Device for heat and mass transfer and reaction of high-viscosity materials

A material and high viscosity technology, applied in induction heating devices, induction heating, chemical/physical processes, etc., can solve the problems of low material surface renewal frequency, small material evaporation or vaporization interface, and high viscosity, and increase the effective heat transfer area. , highlight the performance of energy saving and power saving, and accelerate the effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

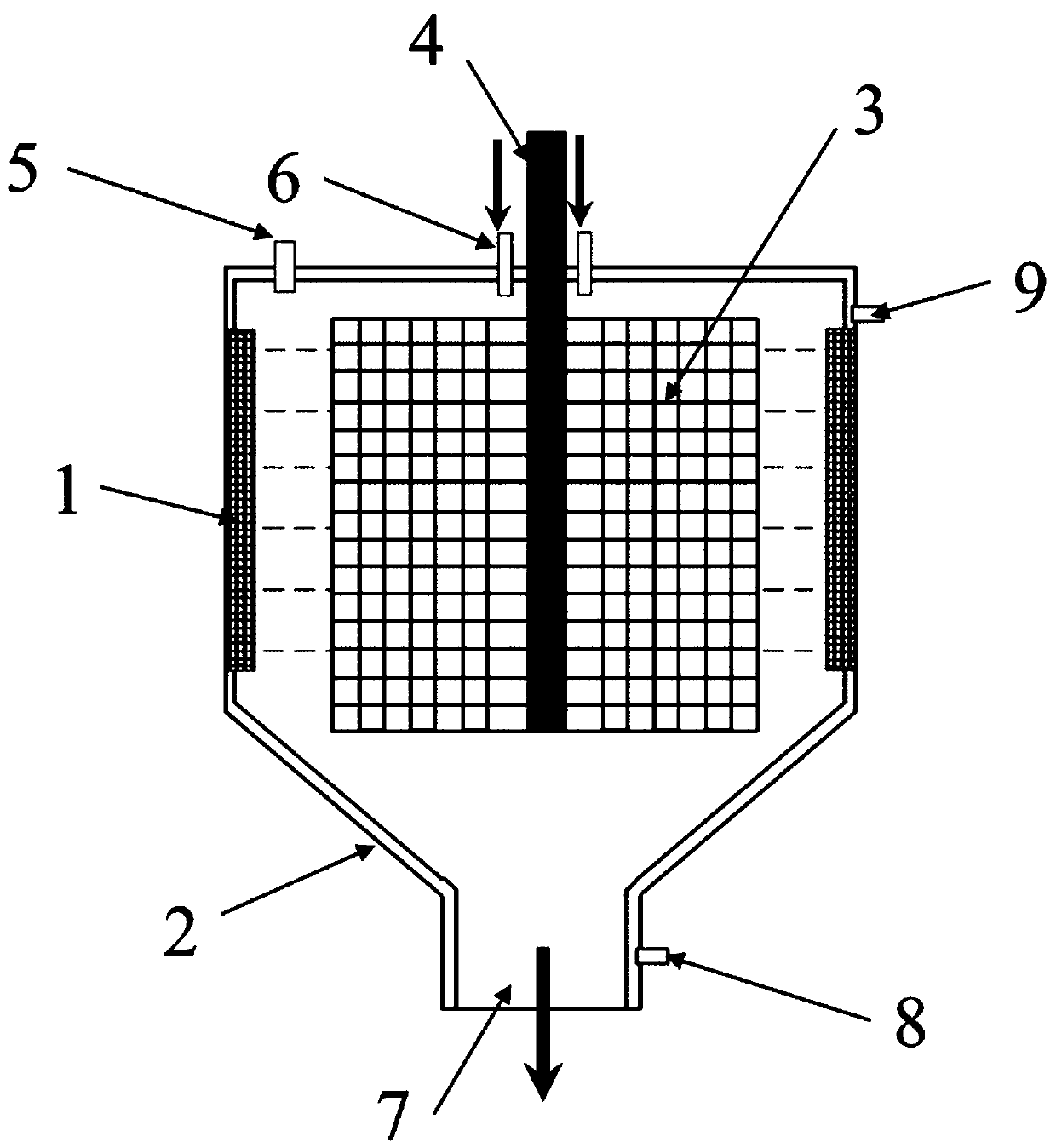

[0023] Such as figure 1 As shown, a mass transfer device for highly viscous materials includes a magnetic generator 1 that can generate a magnetic field for heating, a housing 2 for accommodating materials and installing a magnetic generator, a dispersion assembly 3 for mass transfer, and The hollow shaft 4 that drives the rotation of the dispersing assembly, the dispersing assembly contains metal. The shell is a jacket shell, with a material inlet 6 on the upper part, a material outlet 7 on the lower opening, a vacuum pump interface 5, a jacket circulating fluid inlet 8 and a jacket circulating fluid outlet 9. The hollow shaft is vertically arranged at the center of the housing, the upper end is rotatably connected to the housing, and the lower end is suspended in the housing 2 . The magnetic generator is located inside the casing, and the magnetic generators are arranged opposite to each other left and right.

[0024] The material is injected into the device from the mater...

