehole cuttings created by a cutter head. A casing may be secured to the cutter head such that the cutter head and casing may be rotatable together as a unit. The casing may have larger and smaller diameter sections. An auger may be disposed adjacent the front of the casing.

Owner:BARBCO

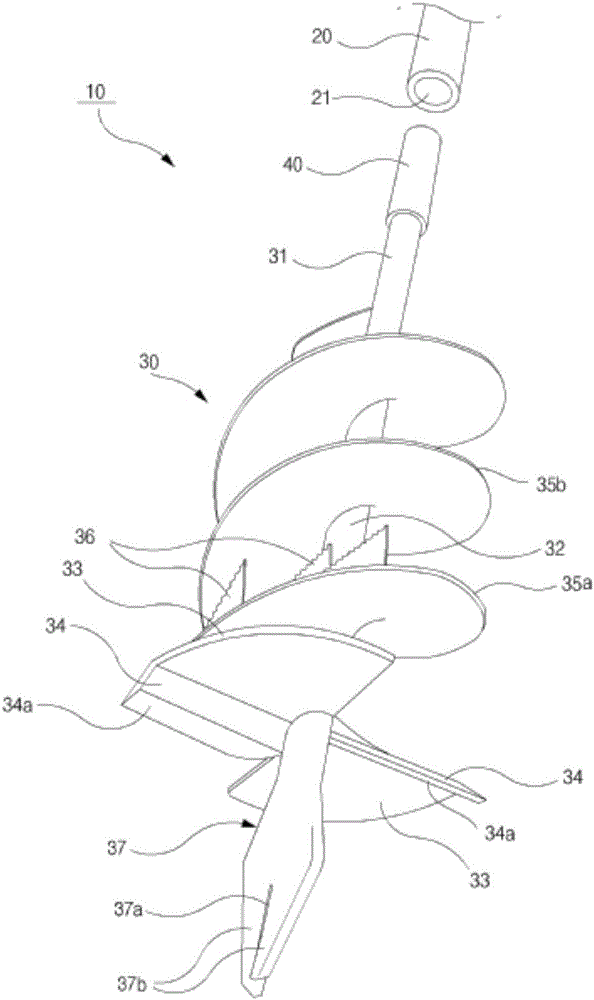

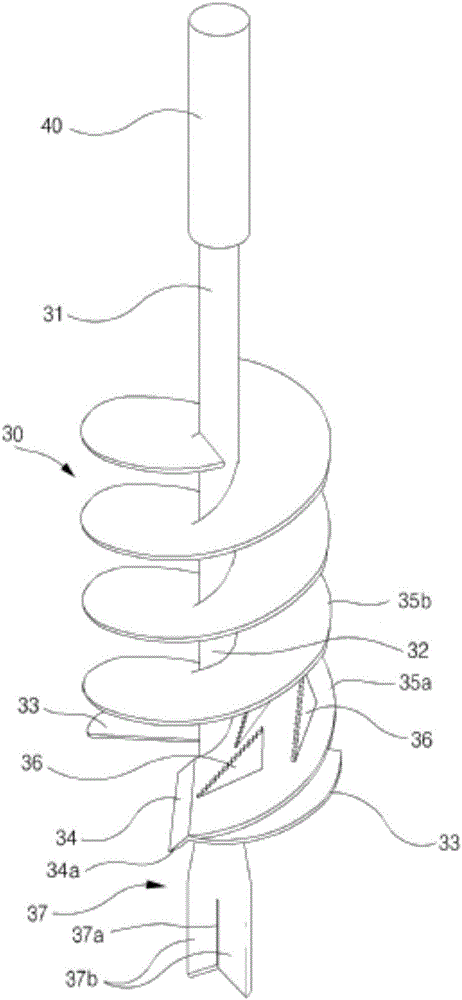

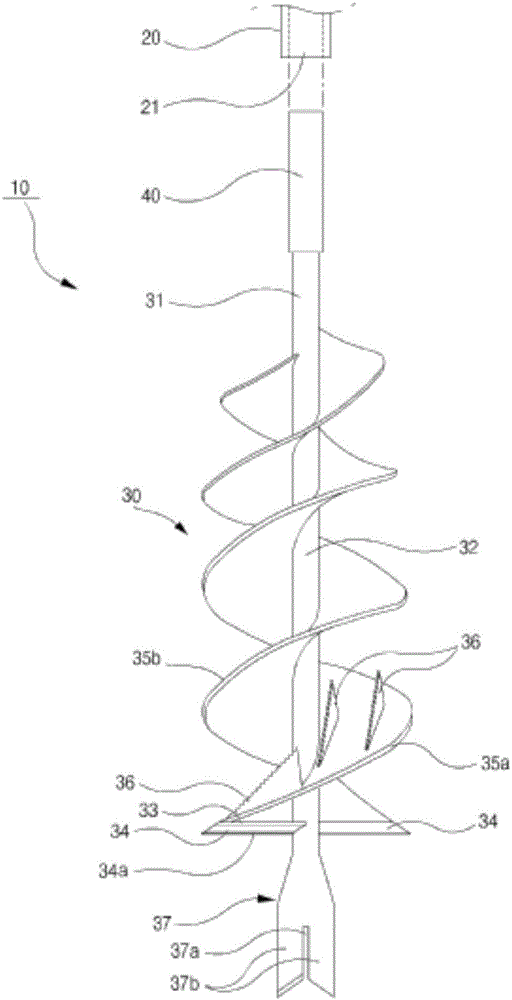

Portable power rotary device provided with drill having earthwork and cut-off functions

InactiveCN106164381AEasy to moveEfficient miningHand-operated machines/dredgersDrill bitsPortable powerPropeller

The present invention relates to a rotary device in which a drill for soil earthwork is rotatably mounted, wherein the drill comprises: a shaft part; a screw, formed along the outer circumferential surface of the shaft part, for earthwork and the transportation of soil generated by the earthwork; a rotary shaft, formed on the upper part of the shaft part; a connection socket, formed on the rotary shaft, for adjusting the length; and a fixed shaft part, formed on the lower part of the shaft part, for being inserted and rotated into the soil for earthwork. More specifically, the present invention relates to a portable power rotary device provided with a drill having earthwork and cut-off functions, wherein a pair of horizontal blades face each other on the connection part between the shaft part and the fixed shaft part; screws, formed in every other layer, are symmetrically and integrally connected to each other on the pair of horizontal blades, for transferring soil upwardly; cutting blades, which are symmetrical with each other, are inclined downwardly and integrally formed on the pair of horizontal blades; a plurality of vertical blades, formed to be spaced apart from each other at a predetermined distance, protrude vertically on the upper portion of the lower wing of the screw; and when performing earthwork, soil and tree roots are cut by the cutting blades, and soil lumps, transferred along the screw, are cut again by the vertical blades.

