Preparation method for fire-retardant heat-insulating foam spray used for fire emergency escape

A spray and foam technology, which is applied in the field of preparation of flame-retardant and heat-insulating foam spray for fire emergency escape, can solve problems such as unsatisfactory emergency escape effects, and achieve the effect of preventing fabric from burning and good heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

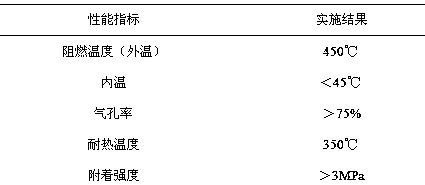

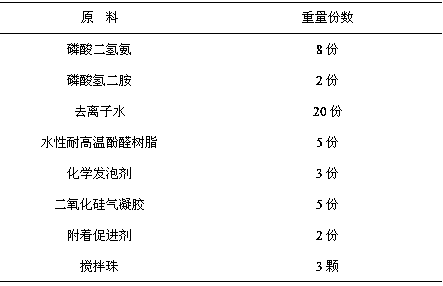

[0019] Phosphate flame retardant solution is mixed with ammonium dihydrogen phosphate and diammonium hydrogen phosphate at a molar ratio of 8:2, fully dissolved in deionized water, and water-soluble high temperature resistant phenolic resin is mixed with deionized water at a ratio of 5:10 , Prepare the solution in the above proportion, then add 5 parts of silica airgel and 2 parts of adhesion promoter in the same proportion, and finally add 3 parts of chemical foaming agent and 3 stirring beads in the same proportion. Mix according to the above ratio, stir in the container for 60 minutes to fully mix the components, then add foaming agent, pour the solution into the tank, and put 3 stirring beads.

specific Embodiment 2

[0021] Phosphate flame retardant liquid is mixed with ammonium dihydrogen phosphate and diammonium hydrogen phosphate at a molar ratio of 7:3, fully dissolved in deionized water, and water-soluble high temperature resistant phenolic resin is mixed with deionized water at a ratio of 3:10 , Prepare the solution in the above proportion, then add 4 parts of silica airgel and 2 parts of adhesion promoter in the same proportion, and finally add 4 parts of chemical foaming agent and 3 stirring beads in the same proportion. Mix according to the above ratio, stir in the container for 60 minutes to fully mix the components, then add foaming agent, pour the solution into the tank, and put 4 stirring beads.

specific Embodiment 3

[0023] Phosphate flame retardant solution is mixed with ammonium dihydrogen phosphate and diammonium hydrogen phosphate at a molar ratio of 9:1, fully dissolved in deionized water, and water-soluble high temperature resistant phenolic resin is mixed with deionized water at a ratio of 4:10 , Prepare the solution in the above ratio, then add 3 parts of silica airgel and 2 parts of adhesion promoter in the same ratio, and finally add 5 parts of chemical foaming agent and 3 stirring beads in the same ratio. Mix according to the above ratio, stir in the container for 60 minutes to fully mix the components, then add foaming agent, pour the solution into the tank, and put 5 stirring beads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com