Culvert passing device for nodular cast iron pipe

A ductile iron pipe and culvert technology, applied in water supply installations, sewer systems, waterway systems, etc., can solve problems such as huge capital costs, large capital costs, traffic congestion, etc., and save installation time, improve construction efficiency, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

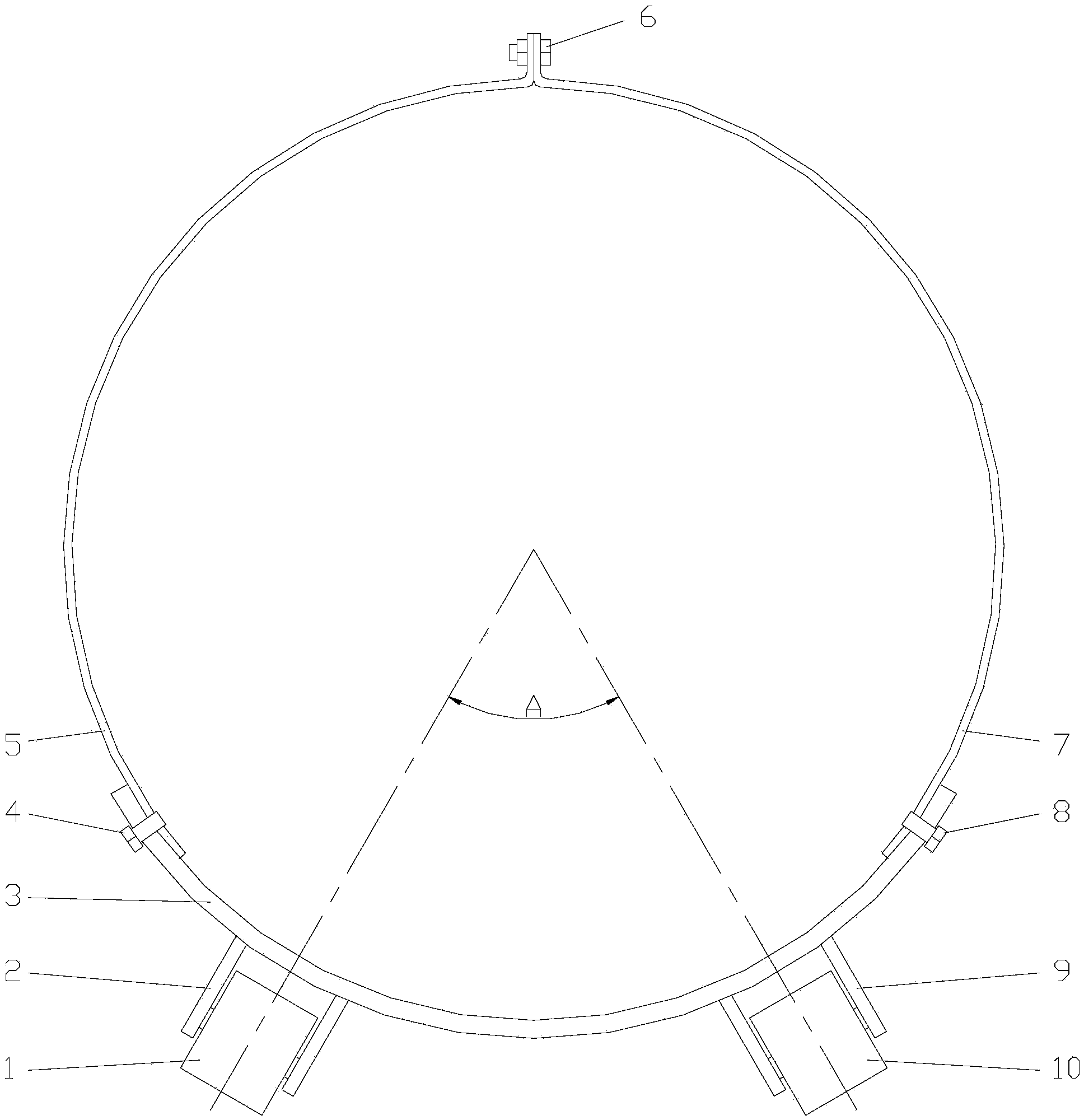

[0009] like figure 1 Shown, the lower end of tugboat fixed plate 3 fixes a plurality of tugboats, and the left and right ends of tugboat fixed plate 3 are respectively detachably fixed with the lower end of left and right locking plates 5,7, and the upper ends of left and right locking plates 5,7 can be Remove and fix.

[0010] The lower end of described tugboat fixed plate 3 is respectively hinged left and right tugboat 1,10 by left and right support 2,9, and left and right support 2,9 and tugboat fixed plate 3 are welded and fixed.

[0011] The left and right ends of the tugboat fixing plate 3 are respectively fixed by the left and right screws 4, 8 and the lower ends of the left and right locking plates 5, 7, and the upper ends of the left and right locking plates 5, 7 are fixed by bolts and nuts. 6 flange fixed.

[0012] The axial angle A between the left and right tugboats 1, 10 is 60 degrees.

[0013] During use, the tugboat fixing plate 3 and the left and right locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com