Composite pipe connection joint using prestressed cables and method of use thereof

A technology of composite material pipes and prestressed cables, which is applied to the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of insufficient bearing capacity, and achieve the effect of improving bearing capacity, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

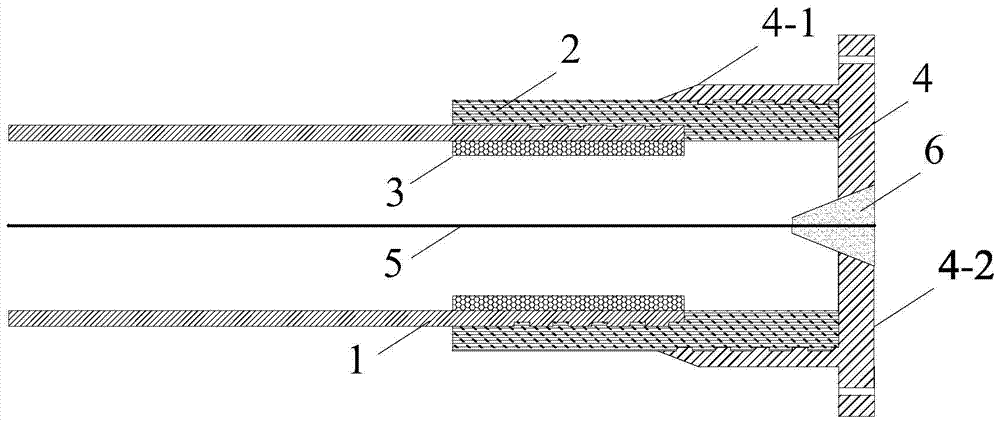

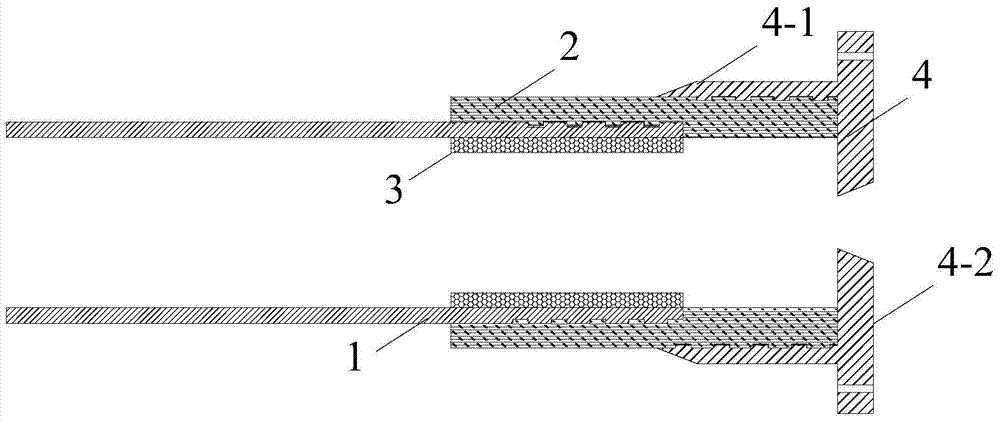

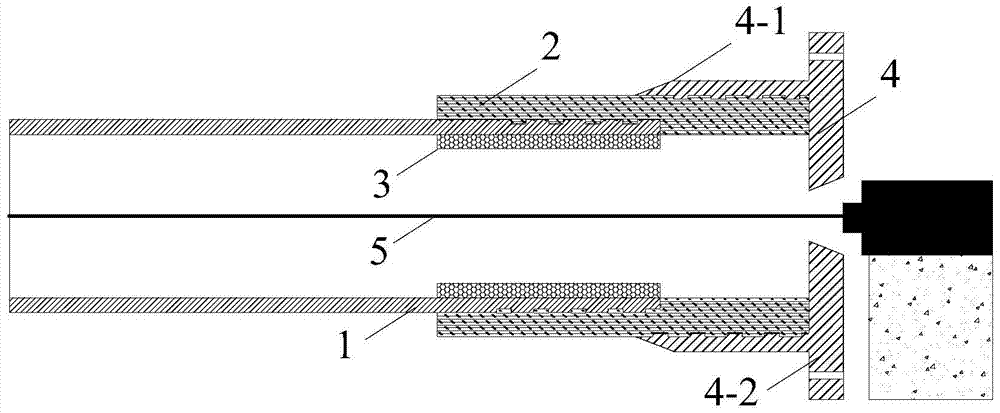

[0046] combine figure 1 and figure 2 , a composite pipe connection joint using prestressed cables, including an outer casing 2, an internal pressure pipe 3, a cap 4, a prestressed cable 5 and an anchor 6. One end of the composite material tube 1 to be connected is threadedly connected to the inner wall of the outer tube 2, and the internal pressure tube 3 is arranged on the inner wall of the connecting section between the outer tube 2 and the composite material tube 1 through interference fit. The material of the cap 4 is steel, including the fixed ring 4-1 and the fixed seat 4-2, the fixed ring 4-1 is welded on the fixed seat 4-2, the center of the fixed ring 4-1 coincides with the center of the fixed seat 4-2, and the outer casing 2. The other end is threadedly connected with the fixing ring 4-1. There is a wedge-shaped hole in the center of the fixing seat 4-2. The prestressed cable 5 passes through the wedge-shaped hole on the fixing seat 4-2 and runs through the composi...

Embodiment 2

[0059] combine figure 1 and figure 2 , a composite pipe connection joint using prestressed cables, including an outer casing 2, an internal pressure pipe 3, a cap 4, a prestressed cable 5 and an anchor 6. One end of the composite material tube 1 to be connected is fixedly connected with the inner wall of the outer tube 2 by pouring glue, the inner pressure tube 3 is arranged on the inner wall of the connecting section between the outer tube 2 and the composite material tube 1 through interference fit, and the cap 4 is integrally formed of a composite material. It includes a fixed ring 4-1 and a fixed seat 4-2, the fixed ring 4-1 is arranged on the fixed seat 4-2, the center of the fixed ring 4-1 coincides with the center of the fixed seat 4-2, and the other end of the outer sleeve 2 is connected to the fixed ring 4-1 is connected by glue filling, a round hole is set in the center of the fixing seat 4-2, the prestressed cable 5 passes through the round hole on the fixing seat...

Embodiment 3

[0072] combine figure 1 and figure 2 , a composite pipe connection joint using prestressed cables, including an outer casing 2, an internal pressure pipe 3, a cap 4, a prestressed cable 5 and an anchor 6. One end of the composite material tube 1 to be connected is threadedly connected to the inner wall of the outer tube 2, and the internal pressure tube 3 is arranged on the inner wall of the connecting section between the outer tube 2 and the composite material tube 1 through interference fit. The cap 4 is manufactured in the whole factory, including the fixing ring 4 -1 and the fixed seat 4-2, the center of the fixed ring 4-1 coincides with the center of the fixed seat 4-2, the other end of the outer sleeve 2 is threadedly connected with the fixed ring 4-1, and the center of the fixed seat 4-2 is provided with a wedge-shaped hole, The prestressed cable 5 passes through the wedge-shaped hole on the fixing seat 4-2 and runs through the composite material pipe 1, and the ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com