Patents

Literature

41results about How to "Improve safety production performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

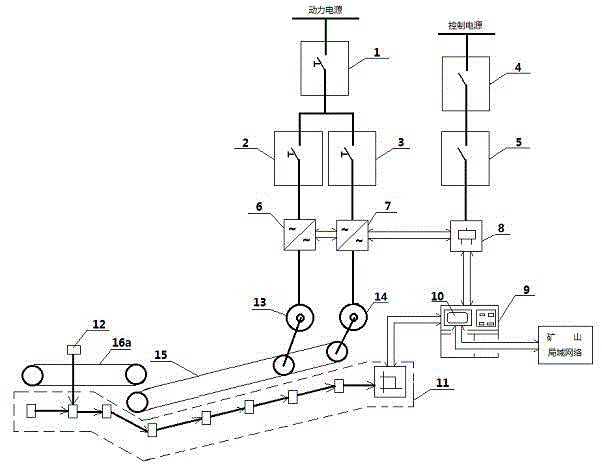

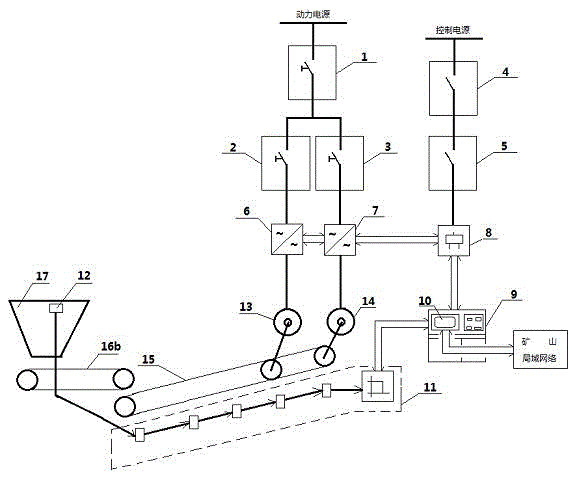

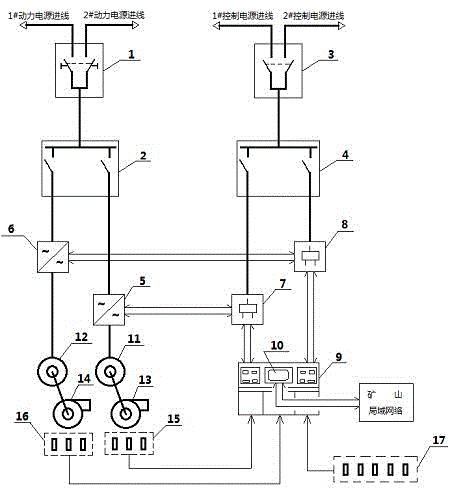

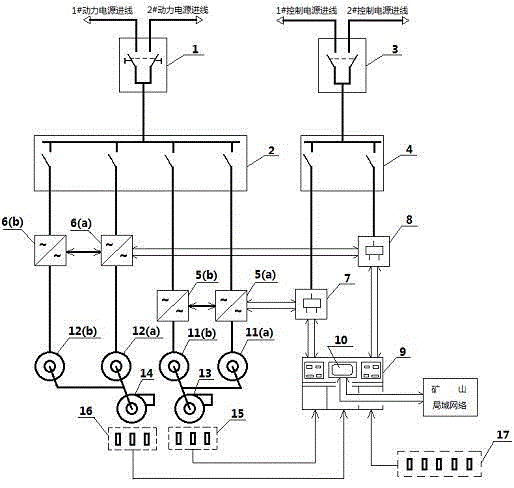

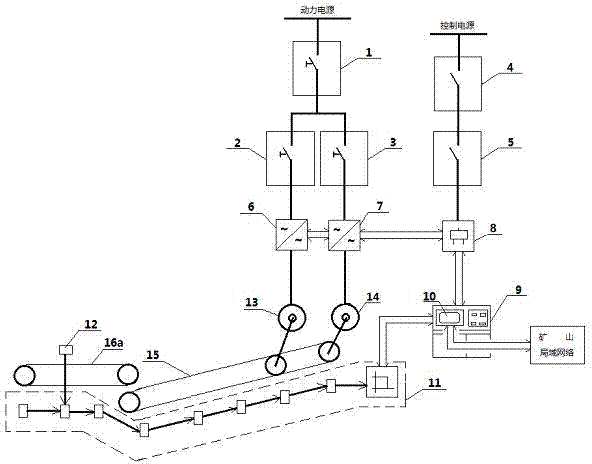

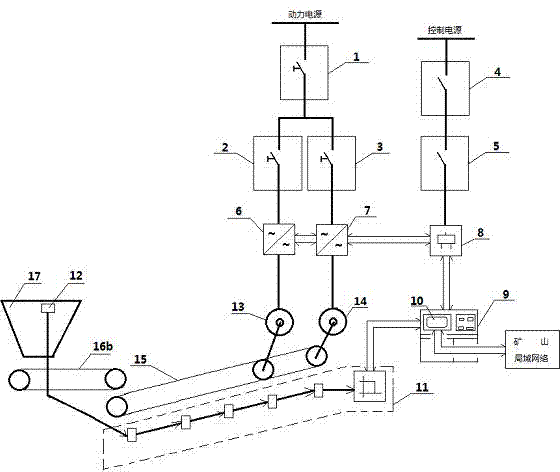

Belt conveyor control system and method capable of adjusting belt speeds automatically according to material flows or material levels

ActiveCN102942039AExtend your lifeReduce usage costsControl devices for conveyorsFrequency changerProgrammable logic controller

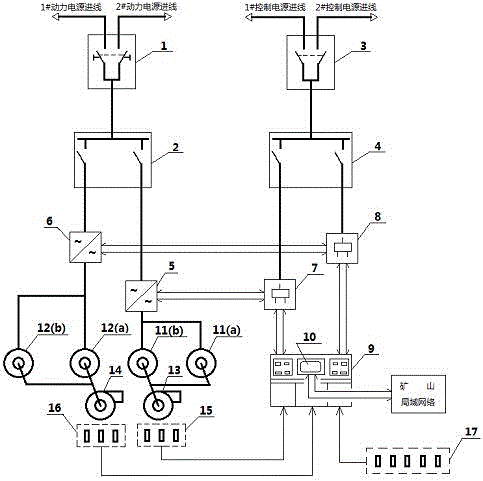

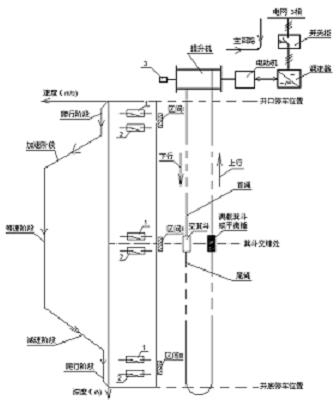

The invention provides a belt conveyor control system capable of adjusting belt speeds automatically according to material flows or material levels, and belongs to the belt conveyor control technology. The control system comprises a frequency conversion system, a programmable logic controller (PLC) system, a monitoring system and a detection system. The frequency conversion system comprises a power wire inlet device, a power feed device and a frequency converter. The PLC system comprises a power wire inlet control device, a power feed control device and a PLC device. The monitoring system comprises an operation platform and a display screen. The detection system comprises a material sensor which can use a contactless sensor. The control system sets the operation speed of a belt conveyor reasonably according to material flows or material levels and the operation state of a front conveyor and in additional conditions of time and motor currents, and the belt speed is adjusted by the controlling of the output frequency of the frequency converter.

Owner:SHANXI SANYUAN COAL IND +1

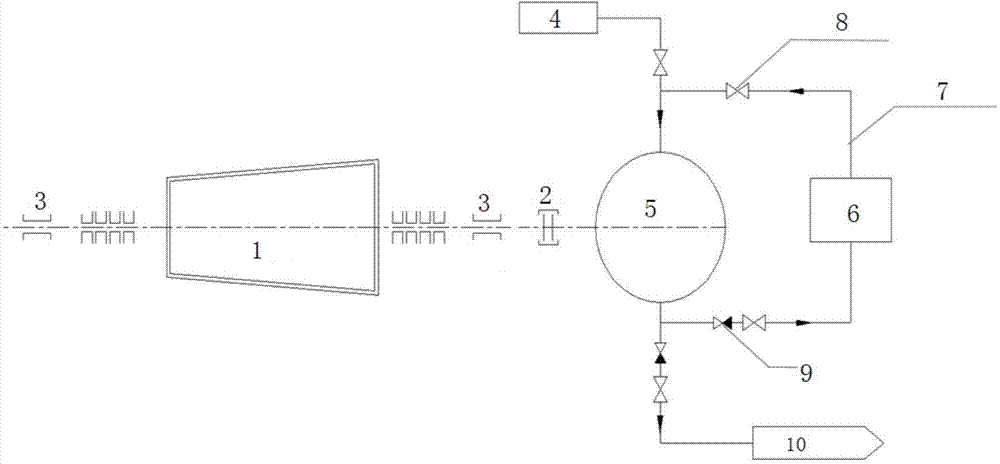

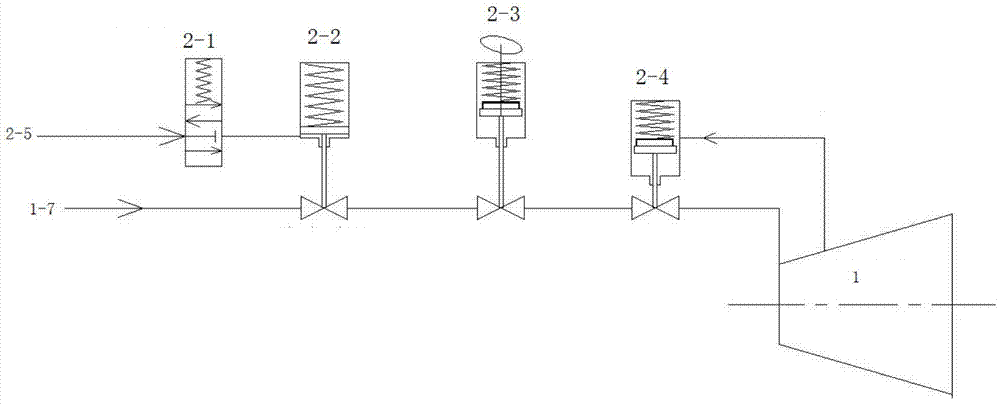

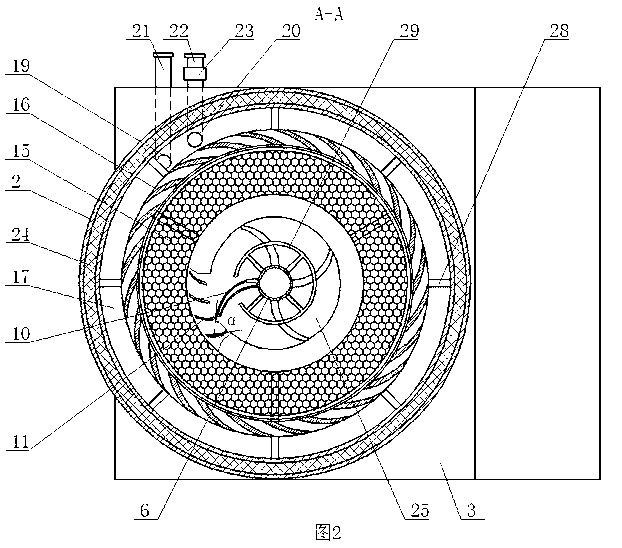

Mine ventilating fan control system capable of automatically adjusting air quantity

InactiveCN103148007ALow failure rateExtended service lifeTunnel/mines ventillationPump controlFrequency changerLoop control

Owner:LUOYANG YUANCHUANG ELECTRIC +1

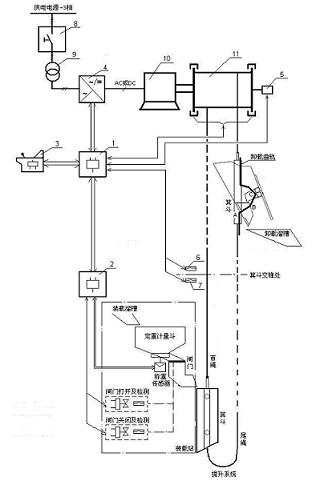

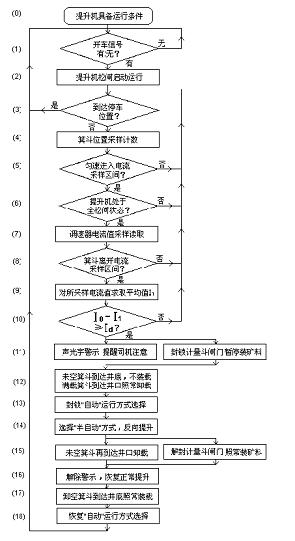

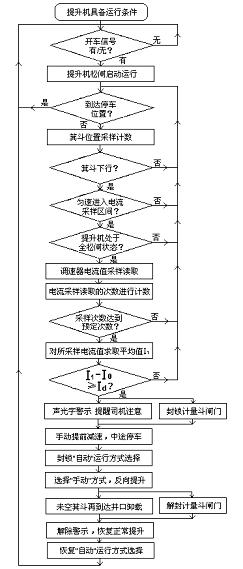

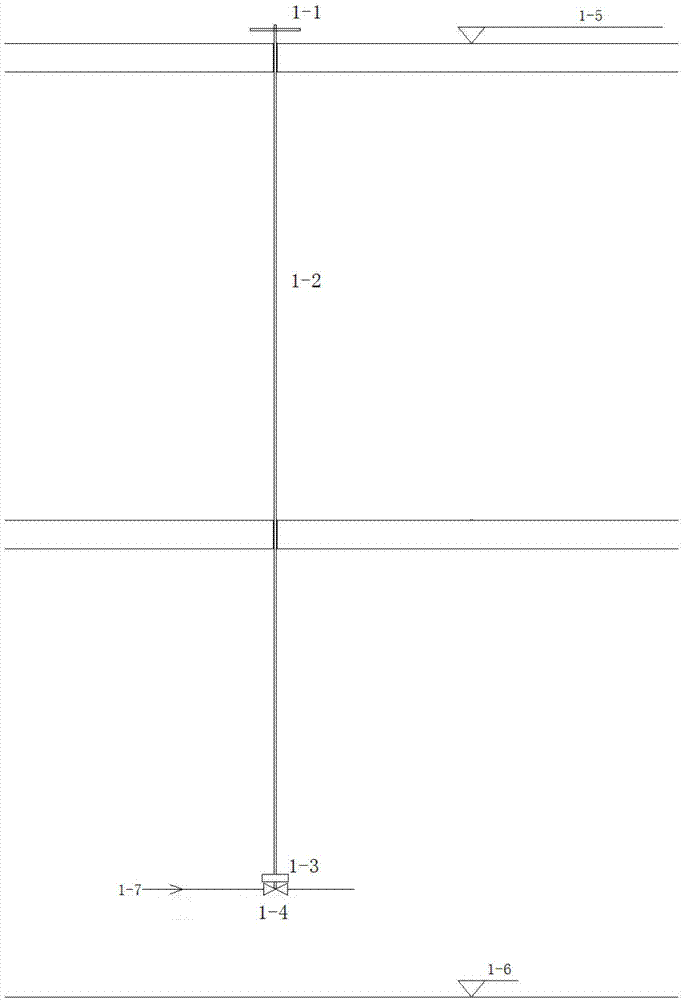

Method for completely unloading mineral aggregates from skip

InactiveCN102424322APrevent reloadingPrevent overloadElevatorsMine liftsControl engineeringMonitoring system

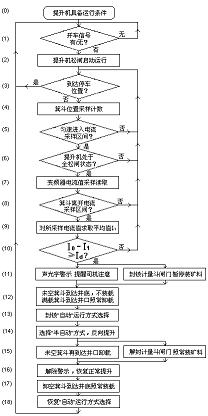

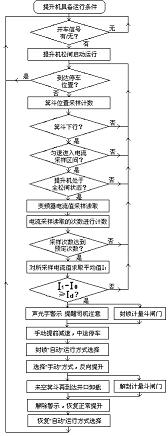

The invention belongs to a control technique for mine hoists, and provides a method for completely unloading mineral aggregates from a skip, The method comprises the following steps that: a fixed interval is set; when a hoist is in an absolute releasing state, and an unloaded skip enters into the fixed interval at a constant speed, the current of a major loop is continuously sampled and read in a circulating mode; through comparing an actually-measured value with a reference value, whether the unloaded skip is empty is determined, if the unloaded skip is not empty, a master controller sends a signal for indicating that the unloaded skip is not empty to a loading station controller and a monitoring system, the loading station controller sends a command for closing a weighing hopper valve, and the unloaded skip enters the shaft bottom and is no longer loaded, then the unloaded skip continues going upwards to be unloaded for the second time, and the working procedure above is repeated until the unloaded skip is empty. By using the method disclosed by the invention, a situation that a main shaft hoist runs in an overload or severe overload mode is avoided, the occurrence of serious accidents caused by the severe overload of the hoist is reduced or avoided, and the safety production capacity of a main-shaft hoisting system is increased.

