Method for preparing palladium membrane module and application of palladium membrane module to reactor used for preparing hydrogen from methanol

A production method and component technology, applied in the production method and its application in the methanol hydrogen production reactor, can solve the problems of incomplete methanol reaction, poor heat and mass transfer effect of the reactor, and low catalyst use efficiency, so as to promote the production of methanol Complete reaction, improve methanol conversion efficiency, and improve the effect of low utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for making a palladium membrane module, comprising the following steps:

[0050] (1) Dissolve nickel salt and reducing agent in deionized water, add additives to adjust the pH to 5, and obtain solution A; the nickel salt is nickel chloride; the reducing agent is sodium hypophosphite; The mass ratio of agent and nickel salt is 3:1; Described auxiliary agent is acetic acid;

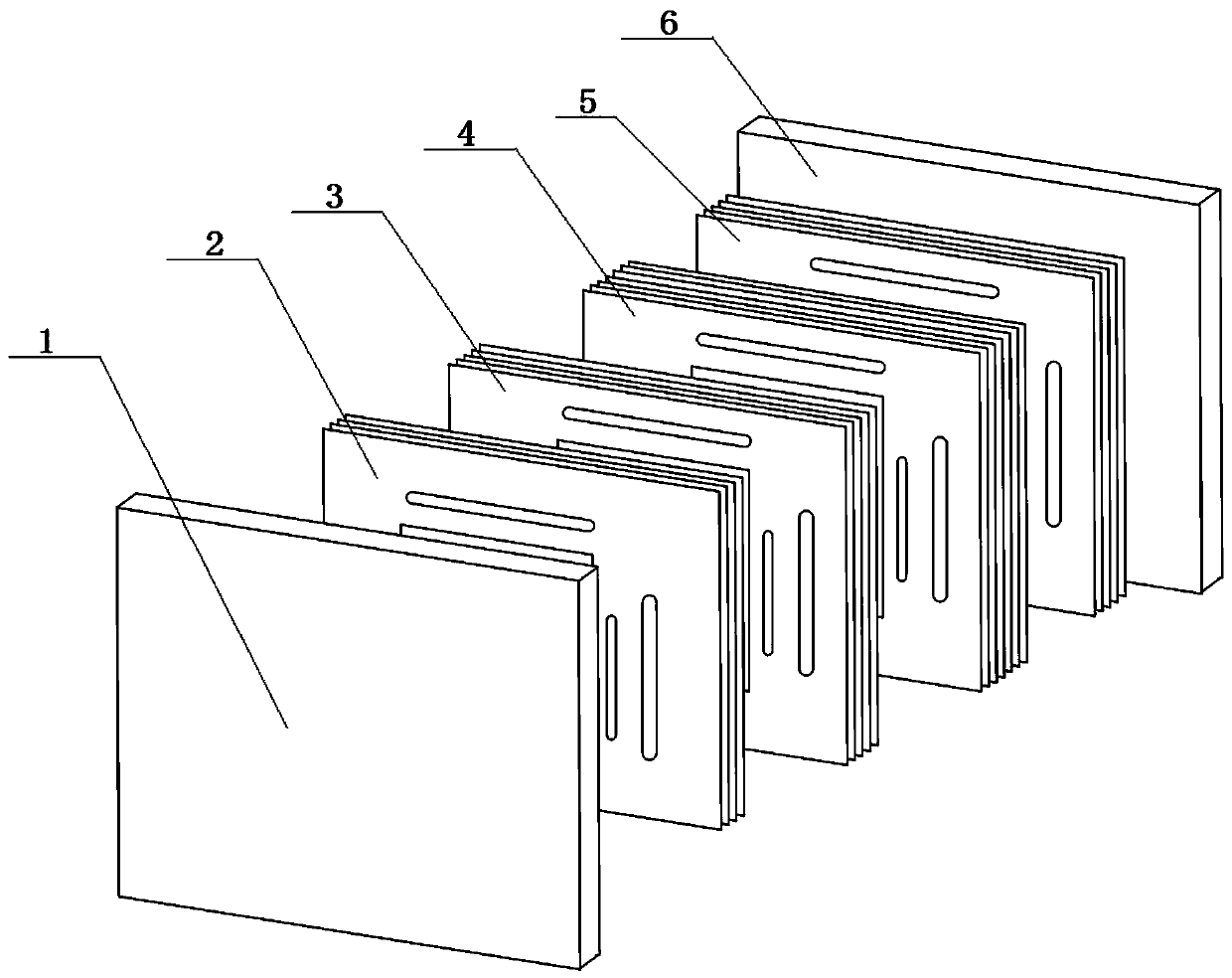

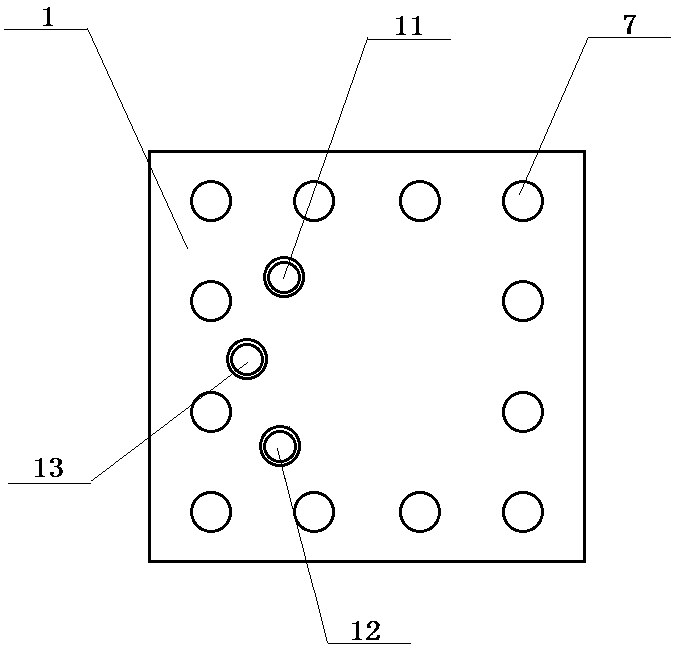

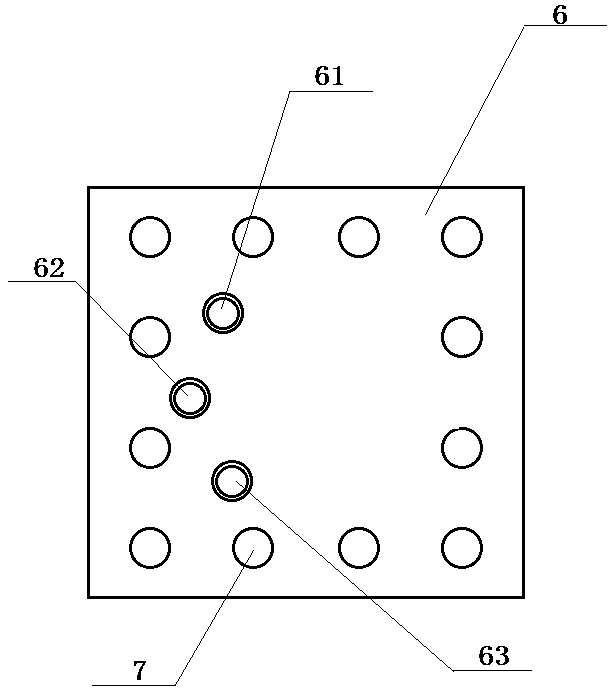

[0051] (2) Immerse the front of the structural support in the above solution A, heat at 60°C for 3h, then wash with deionized water, and dry it at 150°C for 18h before use; the structural support is a porous stainless steel material , and the structural support is a plate-like structure;

[0052] (3) Immerse the front side of the structural support treated in step (2) in a palladium salt solution, immerse at 10°C for 12h, then wash with deionized water, and dry at 150°C for 18h to obtain a palladium-coated film on one side A structural support body; the concentration of the palladium salt ...

Embodiment 2

[0064] A method for making a palladium membrane module, comprising the following steps:

