Spiral soil-squeezing downhole rock embedding device and pile forming method

A helical and down-the-hole technology, which is applied to drilling equipment and methods, earthwork drilling, and driving devices for drilling in boreholes. environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

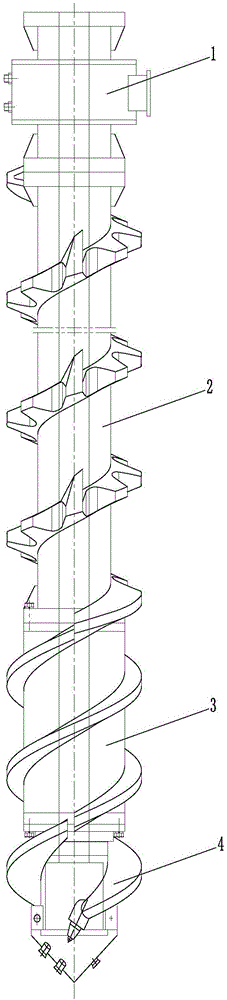

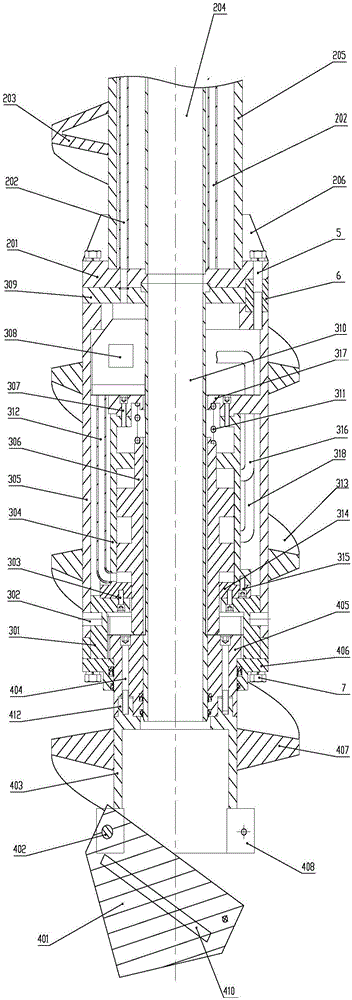

[0039] Such as figure 1— Figure 7 As shown, the spiral earth-extruding down-the-hole rock-socketing device consists of a gyrator (1), a standard earth-extruding drilling tool (2), an impactor (3) and a drill bit (4). The components are torsionally transmitted through pin keys, and the bolts are connected to form a rigid body. When working, the gyrator is connected to the high-torque screw power head device, and at the same time completes the conversion function of the hydraulic oil of the impactor.

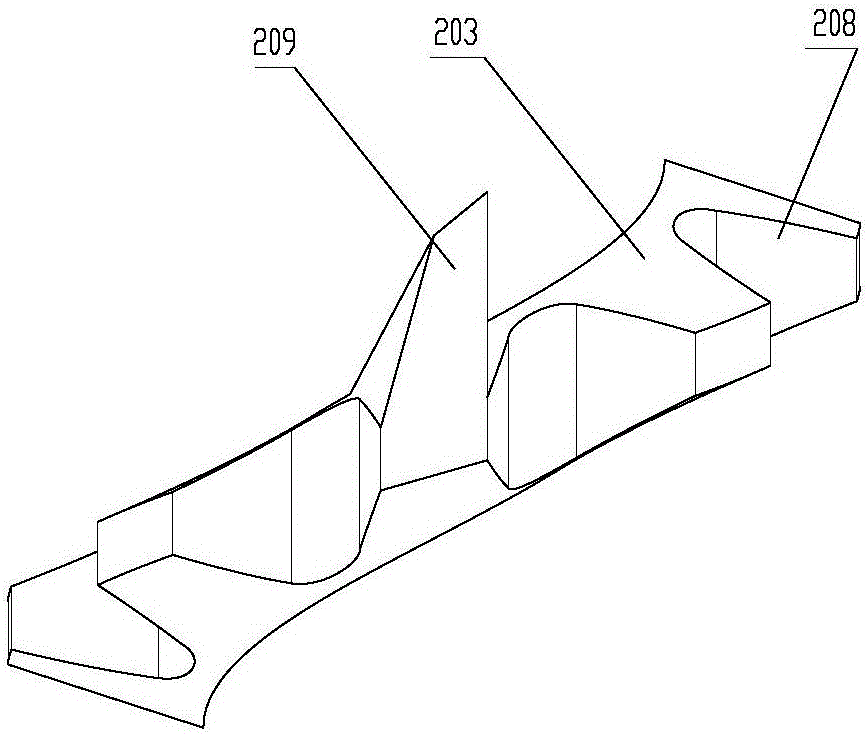

[0040] The standard soil extrusion drilling tool (2): includes standard flange (201), high-pressure oil pipe (202), soil extrusion drilling tool blade (203), inner pipe I (204), outer pipe (205) and reinforcement plate (206); The earth-squeezing drilling tool blade (203) is assembled and welded on the outer pipe (205) with equal pitch, and the inner pipe I (204) is installed in the outer pipe (205) and is coaxial with the outer pipe (205). Rib (206) is connected with outer pip...

Embodiment 2

[0049] like Figure 8 Shown, a kind of spiral extruding submerged hole rock-socketed pile forming method, the method is as follows:

[0050] 1) The site is leveled, and the piles are measured, sampled and checked. Using the high torque (output torque above 150KN·M) power head screw pile driver, the concrete delivery pump, the screw squeeze soil submerged hole rock-socketing device and other related facilities are connected and installed as a complete set. Connect the screw-screw submerged-hole rock-socketing device with the power head of the screw pile machine and the hydraulic control system, connect the high-pressure oil inlet and outlet pipes of the impact device with the accumulator of the hydraulic control system, and align the rock-socketed pile position; the rock-socketed pile is that the rock bearing capacity of the pile-bearing layer is greater than 500Kpa. like Figure 8 (a).

[0051] 2) The screw-squeezing submerged-hole rock-socketing device, driven by the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com