Transfer method for holographic anti-counterfeiting molded film

A holographic anti-counterfeiting and transfer method technology, which is applied in the field of holographic anti-counterfeiting printing, can solve the problems of high cost of plate making, high cost, and complicated production, and achieve the effects of prolonging service life, high dyne value, and increasing transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

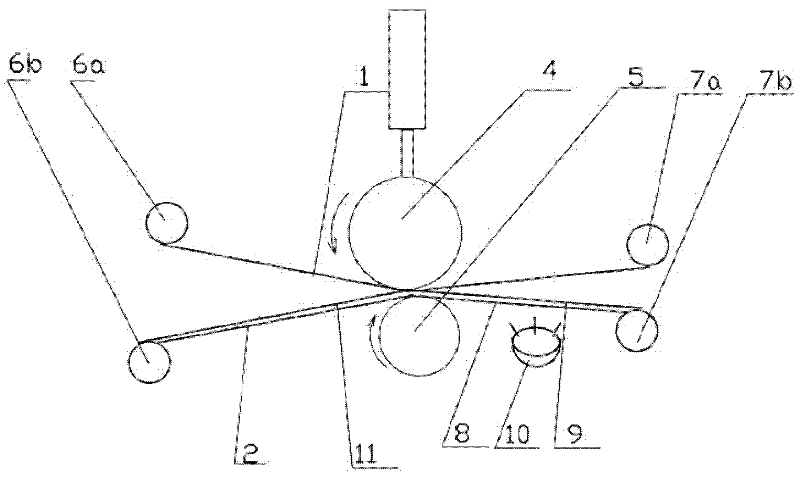

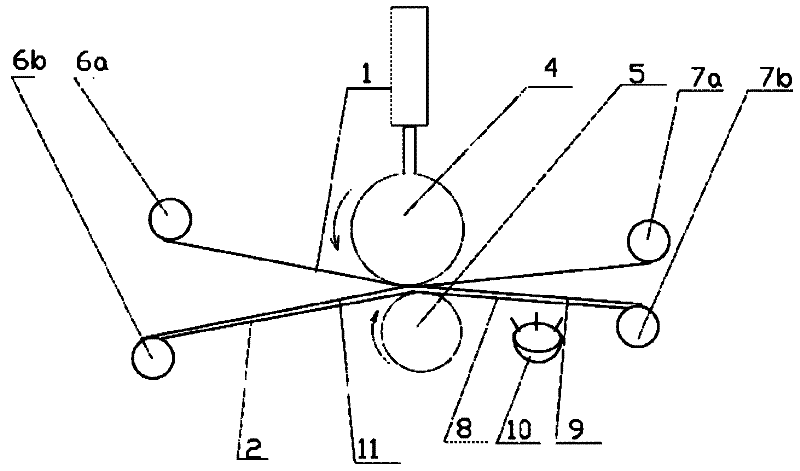

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the present invention: figure 1 Shown is a structural schematic diagram of an embodiment of a transfer method of holographic anti-counterfeiting film embossing, which describes the transfer method of film embossing more intuitively. The specific steps are:

[0019] The first step: make a holographic nickel plate,

[0020] Step 2: On the PET base film, use a molding machine to mold and transfer the holographic nickel plate to make a PET film with a holographic information layer for the master plate, and vacuum-plate titanium on the PET film master plate, that is, on the PET film master plate A titanium nitride layer is coated on the plate to form a strip-shaped holographic titanium film master plate film strip 1; the thickness of the titanium nitride coating is 300-500A, and the holographic groove is clear. like figure 1 As shown, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com