Hydrodynamic pressure suspension double-flow pump

A flow pump, suspension technology, applied in the field of fluid conveying or thermal control device, vane ultra-small pump, can solve the problems of inconvenient use, complex mechanical system, bulky and other problems, achieve good physiological compatibility, simplicity and simplicity. Compact overall structure, eliminates the effect of flow stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

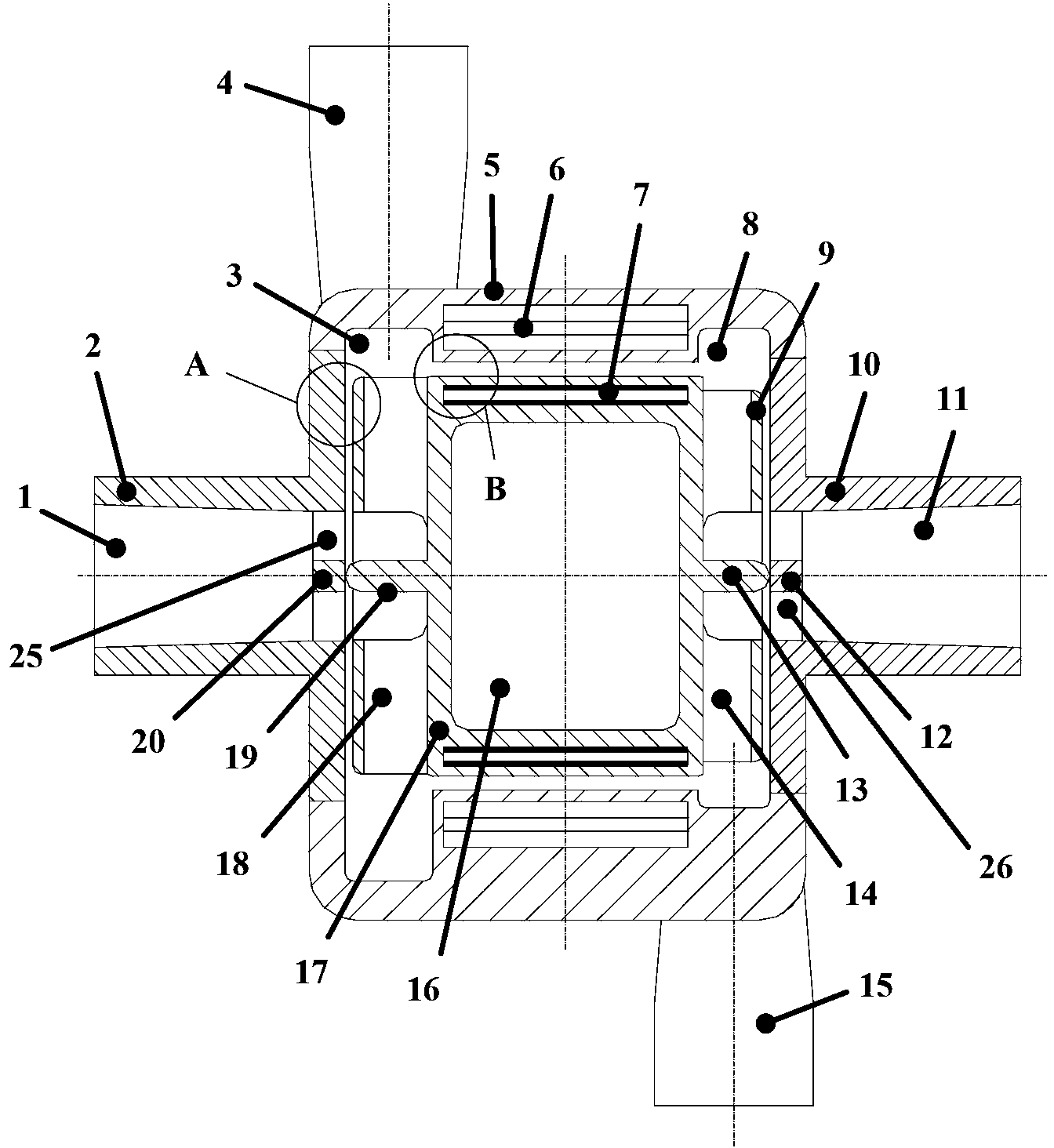

[0017] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

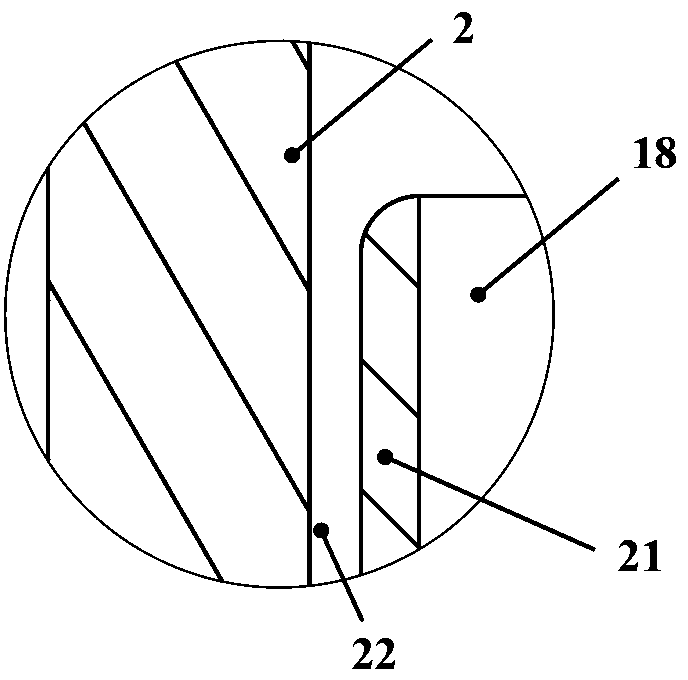

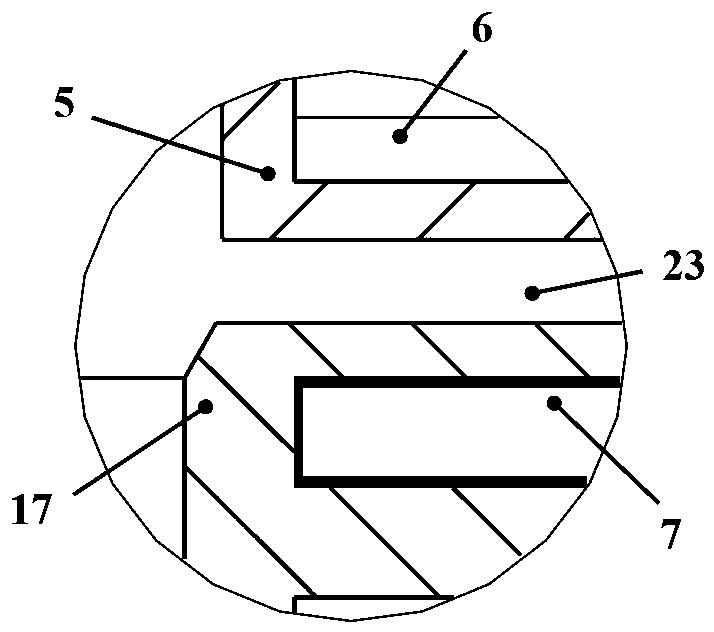

[0018] figure 1 It is a sectional view of a dynamic pressure suspension double-flow pump provided by the present invention. The pump includes a first inlet 1, a first pump cover 2, a first pressurized water chamber 3, a first outlet 4, a pump casing 5, a stator 6, a permanent magnet 7, a first impeller 18, a front cover plate 21 of the first impeller, The second pressurized water chamber 8, the second inlet 11, the second impeller 14, the second outlet 15, the rotor 17, the second pump cover 10 and the second impeller front cover plate 9, wherein the first impeller and the second impeller are respectively mounted on Both ends of the rotor; the first inlet and the second inlet are located on the same axis and are collinear with the axis of the rotor; the first outlet 1 and the second inlet 11 are installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com