Owner:LUOYANG YUANCHUANG ELECTRIC

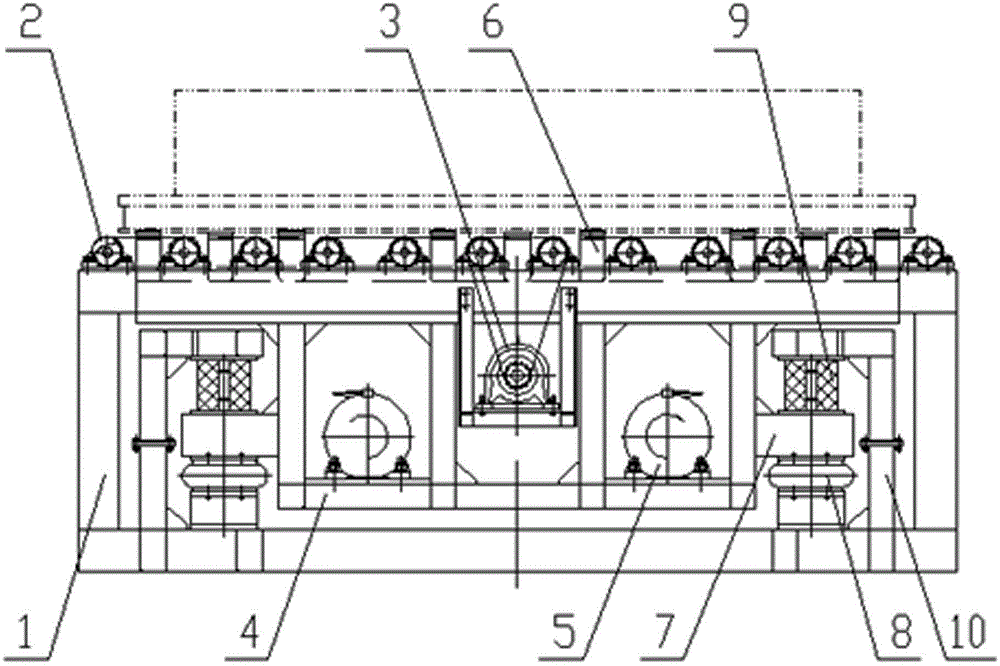

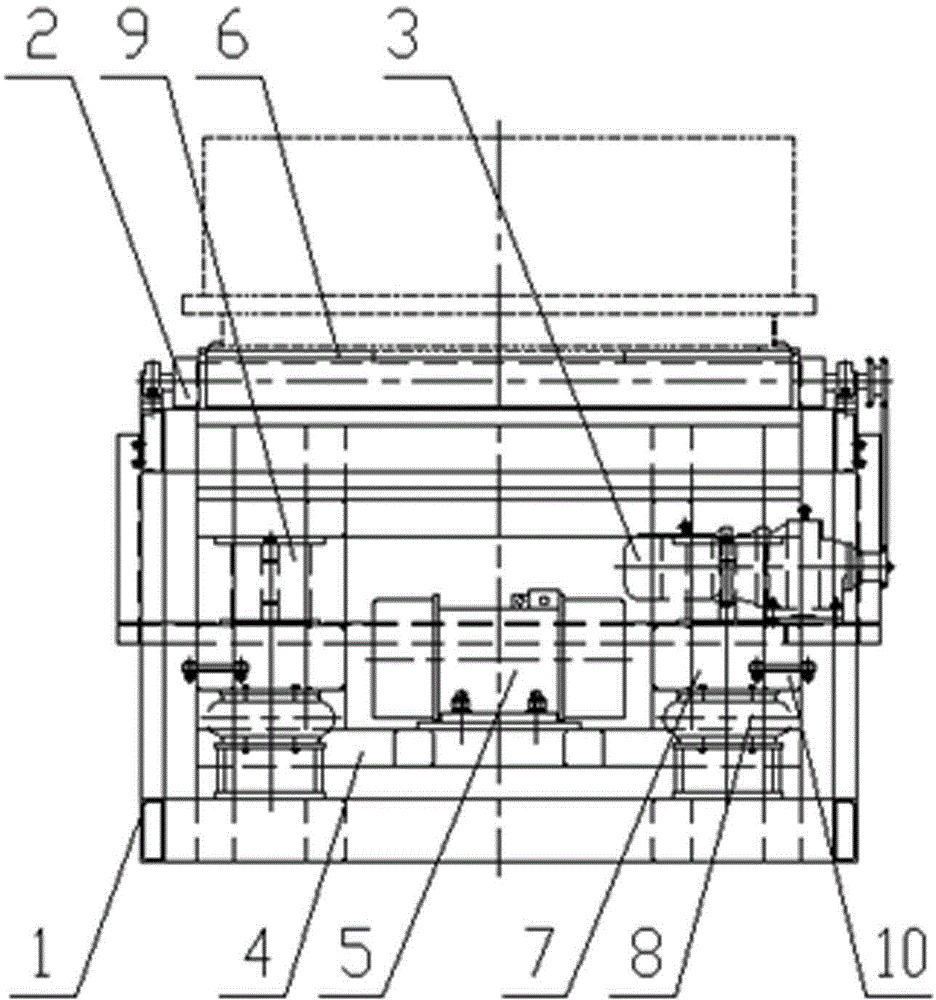

Compacting table for casting moulding

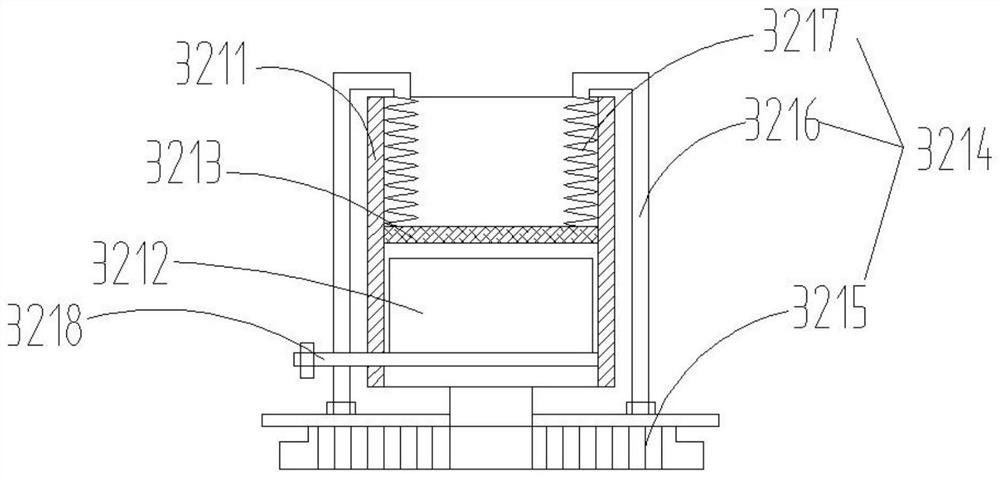

InactiveCN104923743AVibrated evenlyImprove compactionMoulding machinesAir springAgricultural engineering

A compacting table for casting moulding comprises a roller way frame, supporting rollers and a supporting roller driving mechanism. A compacting frame is arranged in the roller way frame, a vibrating motor is arranged on the lower portion of the compacting frame, supporting beams which are transversely arranged among the supporting rollers are arranged at the upper end of the compacting frame, spring assembling seats protruding out of the left side face and the right side face of the compacting frame are distributed on the lower portion of the compacting frame, a rubber air spring is arranged on the lower side of each spring assembling seat, a rubber spring is arranged on the upper side of each spring assembling seat, each rubber air spring and the corresponding rubber spring form a spring combination, a compacting frame seat is arranged on one side of each spring combination, the lower end of each rubber air spring corresponding to the corresponding compacting frame seat is fixed on th eupper side of a bottom seat body at the lower end of the corresponding compacting frame seat, and the upper end of each rubber spring corresponding to the corresponding compacting frame seat is matched with the lower side of an upper seat body at the upper end of the corresponding compacting frame seat. By the compacting table, moulding quality and efficiency can be improved effectively, equipment noise and influence on a workshop foundation during vibration can be reduced substantially.

Owner:QINHUANGDAO DEV ZONE CHUNGUANG CASTING MACHINERY

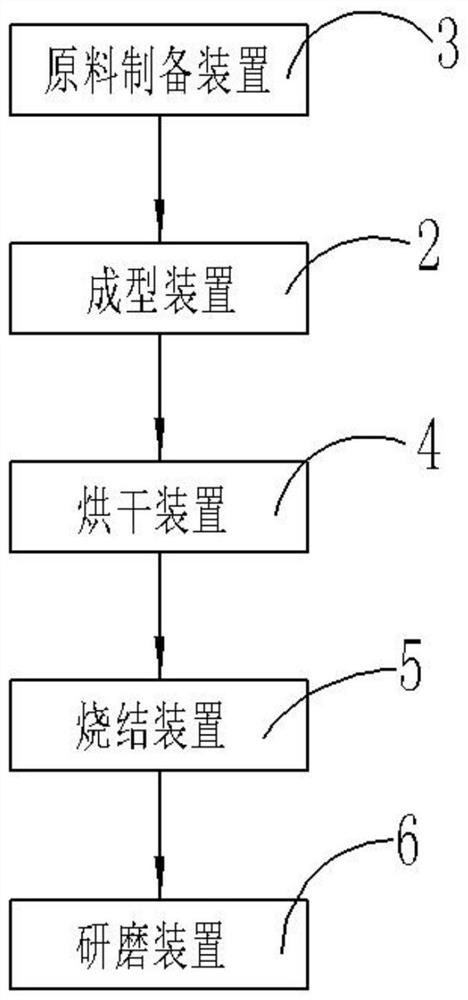

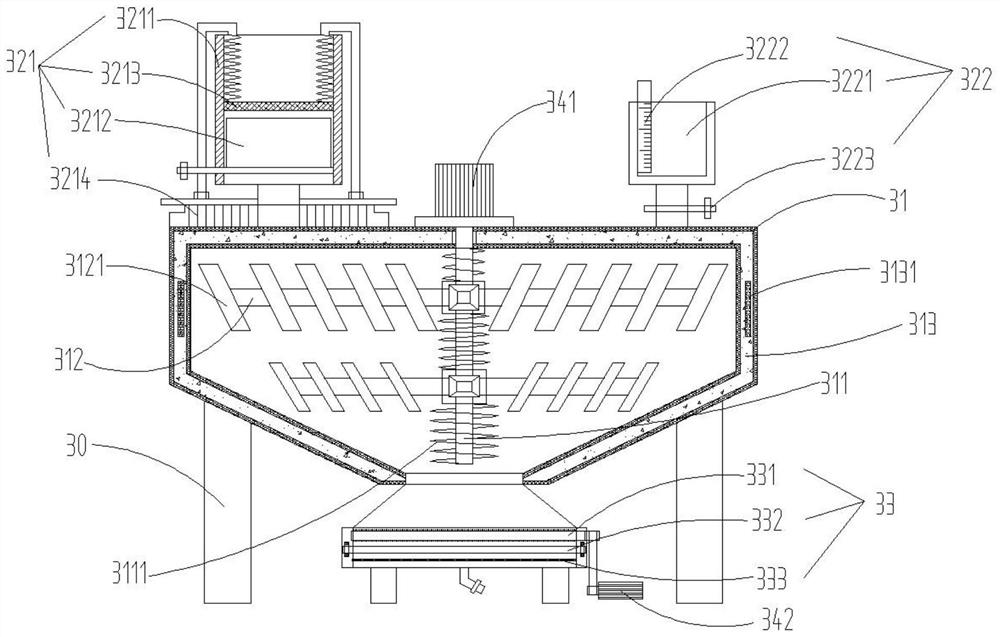

Electronic ceramic production system

ActiveCN111645182AReduce the possibilityGuarantee product qualityGrinding carriagesGrinding drivesMoulding deviceWhole systems

The invention relates to an electronic ceramic production system. According to the electronic ceramic production system, electronic ceramic processing is achieved by combining multiple devices, the whole system is reasonable in processing, firstly, the raw material preparation device is used for preparing high-quality ceramic slurry, then the high-quality ceramic slurry is put into the forming device for automatic forming, a green body is put into the drying device for drying after forming, the green body is preliminarily dried, in order to prevented cracks from being generated in the sintering process, the green body is placed in the sintering device after drying, by designing a feeding and taking structure of the sintering device, a user cannot be scalded in the using process, ceramic production is completed after sintering is completed, surface treatment of a ceramic product is carried out in the next step, the grinding device adopted for surface treatment is good in grinding effect, and meanwhile, dust generated in the grinding process is collected, so that dust pollution in a processing workshop is avoided; and electronic ceramics produced by using the whole system are high inquality, the whole system is used in the workshop, so that cleanliness of the workshop is guaranteed, and the safety production effect is improved.

Owner:新化县正能精细陶瓷有限公司

Lifting control device with skip emptying function

The invention belongs to mine lifting control technologies and provides a lifting control device with a skip emptying function. The lifting control device with the skip emptying function comprises an operating control system for automatically controlling a running process of a lifting system, a speed-adjusting system and a monitoring system, wherein the speed-adjusting system is used for supplying electricity to a motor and adjusting and controlling a running speed of an elevator, and the monitoring system is used for operating and monitoring a running process of the lifting control device. A fixed interval is arranged in a hardware mode or a combination mode of hardware and software; the elevator is in a full brake release state, and when a skip enters the set interval at a constant speed, sampling reading is continuously performed to current of a speed regulator in a circulating mode, and whether the skip is emptied is judged; and if the skip is not emptied, adopted corresponding measures are continuously taken to unload the skip which is not emptied. The lifting control device with the skip emptying function improves safe production capability of the lifting system, eliminates lifting intermittent time during the loading process of the skip, and improves production efficiency.

Owner:LUOYANG YUANCHUANG ELECTRIC

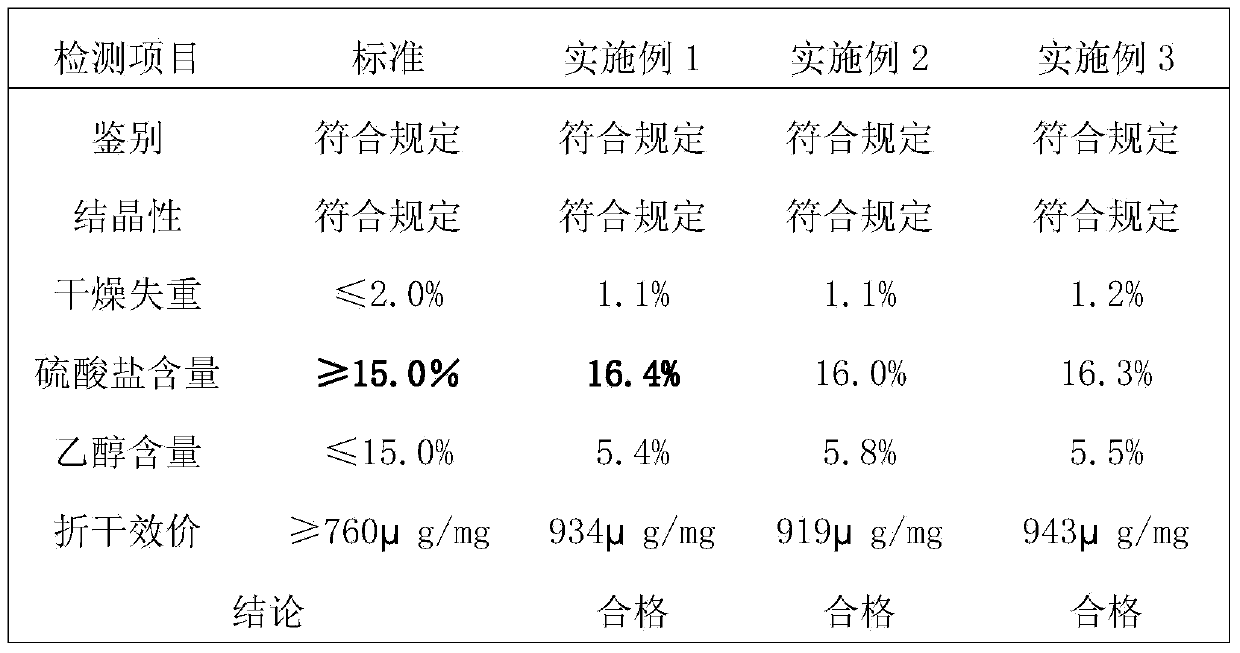

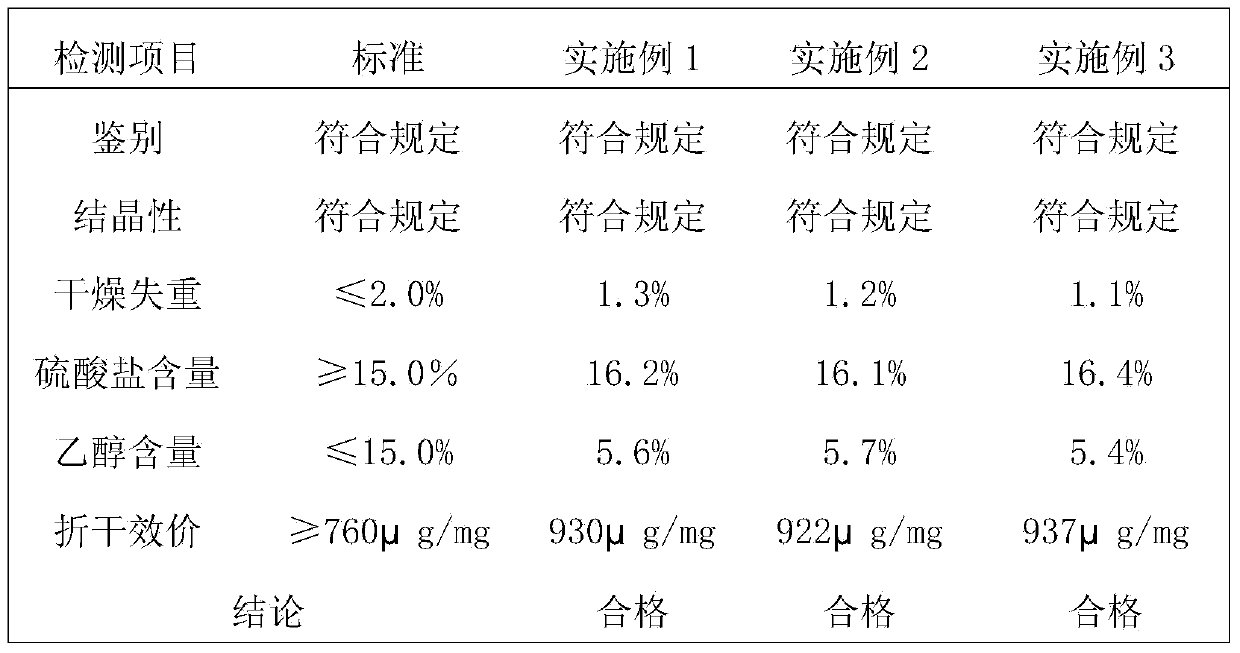

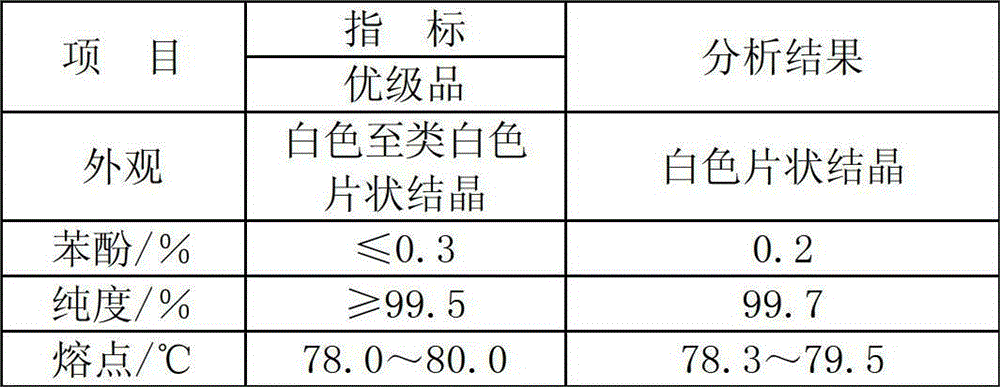

Production method of chlortetracycline bisulfate

ActiveCN103739514AResidue reductionLow ethanol toxicityCarboxylic acid amide separation/purificationChlortetracycline bisulfateSolvent

The invention discloses a production method of chlortetracycline bisulfate. The production method comprises the following steps: dropping a well prepared sulfuric acid / ethanol mixed solution in an ethanol suspension of a chlortetracycline base to dissolve the chlortetracycline base, filtering, then performing crystal growth by using ethanol, filtering, further washing with the ethanol, filtering, and finally performing vacuum drying to obtain the chlortetracycline bisulfate. According to the preparation method disclosed by the invention, the operation procedure is simplified, the production period is shortened, a single solvent is used to facilitate the recovery and the mechanical application of the solvent, the production cost is reduced, and the safety in production, the yield and the product quality are further improved. The chlortetracycline bisulfate prepared by the preparation method disclosed by the invention has the advantages of high yield, high titer, low solvent residue and good stability.

