Cross-flow type air handling device

A cross-flow air and treatment device technology, applied in heating mode, air conditioning system, space heating and ventilation, etc., can solve the problem of low heat and mass transfer efficiency, complex structure of multi-stage dehumidification and regeneration device, and large solution temperature slip and other problems to achieve the effect of avoiding the decline of heat and mass transfer capacity, avoiding the entrainment of solution droplets, and being easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment, but present embodiment is not intended to limit the present invention, and every adopt similar structure of the present invention and similar change thereof, all should be included in the protection scope of the present invention.

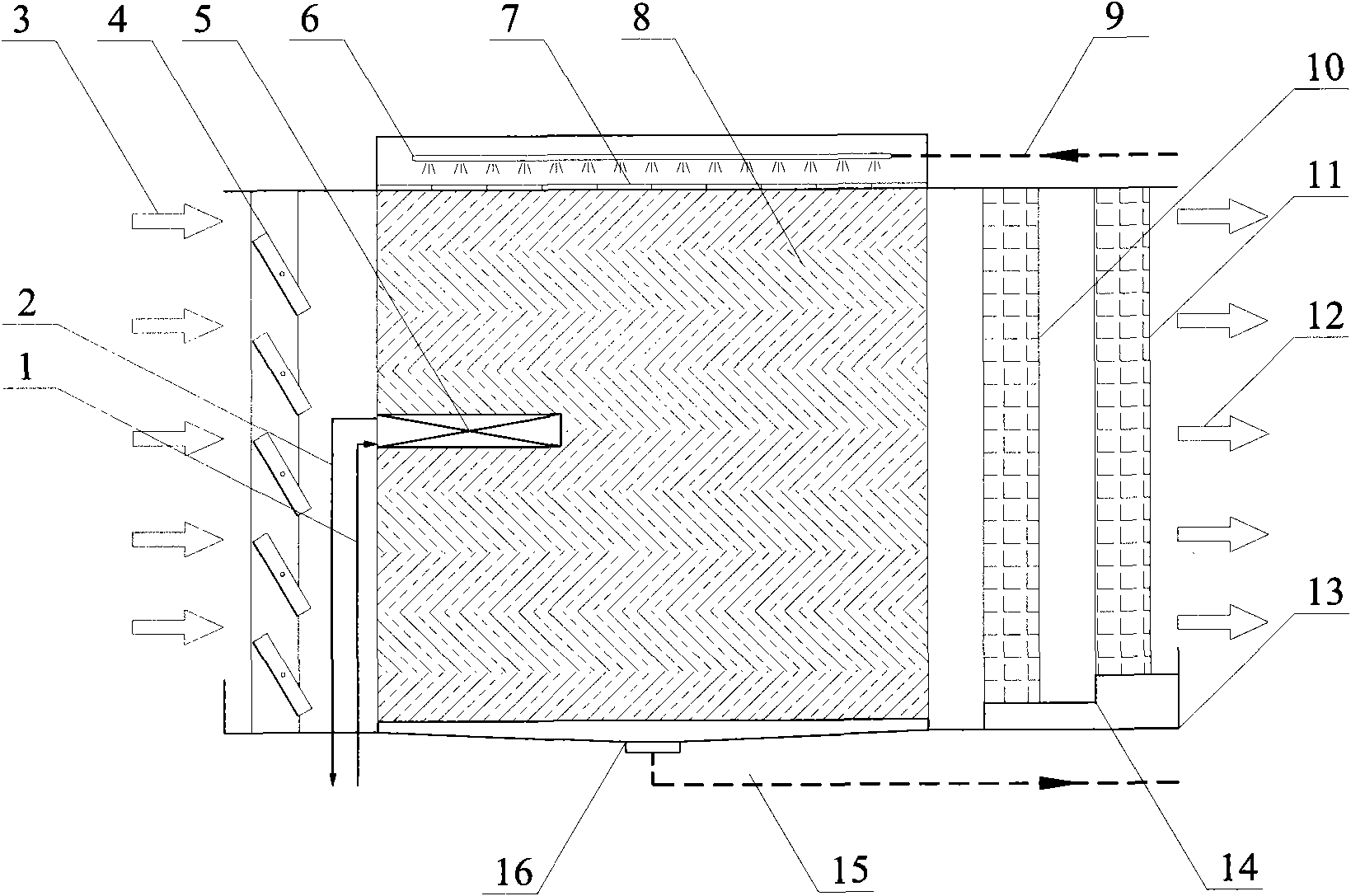

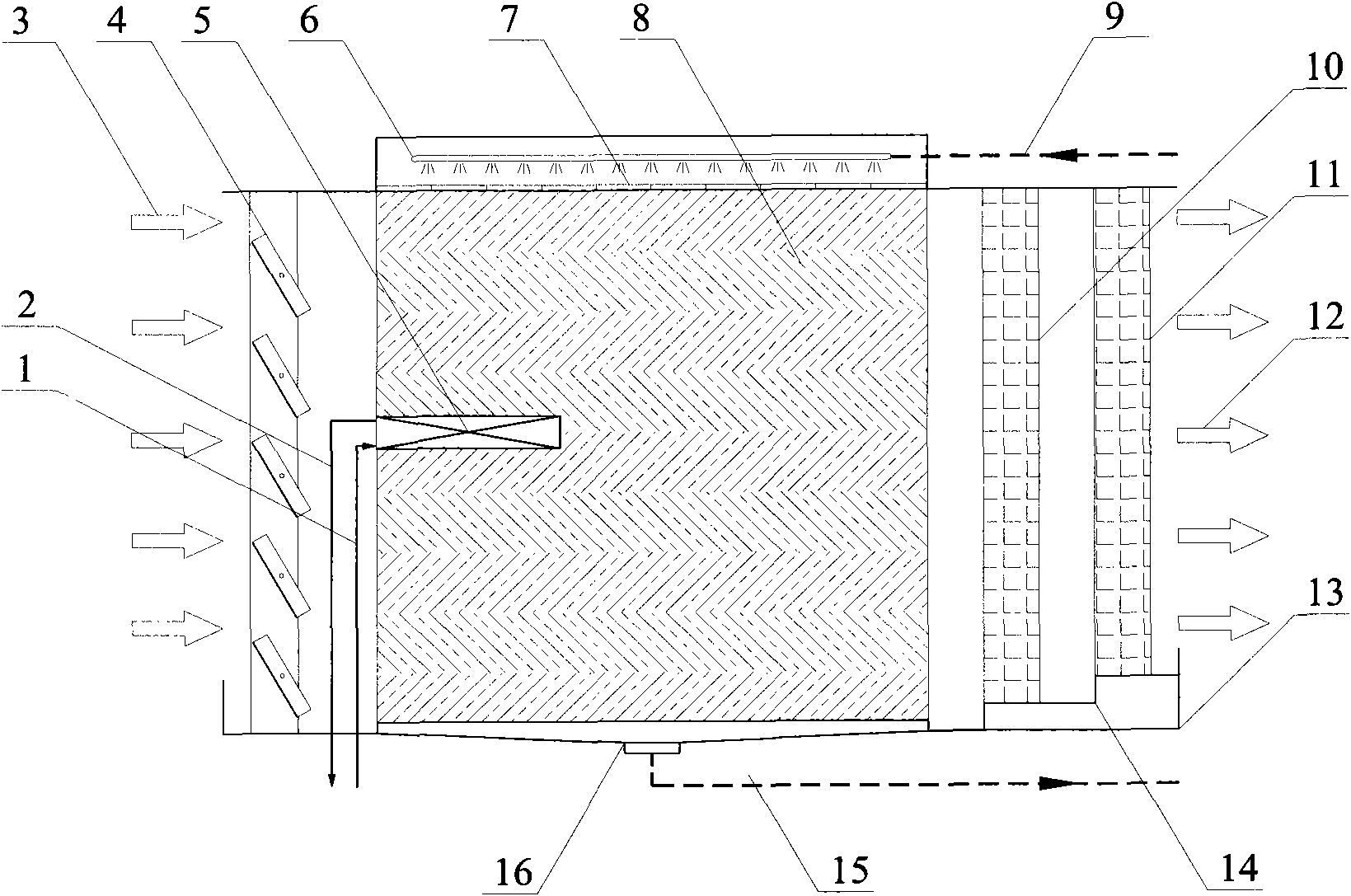

[0014] A cross-flow air treatment device, comprising: stagnant liquid louvers 4, packing layer 8, liquid distributor, defoaming layer and liquid collection tray 13, characterized in that: the air inlet 3 in front of the packing layer 8 is provided with blades for rotation Adjustable stagnant louvers 4, the primary effect defoaming layer 10 and the final effect defoaming layer 11 are arranged in sequence at the air outlet 12 behind the packing layer 8, and the primary liquid distributor 6 is arranged above the packing layer; the primary liquid distributor 6 It is connected with the solution inlet pipe 9, the final liquid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com