Method and apparatus for creating a borehole in the ground

A soil and drill pipe technology, applied in drilling equipment and methods, earth-moving drilling, drilling with mechanical conveying devices, etc. Achieve the effect of good force distribution and high cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

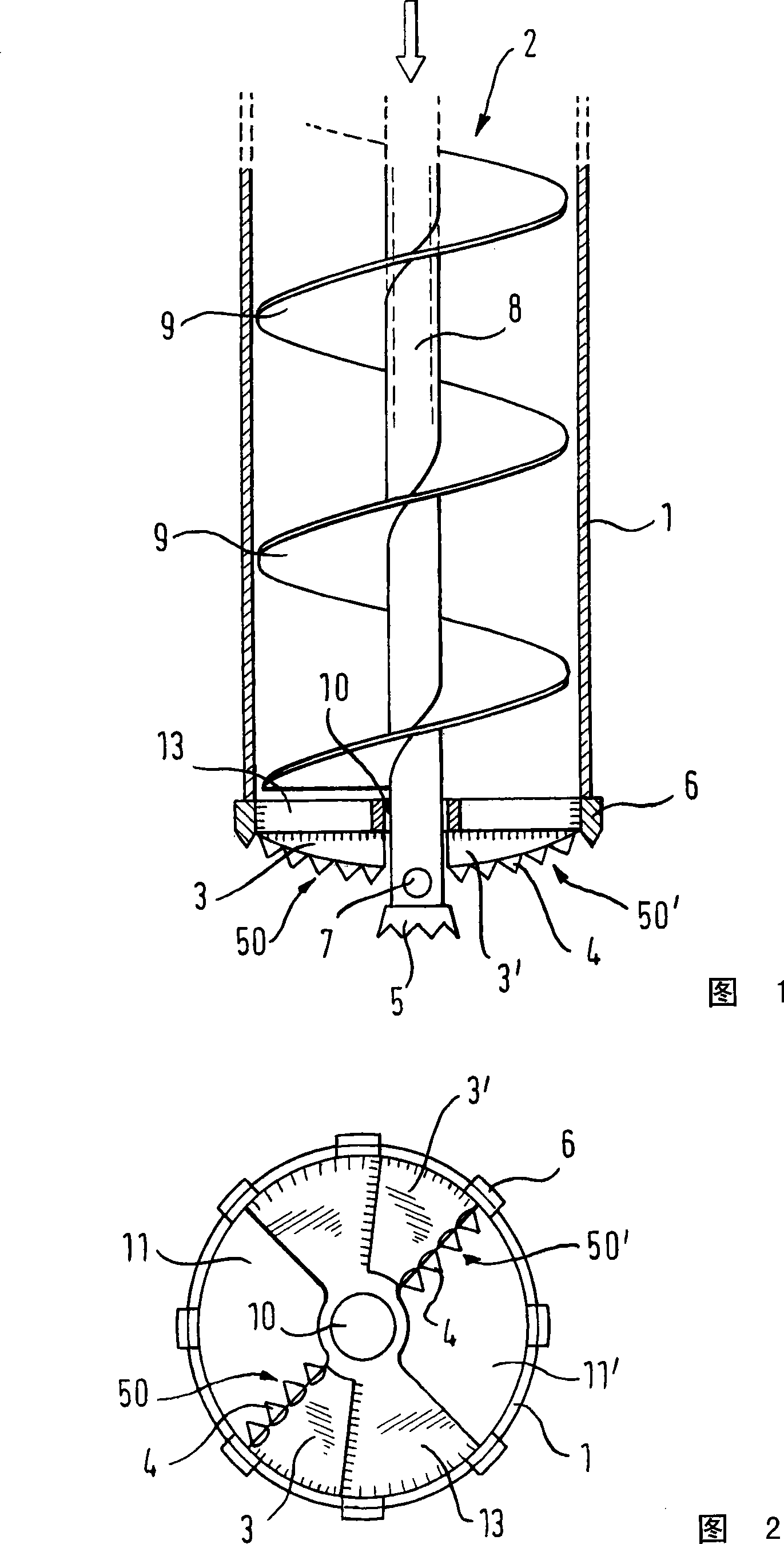

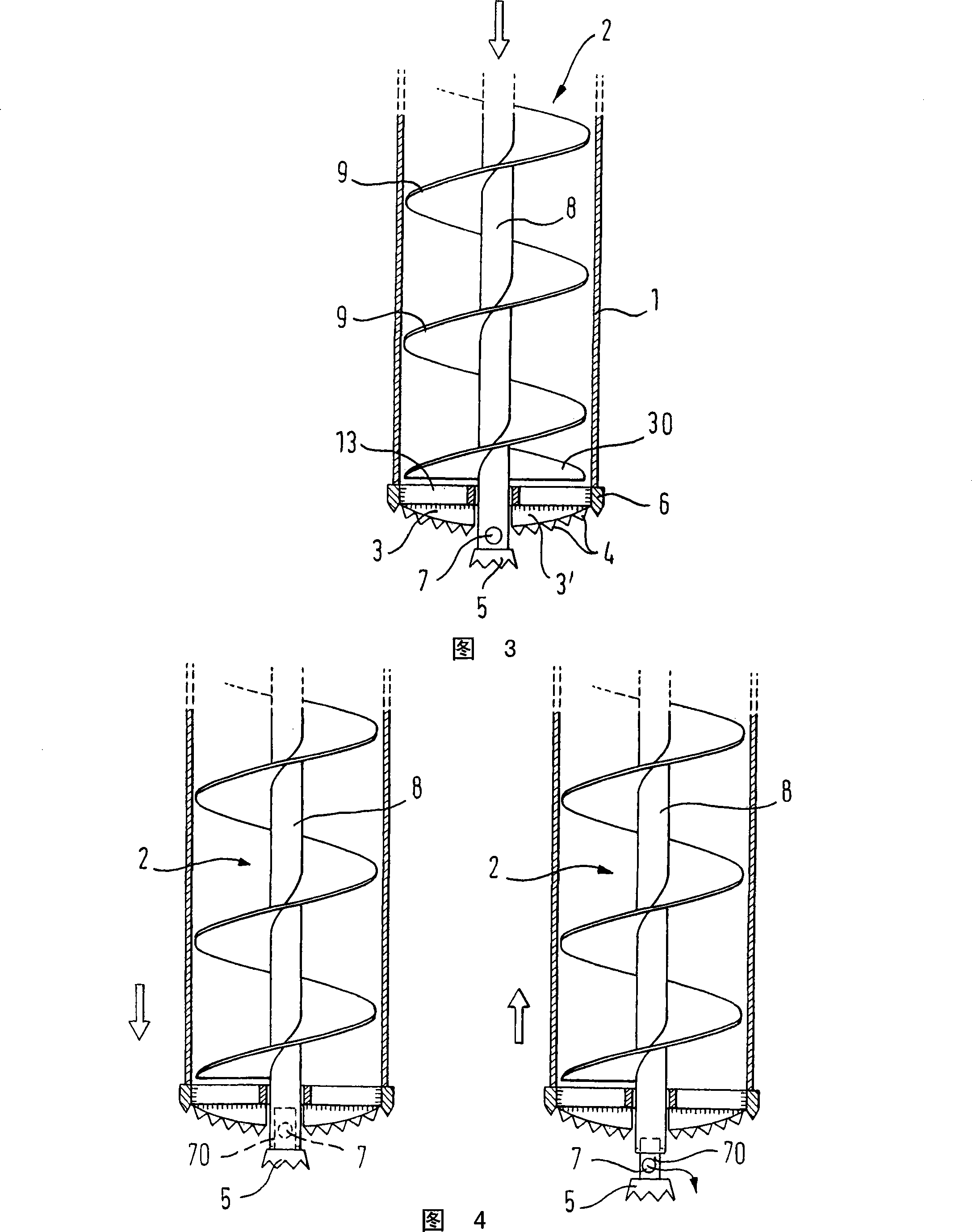

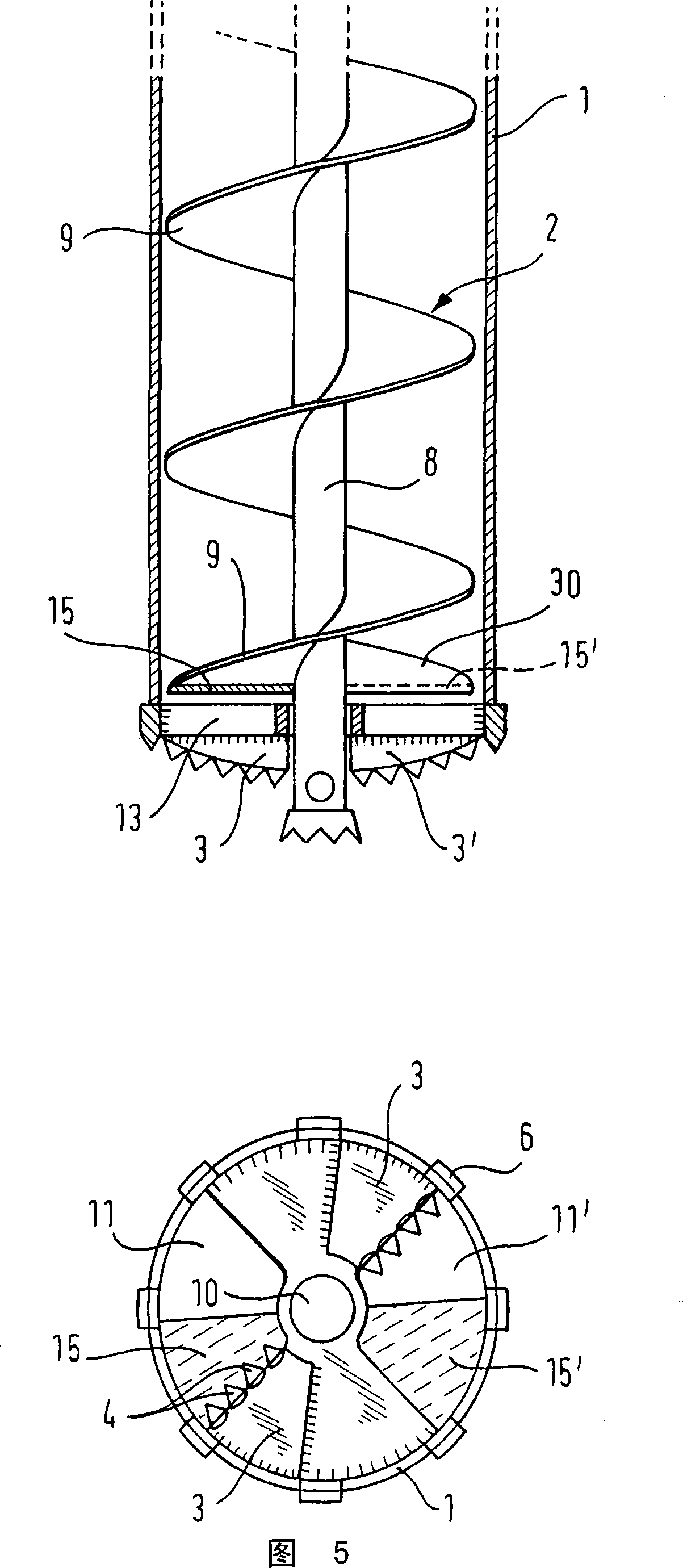

[0042] In Figures 6 to 14, the auger is not shown for clarity. Elements having the same effect are marked with the same reference numerals in all figures.

[0043] Figures 1 and 2 show a first embodiment of a device for producing boreholes in soil according to the invention. The device comprises a rotatably driven drill rod 1 , wherein a screw conveyor 2 is arranged coaxially. The screw conveyor 2 has a core tube 8, on the outside of which a screw flight 9 extends longitudinally.

[0044] At the end of the drill rod 1 facing the borehole, a drill tool holder 13 designed as a cover plate covers the drill rod 1 to some extent. The drill holder 13 extends radially in section from the wall of the drill rod 1 to the longitudinal axis of the drill rod 1 . On the drill holder 13, 2 openings 11, 11' in the shape of a sector are formed to allow the material to be transported through the drill holder 13 towards the inside of the drill pipe and the conveying part of the screw conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com