Heat exchanger apparatus

A heat exchanger and equipment technology, applied in the field of cooling systems and heat exchanger equipment, can solve problems such as poor thermal conductivity, and achieve the effects of reducing flow resistance, optimizing flow rate and cooling efficiency, and improving evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

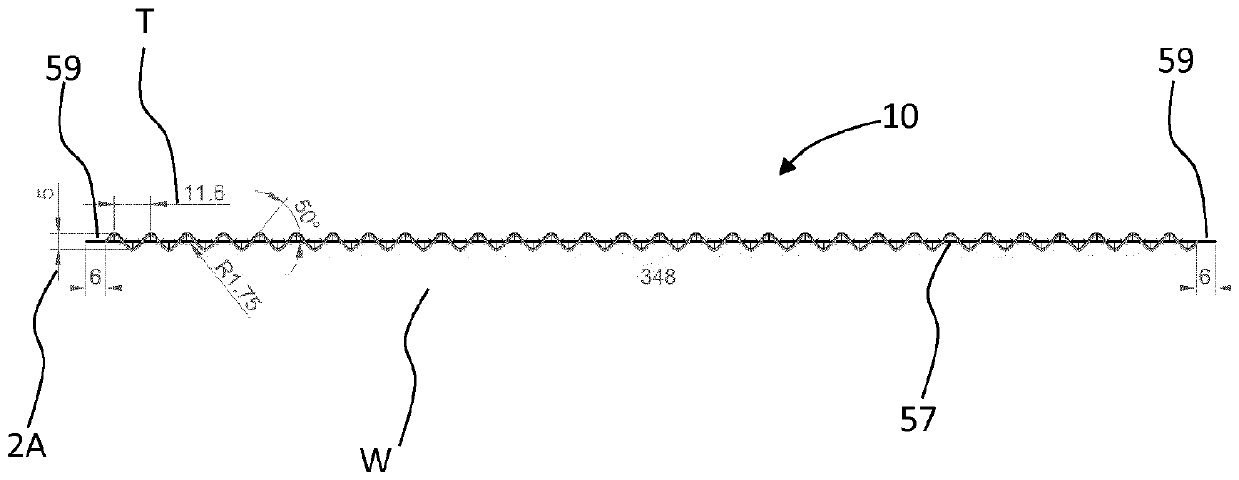

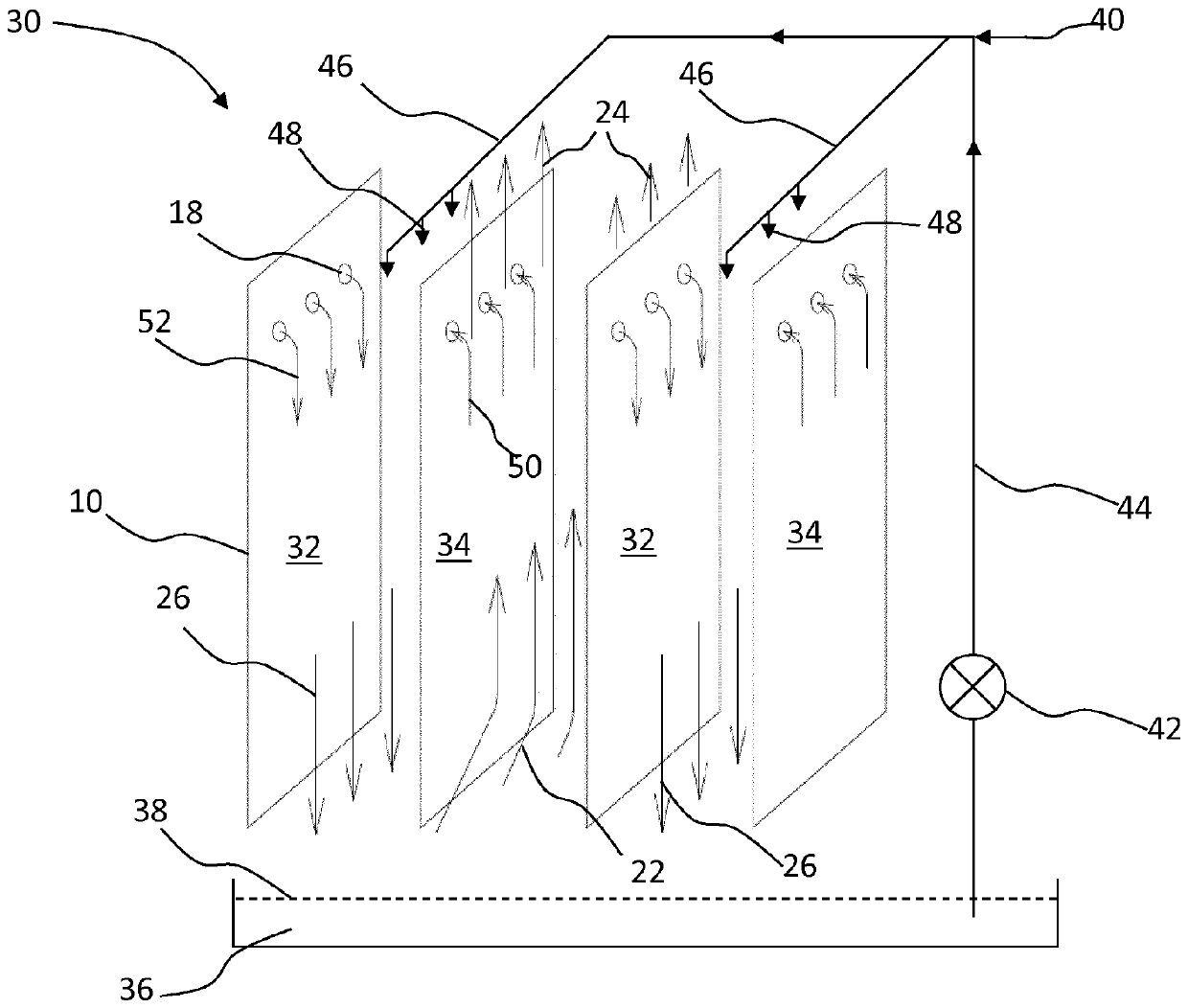

[0040] figure 1 A perspective side view, generally designated 10, of a heat exchanger lamella according to an embodiment of the present invention is shown. exist figure 1 In , the heat exchanger sheets are shown in their normal orientation in use. The heat exchanger sheets 10 are 5005 series aluminum. The heat exchanger foil 10 is corrugated in the upper region 14 . The 5005 series aluminum used to form the heat exchanger sheet 10 provides suitable ductility to form the corrugations and also provides the required thermal conductivity. The upper region 15 of the heat exchanger foil 10 is planar. The lower region 16 of the heat exchanger foil 10 is planar. It is also shown that the transition 17 from each of the upper region 15 and the lower region 16 to the corrugations is smooth. The heat exchanger foil 10 is 360 mm wide and 1000 mm long. The length of the corrugated area of the heat exchanger foil 10 is 860 mm. The length of the planar region 16 is 115 mm and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com