Anchor chain thermal treatment furnace monitoring system

A technology for heat treatment furnaces and monitoring systems, applied in heat treatment furnaces, heat treatment process control, heat treatment equipment, etc., can solve problems such as cumbersome operations, troublesome data processing, and limited work efficiency, so as to improve work efficiency, improve supervision, and facilitate inquiries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

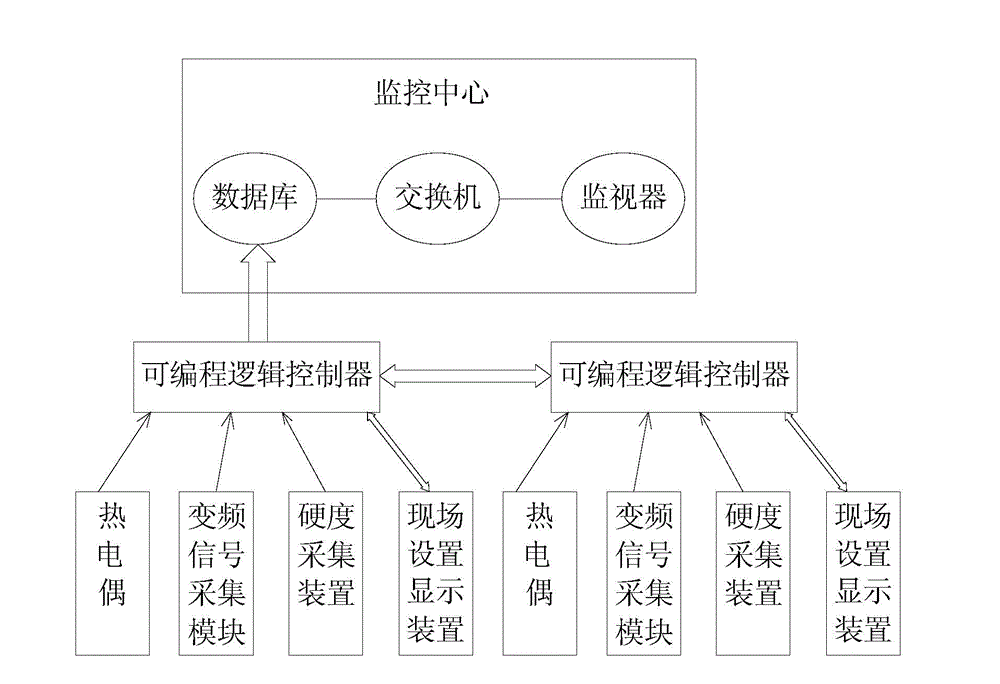

[0024] Such as figure 1 As shown, a chain heat treatment furnace monitoring system includes: a monitoring center, at least one programmable logic controller connected to the monitoring center through Ethernet, and a thermocouple connected to the programmable logic controller, a frequency conversion signal acquisition module, Hardness acquisition device and on-site setting display device.

[0025] Wherein, each programmable logic controller corresponds to a heat treatment furnace. The monitoring center includes: a database server connected to a programmable logic controller, and at least one monitoring device connected to the database server through a switch. There are at least three thermocouples arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com