A spray drying system for easy-to-stick materials

A drying system and material technology, applied in the direction of spray evaporation, can solve the problems of short continuous production time, low equipment output, limited inlet air temperature, etc., and achieve the effect of improving continuous production time, improving production efficiency and reducing overall energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the descriptions do not constitute any limitation to the present invention.

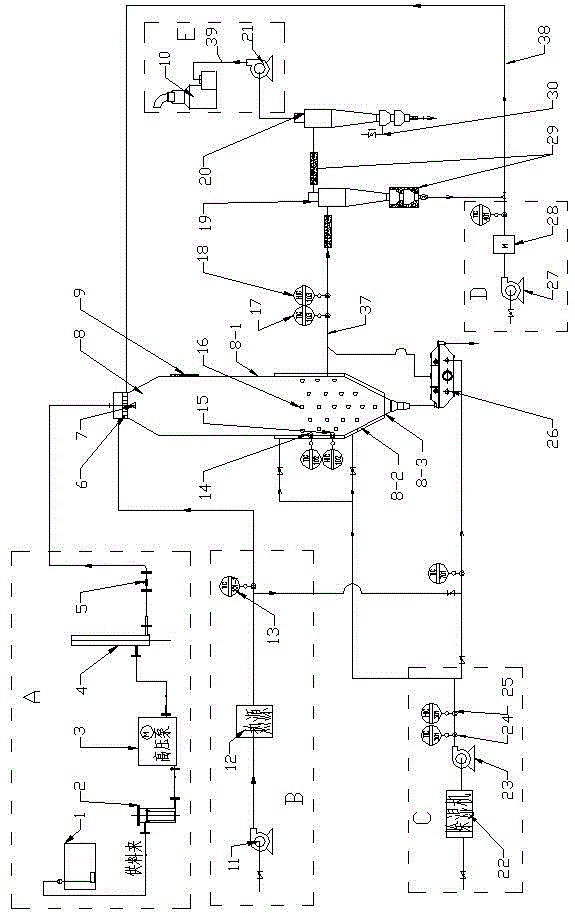

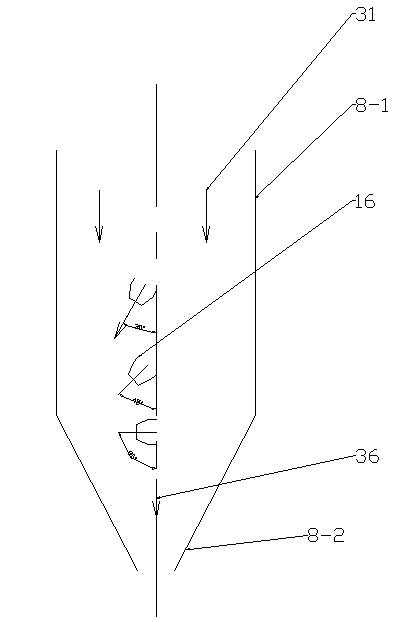

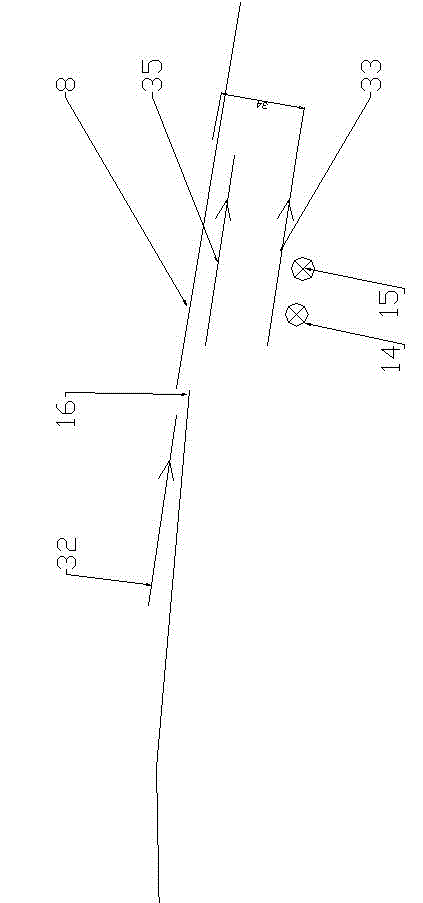

[0035] Such as figure 1 , 2 , shown in 3, the present invention is made up of feeding device A, inlet hot air device B, inlet cold air device C, air delivery device D, drying tower 8, secondary drying device 26, receiving device 19 and 20, emptying device E . The drying tower 8 is composed of a straight cylinder part 8-1 and an inverted cone part 8-2 connected to the lower end of the straight cylinder part 8-1. A discharge port 8-3 is set at the lower end of the inverted cone part 8-2. The secondary drying device 26 is connected on the discharge port 8-3. The upper part of the discharge product 8 - 3 of the drying tower 8 is also connected to the primary cyclone separator 19 and the secondary cyclone separator 20 in sequence through the dust discharge pipe 37 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com