Owner:金荣宽

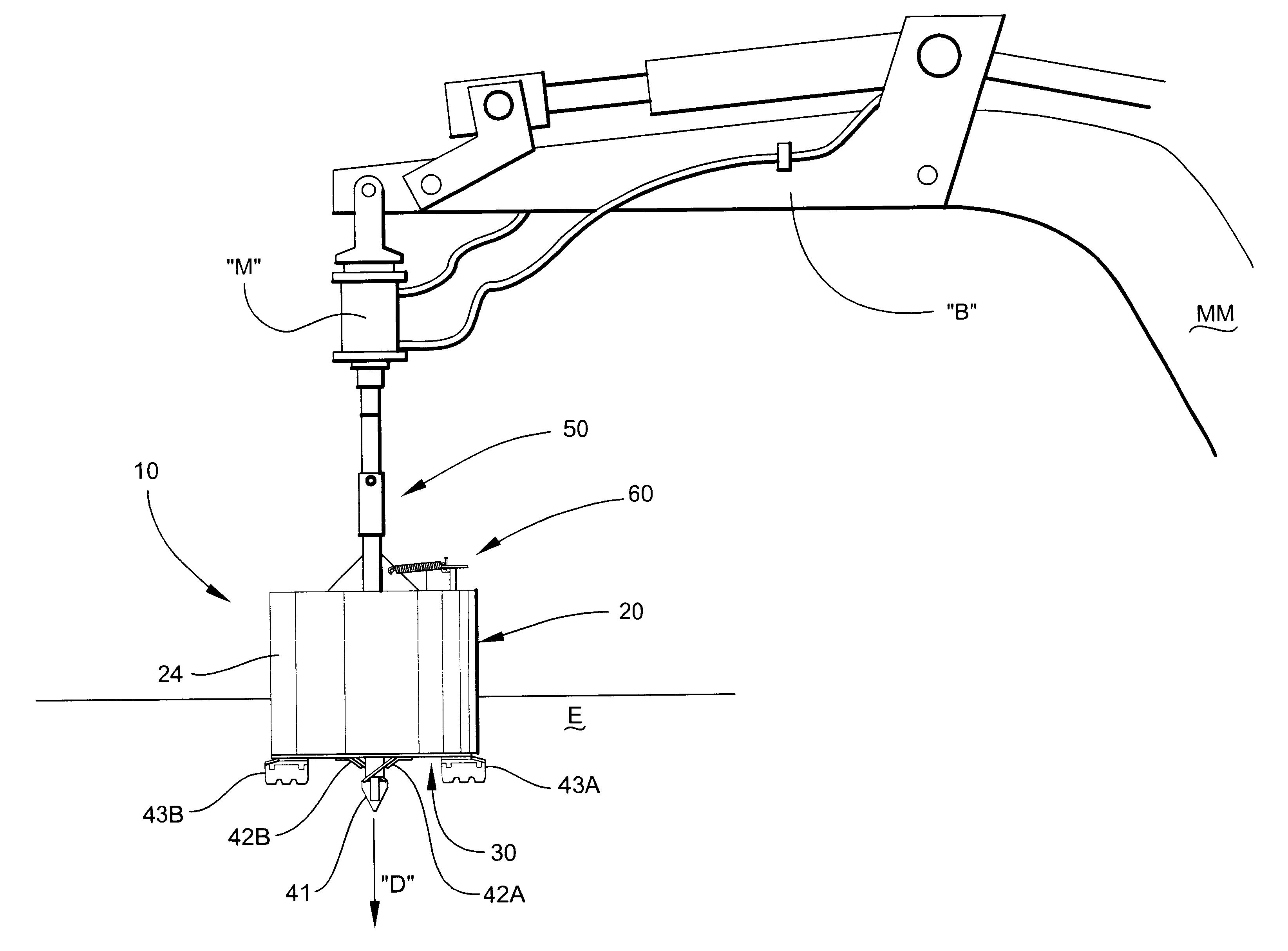

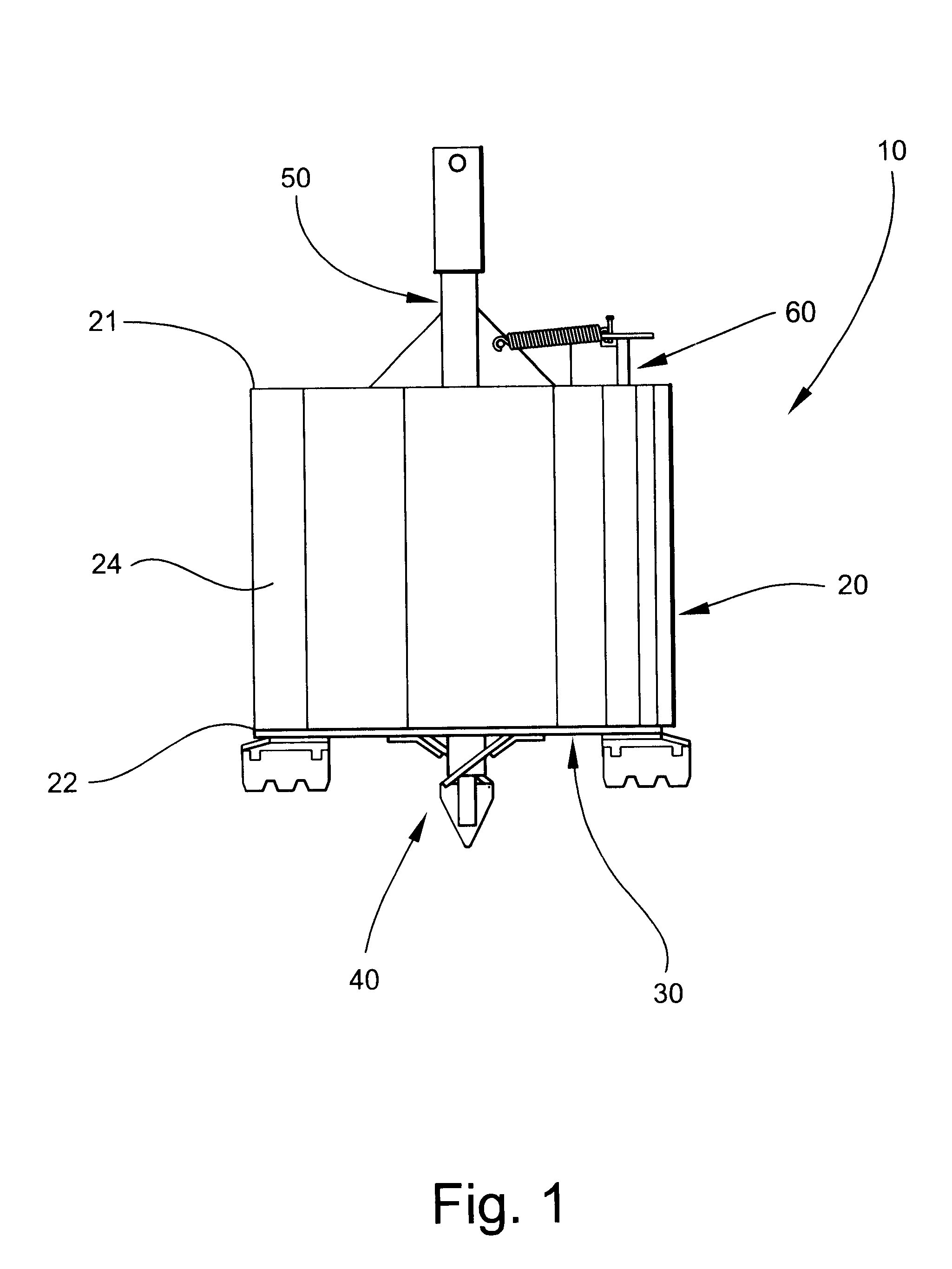

Methods and systems for drilling auxiliary holes

ActiveUS20090183918A1Shorten the timeImprove accuracyDrilling rodsConstructionsSubject matterElectric cables

Systems and methods for drilling auxiliary holes such as conductor holes, ratholes, and mouseholes useful in drilling operations. In certain aspects, the systems and methods include the use of a portable drilling apparatus that is selectively mountable on a rig's drill floor and is removable after an auxiliary hole has been drilled. In one aspect, a movable drive unit is pulled down by a cable system forcing the drive unit down and thereby facilitating drilling of the auxiliary hole. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

Bionic gopher intelligent excavating system

InactiveCN109057707AAchieve mechanical simplificationFast crossingDrilling with mechanical conveyingDerricks/mastsEngineeringAlternative movement

The invention relates to a bionic gopher intelligent excavating system. The system comprises a drill bit, a shell, a driving mechanism, a telescopic assembly and an adjustable support foot. The drillbit is arranged in the front end of the shell, the driving mechanism is arranged in the shell, and an output shaft of the driving mechanism is connected with the drill bit. The telescopic assembly isarranged in the shell and the telescopic end of the telescopic assembly extends from the back end of the shell to the outside of the shell and is rotationally connected with