Method for producing coumarin intermediate through microreactor in pilot-plant-scale manner

A technology of microreactor and coumarin, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of many side reactions and low yield, and achieve good product quality, low energy consumption, The effect of high operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

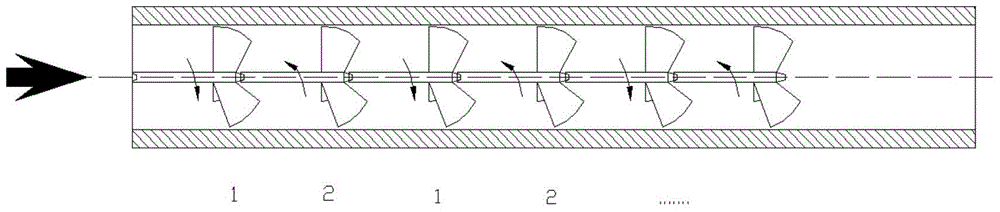

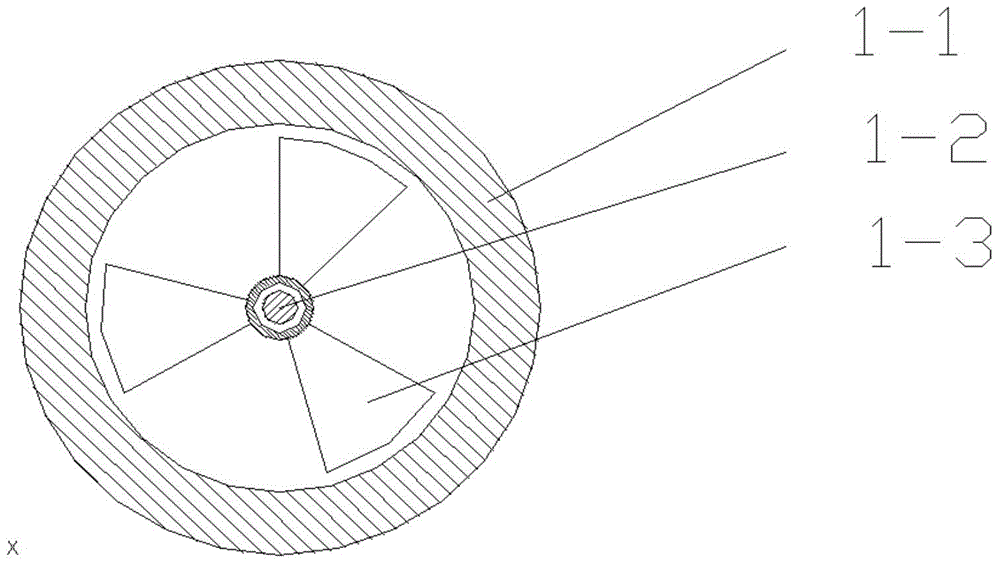

[0025] In the micro-reaction device, the diameter of the connecting pipe is 1cm, the length of the inlet pipe is 2m, the length of the connecting pipe between the T-shaped valve and the microchannel reactor is 3m, and the length of the connecting pipe between the microreactor and the outlet is 3m; The volume of the microchannel reactor is 250L.

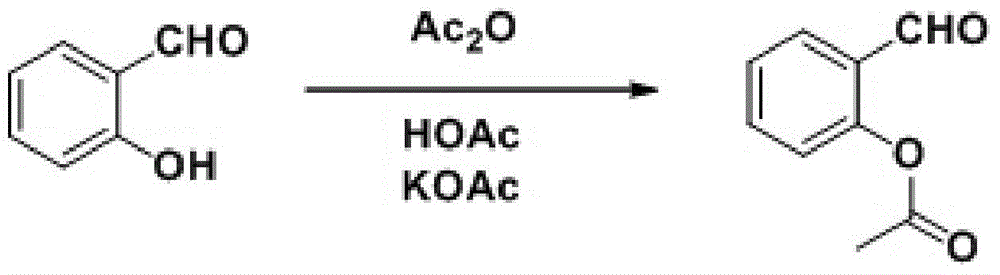

[0026] Weigh 40kg of salicylaldehyde and add it into container A; weigh 42kg and 5kg of acetic anhydride and acetic acid into container B, then weigh 1.9kg of potassium acetate and heat and stir until homogeneous. The two materials are mixed and pumped into the microchannel reactor through the T-valve. The reaction fluid of pump A flows through the microreactor at 10L / min, and the fluid of pump B flows through the microreactor at 15L / min. The reaction time is 10min, the temperature of the reactor is 160°C, and the crude product is collected through cooling at the outlet; the conversion is calculated by HPLC rate, the conversion rate ...

Embodiment 2

[0028] The micro-reaction device is basically the same as in Example 1, except that the diameter of the pipeline of this microchannel reactor is 1cm, the length of the liquid inlet pipe is 2m, and the length of the connecting pipe between the inlet and the microreactor is 3m , the length of the connecting pipe between the microreactor and the outlet is 3m; the volume of the microchannel reactor is 250L.

[0029] Weigh 40kg of salicylaldehyde and add it into container A; weigh 42kg and 5kg of acetic anhydride and acetic acid into container B, then weigh 1.9kg of potassium acetate and heat and stir until homogeneous. The two materials are mixed and pumped into the microchannel reactor through the T-valve. The reaction fluid of pump A flows through the microreactor at 20L / min, and the fluid of pump B flows through the microreactor at 30L / min. The reaction time is 5min, the temperature of the reactor is 140°C, and the crude product is collected after cooling at the outlet; the con...

Embodiment 3

[0031] The micro-reaction device is basically the same as in Example 1, except that the diameter of the pipeline of this microchannel reactor is 1cm, the length of the liquid inlet pipe is 2m, and the length of the connecting pipe between the inlet and the microreactor is 3m , the length of the connecting pipe between the microreactor and the outlet is 3m; the volume of the microchannel reactor is 250L.

[0032] Weigh 40kg of salicylaldehyde and add it into container A; weigh 42kg and 5kg of acetic anhydride and acetic acid into container B, then weigh 1.9kg of potassium acetate and heat and stir until it is homogeneous. The two materials are mixed and pumped into the microchannel reactor through the T-valve. The reaction liquid fluid of pump A flows through the microreactor at 13L / min, and the reaction liquid fluid of pump B flows through the microreactor at 20L / min. The reaction time is 7.6min, the reactor temperature is 140°C, and the crude product is collected after coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com