Plate and frame and spiral wound membrane modules for heat and mass transfer

A technology of heat exchange membranes and membrane plates, which is applied in the field of membrane module manufacturing and layout, can solve the problems of not being able to easily modify changes or repair defects, increase system complexity and size, etc., to facilitate maintenance, reduce pipe connections and Overall size, easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

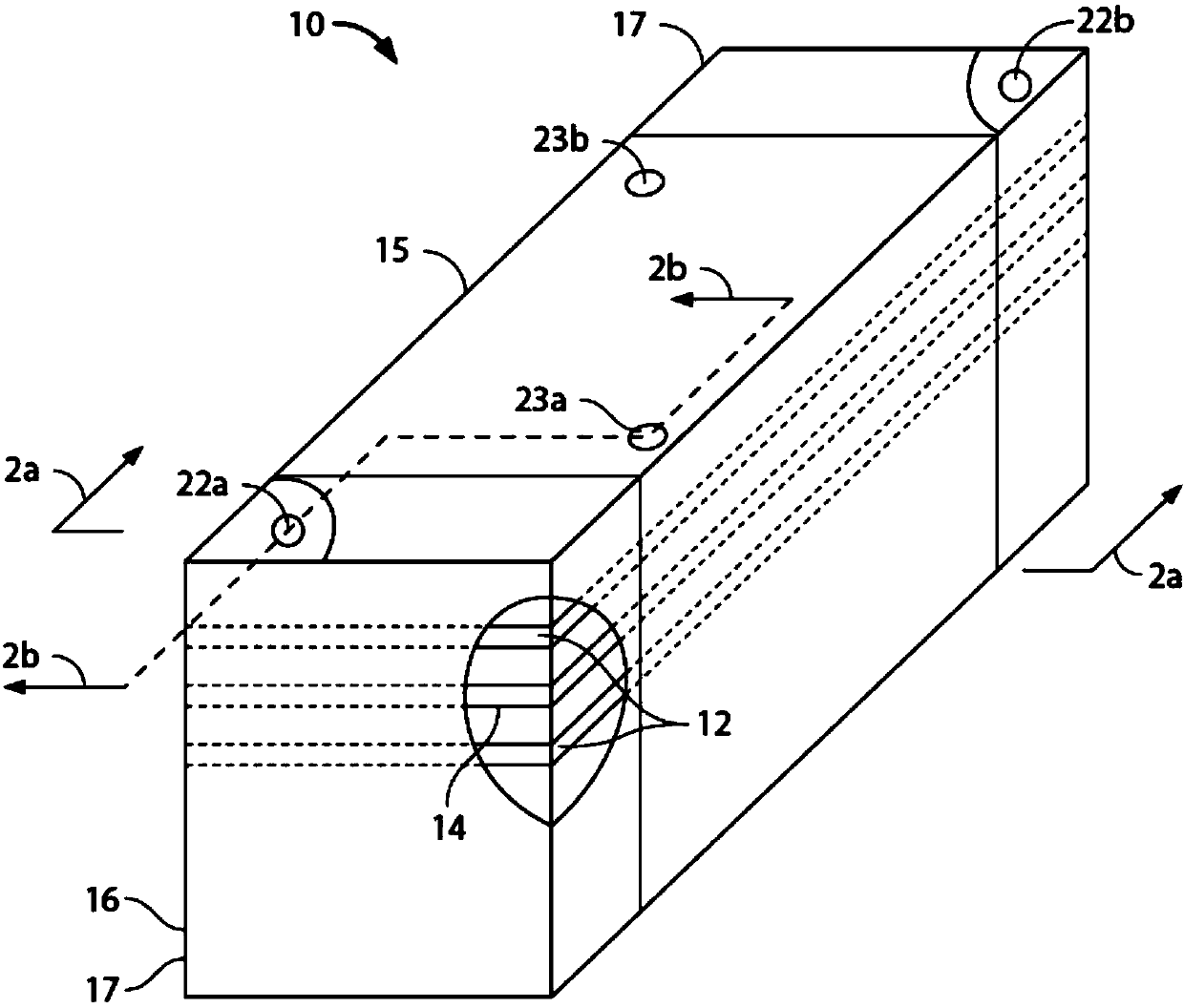

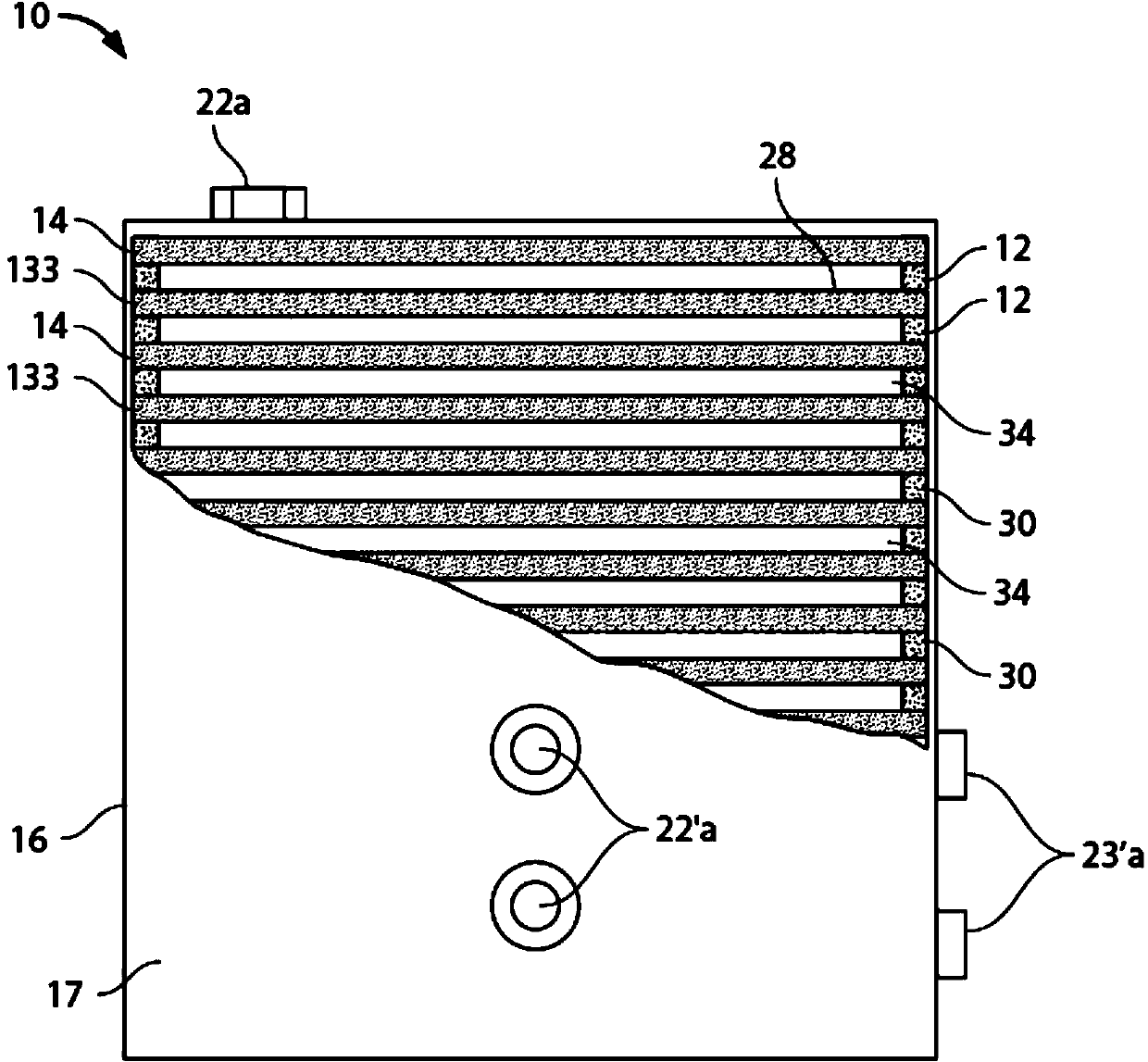

