Bionic gopher intelligent excavating system

A bionic gopher and intelligent technology is applied in the field of bionic gopher intelligent excavation system to achieve the effects of improving construction safety, improving excavation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

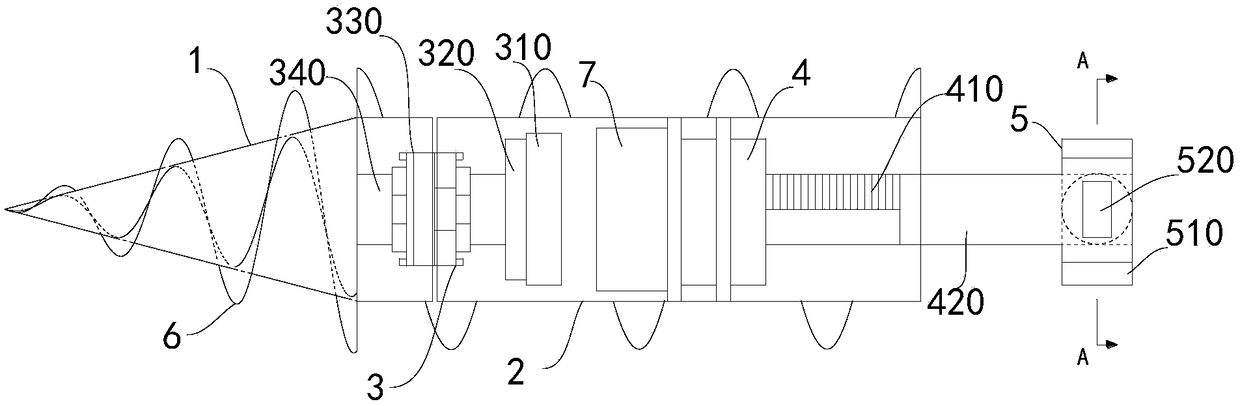

[0028] Such as figure 1 As shown, a bionic hamster intelligent excavation system includes a drill bit 1, a housing 2, a driving mechanism 3, a telescopic assembly 4 and an adjustable support foot 5, wherein the housing 2 is a cylindrical structure with a hollow interior and openings at both ends , the drill bit 1 is arranged at the front end of the casing 2, the driving mechanism 3 is arranged in the casing 2, the output shaft of the driving mechanism 3 is connected with the drill bit 1, the telescopic assembly 4 is arranged in the casing 2, and the telescopic end of the telescopic assembly 4 It protrudes from the rear end of the housing 2 to the outside of the housing 2 and is rotatably connected with the adjustable support foot 5 .

[0029] In the present embodiment, the specific structure of telescopic assembly 4 is as follows:

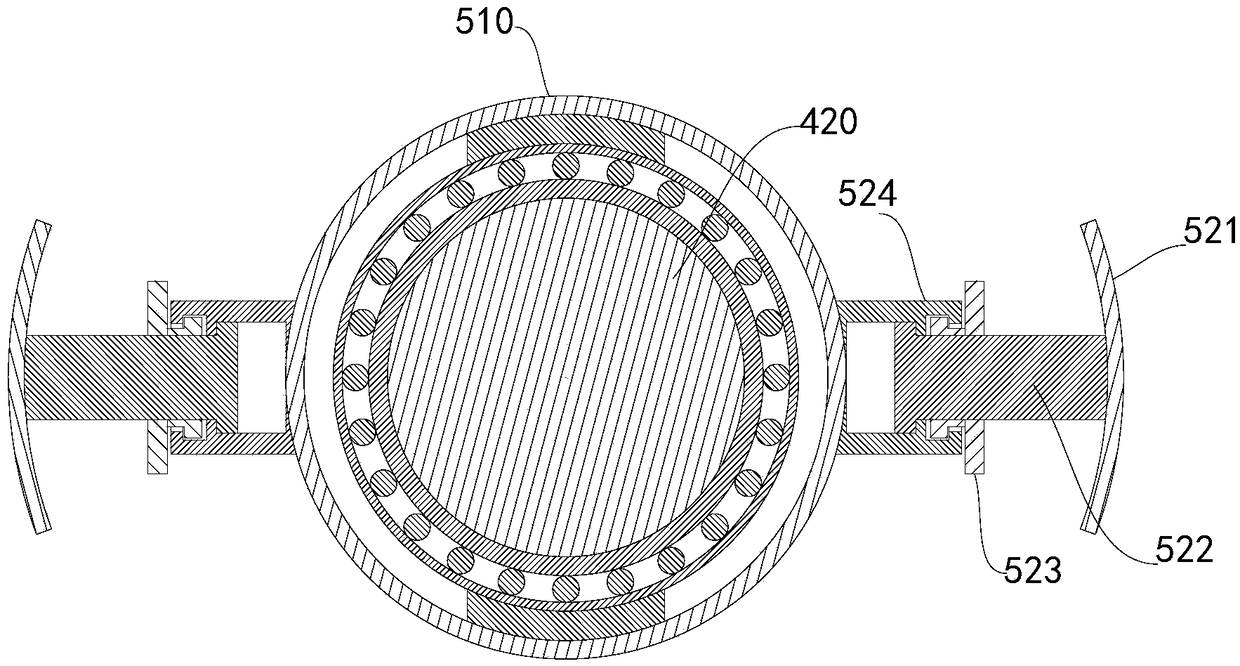

[0030] The telescopic assembly 4 includes a ball screw guide rail slide 410 and an adjustment shaft 420, the ball screw guide rail slide 410 is f...

Embodiment 2

[0037] Such as figure 1 , figure 2 As shown, a bionic hamster intelligent excavation system includes a drill bit 1, a housing 2, a driving mechanism 3, a telescopic assembly 4 and an adjustable support foot 5, wherein the housing 2 is a cylindrical structure with a hollow interior and openings at both ends , the drill bit 1 is arranged at the front end of the casing 2, the driving mechanism 3 is arranged in the casing 2, the output shaft of the driving mechanism 3 is connected with the drill bit 1, the telescopic assembly 4 is arranged in the casing 2, and the telescopic end of the telescopic assembly 4 It protrudes from the rear end of the housing 2 to the outside of the housing 2 and is rotatably connected with the adjustable support foot 5 .

[0038] In the present embodiment, the specific structure of telescopic assembly 4 is as follows:

[0039] The telescopic assembly 4 includes a ball screw guide rail slide 410 and an adjustment shaft 420, the ball screw guide rail s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com