Owner:FUJIAN FUKANG PHARMA

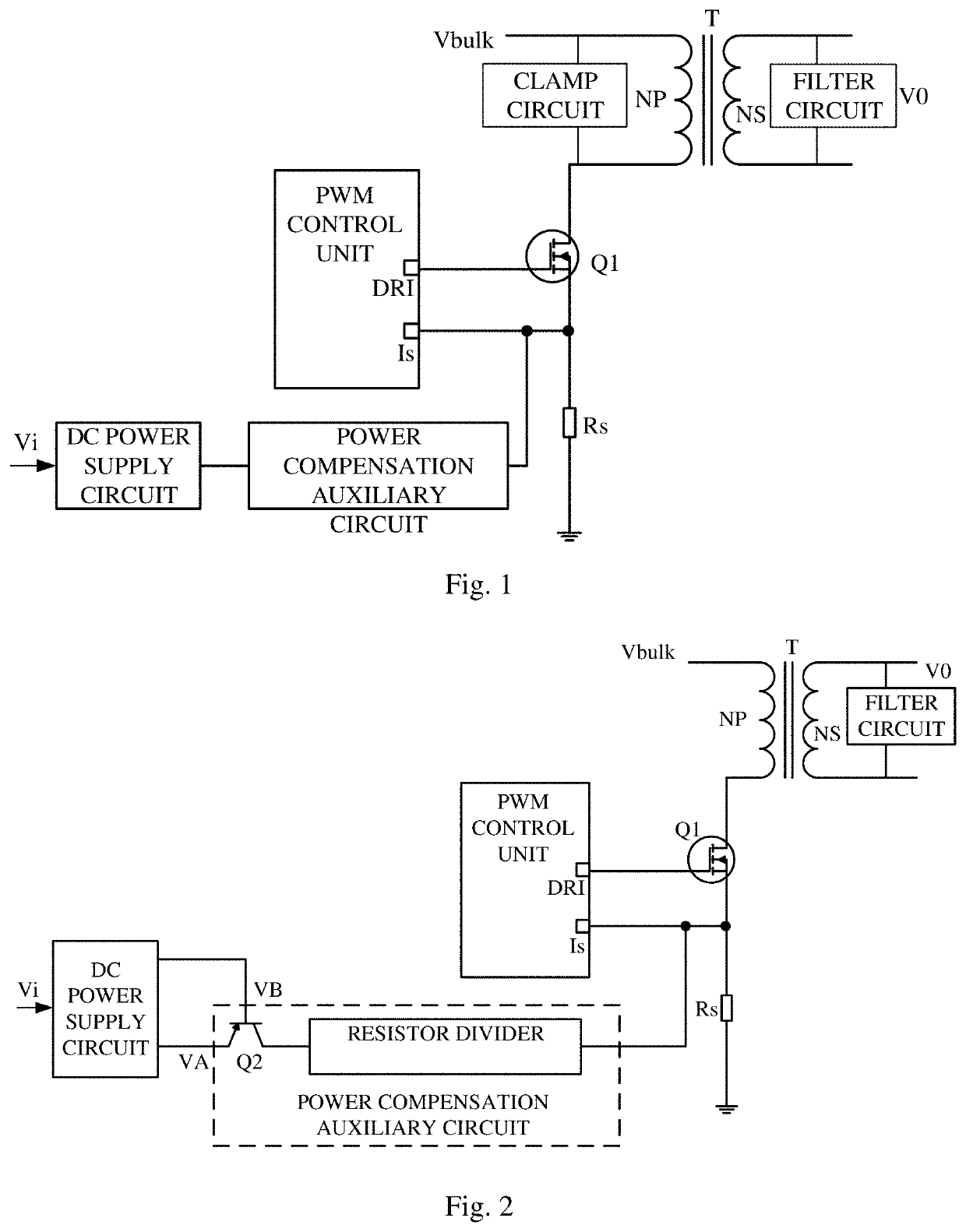

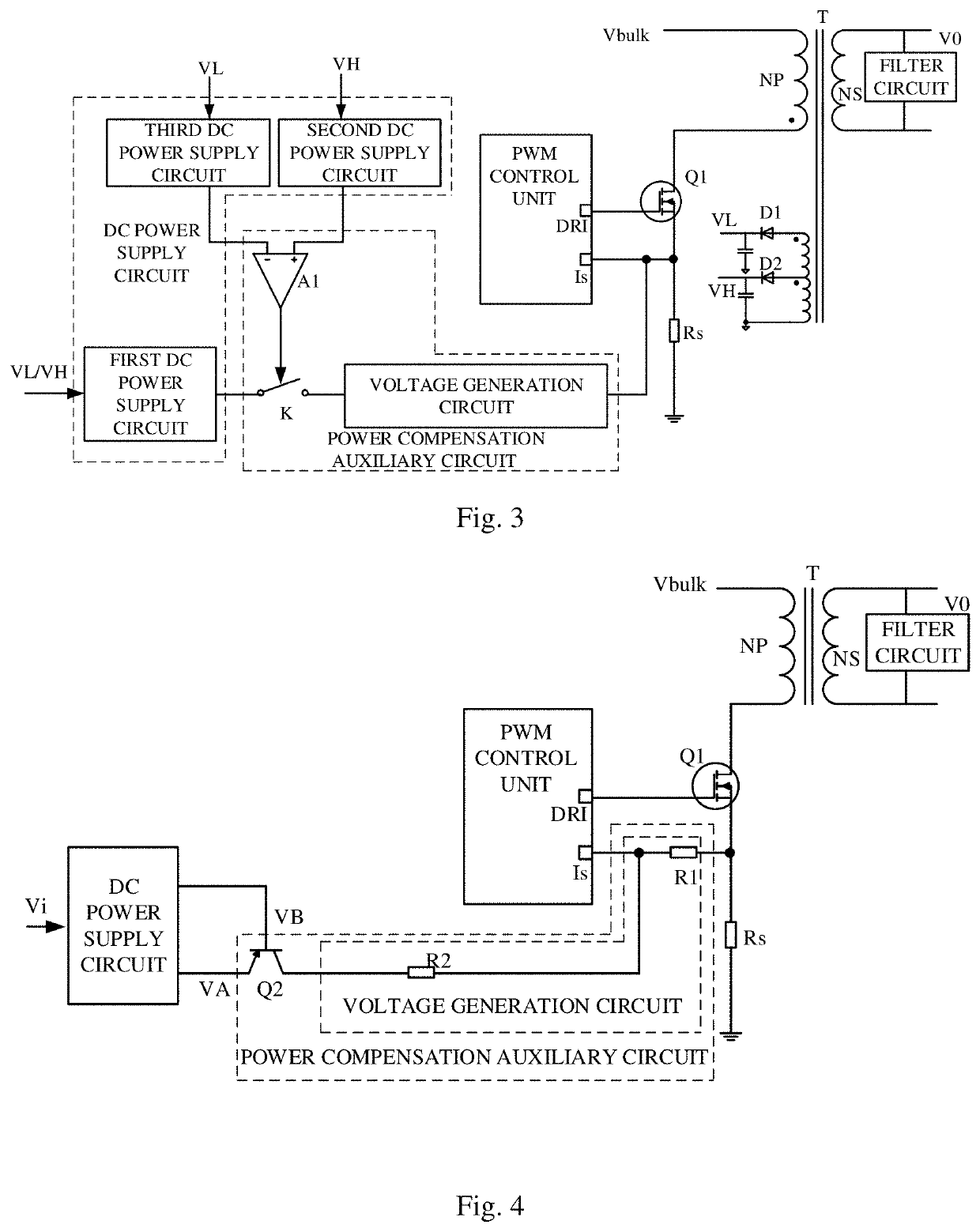

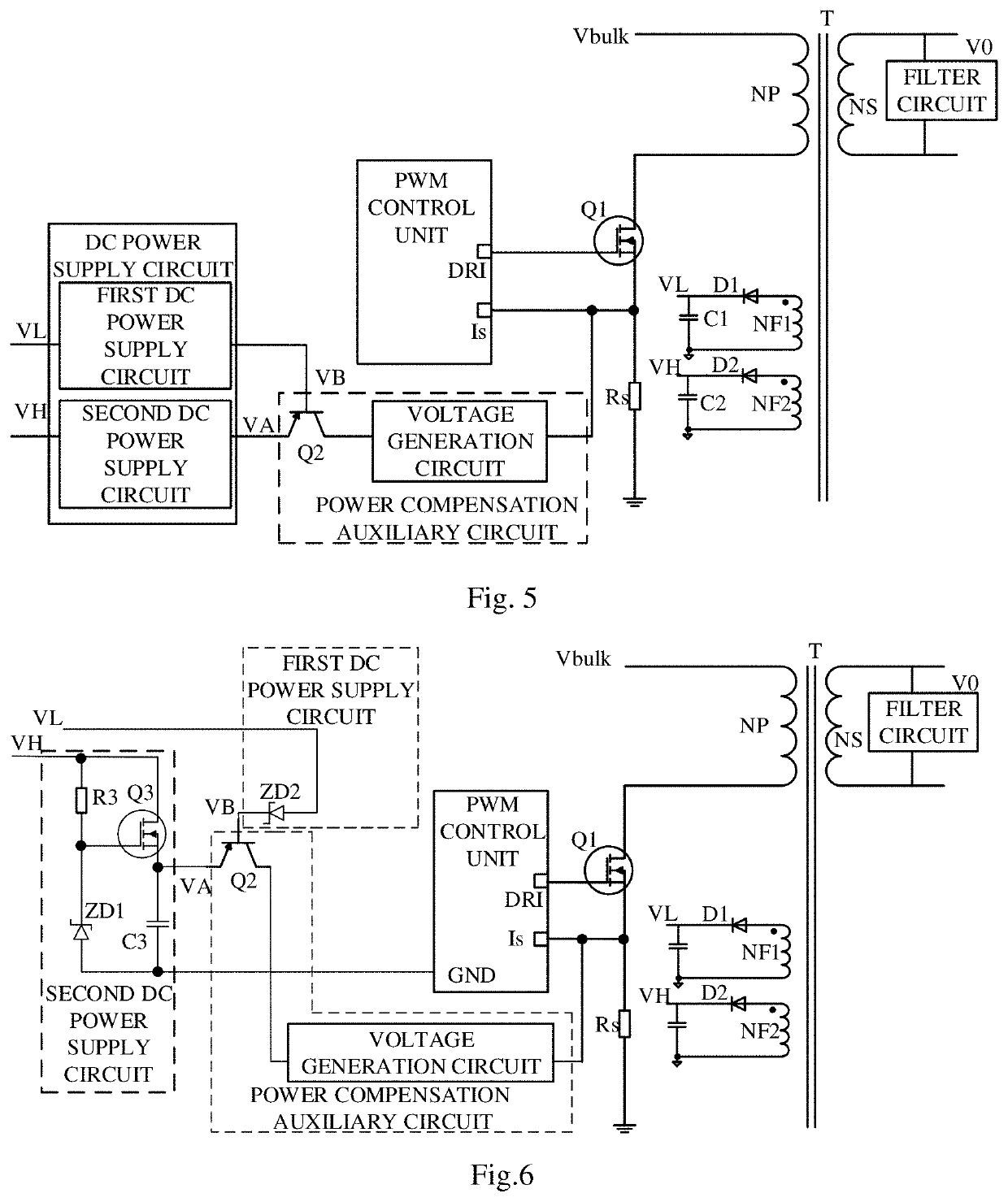

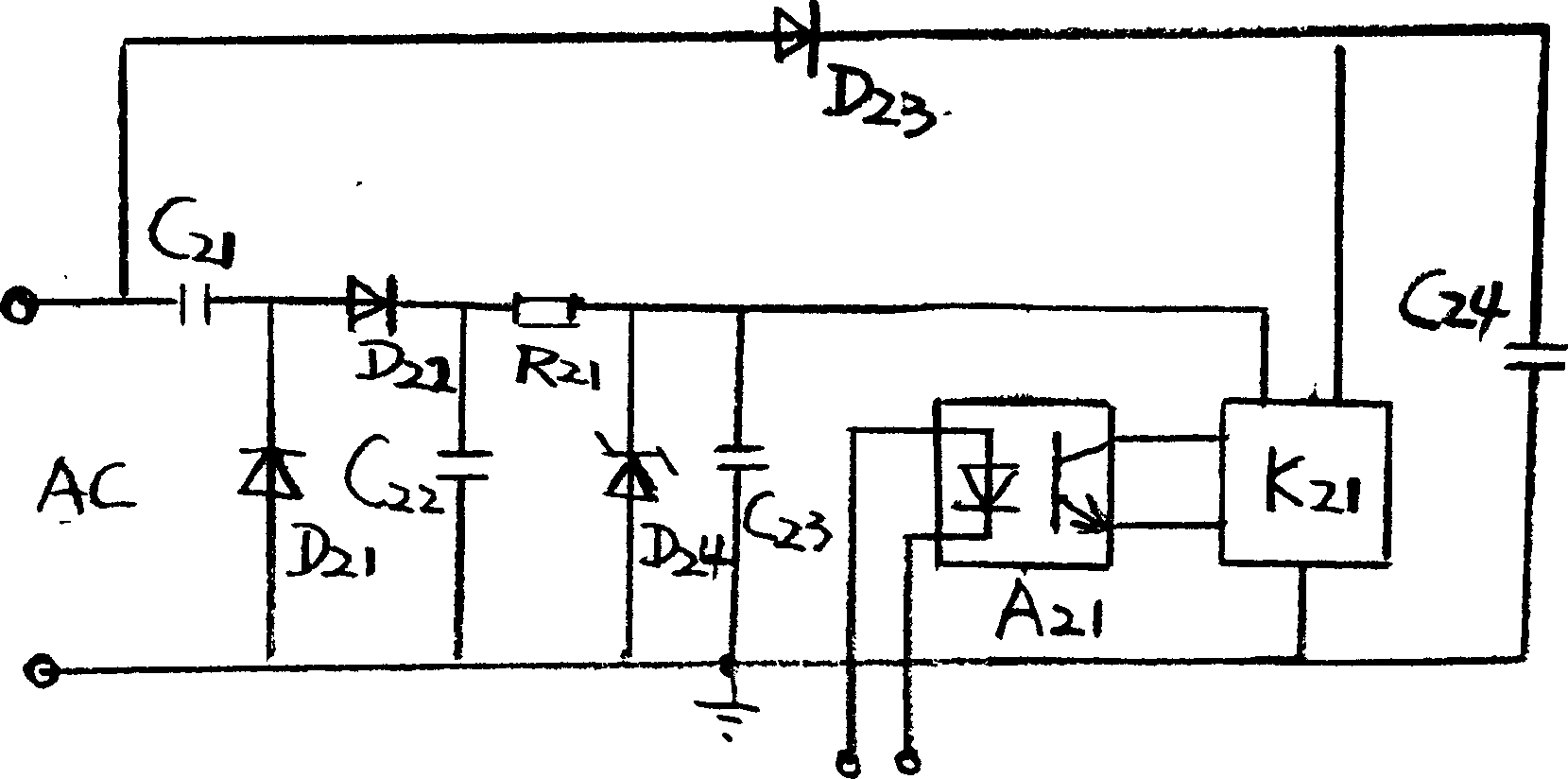

Switching power supply, power adapter and charger

PendingUS20220216796A1Improve safety production performanceEasy to meetBatteries circuit arrangementsDc-dc conversionCurrent mode controlTransformer

A switching power supply, a power adapter and a charger are provided. The switching power supply comprises a current-mode PWM control unit, a transformer, and a DC power supply circuit connected in series to a power compensation auxiliary circuit. The current-mode PWM control unit comprises a current detection terminal. An input of the DC power supply circuit is connected to an auxiliary voltage output. The auxiliary voltage output outputs an auxiliary voltage related to output voltage of the switching power supply. The power compensation auxiliary circuit is used to compare the output voltage and a threshold voltage. When the current output voltage of the switching power supply is not greater than the threshold voltage, the power compensation auxiliary circuit generates a DC voltage, thus providing a compensation voltage to the current detection terminal, otherwise no compensation voltage is provided.

