Process of producing diphenyl carbonate by non-solvent method

A technology of diphenyl carbonate and non-solvent method, which is applied in the field of production technology of diphenyl carbonate, can solve the problems of unstable appearance color, weak market competitiveness, cumbersome synthesis process, etc., so as to avoid sodium chloride mother liquor water and waste water, improving safety and productivity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

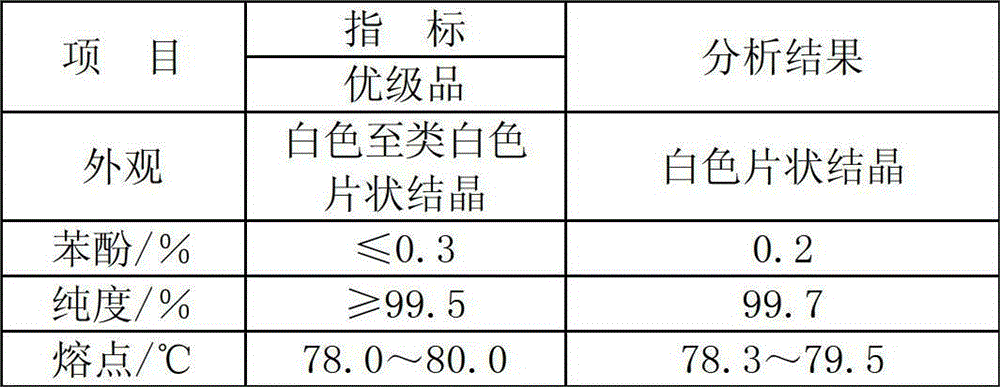

[0033] Put 282g of phenol into a 500ml reaction bottle, heat up and melt, and when it reaches 115°C, add an appropriate amount of catalyst DMF according to 1% of the weight of phenol. Under stirring conditions, the flow rate is controlled to slowly feed phosgene to ensure that the phosgene reaction is complete; after 12 hours of photochemistry, sampling analysis: phenol 2.1%, phenyl chloroformate 0.9%, diphenyl carbonate 96.3%, the reaction is over; phenol and The molar ratio of phosgene actually used is 1:0.8. Raise the temperature to 150°C and keep it warm for 3 hours, and the measured phenyl chloroformate content is <0.1% as the end point. Using oil bath heating distillation process, the oil temperature is 180°C, the internal temperature is 150°C, and the vacuum degree is 0.085Mpa, and the phenol is distilled and separated; the oil temperature is 220°C, the internal temperature is 190°C, and the vacuum degree is 0.096Mpa, and the product is obtained by distillation. The qu...

Embodiment 2

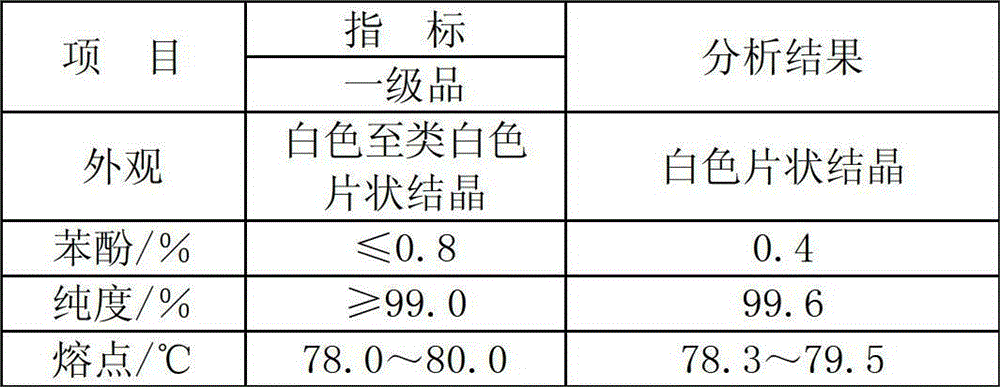

[0038] Put 282g of phenol into a 500ml reaction bottle, heat up and melt, and when it reaches 115°C, add an appropriate amount of catalyst N,N-dimethylaniline according to 1.1% of the weight of phenol. Under stirring conditions, control the flow rate and slowly feed phosgene to ensure that the phosgene reaction is complete; the photochemical time is 13 hours, and the sampling analysis: 3.7% phenol, 3.3% phenyl chloroformate, and 92.3% diphenyl carbonate; add 20g of phenol to carry out After heat preservation, keep heat at 170°C for 4 hours, and measure the content of phenyl chloroformate <0.1% as the end point. The actual molar ratio of phenol to phosgene used is 1:0.9. Using oil bath heating distillation process, the oil temperature is 180°C, the internal temperature is 150°C, and the vacuum degree is 0.086Mpa, and the phenol is distilled and separated; the oil temperature is 220°C, the internal temperature is 190°C, and the vacuum degree is 0.096Mpa, and the product is obtai...

Embodiment 3

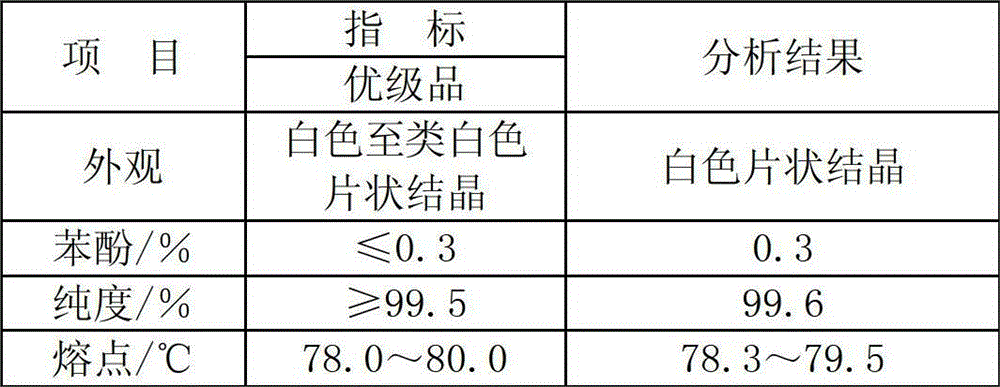

[0042] Put 282g of phenol into a 500ml reaction bottle, heat up and melt, and when it reaches 115°C, add an appropriate amount of catalyst DMF according to 1.1% of the weight of phenol. Under stirring conditions, the flow rate is controlled to slowly feed phosgene to ensure that the phosgene reaction is complete; the photochemical time is 11 hours, sampling analysis: phenol 5.8%, phenyl chloroformate 0.3%, diphenyl carbonate 92.3%, the reaction is over; phenol and The actual molar ratio of phosgene used is 1:0.6. Raise the temperature to 160°C and keep it warm for 4 hours, and the measured phenyl chloroformate content is <0.1% as the end point. Using oil bath heating distillation process, the oil temperature is 180°C, the internal temperature is 150°C, and the vacuum degree is 0.083Mpa, and the phenol is distilled and separated; the oil temperature is 220°C, the internal temperature is 190°C, and the vacuum degree is 0.097Mpa, and the product is obtained by distillation. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com