the adjustable support foot. The system has the advantages that the bionic gopher intelligent excavating system realizes the mechanical simplification of the excavating function of a gopher, makes a whole system structure simple and small, fully considers the coordination of the adjustable support foot and the drill bit which are used as surrounding rocks, and through the expansion of the system itself and alternative movement, the whole system is moved forward, so that the excavation efficiency is improved, the hard bottom layer is adapted, the risk of drilling accidents is reduced, the stratum is quickly went through, the geological data is explored, the safety and accuracy of the drilling construction are improved.

Owner:WUHAN UNIV

Quick-detach vehicle-mounted auger driver

InactiveUS20050103529A1Effective mechanical communicationConstructionsReciprocating drilling machinesOn boardMotorized vehicle

The present invention provides a device useful for boring holes into the earth, and is especially useful for drilling holes in which fence posts are to be placed. A device according to the invention is completely self-powered, having its own on-board engine which supplies all of the power necessary for the boring operation and other movements of the device associated therewith. A device according to the invention is readily removable from and attachable to a motorized vehicle equipped with a trailer hitch, and is adapted to configure itself in a retracted position for ease in storage and transportation.

Owner:ROSSI FR W

Tunnel drilling-blasting construction, tunneling and risk elimination apparatus and method of using same

InactiveCN106703690AShorten the timeImprove securityConstructionsDrilling with mechanical conveyingTreatment systemAutomation

The invention discloses a tunnel drilling-blasting construction, a tunneling and risk elimination apparatus and a method of using the same; the tunnel drilling-blasting construction, a tunneling and risk elimination apparatus comprises a traveling unit, a rotating unit, an arm frame unit, and a hydraulic breaking and drilling unit; the traveling unit comprises wheels, a chassis, a conveyer belt and a motor; the rotating unit comprises a rotating chassis, a cab, and a machine chamber; the arm frame unit comprises a primary mechanical arm, a primary cylinder, a secondary cylinder, a secondary mechanical arm, a tertiary cylinder, a quaternary cylinder, and a dust treatment system; the hydraulic breaking and drilling unit comprises a fixed base, a slide rail, an explosive clamp, a percussion drill and a drill pipe. The tunnel drilling-blasting construction, a tunneling and risk elimination apparatus is a tunnel drilling-blasting construction, tunneling and risk elimination machine having risk elimination, drilling and charging functions, has high automation level, good flexibility and high safety, is convenient and simple to operate, has reasonably set system functions, enables effectively improved working efficiency and greatly saved construction time, and is applicable to the construction in various complex tunnel environments.