Owner:SHENZHEN HUNTKEY ELECTRIC

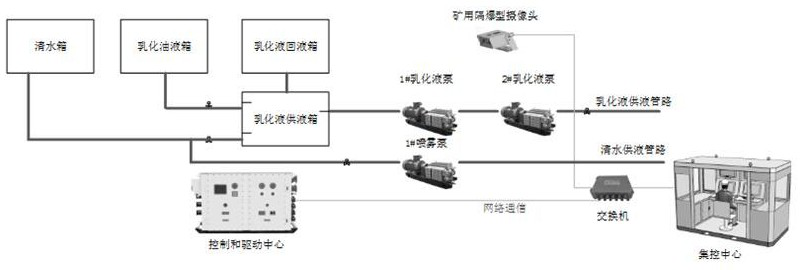

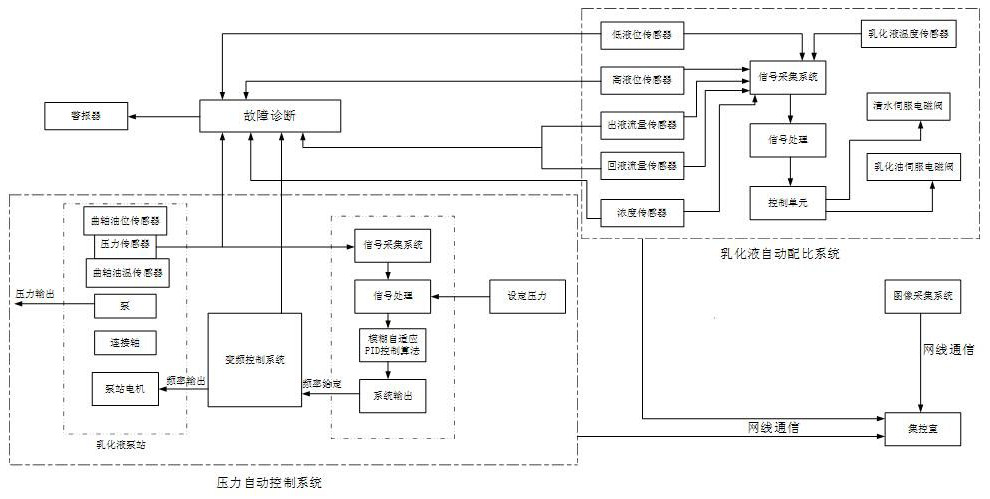

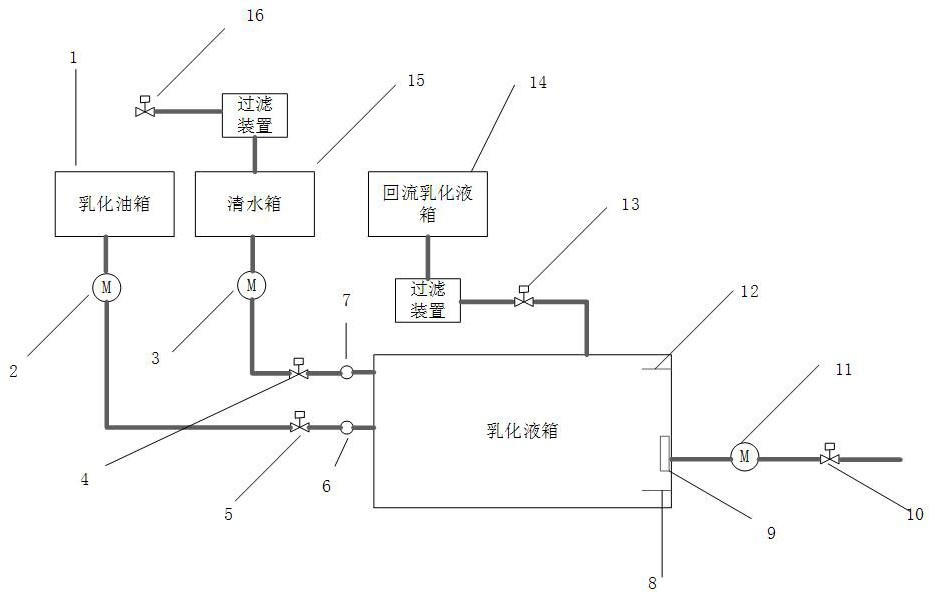

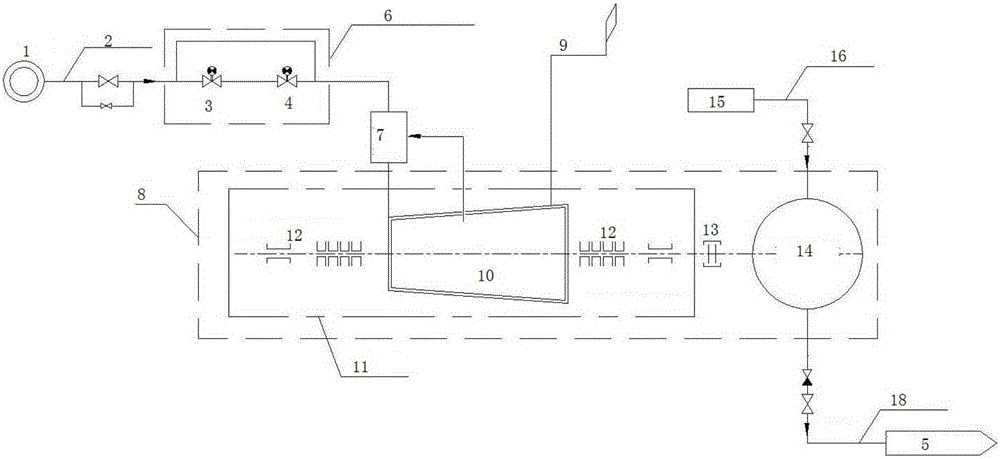

Unmanned intelligent control system for mining emulsion pump station

PendingCN112412765AReduce labor inputRealize unmanned intelligent controlPump testingPositive displacement pump componentsSolenoid valveAutomated control system

The invention relates to an emulsion pump station control system, in particular to an unmanned intelligent control system for a mining emulsion pump station. The system comprises an automatic pressurecontrol system, an automatic emulsion proportioning system, a remote data transmission system and a data monitoring and fault diagnosis system which are electrically connected, wherein the automaticpressure control system compares pressure set by the system with the value of a pressure sensor; the automatic emulsion proportioning system is used for controlling the sizes of a clear water solenoidvalve and an emulsified oil solenoid valve according to the concentration of emulsion; and the remote data transmission system has a data transmission function. Through the system, a series of problems such as large manual input, low emulsion proportioning precision, unstable pump station pressure output, high production cost and the like are solved; and meanwhile, the system has protection and monitoring functions, is stable and reliable, and has important significance for realizing intelligent mine and coal mine safety production.

Owner:JINING TUOXIN ELECTRIC

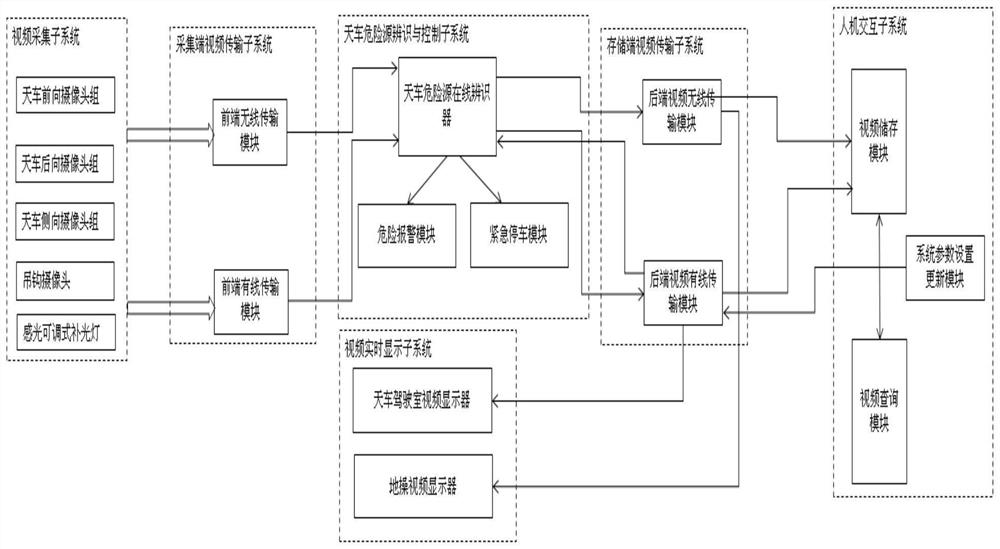

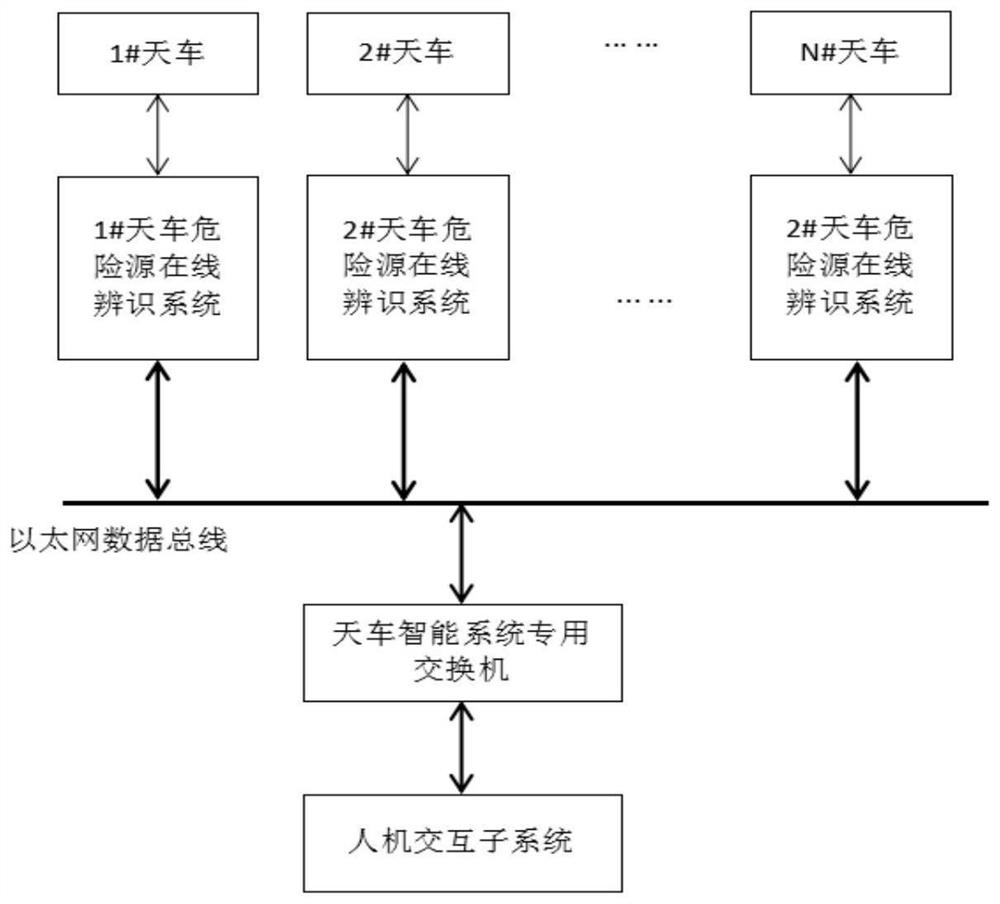

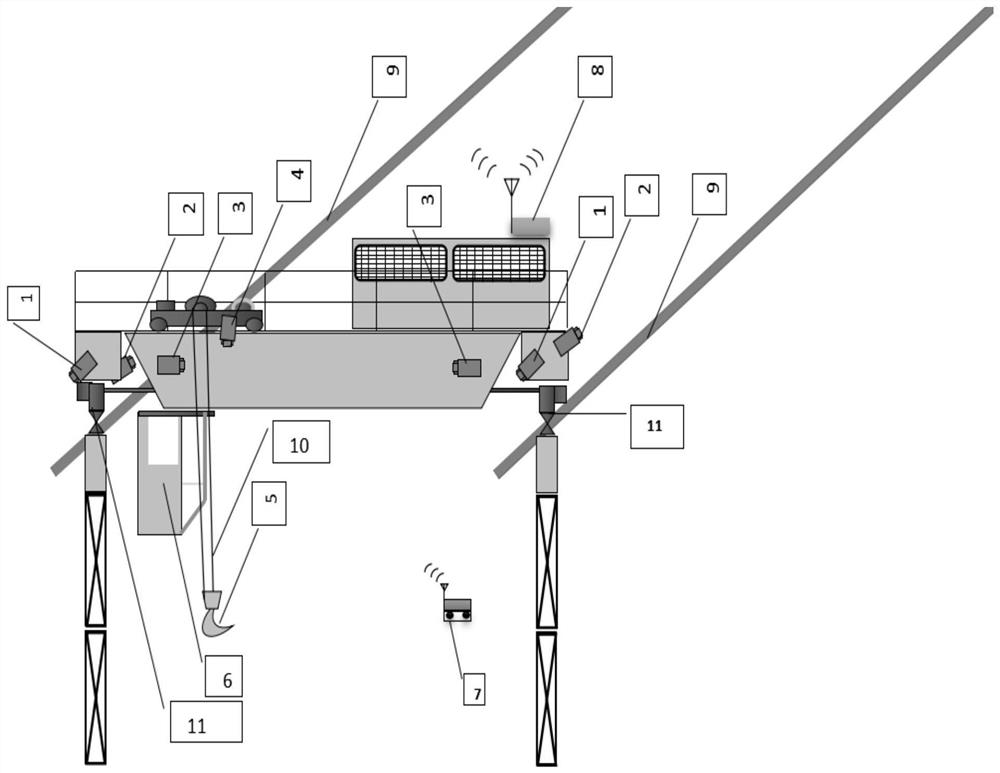

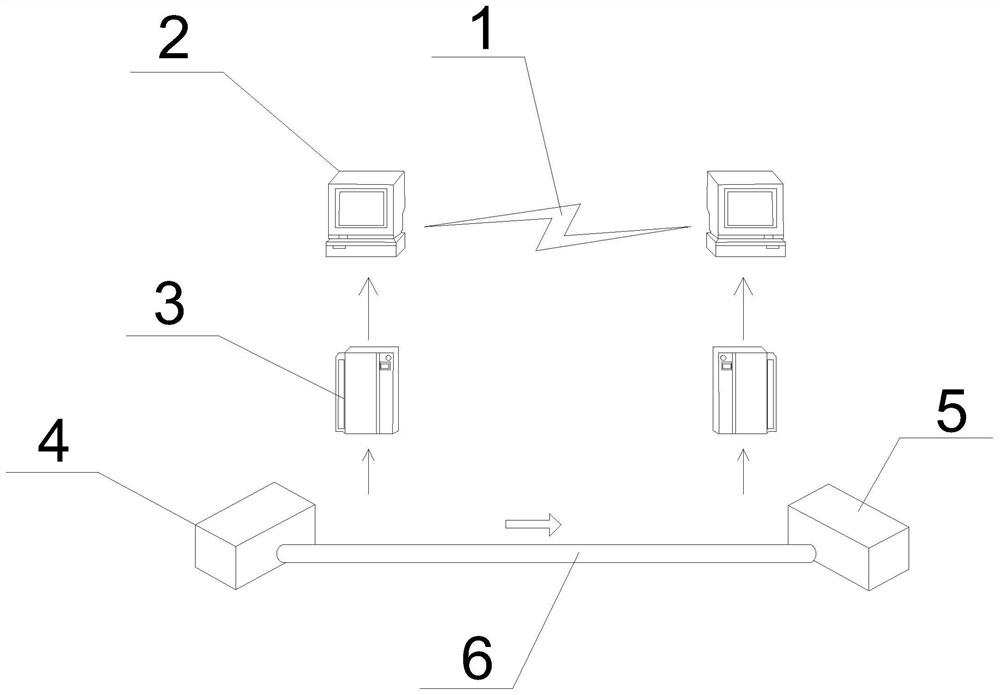

Automatic identification and control system and method for dangerous sources around crown block

ActiveCN112010185AImprove safety production performanceInvestment protectionClosed circuit television systemsTotal factory controlControl systemSimulation

The invention provides an automatic identification and control system and method for dangerous sources around a crown block, and relates to the technical field of crown block design and safety production. According to the system and method, a video acquisition subsystem is formed by camera groups arranged around a crown block track to acquire real-time video data around the crown block and transmit the real-time video data to a crown block danger source identification and control subsystem; the subsystem analyzes each frame of received video data, identifies whether the danger sources for inducing a production accident exist in the video, sends out different danger warning information according to an identification result, gives out an alarm according to the danger warning information andcontrols the operation of the crown block; meanwhile, s man-machine interaction subsystem receives and stores the analyzed video data and provides a function of querying historical video data; and a video real-time display subsystem displays the analyzed video data in real time at a crown block cab and a ground operation controller end. According to the system and method, the traveling safety of the crown block is essentially improved.

Owner:陈兆娜

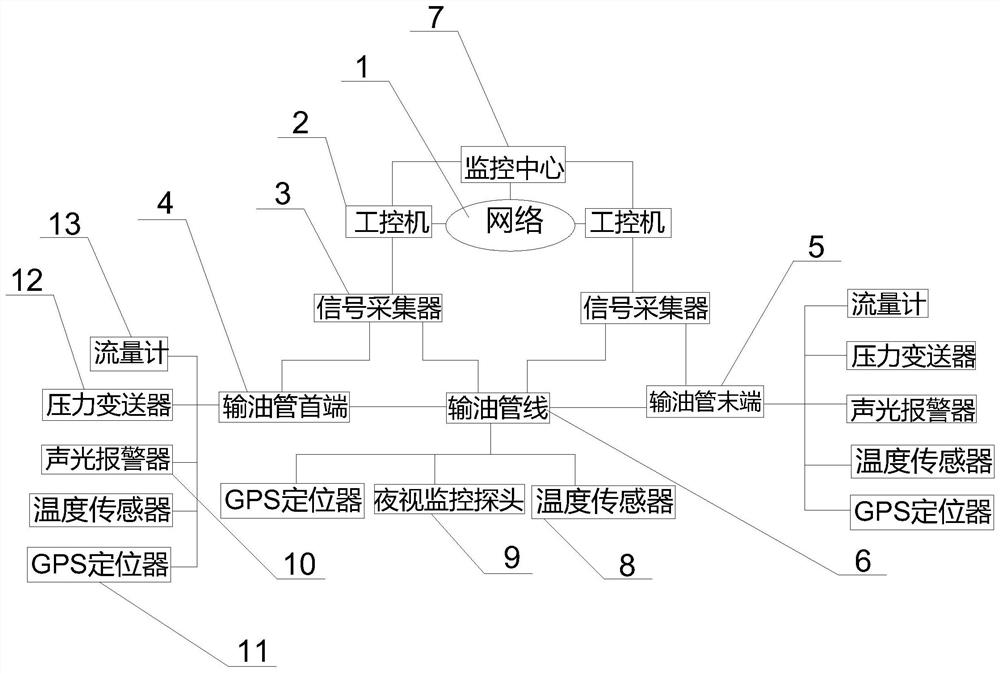

Pipeline leakage monitoring alarm system and positioning method

PendingCN111734960AGuaranteed safe useImprove monitoring efficiencyPipeline systemsPositioning equipmentOil spill

The invention relates to the technical field of pipeline monitoring alarm, in particular to a pipeline leakage monitoring alarm system and a positioning method. The pipeline leakage monitoring alarm system comprises monitoring terminals, a network, a signal collector, a monitoring alarm positioning equipment and an oil conveying pipeline. The monitoring alarm positioning equipment is installed onthe oil conveying pipeline and at the oil conveying pipe first end and the oil conveying pipe tail end of the oil conveying pipeline in a matched mode, the monitoring alarm positioning equipment is connected with the monitoring terminals through the signal collector, the monitoring terminals are connected through the network, and the monitoring terminals are connected with the monitoring center through the network. According to the pipeline leakage monitoring alarm system and the positioning method, the oil conveying pipeline can be monitored in real time, the problems that petroleum is wastedand the oil conveying potential safety hazards appear due to the fact that the oil conveying pipe is leaked and the detection and positioning are not in time can be solved, the petroleum is automatically detected and reported, leakage data are accurately detected, manpower, material resources and financial resources are saved, and the environmental pollution is reduced.