Embodiment 1

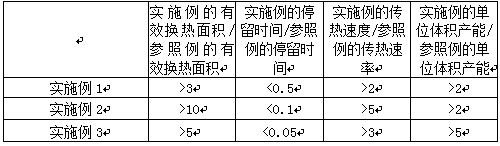

[0027] Keeping the test material, heating medium and test conditions unchanged, the test results of the ordinary scraped film evaporator are used as the reference group.

[0028] This embodiment can at least increase the effective heat transfer area by more than 3 times, shorten the residence time by more than one time, greatly increase the renewal frequency of the material surface, make the material evaporation or vaporization interface too small, increase the heat transfer rate by more than one time, and within a unit volume of equipment Production capacity increased by more than 2 times.

Embodiment 2

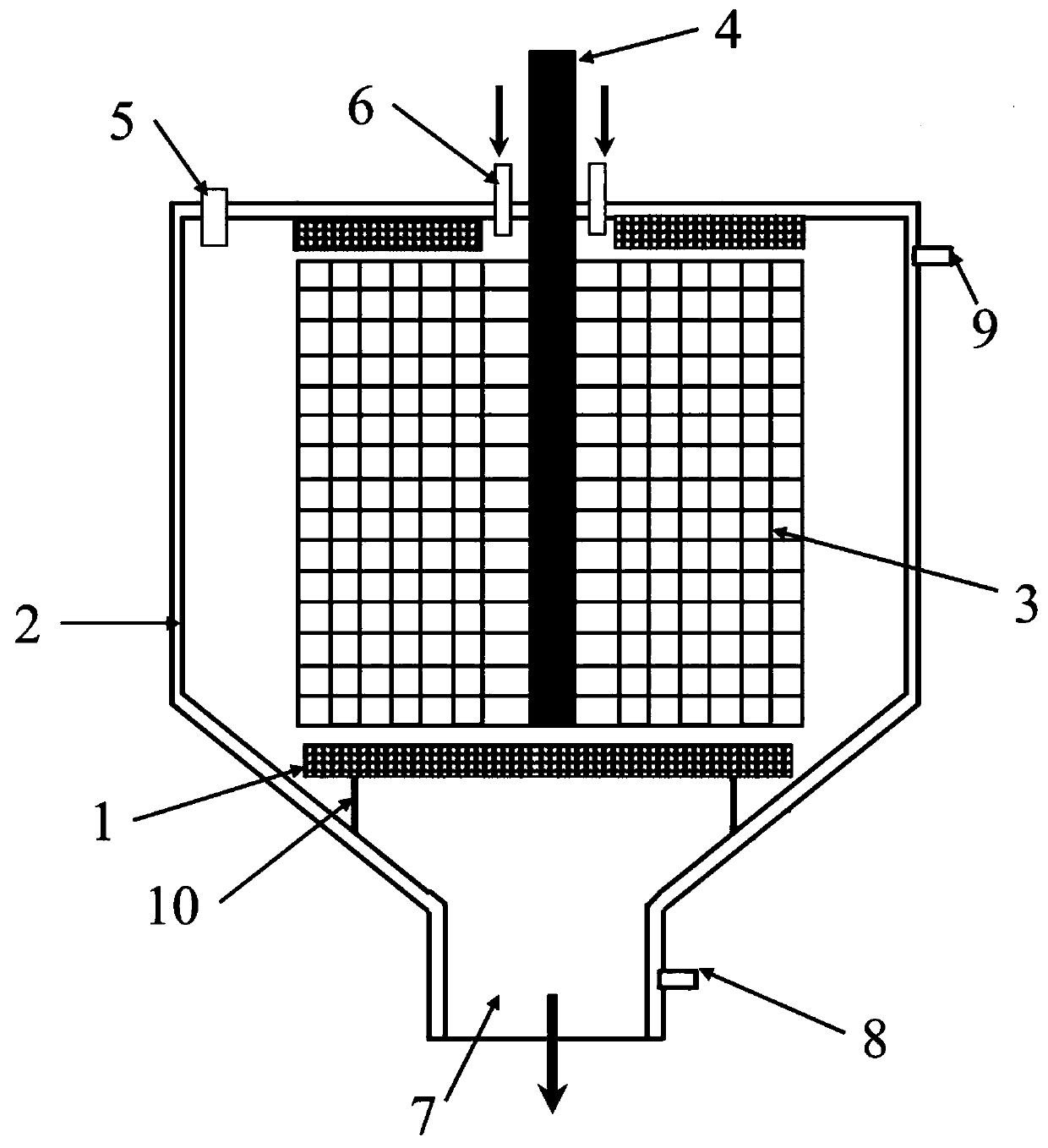

[0030] Such as figure 2 As shown, a mass transfer device for highly viscous materials includes a magnetic generator 1 that can generate a magnetic field for heating, a housing 2 for accommodating materials and installing a magnetic generator, a dispersion assembly 3 for mass transfer, and The hollow shaft 4 that drives the rotation of the dispersing assembly, the dispersing assembly contains metal. The shell is a jacket shell, with a material inlet 6 on the upper part, a material outlet 7 on the lower opening, a vacuum pump interface 5, a jacket circulating fluid inlet 8 and a jacket circulating fluid outlet 9. The hollow shaft is vertically arranged at the center of the housing, the upper end is rotatably connected to the housing, and the lower end is suspended in the housing 2 .

[0031] The magnetic generator is located inside the housing, and the magnetic generator is arranged facing up and down. The magnetic generator at the upper end is divided into two parts and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com