Owner:SHANDONG UNIV

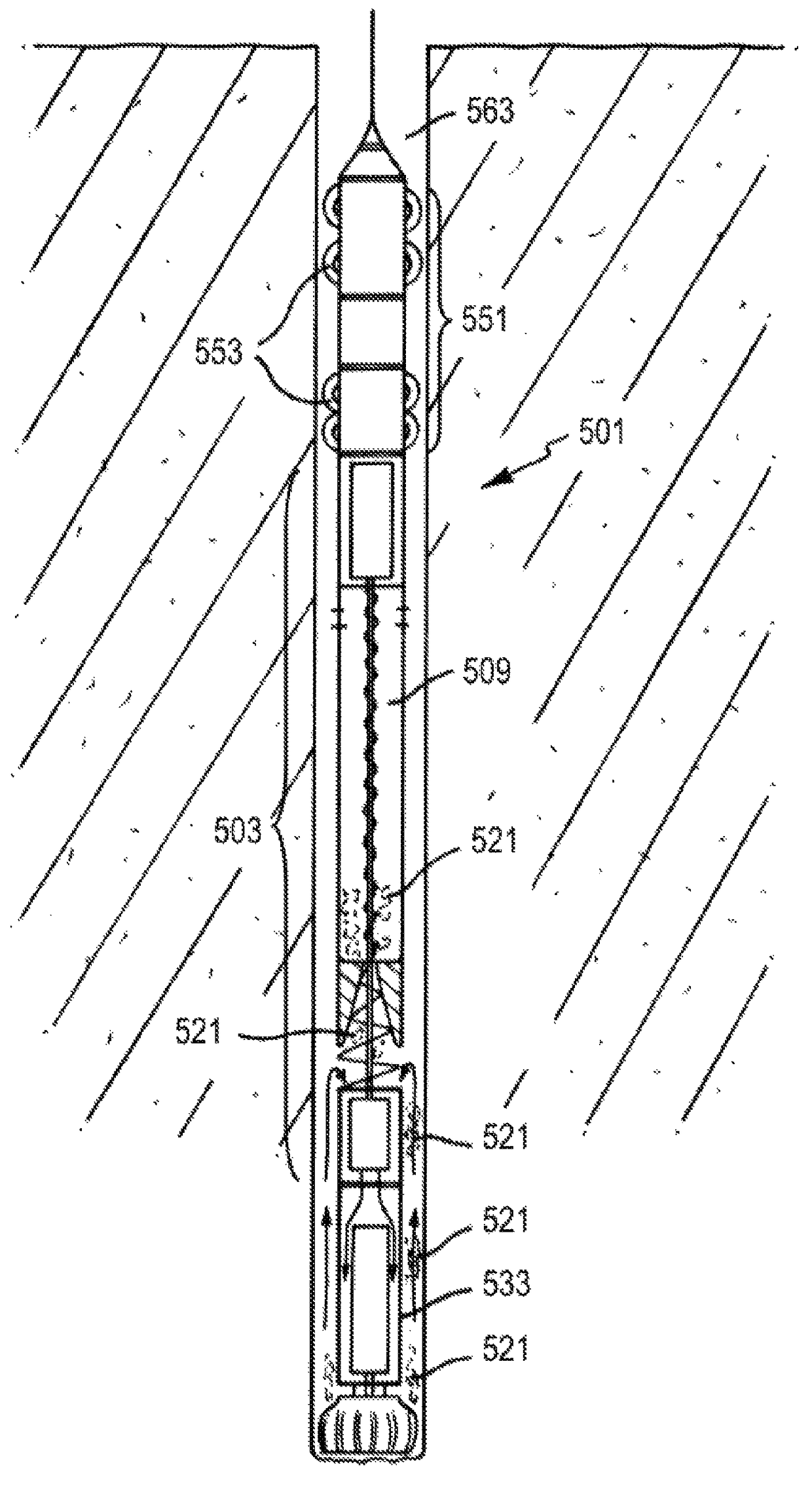

Wireline drilling system

ActiveUS9850728B2Reduce decreaseDrilling rodsDrilling with mechanical conveyingWell drillingDrill cuttings

Owner:WIRELINE DRILLING TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com