Vibration type multifunctional combined drying device capable of automatically controlling temperature and humidity

A multi-functional combination and drying device technology, applied in the direction of drying gas arrangement, non-progressive dryer, heating device, etc., can solve the problems of poor flexibility and poor drying uniformity, and achieve energy saving, fast drying and uniform drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

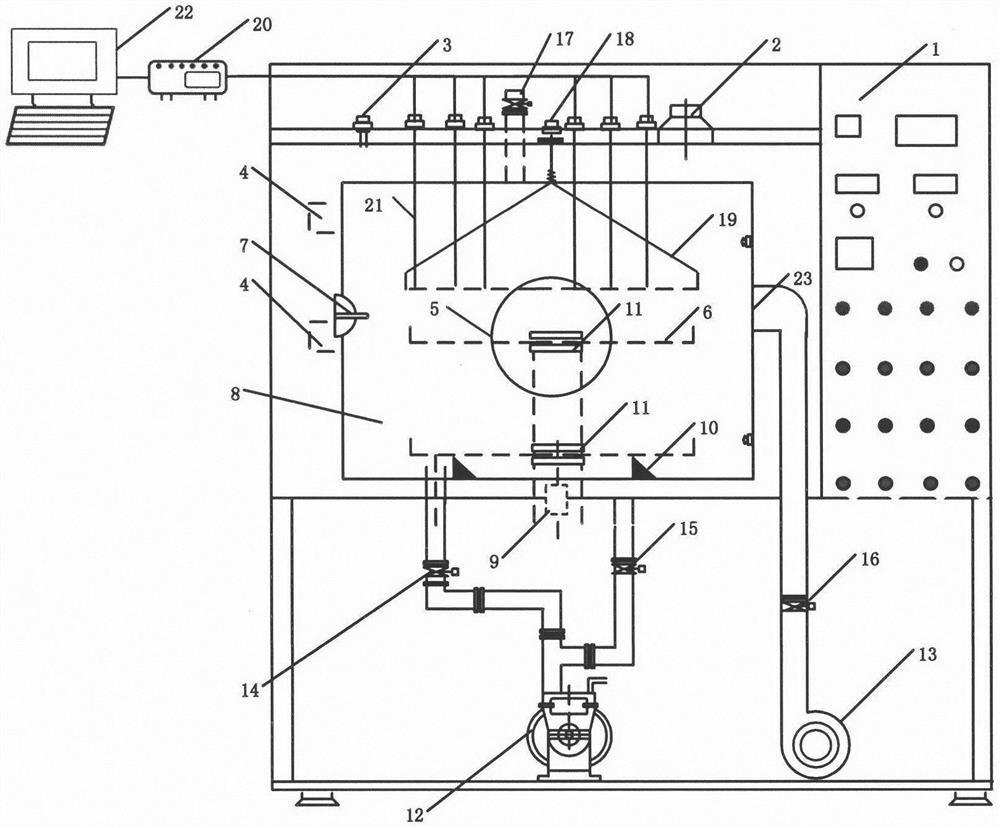

[0018] EXAMPLE 1: When the present invention works, the temperature controlled moisture wet system is connected to the computer. Taking vibratory vacuum microwave drying green peas as an example: first determined the water content of green peas by national standard method, and enter the measured sample water rate value on the computer. It is said that approximately 250 g of peas is placed in a dry cavity material tray 6, and the light probe 21 is inserted into the green pea, and the dry cavity door is closed. Real-time weight and internal temperature of the peas can be observed by the computer interface. At the beginning of the drying, the vacuum pump 12 is connected to the microwave drying chamber 8 by the suction line, and the electromagnetic valve 12 and the vacuum pump 12 are opened by the control device 1, and the vacuum pump 12 starts working and the dry cavity 8 is pulled into vacuum. State, vacuum pressure 50 kPa; adjustment power, microwave power 800W, the microwave magne...

Embodiment 2

[0019] Embodiment 2: Temperature controlling and moisture and moisture system is connected to the computer when the present invention works. Taking vibratory microwave coupling hot air dry corn grains as an example: first determined the moisture content of corn grains by national standard method, and enter the measured sample water rate value on the computer. It is called approximately 200 g of corn particles to be placed in the drying chamber material tray 6, and the light probe 21 is inserted into corn grains, and the dry cavity door is closed. The real-time weight and internal temperature of corn grains can be observed by the computer interface. At the beginning of the drying, the electromagnetic valve four 16, the hot air heat heating device 23 is opened by the control device 1; the adjustment temperature is 60 ° C, adjust the microwave power 700W, and the microwave magnetron 4 and the rotary device 9 are opened by the control device 1; through the position regulator 11 And th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com