Equipment for promoting heat and water transfer on surface of wood

A wood surface and wood technology, applied in the wood drying process to promote wood heat and moisture transfer, wood drying equipment and drying fields, can solve problems such as high energy consumption, moisture and heat transfer obstacles, and long drying cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] 1. Pretreatment of wood to be dried

[0130] The Chinese fir raw wood is made into a thickness of 2-6cm, preferably 4cm; a length of 6-7.9m, preferably 7.5m, to be dried, and it is set aside; wherein, the thickness of the Chinese fir board is the same.

[0131] 2. Feeding

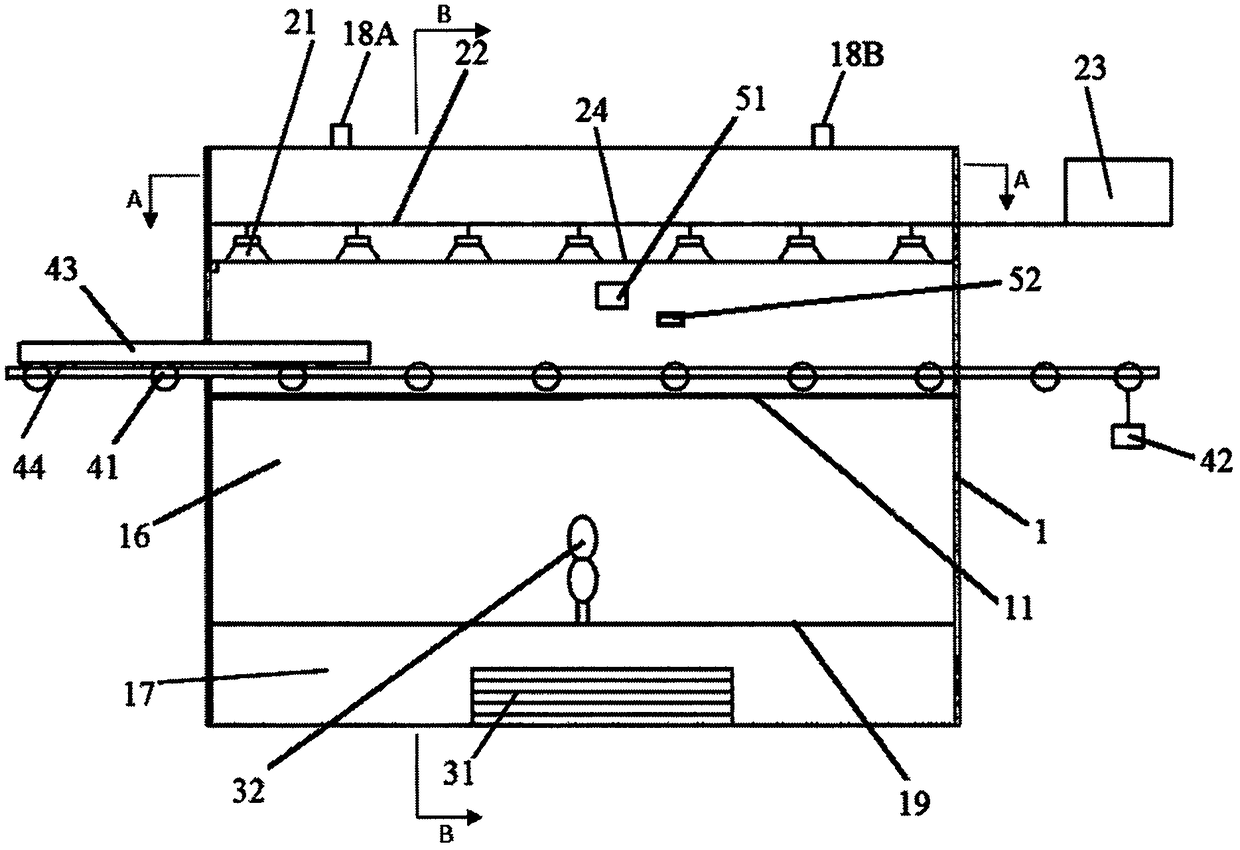

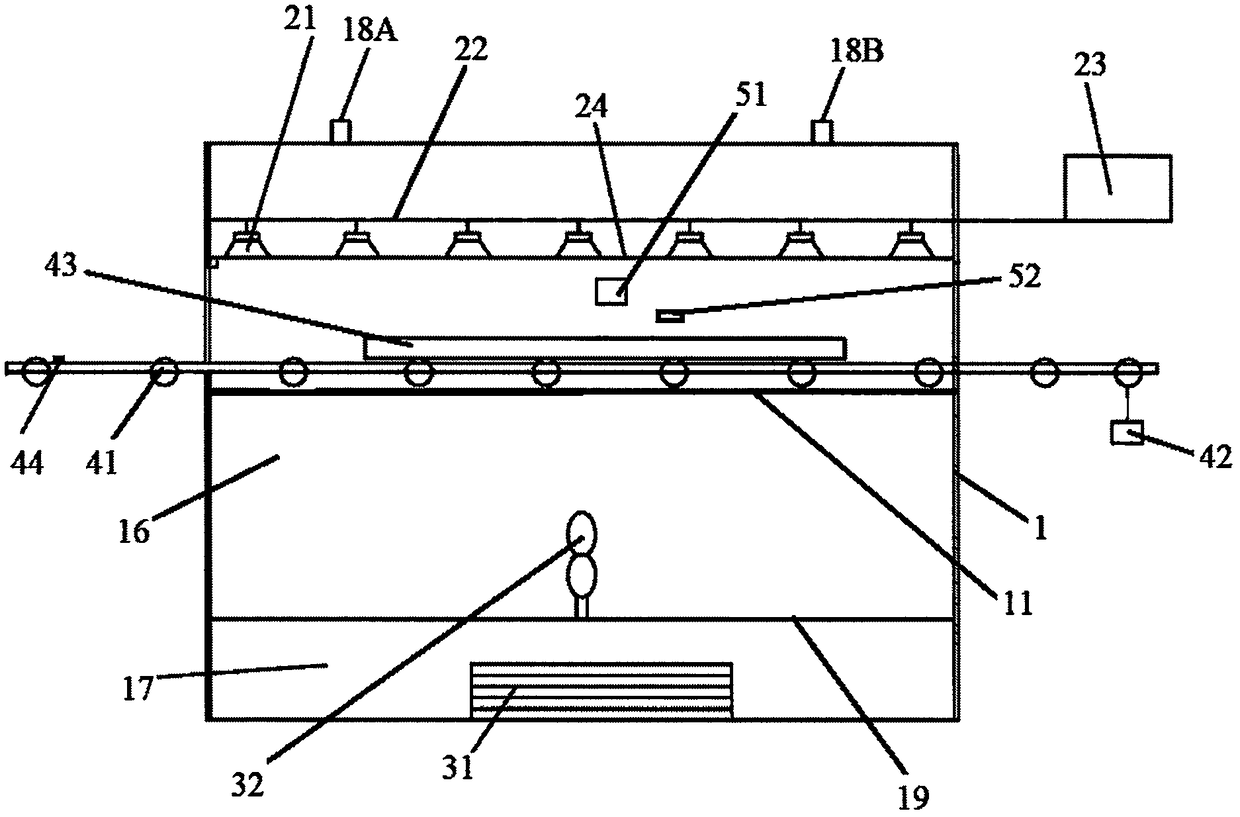

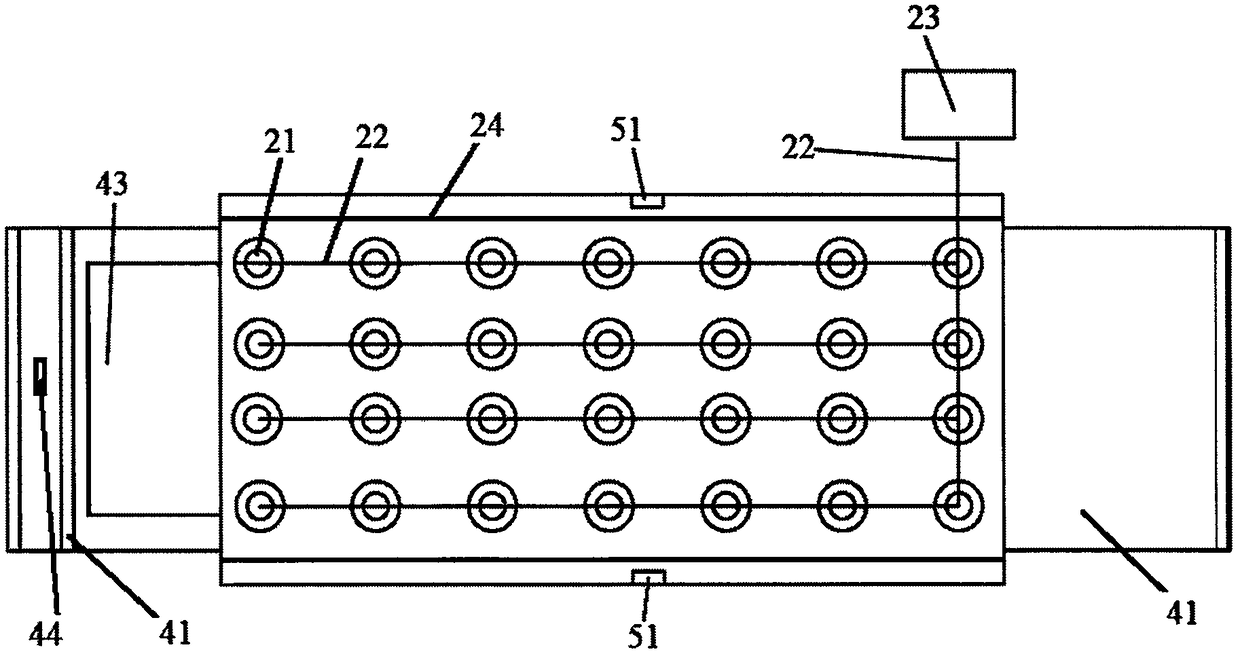