Owner:兰州科翔自控技术有限公司

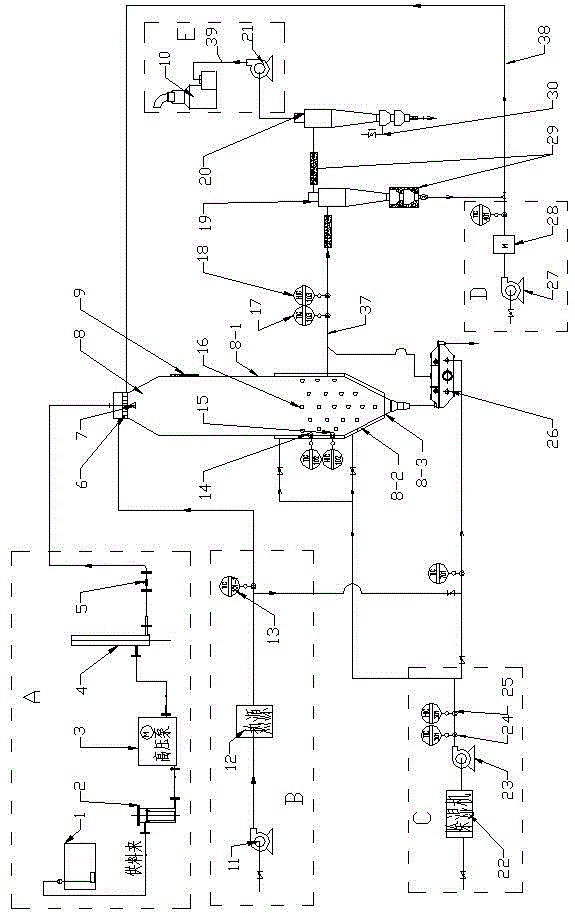

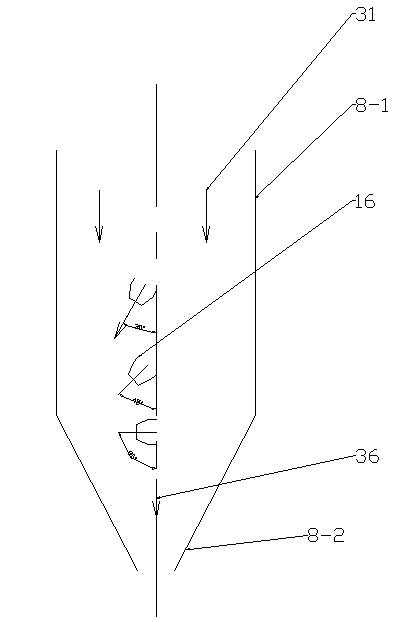

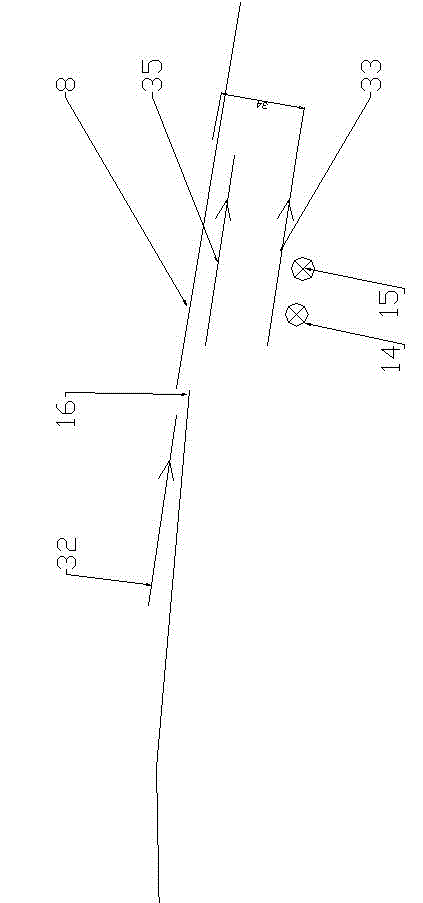

A spray drying system for easy-to-stick materials

ActiveCN103920299BAvoid stickingSolve the sticky situationEvaporation by sprayingAir volumeEngineering

The invention relates to a spray drying system for wall-attaching materials, and relates to the technical field of material drying. According to the invention, a layer of air wall wind with adjustable temperature, humidity and air volume is directly formed at the power-attaching part in a tower, the temperature and the humidity of the air wall wind are lower than the thermal boning temperature and the moisture absorption humidity of powder and particle materials, the air wall wind and the wind in the tower are finally mixed to form mixed wind, the temperature and humidity of the mixed wind are lower than the thermal boning temperature and the moisture absorption humidity of the powder and particle materials, and the temperature of the particle materials under the action of air wall wind before contacting the tower wall is lower than the thermal boning temperature. With the adoption of the system provided by the invention, three wall-attaching conditions of materials can be solved or reduced, and the effects of improving the production efficiency, improving the per unit yield, reducing energy consumption, prolonging the continuous production time, improving the production safety and the improving the quality of a product are achieved through high air inlet temperature.

Owner:陈林书

Belt conveyor control system and method for automatically adjusting belt speed according to material flow or material level

ActiveCN102942039BExtend your lifeReduce usage costsControl devices for conveyorsProgrammable logic controllerControl system

The invention provides a belt conveyor control system capable of adjusting belt speeds automatically according to material flows or material levels, and belongs to the belt conveyor control technology. The control system comprises a frequency conversion system, a programmable logic controller (PLC) system, a monitoring system and a detection system. The frequency conversion system comprises a power wire inlet device, a power feed device and a frequency converter. The PLC system comprises a power wire inlet control device, a power feed control device and a PLC device. The monitoring system comprises an operation platform and a display screen. The detection system comprises a material sensor which can use a contactless sensor. The control system sets the operation speed of a belt conveyor reasonably according to material flows or material levels and the operation state of a front conveyor and in additional conditions of time and motor currents, and the belt speed is adjusted by the controlling of the output frequency of the frequency converter.

Owner:SHANXI SANYUAN COAL IND +1

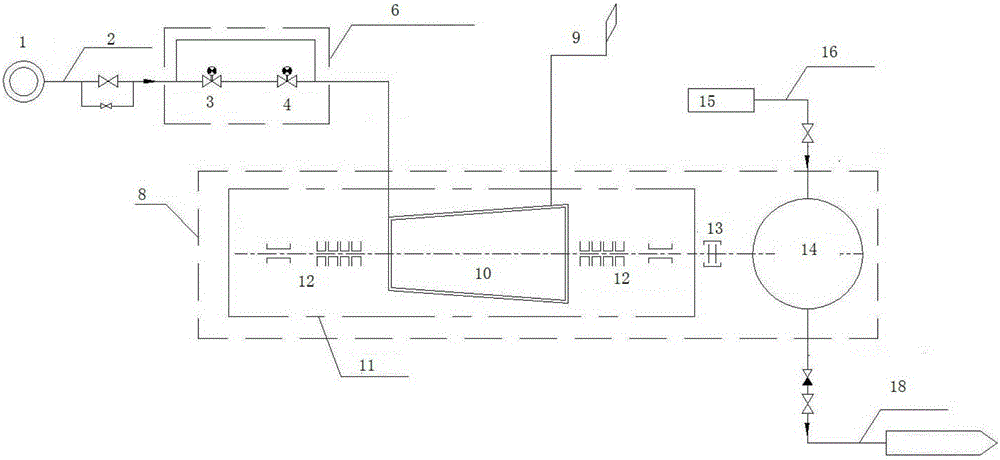

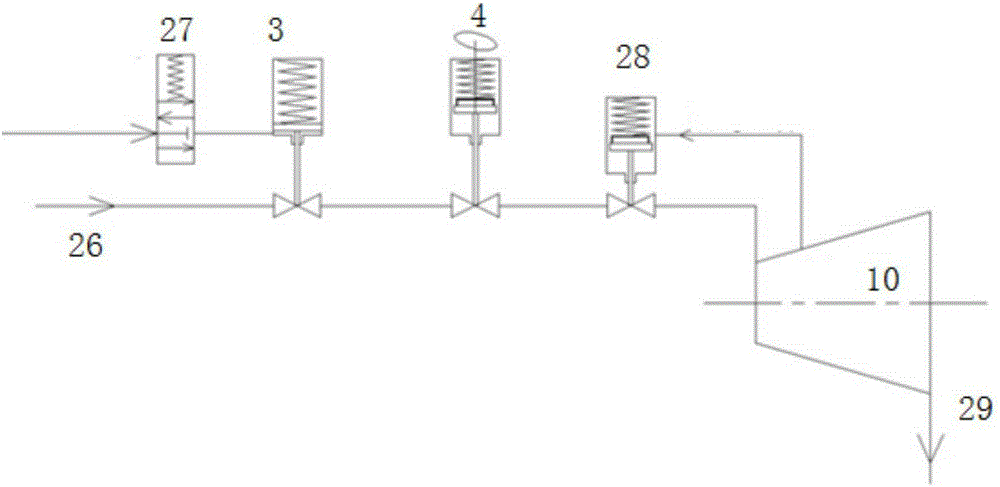

Experimental system and method of emergency steam-driven oil pump

ActiveCN104847421ASafe and reliable operationGuaranteed reliabilityPump testingEngine componentsFuel tankCheck valve

The invention discloses an experimental system and method of an emergency steam-driven oil pump. The experimental system comprises the emergency steam-driven oil pump of a steam turbine, an external experimental oil tank, a lubricating oil pipe, a check valve and a manual gate; the external experimental oil tank is connected with inlet and outlet lines of the emergency steam-driven oil pump through the lubricating oil pipe; the lubricating oil pipe is connected with the inlet and outlet lines of the emergency steam-driven oil pump to form a self-circulating lubricating oil line; the self-circulating lubricating oil line is provided with the check valve and the manual gate. The experimental system and method has the advantages that the emergency steam-driven oil pump system can be kept in the pre-start state anytime, all aspects of the system are in good condition, the system can run safely and reliably in case that a factory is powered off and that a DC oil pump is unable to start, and a steam turbine system is more reliably ensured.

Owner:JINAN DANENG POWER TECH

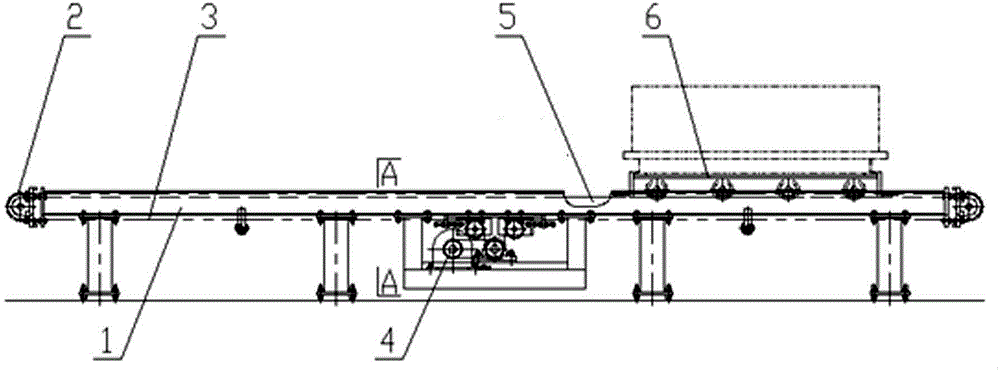

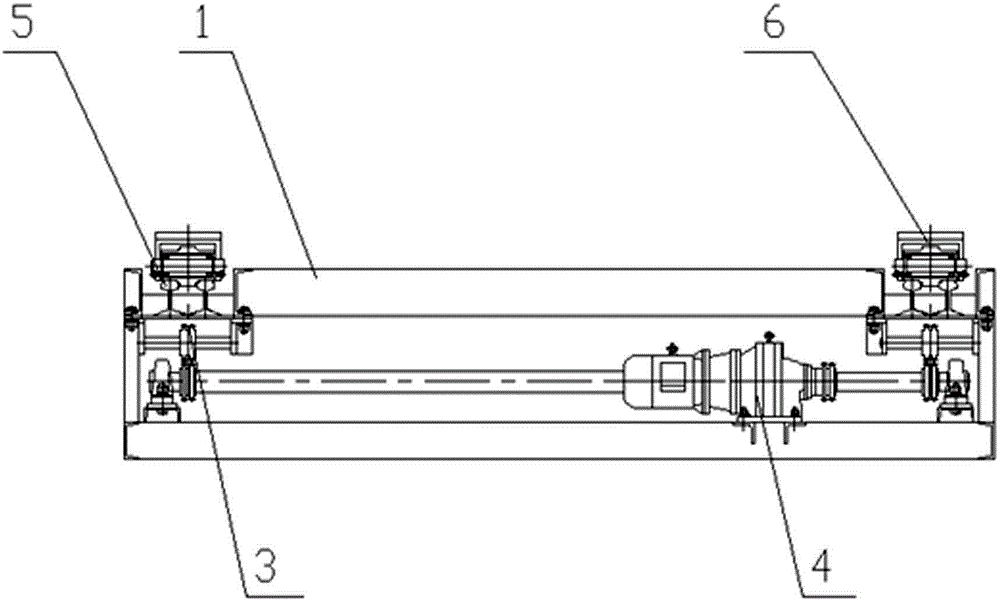

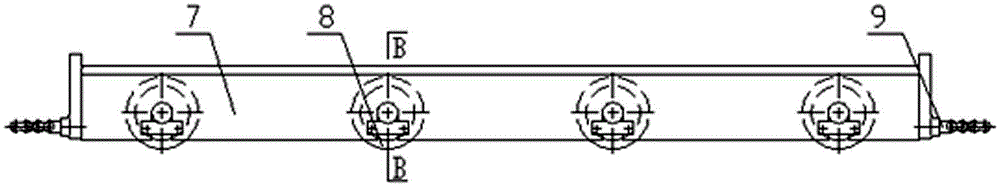

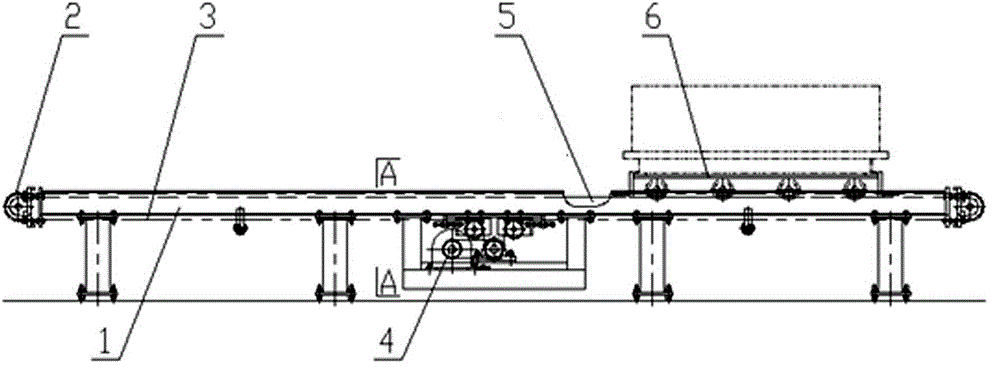

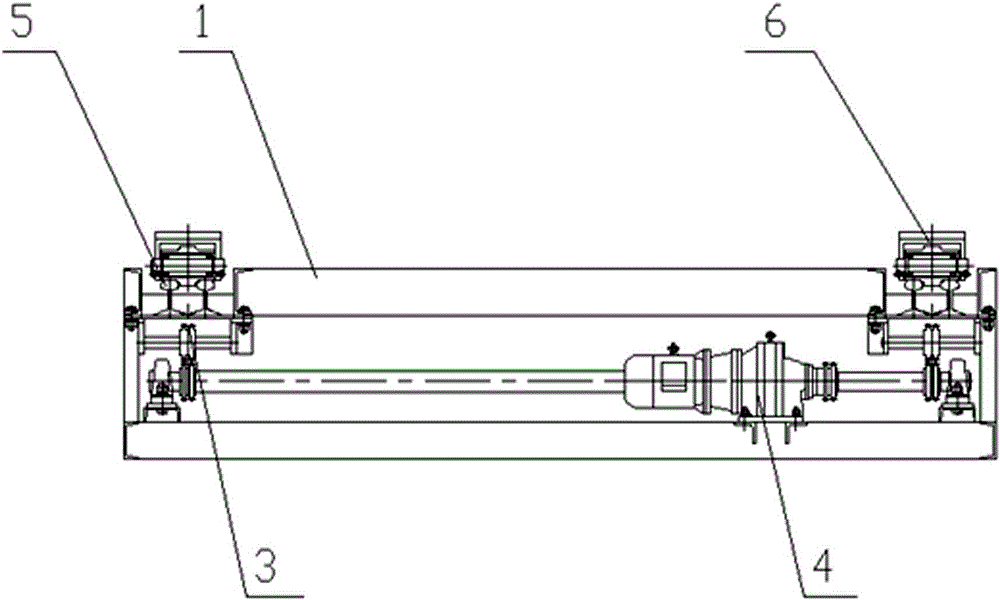

Model bottom plate and sand box transfer device

ActiveCN104923747AGuaranteed normal transferGuaranteed smooth productionMoulding toolsSprocketFlange

A model bottom plate and sand box transfer device comprises a frame, a pair of chain wheels is coaxially mounted at two ends of the frame respectively, a towing chain is assembled on the two front and back chain wheels, a towing chain driving mechanism is arranged on the frame, bearing rails composed of two parallel steel rails are arranged on two sides of the upper portion of the frame respectively, each bearing rail is provided with a model bottom plate and sand box trailing device respectively, and the model bottom plate and sand box trailing devices are provided with groove-steel bearing guide beams respectively. Bearing rollers with flanges in the roller surface middle portions are distributed on the bearing guide beams, the roller surfaces on two sides of the flanges are matched with steel rail surfaces of the corresponding bearing rails respectively, and two ends of the bearing guide beams are connected with the corresponding towing chains via chain joints. The model bottom plate and sand box transfer device is used for casting modeling lines and can ensure normal transfer of model bottom plates and sand boxes at the T-shaped and crisscrossed positions. In addition, manufacturing cost of equipment can be greatly reduced, and operation reliability of equipment is improved.

