Agitating kettle with mechanical seal convenient to change

A technology of stirring tank and mechanical seal is applied in the field of stirring tank which is easy to replace the mechanical seal, which can solve problems such as excessive screw change, and achieve the effects of convenient separation, stable structure and stable power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

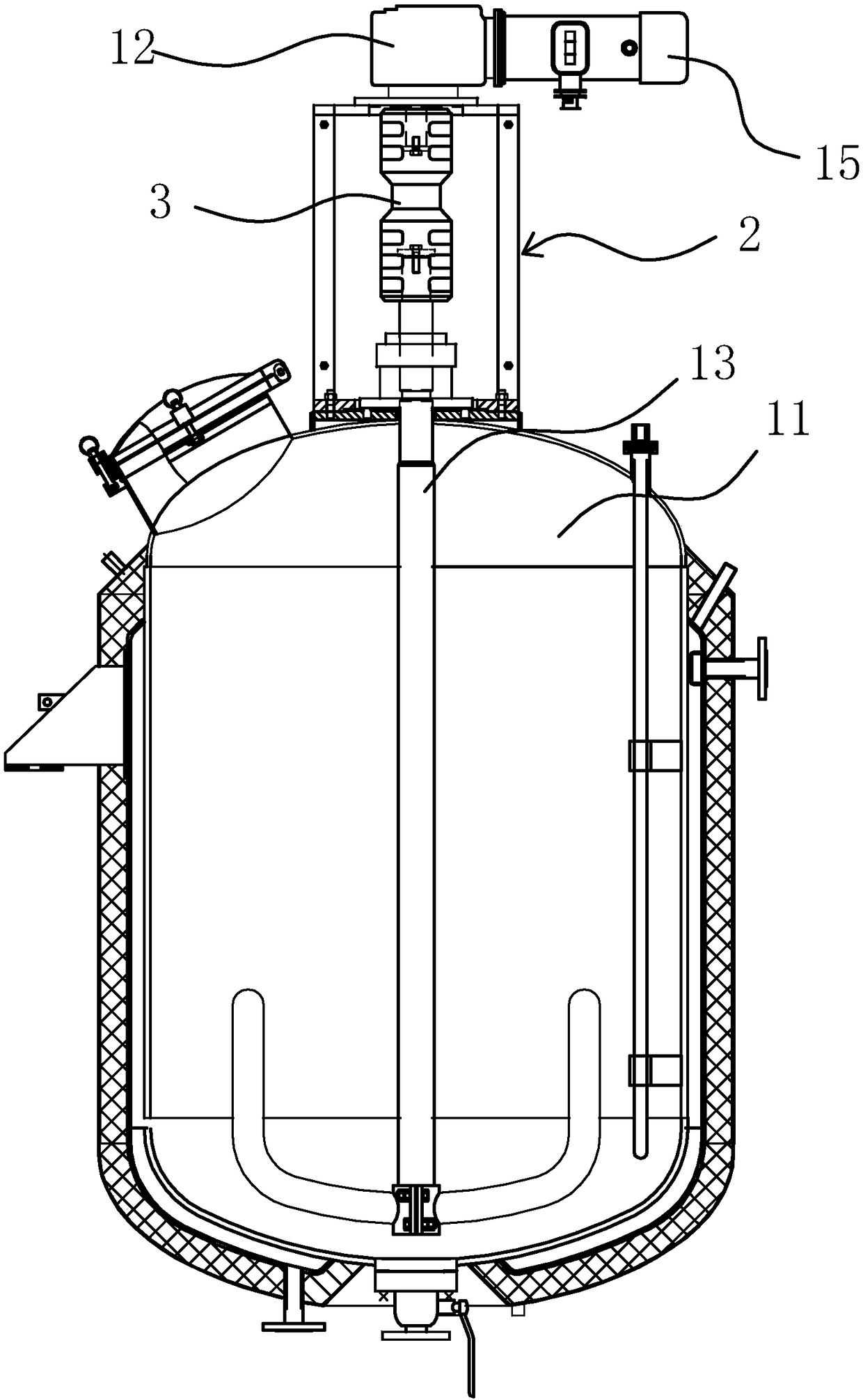

