Solid hydrogen source device for hydrogen fuel

A hydrogen fuel, solid-state technology, applied in the installation device of container structure, fuel cell, fuel cell auxiliary, etc., can solve the problems of affecting kinetics, durability, slow hydrogen absorption and desorption, and achieve stable hydrogen supply pressure and The effect of flow, lower cost of use, easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

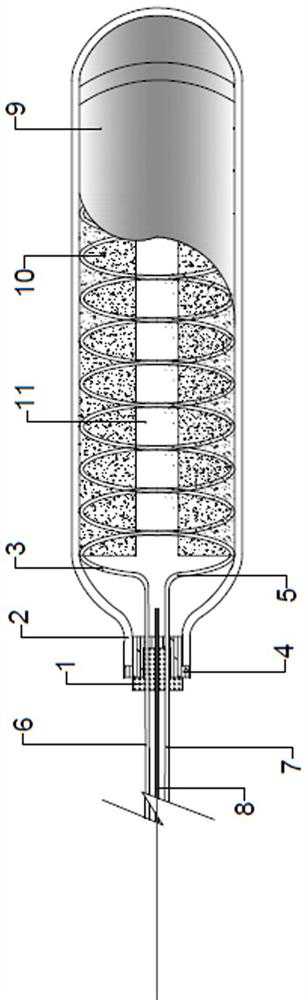

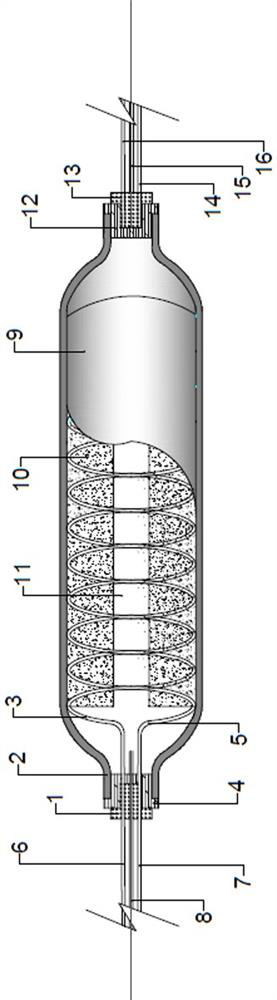

[0027] Such as figure 1 A solid hydrogen source device for hydrogen fuel is shown, which includes a hydrogen storage tank 9, a diaphragm and heat exchange pipes 3, 5, the hydrogen storage tank is a low-pressure hydrogen storage tank, and the material of the hydrogen storage tank is Lightweight aluminum alloy, the wall thickness of the hydrogen storage tank is 0.5 cm, wherein: one end of the hydrogen storage tank 9 is provided with a tank mouth 2, which is used to control the installation of the valve 1 that hydrogen enters the hydrogen storage tank 9 or discharges from the hydrogen storage tank 9 At the position of the tank mouth 2, a sealing ring 4 is installed between the valve 1 and the tank mouth 2; the heat exchange pipes 3, 5 are fixed on the inner wall of the hydrogen storage tank 9 in a double helix structure, and the heat exchange pipes 3, 5 are fixed on the inner wall of the hydrogen storage tank 9. The material of 5 is a copper tube with a diameter of 0.5 cm. The he...

Embodiment 2

[0030] Filling operation according to the mode of example one, the difference between the second embodiment and the first embodiment is that the material of the solid hydrogen storage alloy powder filled in the material bin 10 is different, and the material of the solid hydrogen storage alloy powder in the second embodiment is LaNi 4.85 al 0.15 Hydrogen storage alloy powder, the hydrogen storage capacity is 1.41 wt.% (mass percentage), the filling mass is 22 Kg, the particle size of the solid hydrogen storage alloy powder is 400 mesh, which can provide 0.2 MPa of hydrogen at 20 °C, With water as heat and mass transfer, when heated to 80°C, it can provide 5.6MPa of hydrogen.

Embodiment 3

[0032] Filling operation according to the mode of example one, the difference between the present embodiment three and the embodiment one is that the material of the solid hydrogen storage alloy powder filled in the material bin 10 is different, and the material of the solid hydrogen storage alloy powder in the present embodiment three is La 0.8 Ce 0.2 Ni 4.8 co 0.1 al 0.1 Hydrogen storage alloy, the difference is that the particle size of the solid hydrogen storage alloy powder is 300 mesh, the hydrogen storage capacity is 1.33 wt.% (mass percentage), and the filling quality is 18 Kg, which can provide 0.46 MPa at 20 °C Hydrogen, using oil as heat and mass transfer, can provide 10 MPa of hydrogen when heated to 125°C.

[0033] Comparing the results of the first to third examples above, it can be seen that the hydrogen capacity of the solid hydrogen source device provided by the present invention is mainly determined by the material of the filled alloy powder, and its hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com