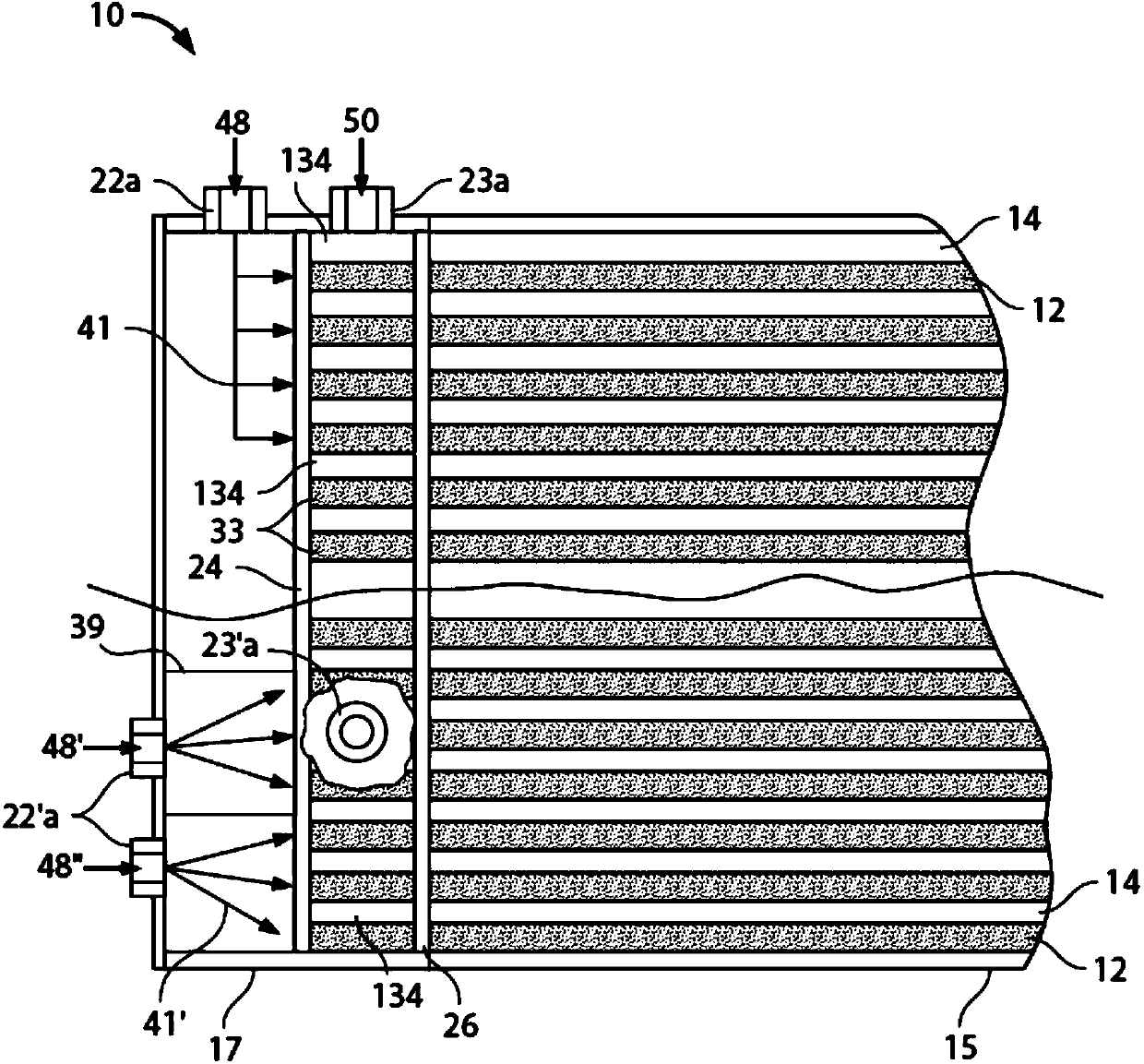

[0036] figure 1 A perspective view of a membrane module 10 according to one or more embodiments of the invention is shown. The module 10 has a plate-and-frame arrangement and includes a housing 16 and a plurality of diaphragms 12 , 14 arranged therein. It should be noted that there may be two or more different diaphragm configurations included in any given module to direct the flow of multiple streams through the module; however, the diaphragms may also differ in type to The uses perform different functions. For example, modules may include any combination of permeable membranes, vapor contacting membranes, and heat exchange membranes. In one embodiment, housing 16 includes a central body 15 and plugs 17 disposed on each end of body 15 . Such as figure 1 As shown, the housing 16 has a generally rectangular shape; however, other shapes are contemplated and contemplated within the scope of the present invention, eg, cylindrical with a domed plug, similar to a typical pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com