Device with an internal conductor and method for manufacturing such a device

A technology of inner conductor and inner space, applied in the direction of insulators, cable terminals, pipes, etc., can solve the problems of unsatisfactory mechanical stability and high requirements, and achieve the effect of offsetting cracking and improving tolerance compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

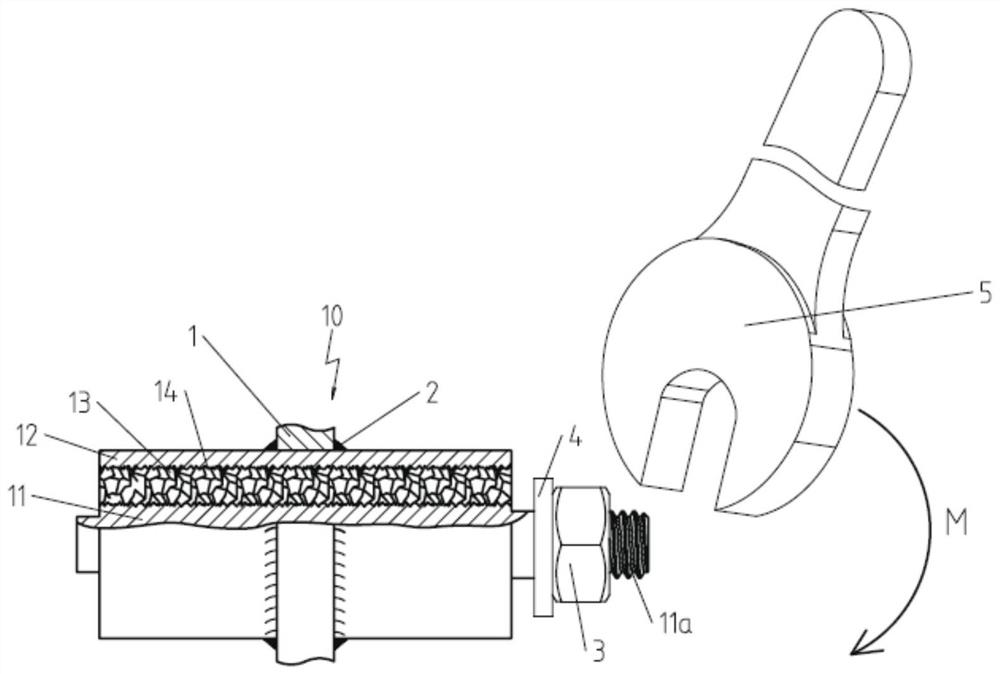

[0040] figure 1 Shown is a device 10 embodied as a bushing through a metal wall 1 , which is welded with a weld seam 2 to the metal wall 1 through which the device 10 is led through. The device 10 has an inner conductor 11 arranged within the tube interior space of a tubular metal sheath 12 and electrically insulated from the tubular metal sheath 12 using a compacted electrical insulating material 13 . The connecting section 11 a of the inner conductor 11 protrudes from the tubular metal sheath 12 and is provided on the end side with a thread introduced into the connecting section 11 a of the inner conductor 11 , on which thread the electrical contact 4 is fixed using a nut 3 . Consequently, the device 10 is subjected to considerable torques M, which must be absorbed by the electrically insulating material 13 , when temporarily used as intended, ie especially when the nuts 3 are tightened with the screw wrench 5 to fix the contacts 4 .

[0041] This is achieved in that the elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com