Experimental system and method of emergency steam-driven oil pump

An experimental system and steam-powered technology, applied in pump testing, engine components, machines/engines, etc., can solve the problem of not being able to grasp the working status of the emergency fuel supply system in time, so as to improve safety production performance, ensure reliability, and prevent major problems. effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

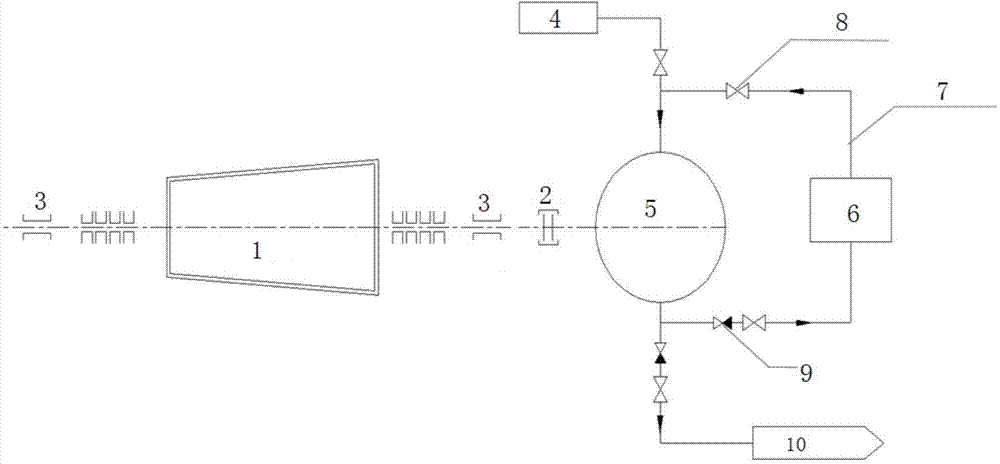

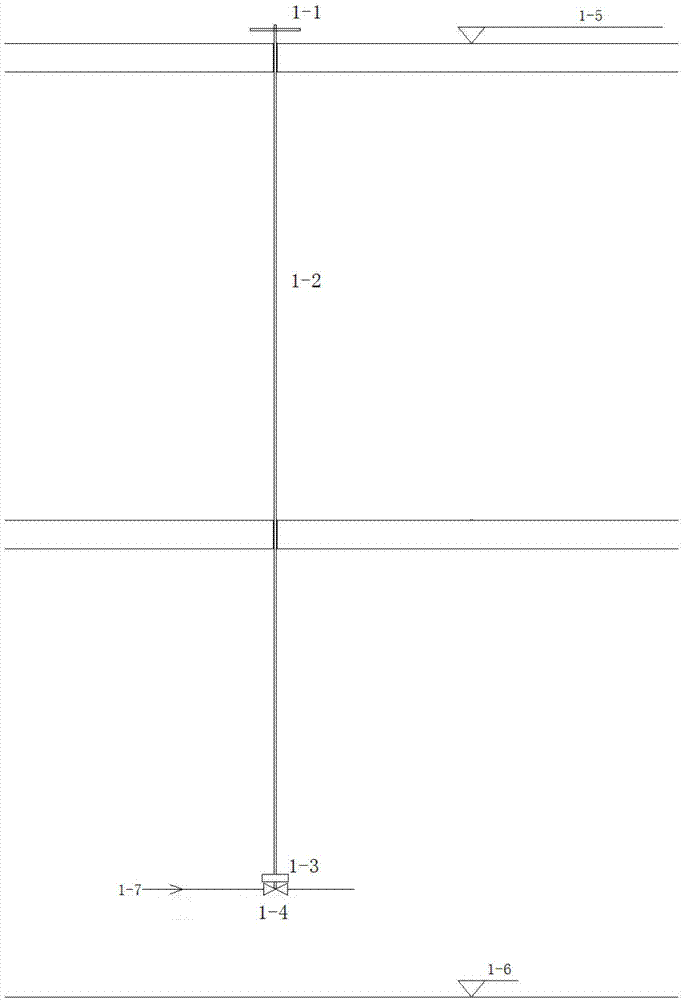

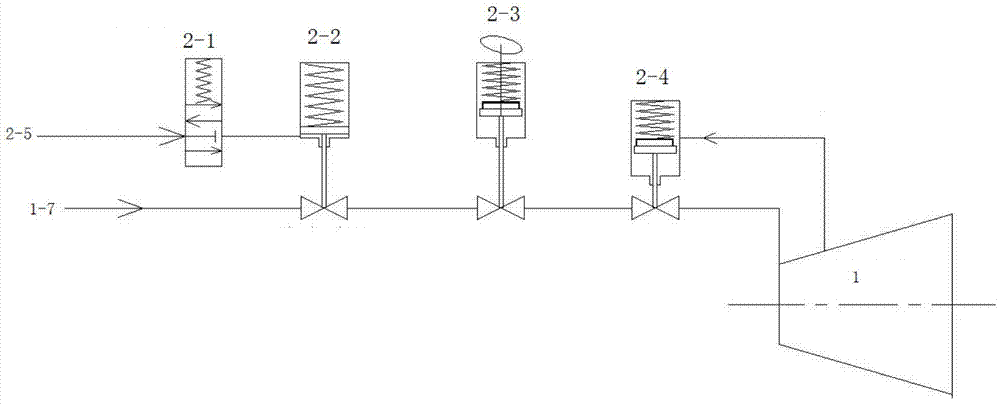

[0039] Generally, the steam turbine emergency steam-driven oil pump 5 system includes: the emergency steam source 3-1 is connected to the steam turbine body 1 through the steam pipeline, the steam turbine start control device 3-2, and the steam inlet adjustment device 2-4, and the steam turbine body 1 is connected to the emergency steam The moving oil pump 5 is connected.

[0040] Bearing oil breakage is a serious accident of turbogenerators, which will cause serious damage to equipment, such as wear of journals and thrust discs, burning of supports and thrust bearings, and the resulting collision between rotating parts and stationary parts, and even cause Bearing housing catches fire or explodes.

[0041] Therefore, in order to ensure the safety of the steam turbine body 1, in some other embodiments, a drive steam turbine is designed, such as Figure 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com