Chemical reaction kettle convenient for temperature adjustment

A chemical reaction and temperature adjustment technology, applied in the field of chemical reaction kettles, can solve the problems of difficult temperature control, slow temperature adjustment, large cost and investment, etc., to increase the contact area, increase the transfer area, Realize the effect of quick control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

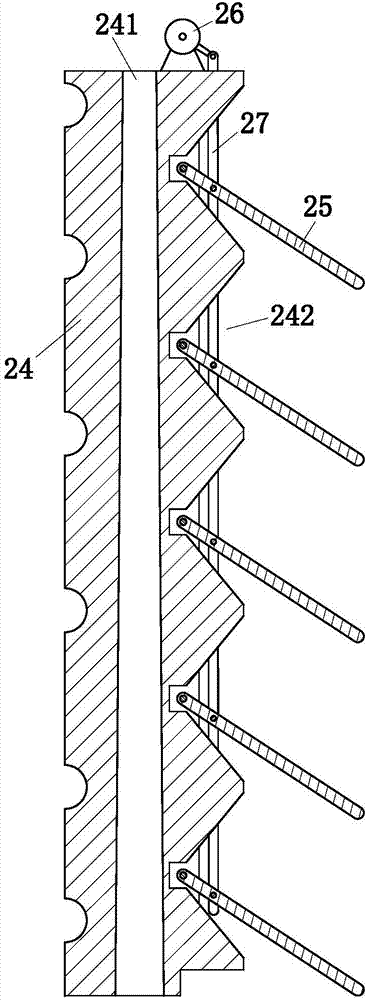

[0016] As an embodiment of the present invention, the heat conducting seat 24 is provided with a triangular opening groove 242, one end of the fin 25 is installed in the opening groove 242, and the fin 25 can be connected to the opening groove when it rotates upward or downward. The sidewalls of 242 are in contact, and the fins 25 are in contact with the sidewalls of the opening grooves 242, which can increase the contact area between the fins 25 and the heat-conducting seat 24, thereby helping to increase the heat transfer between the fins 25 and the heat-conducting seat 24 effectiveness.

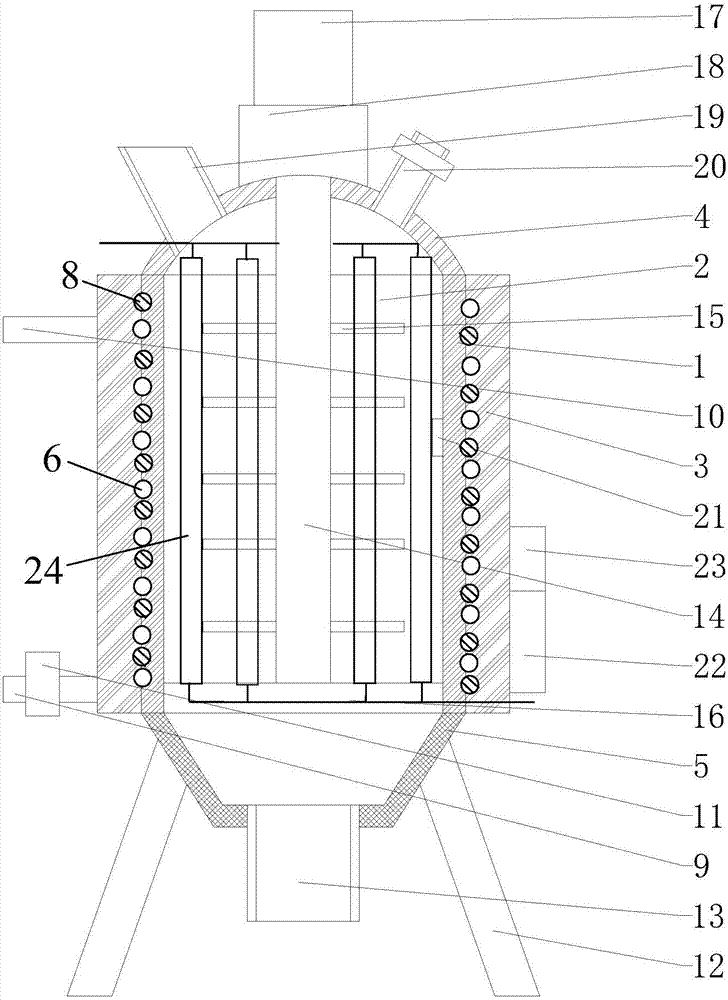

[0017] As an embodiment of the present invention, the inside of the jacket 3 is provided with a spiral cooling water channel 6 and a spiral heating resistor 8 wound along the outer wall of the kettle body 1, and the back of the heat conducting seat 24 is provided with a cooling water channel 6 and The matching groove of the heating resistor 8 is in a sealed connection between the heat conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com