A slurry mixing device for shoe and hat processing

A mixing device and slurry technology, applied in mixers, mixing methods, shaking/oscillating/vibrating mixers, etc., can solve the problems of affecting the mixing effect of the slurry, difficult to stir thoroughly, sinking to the bottom, etc., to improve the mixing effect , to avoid slurry agglomeration, to avoid the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

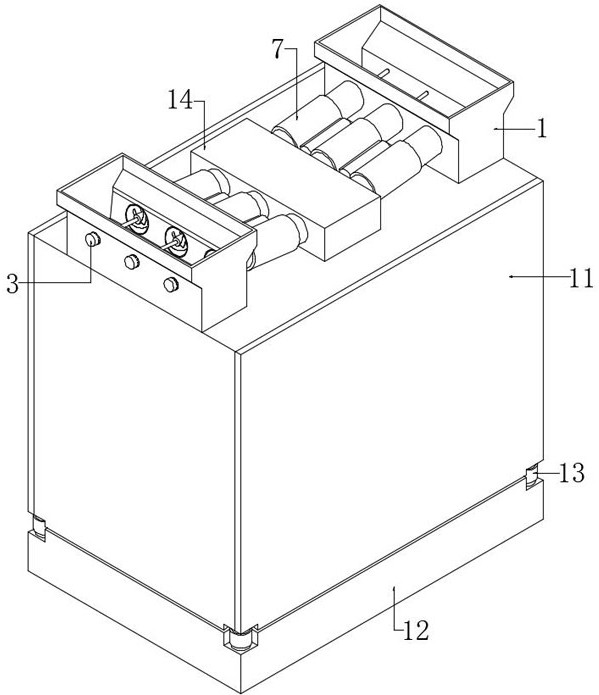

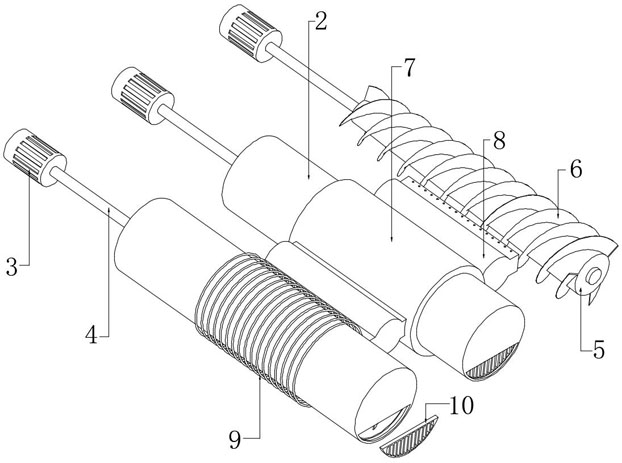

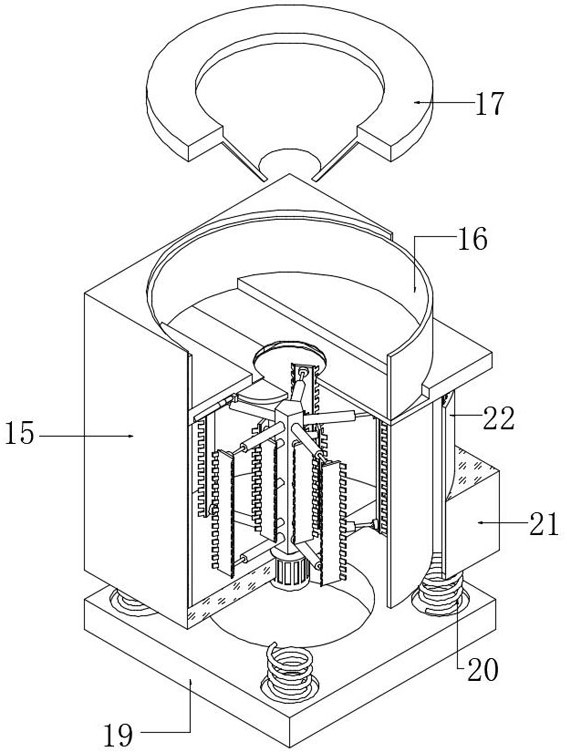

[0031] One kind of footwear processing slurry mixing apparatus, such as figure 1 with figure 2As shown, two addition boxes 1 are included, and the two addition boxes are placed, and the two addition boxes are opened, and the inner walls of the alvearters are connected, and the inner wall of the circular hole is connected by a bolt. 2, and two The addition of three isometric grooves are opened, and the inner wall of the groove is connected to the first motor 3 by a bolt. The output of the first motor 3 is connected to the coupling 4, and the rotor 4 One end is connected to the broken shaft 5 by bolt, and the broken shaft 5 is circularly stable, and the other end of the crush s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com