Lifting control device with skip emptying function

A technology of control devices and skips, which is applied to lifting equipment, elevators, transportation and packaging in mines, to achieve the effects of eliminating lifting intermittent time, improving safety production capacity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

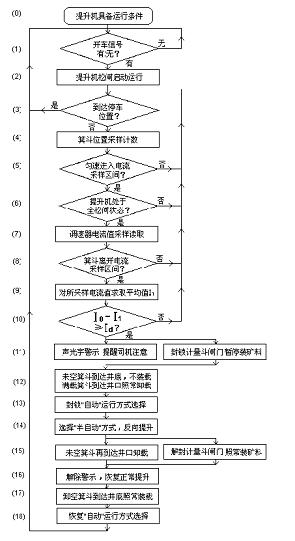

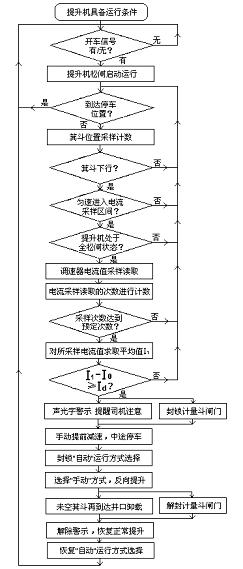

[0028] Embodiment of the present invention is described in conjunction with accompanying drawing:

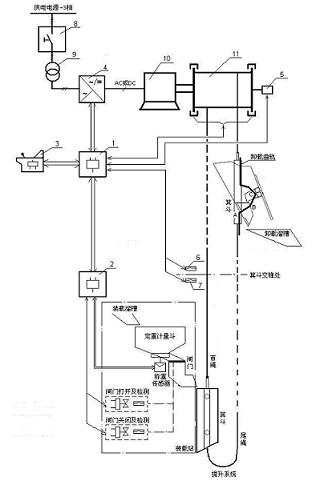

[0029] Such as figure 1 As shown, a lifting control device with the function of ensuring skip emptying, the lifting control device includes an operation control system for automatically controlling the operation process of the lifting system, for supplying power to the motor 10, and controlling the hoist 11, a speed regulating system for adjusting and controlling the operating speed and a monitoring system for operating and monitoring the operation process of the lifting control device; the operation control system includes a main controller 1, a loading station controller 2, installed in The sensor on the hoist 11 and the position detection device for detecting the actual position of the skip; the loading station controller 2, the sensor and the position detection device are respectively connected with the main controller; The switchgear 8 connected with the switchgear 8, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com