Steam turbine heater

A heating machine, steam turbine technology, applied in lighting and heating equipment, direct contact heat exchangers, heat exchanger types, etc., can solve the difficulty of adjusting the angle of the air inlet and outlet, the high maintenance rate of the heat exchanger, and the energy consumption. High safety hazards and other problems, to achieve the effect of improving safety production capacity, eliminating unsafe hazards, and reducing dust flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

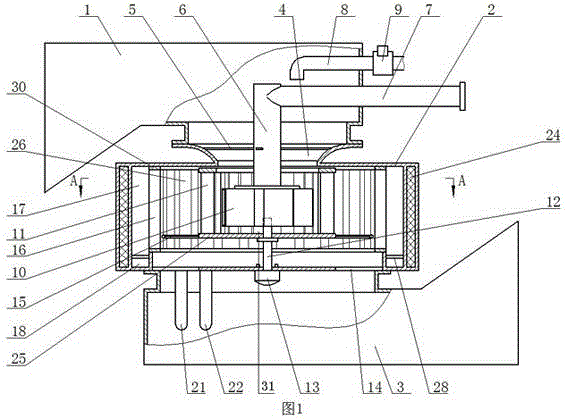

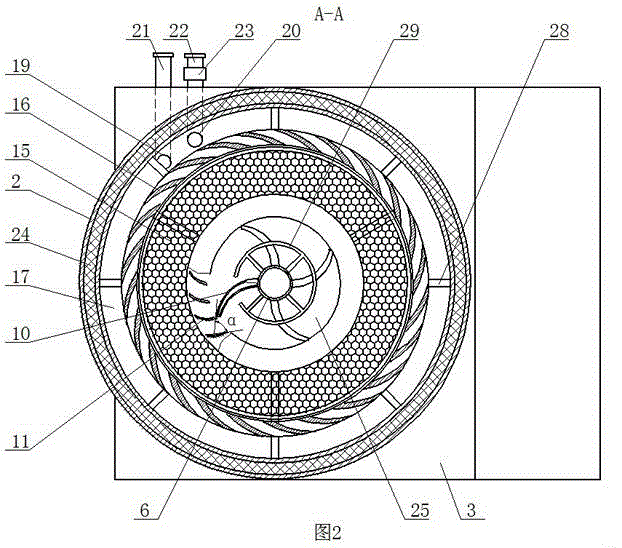

[0007] The present invention will be further described with reference to the accompanying drawings, but the present invention is not limited to the scope of the embodiments and the structures shown in the accompanying drawings.

[0008] The steam turbine heater of the present invention uses steam as power to drive the centrifugal impeller to rotate, mixes the air with the steam and removes excess water through a mist eliminator, and blows the heated air with a small amount of water. The structure that realizes the above functions includes an air inlet duct, a steam inlet duct and a hot air outlet duct. Air and steam enter the mixing chamber through their respective pipes for mixing. Steam nozzles are installed at the end of the steam inlet pipe located in the casing of the main engine. The steam nozzles are evenly distributed along the circumference of the steam inlet pipe. The outlet channel of the steam nozzle is in the shape of a long arc. The outer circumference of the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com