Owner:QINHUANGDAO DEV ZONE CHUNGUANG CASTING MACHINERY

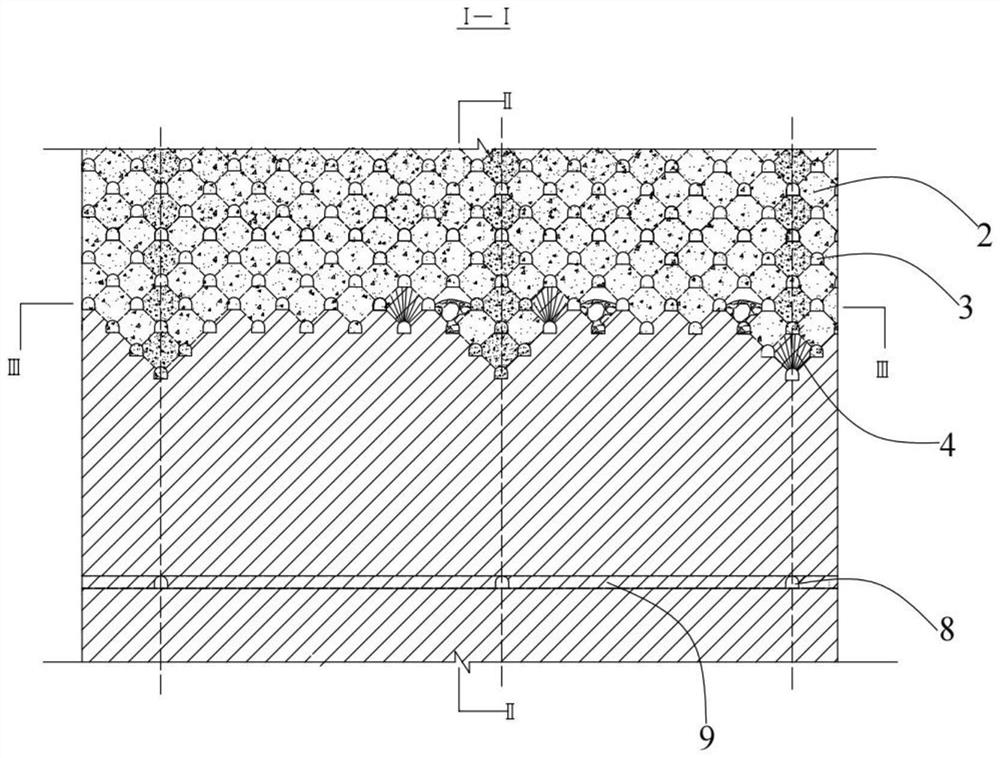

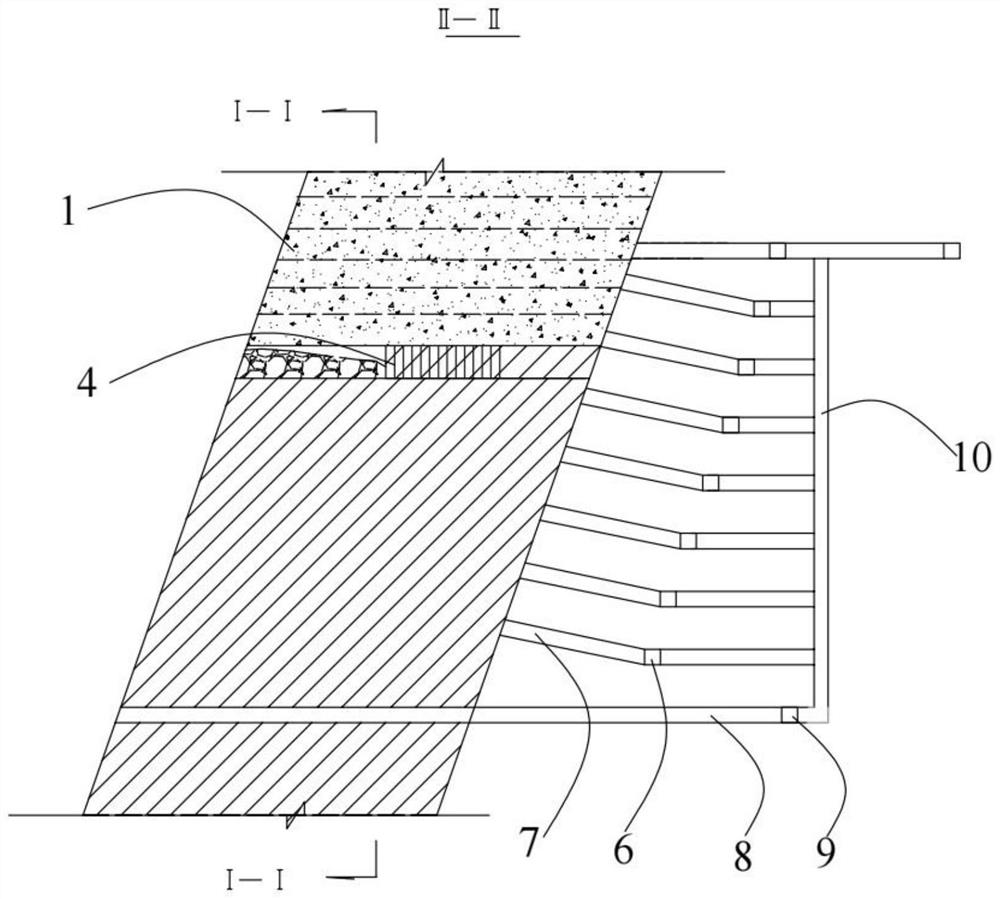

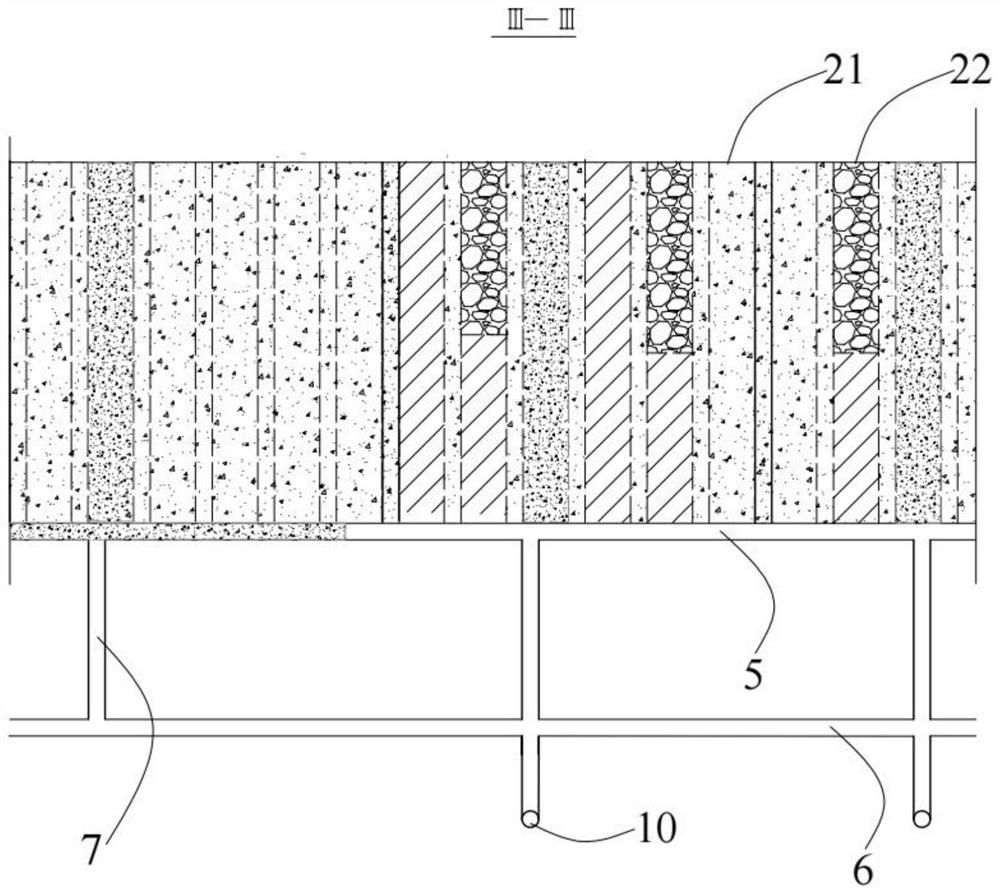

Divided unloading and sublevel filling mining method based on rhombic stoping structure

ActiveCN114562268AIncrease costSolve the costUnderground miningBlastingMechanical engineeringMineralogy

The invention provides a zoning unloading and sublevel filling mining method based on a rhombic stoping structure. A to-be-mined panel is provided with a middle section stope and divided into sublevel stopes, and zoning is carried out along the trend of an ore deposit; in the middle-section stope, the rhombic stoping structures are adopted for stoping from top to bottom in sequence, mining is conducted in a step-by-step and filling-while-mining mode, and the rhombic stoping structures between the subareas are firstly mined. According to the method, the rhombic stoping structures of the lower mining units between the subareas are mined in advance, so that unloading is achieved to relieve damage of horizontal tectonic stress to the lateral wall of the stope; the large-size rhombic stoping structure is large in structural parameter, the bearing capacity is remarkably improved, the problem that the lateral walls of the adjacent stopes of the soft and broken ore deposit are extremely prone to collapse is solved, and the safety production capacity of the stopes is improved. In addition, the rhombic stoping structures are distributed in an up-and-down staggered mode, ore loss can be reduced, and mining efficiency is improved. According to the method, the aim of safely, efficiently and economically exploiting the low-grade soft broken thick and large ore deposit at low cost under the condition of high-level tectonic stress is achieved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Process of producing diphenyl carbonate by non-solvent method

ActiveCN103044259BQuality improvementIncrease productionPreparation from phosgene or haloformatesDimethylaniline N-oxideDistillation

The invention aims to provide a process of producing diphenyl carbonate by non-solvent method. The process can improve the quality of proeducts and also reduce the production cost of products and the waste discharge. The method comprises the following steps: melting phenol, and heating up to 110-130 DEG C; adding DMF or N,N-dimethylaniline or analogs thereof as catalyst in an amount of 0.03-3% of phenol; maintaining the temperature, and introducing phosgene for photochemical reaction while stirring; heating up to 140-180 DEG C and maintaining for 1-5 hours; and performing reduced pressure distillation to obtain the final product. The new process provided by the invention improves the quality and yield of products, completely eliminates sodium chloride mother liquid and waste water and reduces distillation residues, reduces the production cost, and achieves the purpose of clean production. The operation of phenol system recovery and the procedure of ingredients are reduced, the production efficiency is greatly increased, the operation is more stable, and the safety of production is improved.

Owner:CHONGQING CHANGFENG CHEM IND

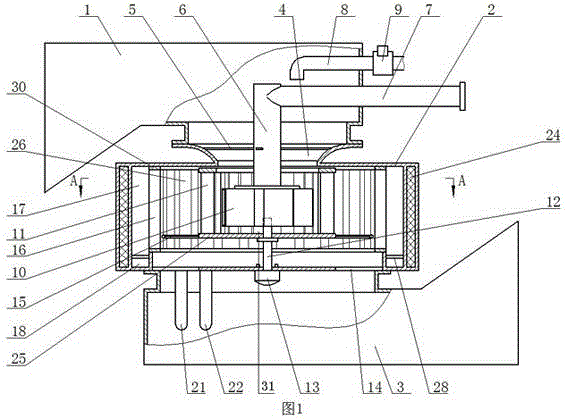

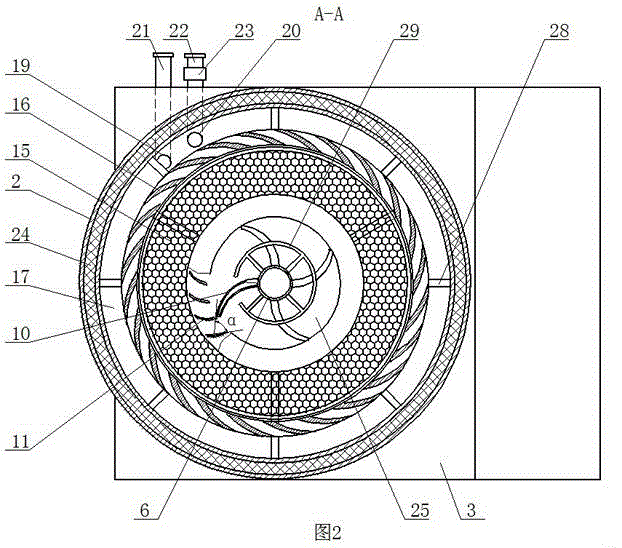

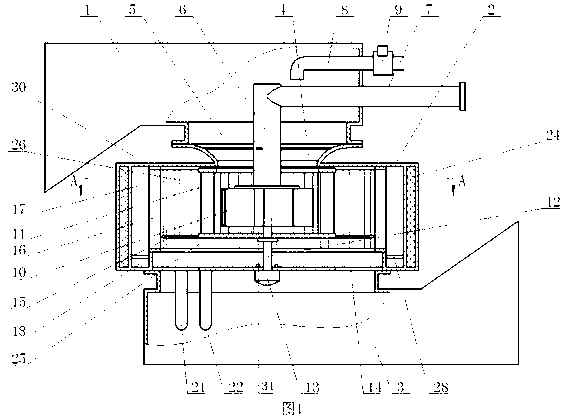

Steam turbine heater

ActiveCN103306639BEasy to installExtended service lifeInsulationDirect contact heat exchangersImpellerSpray nozzle

The invention provides a turbine heater which comprises an air inlet passage, a steam inlet pipe and a hot air outlet passage. Air and steam enter a mixing chamber through corresponding pipelines to be mixed; the mixing chamber is positioned in a host housing; the air inlet passage is connected with the host housing in a sealing manner; steam spray nozzles are arranged at the end part of the steam inlet pipe, which is positioned in the host housing; the steam spray nozzles are uniformly distributed into a strip arc shape along the periphery of the steam inlet pipe; centrifuge blades are uniformly distributed on the peripheries of the steam spray nozzles; the tangential direction of each arc steam spray nozzle outlet passage is opposite to that of each arc centrifuge blade; a centrifugal impeller consisting of the centrifuge blades is connected with a rotating shaft by a fixing part; the maximum included angle alpha between the tangential direction of an outlet of each steam spray nozzle outlet passage and a string of each arc centrifuge blade is 90 degrees; and a demister is arranged in the host housing or in the hot air outlet passage. The turbine heater adopts steam as a heating source and a fan power source, enables the air to be directly heated, and does not require a heat exchanger and an electric motor so as to overcome the defects in the prior art.

Owner:山东三钻硬质合金有限公司

Process for producing deiphenyl carbonate by using non-solvent method

InactiveCN107868002AQuality improvementIncrease productionPreparation from phosgene or haloformatesDimethylaniline N-oxideDistillation

The purpose of the present invention is to provide a process for producing diphenyl carbonate by non-solvent method, which can improve product quality and reduce product production cost and waste discharge; the steps of the process include: melting phenol and heating up to 110-130°C ; Use DMF or N, N-dimethylaniline or the analogue of the two as a catalyst, the charging amount is 0.03-3% of phenol; keep the temperature, feed phosgene under stirring conditions and carry out photochemical reaction; then be warming up to 140 ‑180°C for 1‑5 hours; then distilled under reduced pressure to obtain the product. The new process of the invention improves product quality and output, completely avoids sodium chloride mother liquor water and waste water, reduces distillation residue, reduces production cost, and achieves clean production. The operation of phenol system recovery and the special batching process are reduced, which greatly improves the production efficiency; the operation is more stable, and the safety and productivity are improved.

Owner:青岛九洲千和机械有限公司

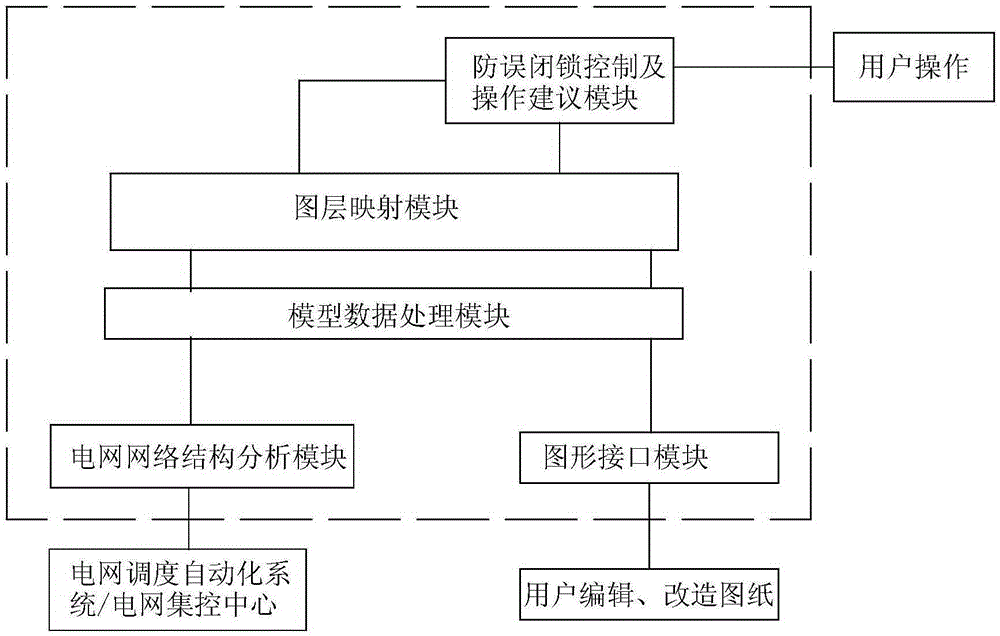

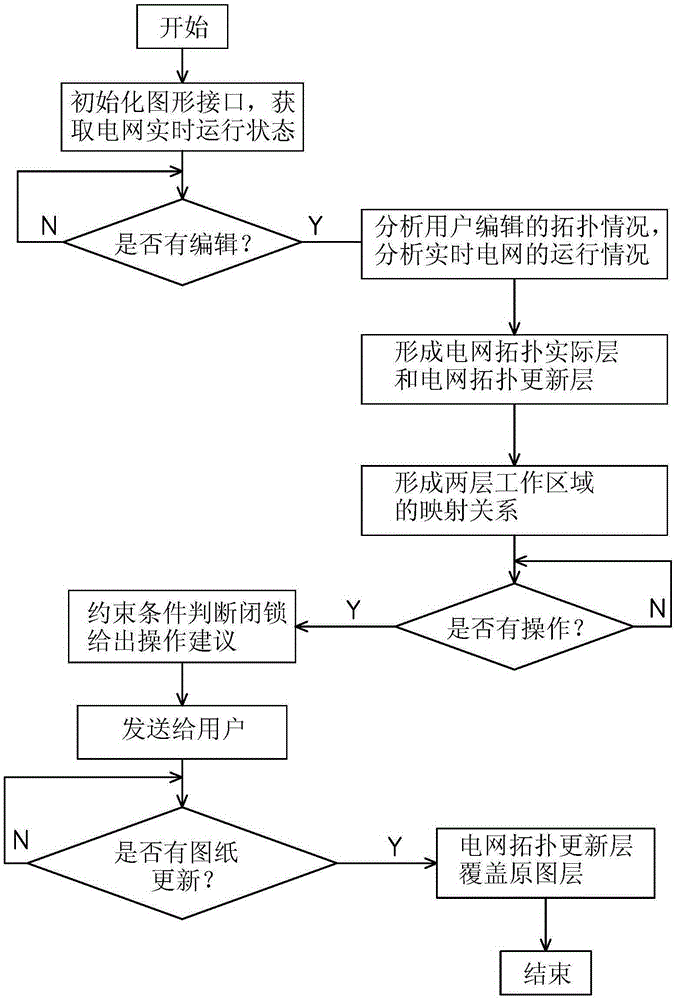

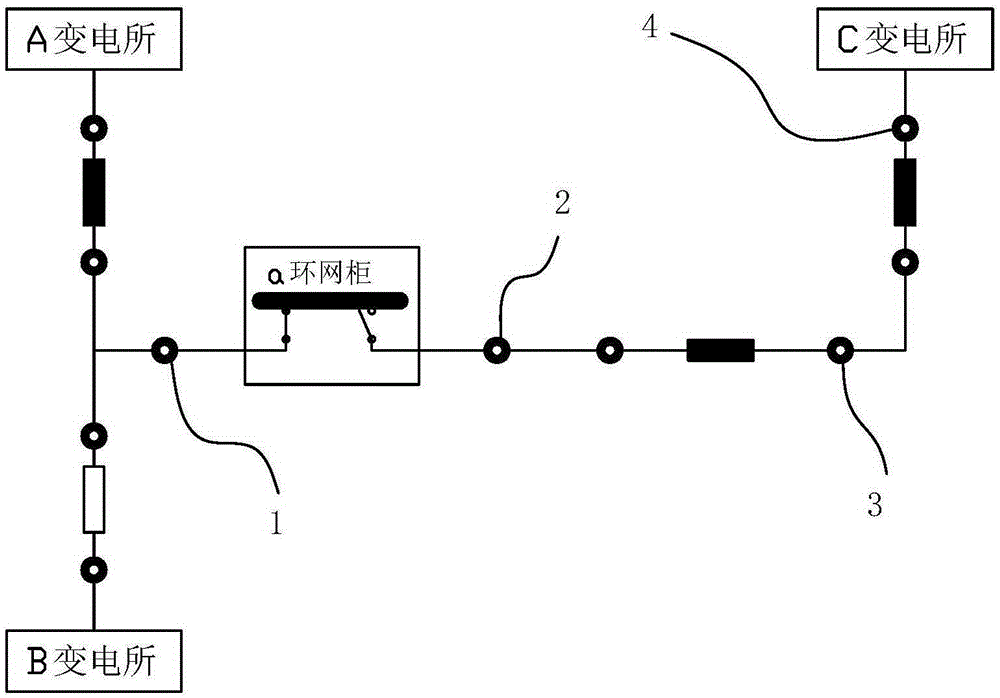

Line predictive transformation system and its working method based on power grid dispatching error prevention system

