H-Q characteristic curve-based pipeline breakage and leakage positioning method

A technology of characteristic curve and positioning method, applied in the field of leak detection, can solve the problems of high false alarm rate and failure to locate the leakage point of the pipeline, and achieve the effect of preventing pipeline overpressure and improving safety production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

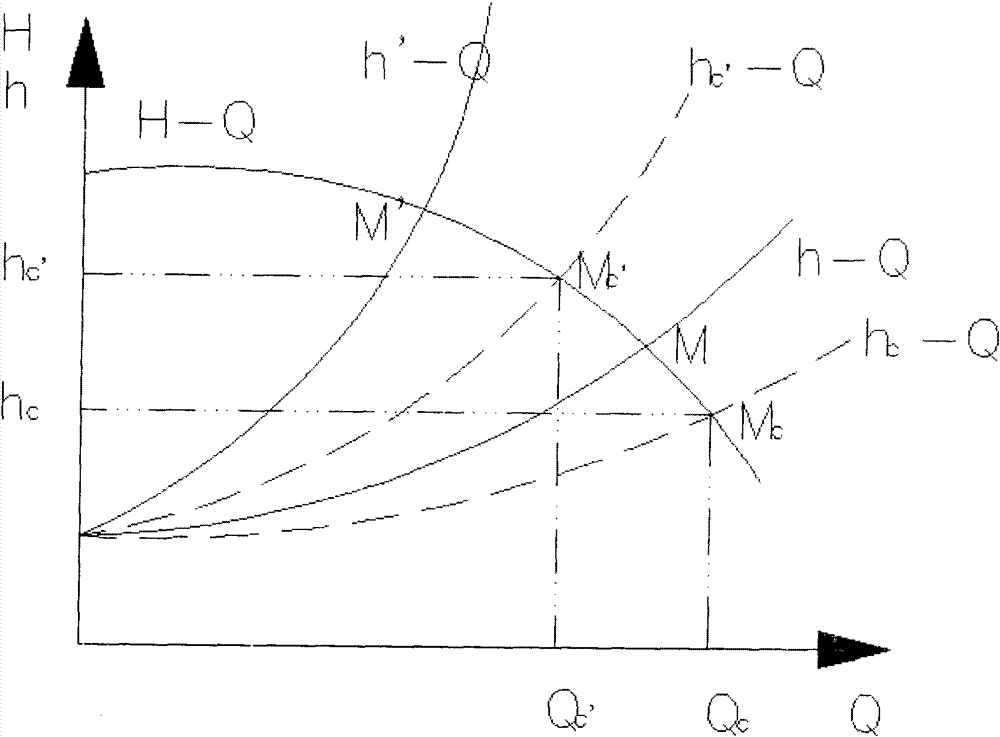

[0023] The head performance curve H-Q of the pump is a fixed curve when the pump type selection is determined and the speed is constant. Under normal working conditions, the pipeline characteristic h-Q curve changes with the change of the output Q (at h c′ -Q~h c -Q), which has an intersection point M with the head performance curve H-Q of the pump. When the pipeline breaks and leaks, the change of the pipeline characteristic h-Q curve exceeds the above-mentioned change range, and the monitoring and positioning system will alarm in time. The system automatically obtains the pipeline characteristic curve h and Q parameter values corresponding to M′, and locates the leakage point through calculation. The current leakage point is displayed with a red flashing mark on the pipeline routing graph, and the alarm data is printed at the same time; quantity.

[0024] The steps of the pipeline leak location method based on the H-Q characteristic curve are:

[0025] A. Initialization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com