Microwave calcium carbide furnace reactor and method for preparing calcium carbide by using same

A microwave reaction and reactor technology, applied in the field of coal chemical industry, can solve the problems of difficult exhaust gas treatment, high power consumption, and high raw material requirements, and achieve the effects of improving effective utilization, reducing CO2 emissions, and increasing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

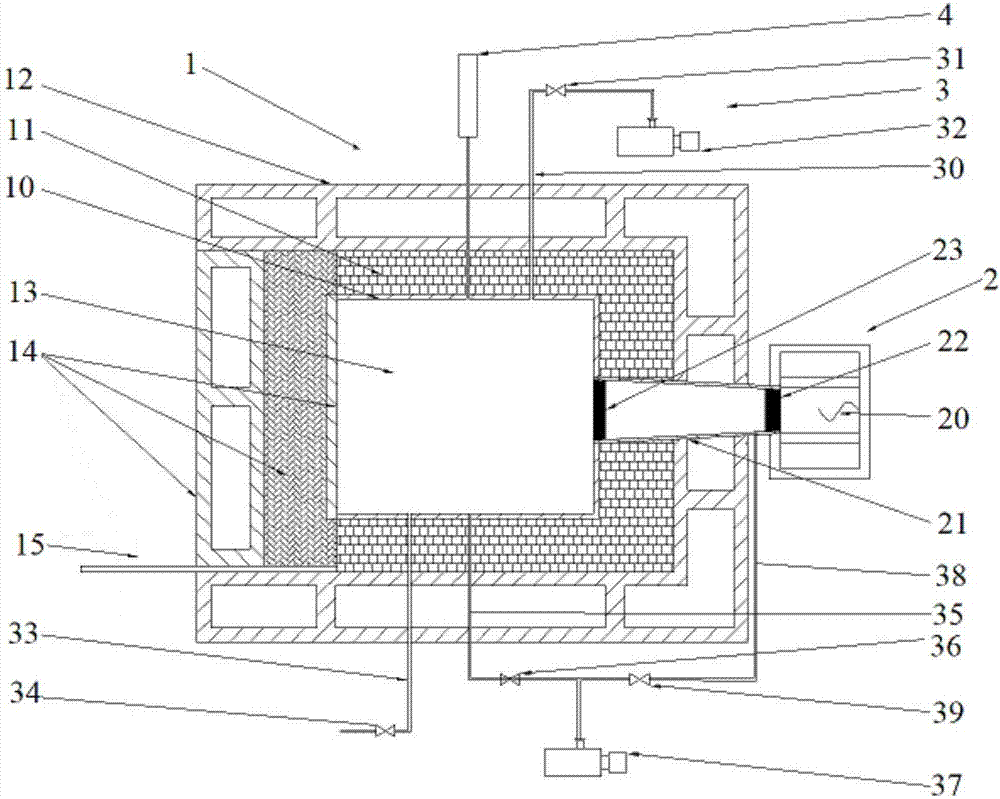

[0050] Such as figure 1 Shown is a microwave calcium carbide furnace reactor, including a microwave reaction furnace body 1, and the microwave reaction furnace body 1 includes a microwave energy gathering cavity 10, a shell 12, and an insulating layer 11 between the shell and the energy gathering cavity. A reaction chamber 13 for forming materials in the microwave energy gathering chamber 10; the energy gathering chamber is provided with an exhaust gas system 3 for providing an atmosphere for the reaction chamber 13 and simultaneously adjusting the pressure of the reaction chamber 13, and the energy gathering chamber is also provided with Temperature measurement and monitoring system 4;

[0051] It also includes a microwave energy generating system 2 for conducting microwaves in the energy-gathering cavity, that is, the reaction chamber 13; the microwave energy generating system 2 and the microwave energy-gathering cavity 10 are also connected to a water circulation cooling sy...

Embodiment 2

[0053] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the microwave energy-gathering cavity 10 is a fully-sealed graphite energy-gathering microwave resonator cavity, and the inner layer of the energy-gathering cavity is integrally formed with mirror graphite; the outer shell 12 is a fully-sealed stainless steel Outer chamber; the insulation layer 11 is made of alumina, zirconia, silicon oxide, monetite, graphite and other heat-resistant heat-insulating materials;

[0054] One side of the microwave reaction furnace body 1 is provided with the same furnace door 14 as a part of the furnace body structure; the furnace door 14 is welded on the furnace door trolley 15; the furnace door 14 is connected with the furnace body The flanges are used for compression connection between them, and when the furnace door is in the closed state, it forms an airtight whole with the same structure as the furnace body.

Embodiment 3

[0056] Such as figure 1 As shown, the present embodiment is based on Embodiment 1, and the microwave energy generating system 2 includes a microwave source, a circulator 20, and a waveguide 21 for microwave transmission; The window is sealed to prevent the high-temperature gas generated by the reaction from entering the waveguide 21 to cause ionization and cause adverse effects on the microwave energy generation system 2; one end of the window is connected to the microwave source, and the other end of the window is used as part of the inner wall of the energy-gathering cavity for conduction into the cavity microwave.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Gas output | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com