ActiveCN103425847BImprove intelligenceEliminate live power outage coordination operation sequence errorSpecial data processing applicationsGraphicsPower grid

The invention discloses a line predicting and reforming system based on a power grid dispatching anti-error system and a working method of the line predicting and reforming system and relates to a system for predicating and changing line conditions at the intermediate and later stages of line reforming and a working method of the system. The line predicting and reforming system and the working method thereof can be used for realizing predication by misoperation-preventive locking and operating recommendation of whole-network equipment as well as reforming renewal. The line predicting and reforming system comprises a graphical interface module, a model data processing module, a layer mapping module and a misoperation-preventive locking control and operation recommendation module. The working method comprises the following step of (1) initializing; (2) analyzing; (3) establishing and mapping layers; (4) carrying out recommendation judgment; (5) giving an operation recommendation; (6) carrying out renewal judgment of drawings; (7) substituting an actual area chart; and (8) finishing predicting and reforming. The system disclosed by the invention can be used for furthest eradicating sequence error in power-on / power-off coordinated operation and has important significance on guarantee of safety production of power grid reforming. The power grid predicting anti-error system automatically adapts to topological structure change, and drawings for network reforming are maintained in advance, so that the use workload is greatly reduced.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +2

A steam-driven lubricating oil pump emergency oil supply system and method thereof

ActiveCN104863648BGuaranteed reliabilityEfficiently provideMachines/enginesEngine startersElectricityTurbine

The invention discloses a steam-driven lubricating oil pump emergency oil supply system and a method thereof. The steam-driven lubricating oil pump emergency oil supply system comprises an emergency steam source, an automatic power-losing emergency starting system, a drive turbine, a centrifugal oil pump body and an experiment system. The steam inlet end of a turbine body is connected to the emergency steam source, and the automatic power-losing emergency starting system is arranged on a steam pipe connected with the emergency steam source. The drive turbine is coaxially connected with the centrifugal oil pump body. The automatic power-losing emergency starting system comprises an electromagnetic pneumatic linkage door and a quickly-closing main steam door which are connected in series. By means of the steam-driven lubricating oil pump emergency oil supply system and the method, the reliability of an emergency pneumatic oil pump is guaranteed, lubricating oil can be effectively provided when turbine accidents occur, a rotor can stop walking safely in the idling curve time, occurrence of serious accidents is prevented, and the safety production performance of a power plant is improved.

Owner:JINAN DANENG POWER TECH +1

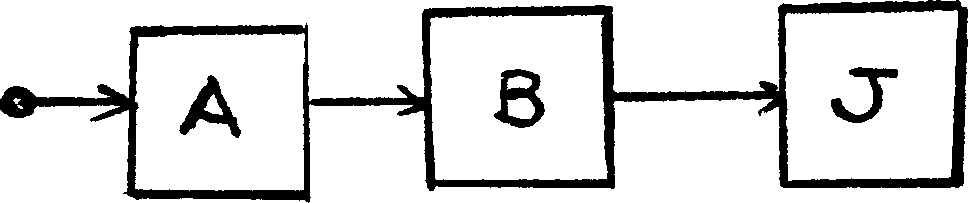

Optical coupling type electromagnetic relay

InactiveCN1822276ASimple designEfficient use ofElectronic switchingRelaysControl systemSwitching signal

An optical coupling type electromagnetic relay includes one optical coupling A, one relay drive circuit B, one electromagnetic type relay J, wherein optical coupling A for realizing power supply isolation between control system circuit and controlled electric system and transmitting switching signal, relay drive circuit B providing drive electric energy for electromagnetic type relay J switch.

Owner:陈俊峰

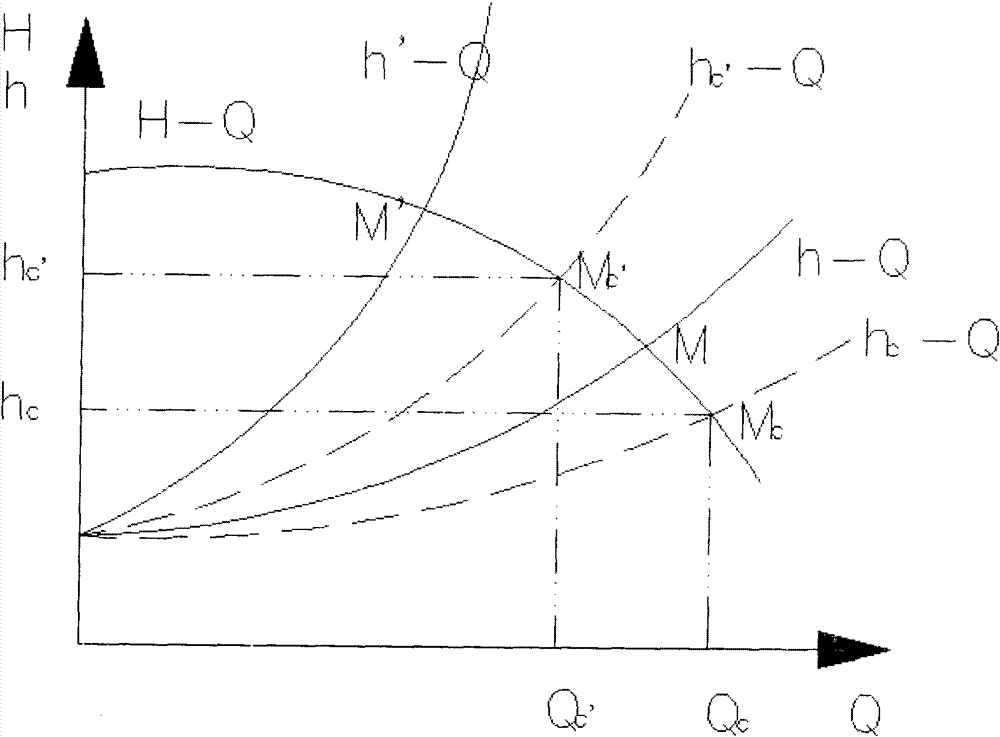

H-Q characteristic curve-based pipeline breakage and leakage positioning method

ActiveCN101737631BMonitor running status in real timeProtection against dangerous situations such as overpressureMeasurement of fluid loss/gain rateEconomic benefitsReliability engineering

Owner:XIAN CHANGQING TECH ENG

Model bottom plate and sand box transfer device

ActiveCN104923747BGuaranteed normal transferGuaranteed smooth productionMoulding toolsSprocketEngineering

A model bottom plate and sand box transfer device, including a frame, a pair of sprockets are coaxially installed at both ends of the frame, a drag chain is assembled on the two corresponding front and rear sprockets, and a The drag chain drive mechanism is equipped with load-bearing rails composed of two parallel steel rails on both sides of the upper part of the frame. A model bottom plate and sand box hauling device are respectively installed on each load-bearing track. The model bottom plate and sand box haul The device has a channel-shaped load-bearing guide beam, on which there are load-bearing rollers with flanges in the middle of the roller surface, and the roller surfaces on both sides of the flange are respectively matched with the rail surface of the corresponding load-bearing track. Both ends of the guide beam are respectively connected with corresponding drag chains through chain joints. The invention is used in a casting molding line, can ensure the normal transfer of the model bottom plate and the sand box at the T-shaped and cross-shaped intersection positions, can greatly reduce the manufacturing cost of the equipment, and improve the working reliability of the equipment.

Owner:QINHUANGDAO DEV ZONE CHUNGUANG CASTING MACHINERY

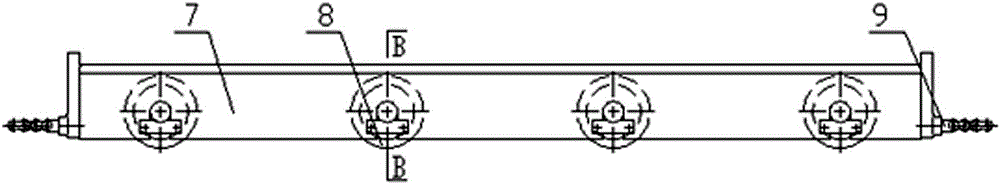

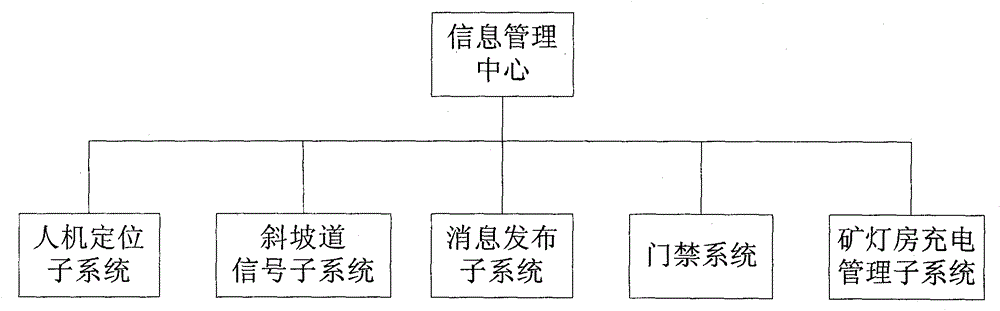

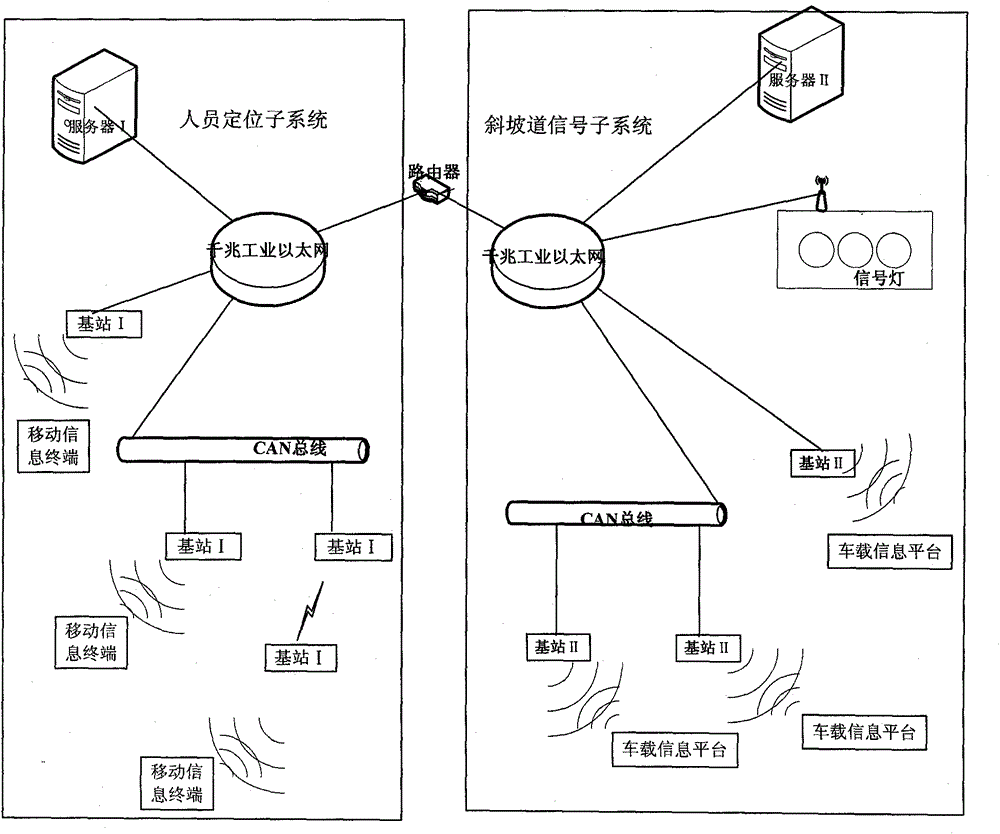

Downhole man-machine positioning and ramp signal system

ActiveCN102562160BImprove safety production performanceStrengthen supervisionMining devicesControl signalSafety control

The invention relates to the technical field of safety control of mines, in particular to an underground man and machine positioning and slope ramp signal system, which can position underground personnel and equipment, controls signal lamps of a slope ramp vehicle in real time according to the position of the vehicle and comprises a man and machine positioning subsystem and a slope ramp signal subsystem. The man and machine positioning subsystem comprises mobile information terminals, a base station I and a server I; the server I is used for receiving information, which is acquired by the base station I, of the mobile information terminals and positioning and recording the personnel with the mobile information terminals and equipment with the mobile information terminals; and the slope ramp signal subsystem comprises a vehicular information platform, a base station II and a server II, the server II is used for receiving information, which is obtained by the base station II, of the vehicular information platform, positioning the vehicle with the vehicular information platform and controlling states of corresponding signal lamps on a slope ramp according to the position of the vehicle. The underground man and machine positioning and slope ramp signal system can effectively improve safety production ability of a mine, and strengthens supervision to the personnel into the mine and supervision to the environmental monitoring equipment.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

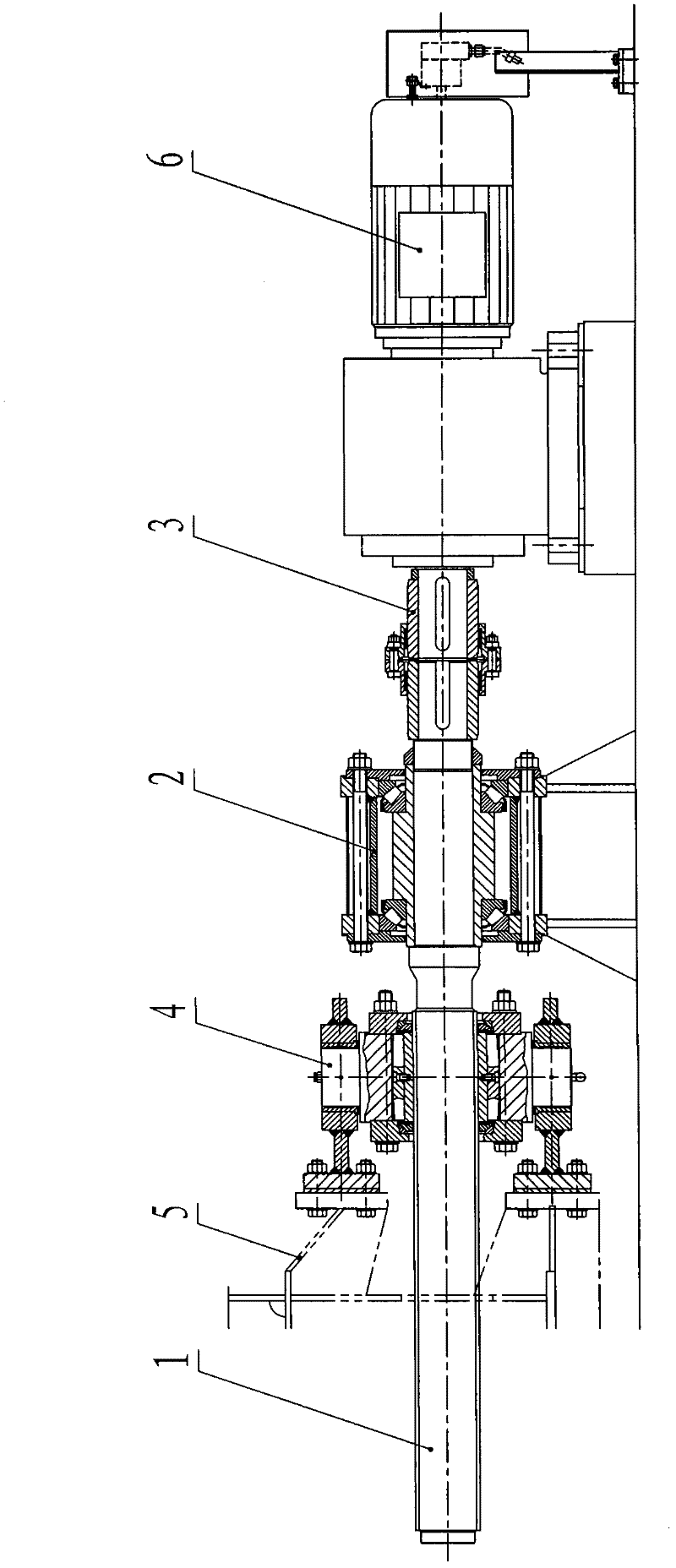

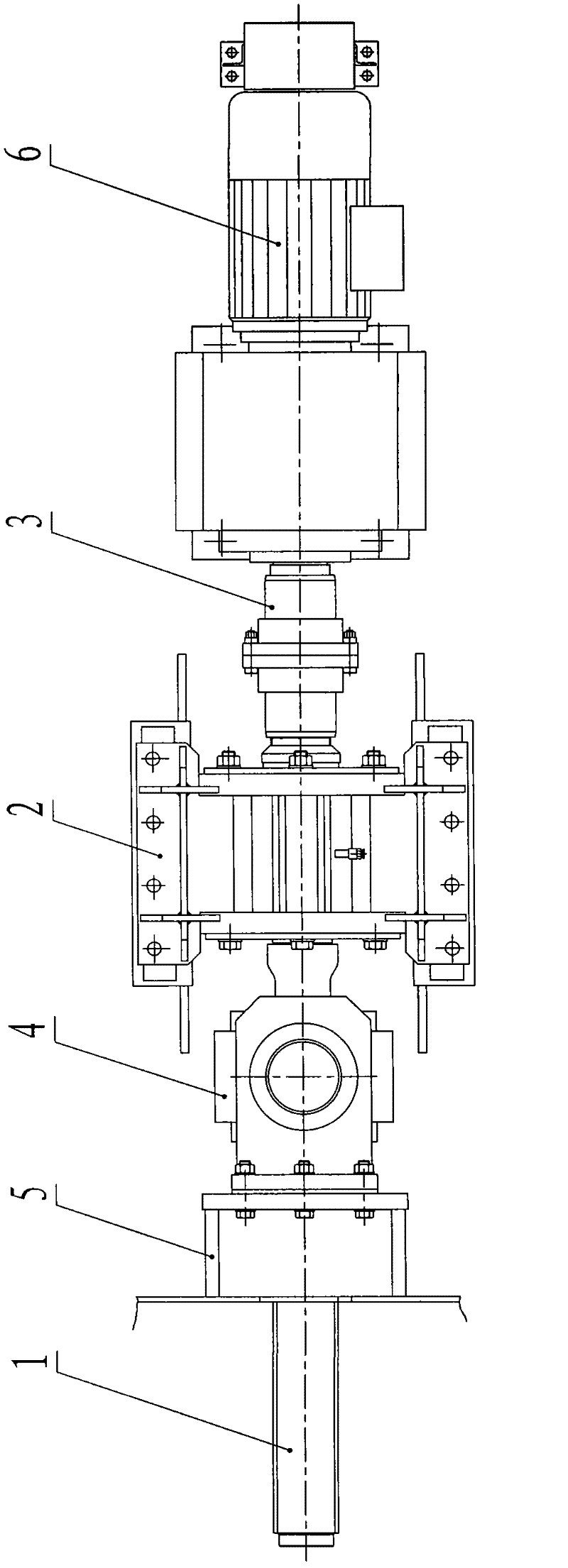

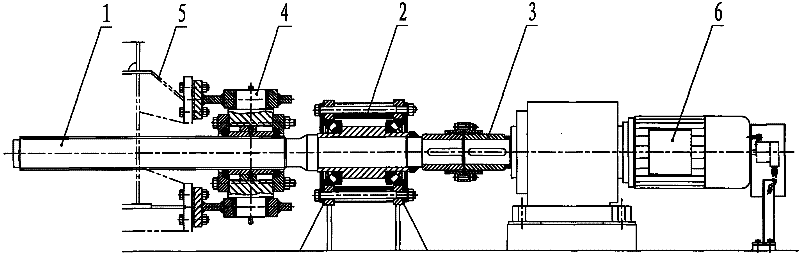

Inter-hook space adjustment mechanism for large gantry cranes

InactiveCN102363503ALifting deflection angle reducedExtended service lifeLoad-engaging elementsCouplingGantry crane