[0132] The wood is placed on the rollers at the input end of the roller conveyor of the wood transport device through the wood loading and unloading device. The electric switch set between the two rollers at the input end of the roller conveyor is pressed by the wood and turned on, and the driving motor is started to drive the rollers to run. The wood is transported into the drying room from the entrance door on the left side of the drying room. When the wood enters the drying room through the entrance door, the wood blocks the infrared rays of the infrared transmitter A of the infrared monitor A installed on both sides of the entrance door, resulting in The infrared receiver A cannot receive the in...

Embodiment 2

[0146] 1. Pretreatment of wood to be dried

[0147] The Chinese fir raw wood is made into a thickness of 4cm; the length is 7.5m to be dried, and it is set aside; wherein, the thickness of the Chinese fir board is the same.

[0148] 2. Measure the dry and wet bulb temperature of the drying medium, and calculate the relative humidity of the drying medium (ψ 介 )

[0149] The wood is automatically sent into the drying kiln through the transport device. When the infrared receiver A of the infrared monitor A can receive the signal from the transmitter A, the drive motor is turned off through the automatic control system, and the wood stops moving forward. At the same time, the heater and circulation are turned on. The fan heats the wood in the drying kiln, and controls the temperature of the drying medium in the drying kiln to be 50°C; and measures the dry and wet bulb temperatures of the drying medium in the drying kiln through the temperature sensor 51 installed in the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com