Combined type vertical roller ring

A combined vertical roll technology, which is applied in the field of roll manufacturing, can solve the problems of low strength and non-abrasion resistance of the vertical roll ring, and achieve the effects of strong wear resistance, long service life and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

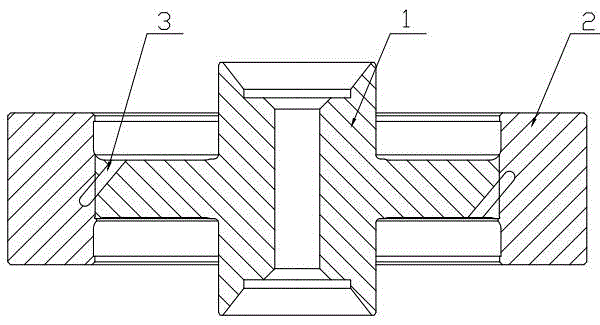

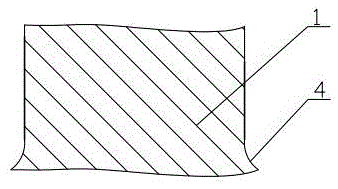

[0031] Such as figure 1 As shown, a combined vertical roller ring includes a ring sleeve 2 made of semi-steel and a shaft core 1 made of forged steel. The ring sleeve 2 and the shaft core 1 are fixedly connected by a connecting piece 3 composed of four evenly arranged positioning pins. , the angle between the joint surface of the ring sleeve 2 and the shaft core 1 and the positioning pin is 30°, among the four positioning pins, the positioning direction of two of them is 30° upward obliquely, and the positioning direction of the other two is 30° downward obliquely , the positioning pin is made of material with tensile strength ≥ 600Mpa and yield strength ≥ 360Mpa, such as 45# steel; figure 2 As shown, the edges and corners of the shaft core 1 are transitioned through the arc 4, and the radius R of the arc 4 is 5 mm.

[0032] After inspection, the safety factor of the vertical roller ring connected by the positioning pin is 5.0, which fully meets the requirements for use. Of...

Embodiment 2

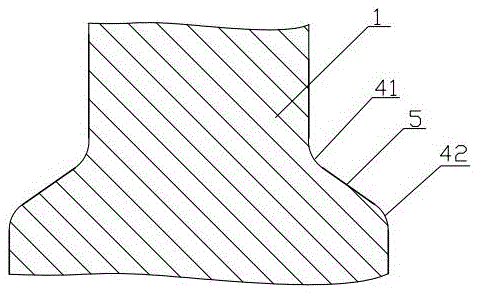

[0034] The difference between this embodiment and embodiment 1 is: see image 3 , the edge and corner of the shaft core 1 adopt the combination of arc 4 and oblique line 5, arc 4 includes arc ㄧ 41 and arc Ⅱ 42 separated from each other, and the radius R of arc ㄧ 41 and arc Ⅱ 42 Both are 5mm~20mm, they can be the same or different, for example, both can be 13mm, or they can be 12mm and 15mm respectively; the edge lines at the edges and corners are smoothly connected with arc ㄧ 41, and the arc ㄧ 41 is smoothly connected Oblique line 5, oblique line 5 is then smoothly connected to arc II 42, the angle between oblique line 5 and the horizontal line is 45-65°, for example, it can be 50°, 54°, 60°, so that the effective contact area is larger and the stress is smaller .

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is: the angle between the joint surface of the ring sleeve 2 and the shaft core 1 and the positioning pin is 45°, the number of positioning pins is three, and the positioning direction of one of them is 45° upward obliquely, The positioning directions of the other two are obliquely downward at 45°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com