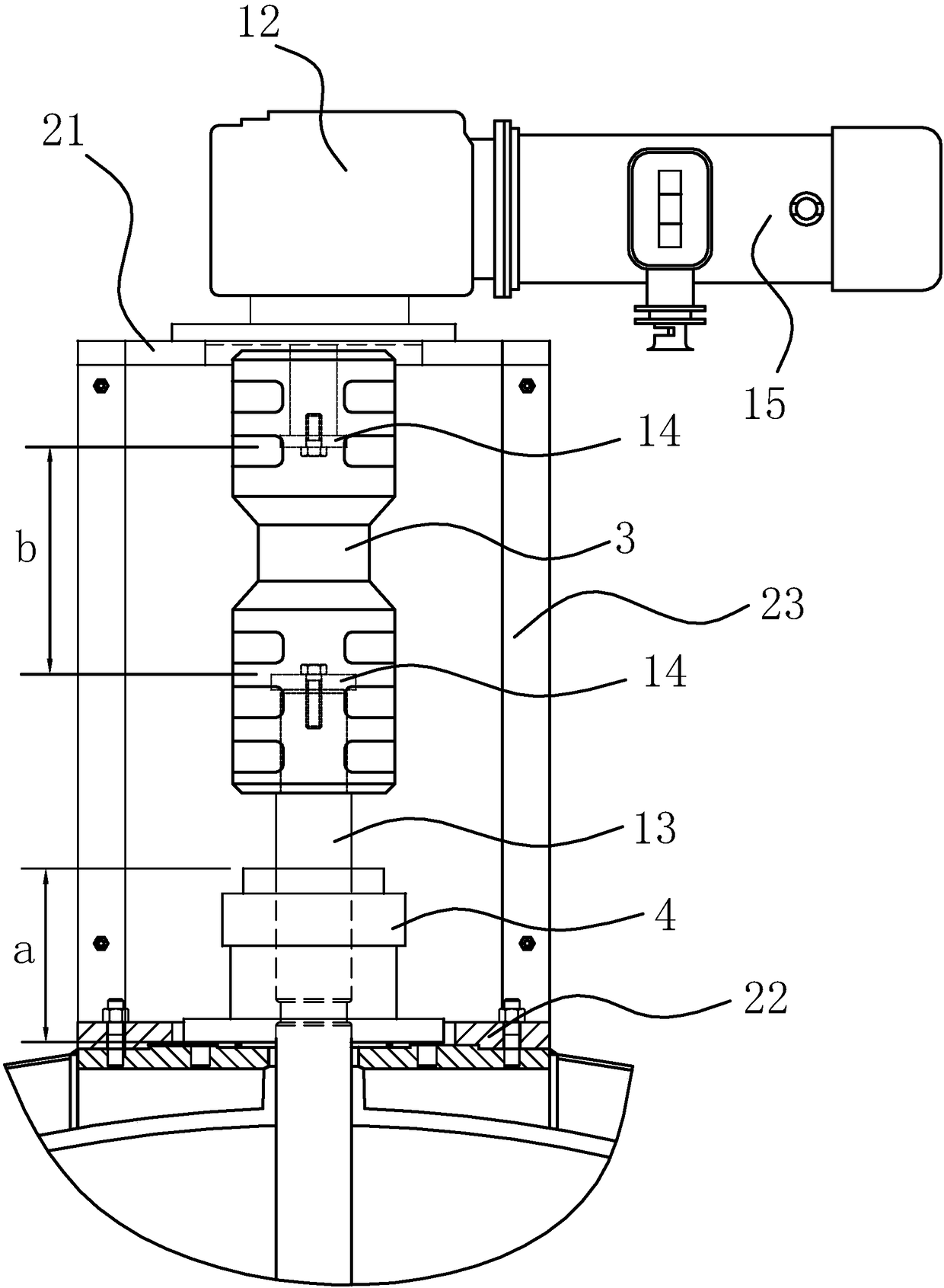

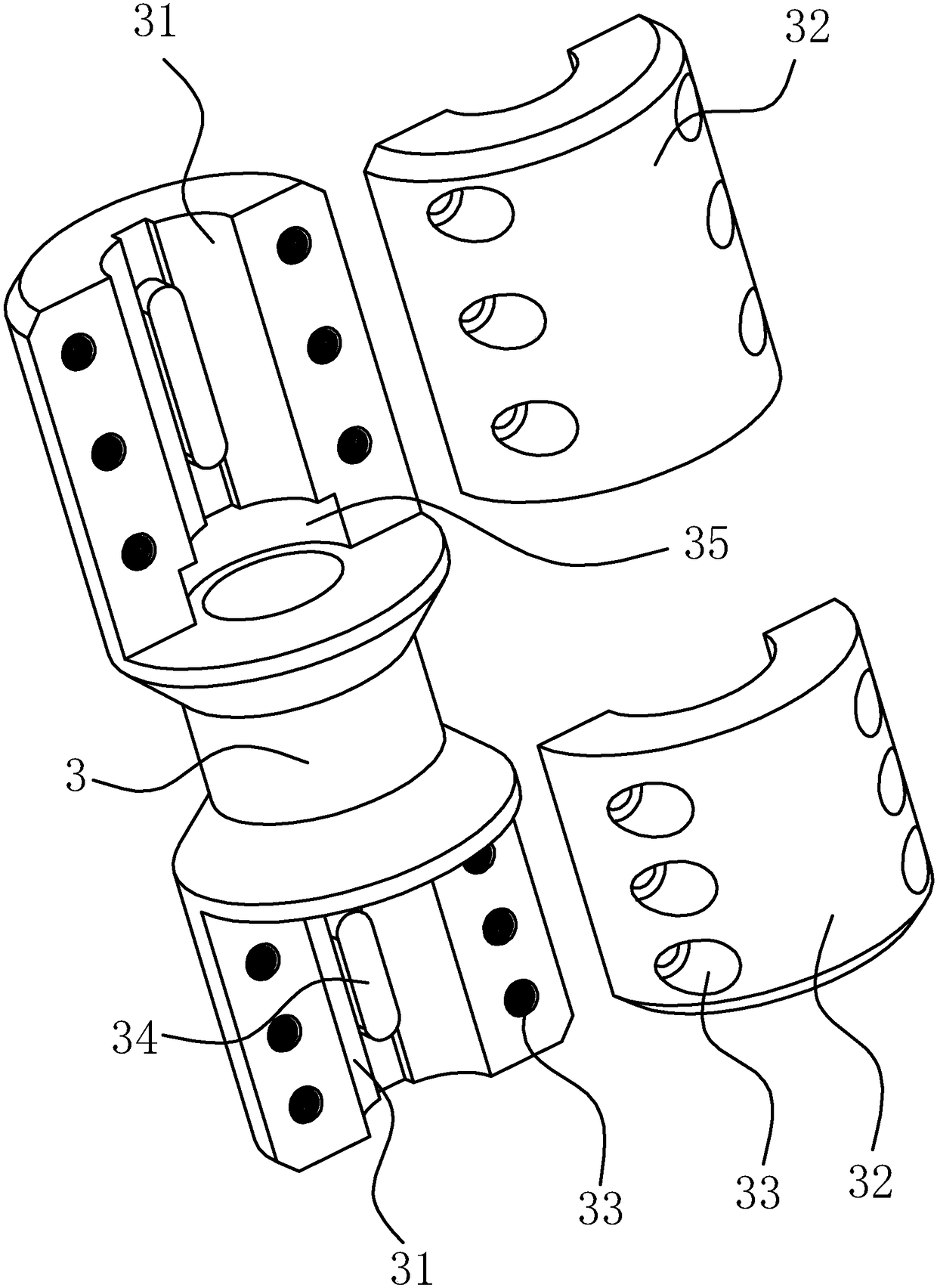

[0028] Such as figure 1 and figure 2 As shown, a stirred tank that is easy to replace the mechanical seal includes a kettle body 11, a frame 2 is arranged on the top of the kettle body 11, a reducer 12 is arranged on the frame 2, and the input end of the reducer 12 is connected with a The drive motor 15, the output end of the reducer 12 is located inside the frame 2. The kettle body 11 is provided with a stirring shaft 13 penetrating through the surface of the kettle body 11 , and a connecting piece 3 for power transmission is provided between the end of the stirring shaft 13 and the output end of the reducer 12 . The driving force of the driving motor 15 is decelerated by the reducer 12 and then transmitted to the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com