[0065] (1) Dissolve the nickel salt and the reducing agent in deionized water, add an auxiliary agent to adjust the pH to 6, and obtain solution A; the nickel salt is nickel sulfate; the reducing agent is hypophosphorous acid; the reducing agent and The mass ratio of nickel salt is 1:1; The auxiliary agent is acetic acid-sodium acetate buffer solution and hydrochloric acid;

[0066] (2) Immerse the front of the structural support in the above solution A, heat at 70°C for 4h, then wash with deionized water, and dry it at 200°C for 24h before use; the structural support is a porous stainless steel material , and the structural support is a tubular structure;

[0067] (3) Immerse the front side of the structural support treated in step (2) in a palladium salt solution, immerse at 30°C for 14h, then wash with deionized water, and dry at 200°C for 24h to obtain a palladium-coated film on one ...

Embodiment 3

[0079] A method for making a palladium membrane module, comprising the following steps:

[0080] (1) Dissolving nickel salt and reducing agent in deionized water, adding additives to adjust the pH to 5, and obtaining solution A; the nickel salt is nickel nitrate; the reducing agent is potassium hypophosphite and sodium phosphite; The mass ratio of described reductant and nickel salt is 10:1; Described auxiliary agent is citric acid and sulfuric acid;

[0081] (2) Immerse the front side of the structural support treated in step (2) in the above solution A, heat at 80°C for 2 hours, then wash with deionized water, and dry at 90°C for 18 hours before use; the structural support The body is a porous material of porous ceramics, and the structural support is a plate-like structure;

[0082] (3) Immerse the side of the structural support that has been treated in step (2) in the palladium salt solution, and at the same time add silver nitrate solution to the palladium salt solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com