The invention discloses an inter-hook space adjustment mechanism for large gantry cranes, which comprises a screw, a fixed base, a power rotating device, a coupling and a big nut, the screw is arranged on the fixed base and can rotate in situ, the output shaft of the power rotating device is connected with one end of the screw through the coupling, the big nut is screwed on the screw at one side of the fixed base far from the coupling, and moreover, one side of the big nut, which is far from the fixed base, is firmly connected with a hoisting mechanism of a large gantry crane, which is provided with hooks. Preferably, the power rotating device is a three-in-one motor. The inter-hook space adjustment mechanism has the advantages of compact structure, reasonable arrangement and stable operation, can reduce the hoisting deflection of wire ropes to the max, and therefore can prolong the service lives of the wire ropes and enhance the safe production performance of the hoisting mechanism.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

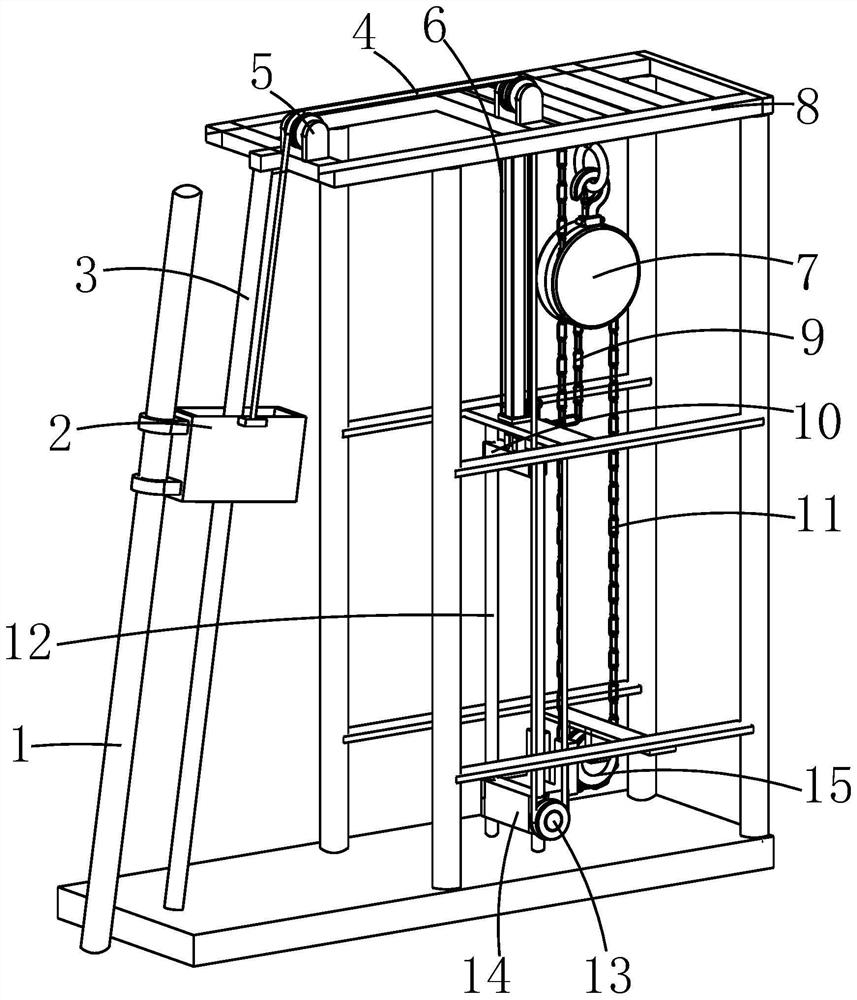

Emergency safety lifting device for oxygen lance

PendingCN114394547AEasy to liftImprove safety production performancePortable liftingLifting devicesEmergency encounterSprocket

The invention discloses an emergency safe lifting device for an oxygen lance, and relates to the technical field of safe lifting. The oxygen lance emergency safety lifting device comprises a base frame, a sliding rail is fixedly connected to the outer surface of one side of the base frame, a sliding block is slidably embedded in the outer surface of the sliding rail, and an oxygen lance is fixedly connected to the outer surface of one side of the sliding block. According to the emergency safety lifting device for the oxygen lance, the air cylinder retracts the small lifting platform to descend or ascend, so that the steel wire rope drives the sliding block to slide along the sliding rail, the oxygen lance descends or ascends, for example, under the emergency condition, a manual chain of the hand chain block is pulled clockwise or anticlockwise, a chain wheel of the hand chain block is driven to rotate, and a lifting chain ascends or descends; the steel wire rope drives the small lifting platform to ascend or descend along the guide sliding rod, so that the steel wire rope drives the sliding block to slide along the sliding rail, ascending or descending of the oxygen lance is achieved, workers can ascend or descend the oxygen lance conveniently, time and labor are saved, and the safety production performance of enterprises is improved.

Owner:DUJIANGYAN RUITAI TECH

Turbine heater

ActiveCN103306639AEasy to installExtended service lifeInsulationDirect contact heat exchangersImpellerSpray nozzle

The invention provides a turbine heater which comprises an air inlet passage, a steam inlet pipe and a hot air outlet passage. Air and steam enter a mixing chamber through corresponding pipelines to be mixed; the mixing chamber is positioned in a host housing; the air inlet passage is connected with the host housing in a sealing manner; steam spray nozzles are arranged at the end part of the steam inlet pipe, which is positioned in the host housing; the steam spray nozzles are uniformly distributed into a strip arc shape along the periphery of the steam inlet pipe; centrifuge blades are uniformly distributed on the peripheries of the steam spray nozzles; the tangential direction of each arc steam spray nozzle outlet passage is opposite to that of each arc centrifuge blade; a centrifugal impeller consisting of the centrifuge blades is connected with a rotating shaft by a fixing part; the maximum included angle alpha between the tangential direction of an outlet of each steam spray nozzle outlet passage and a string of each arc centrifuge blade is 90 degrees; and a demister is arranged in the host housing or in the hot air outlet passage. The turbine heater adopts steam as a heating source and a fan power source, enables the air to be directly heated, and does not require a heat exchanger and an electric motor so as to overcome the defects in the prior art.

Owner:山东三钻硬质合金有限公司

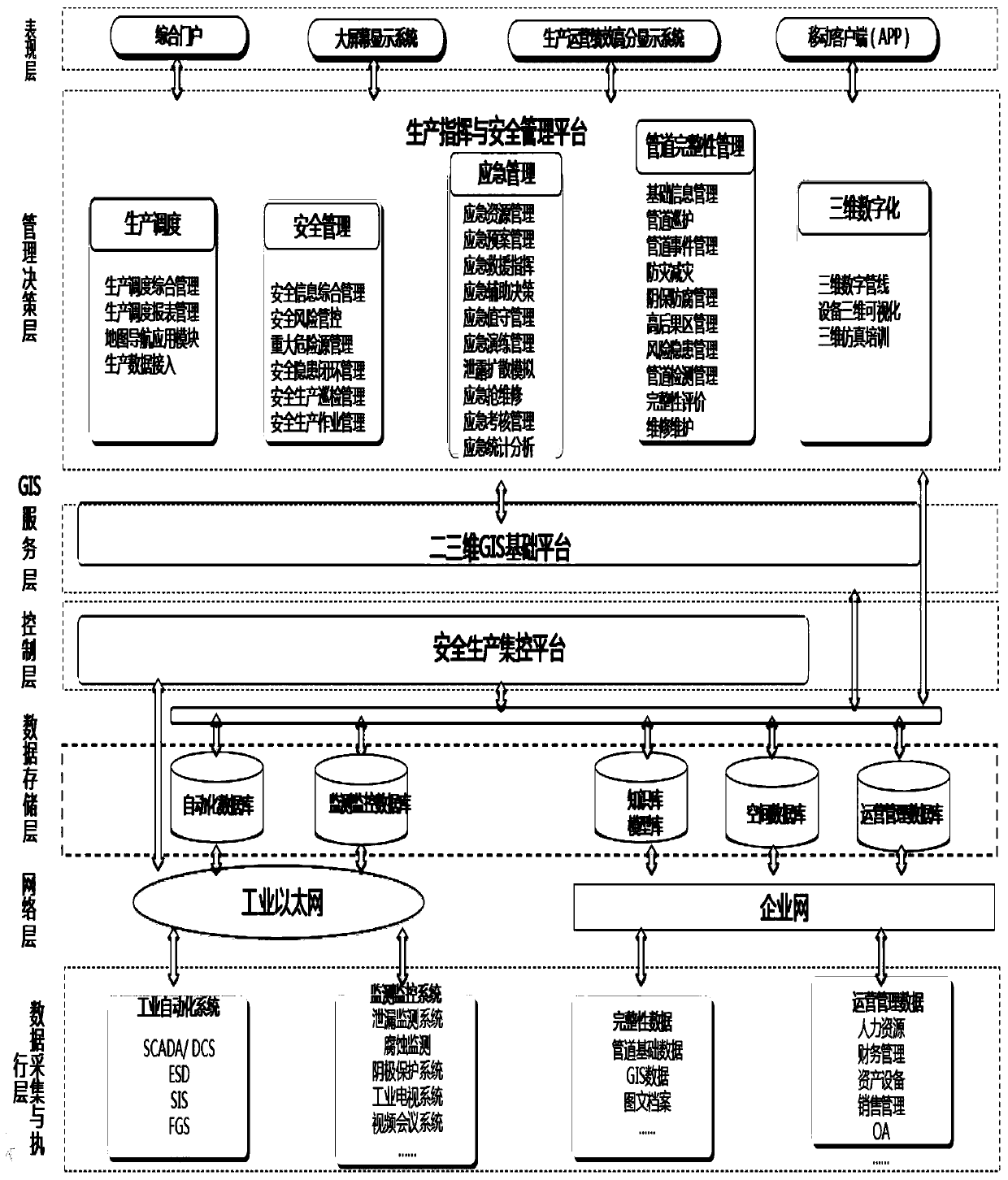

A Production Scheduling and Safety Control System

ActiveCN106598000BImprove safety production performanceStrengthen integrated management and controlProgramme total factory controlVideo monitoringGraphics

A production scheduling and safety management and control system comprises a system hardware and network platform, and the system hardware and network platform collects production related data and transmits the data to a database management system platform. The system is characterized by also comprising a production scheduling subsystem, a safety management and control subsystem, an emergency management subsystem and a production and operation integrated display subsystem; and the production and operation integrated display subsystem displays production and operation integrated information of a company, concentratedly manages, integratedly displays and unifiedly regulates an SCADA system, a production scheduling system, a safety management and control system, vehicle positioning management and a 3D simulated training system, can call and display all information conveniently and flexibly, can be associated with a computer network system, a video monitoring system and other independent computer work stations, realizes integrated display for graph and video image information of computers, and satisfies different display requirements for monitoring, commanding and scheduling.

Owner:北京华科合创科技发展有限公司

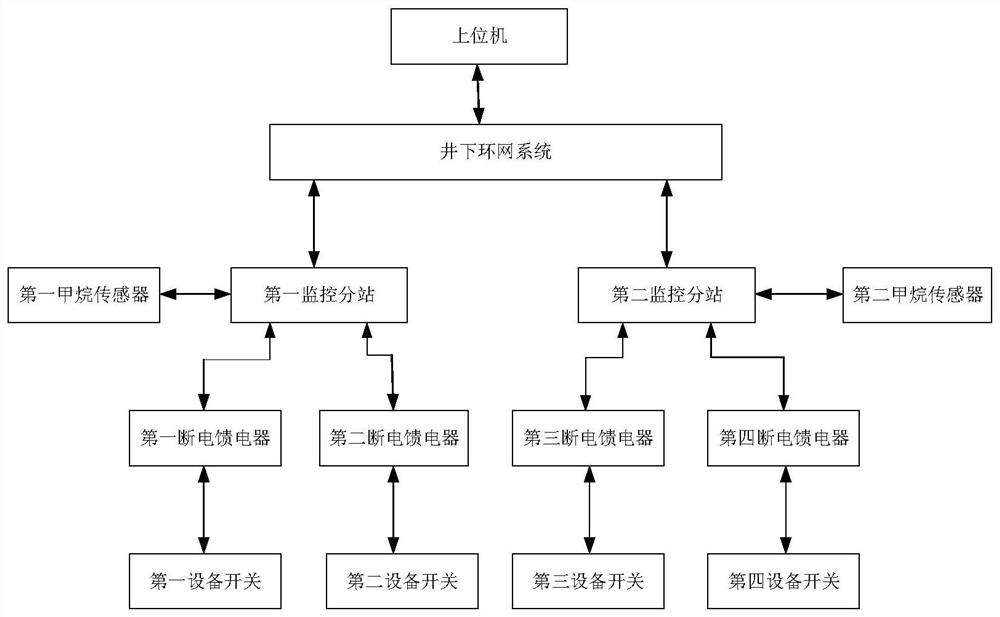

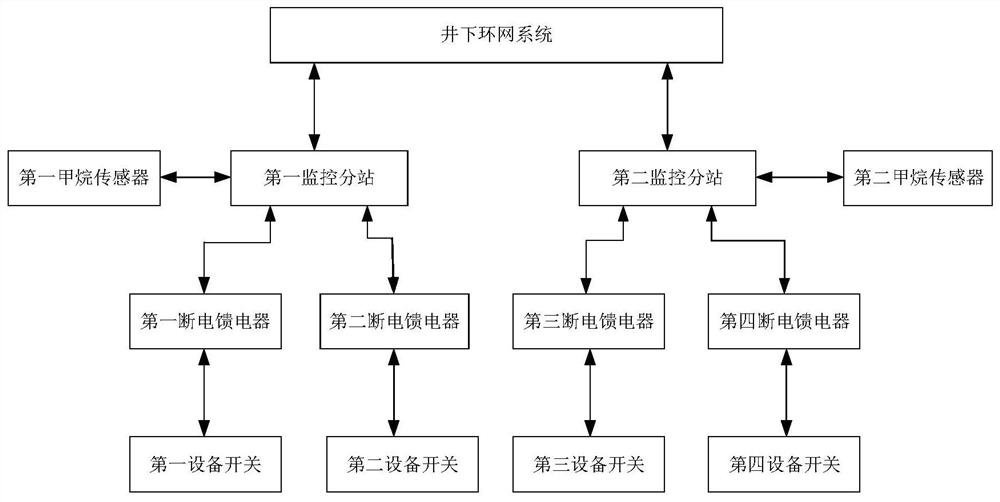

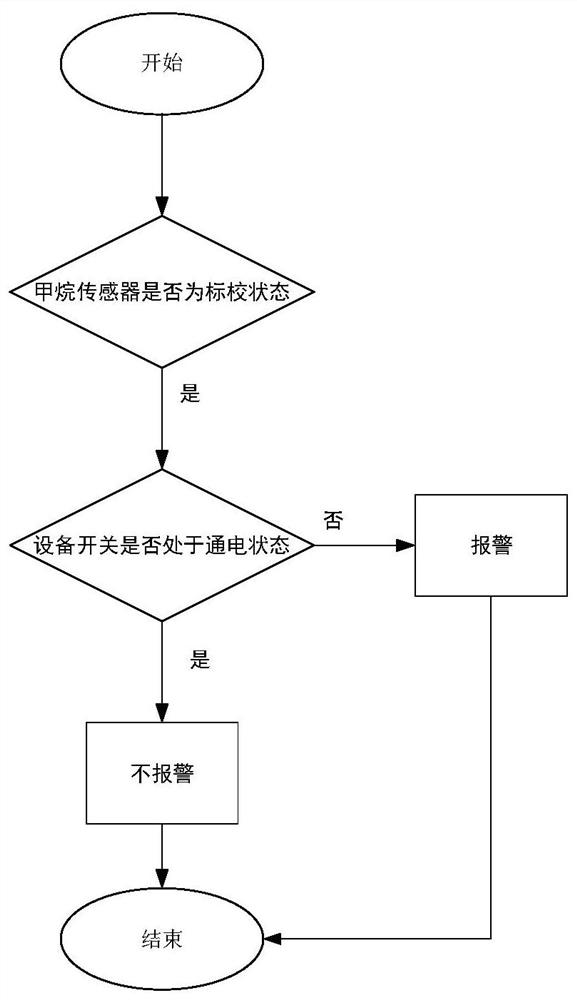

A method and system for testing methane electric blocking function

ActiveCN109975635BImprove safety production performanceAvoid safety hazardsElectrical testingField testsHazard

The invention provides a method and system for testing the methane electric blocking function. When testing the methane electric blocking function, it is first judged whether the methane sensor is in the calibration state; If the switch of the equipment controlled by the sensor is in the power-off state, an alarm will be issued to remind the relevant testers to stop the test, which ensures that the on-site testers can always conduct on-site tests when the switch of the equipment is powered on, and avoid potential safety hazards.

Owner:GL TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com